7

2-3. Caution items

CAUTION

・

Contact to the end surface of metal

When required to contact the end surface such as iron plate, enough attention and care

should be taken so that any damage cannot take place.

・

Do not use the Walky-talky near the product

When use the walky-talky etc which emits electric wave near the cable or product, there is

the case that the correct measurement cannot be carried out and the attention for

it would be required. When use such walky-talky etc, use it where there is no influence.

・

Procedure of power on

Make power on after Operating System (OS) for Personal Computer is set up. If the power

gets on before Operating System is set up, it may cause the error of operation.

・

Power on again

When make power on again, wait more than 5 minutes after power off. When make power on

within 5 minutes, there is the case that the normal operation cannot be carried out.

・ Operation at the unstable place

Do not put it at the suitable place such as slant and vibrating place. It may not do the normal

operation.

・

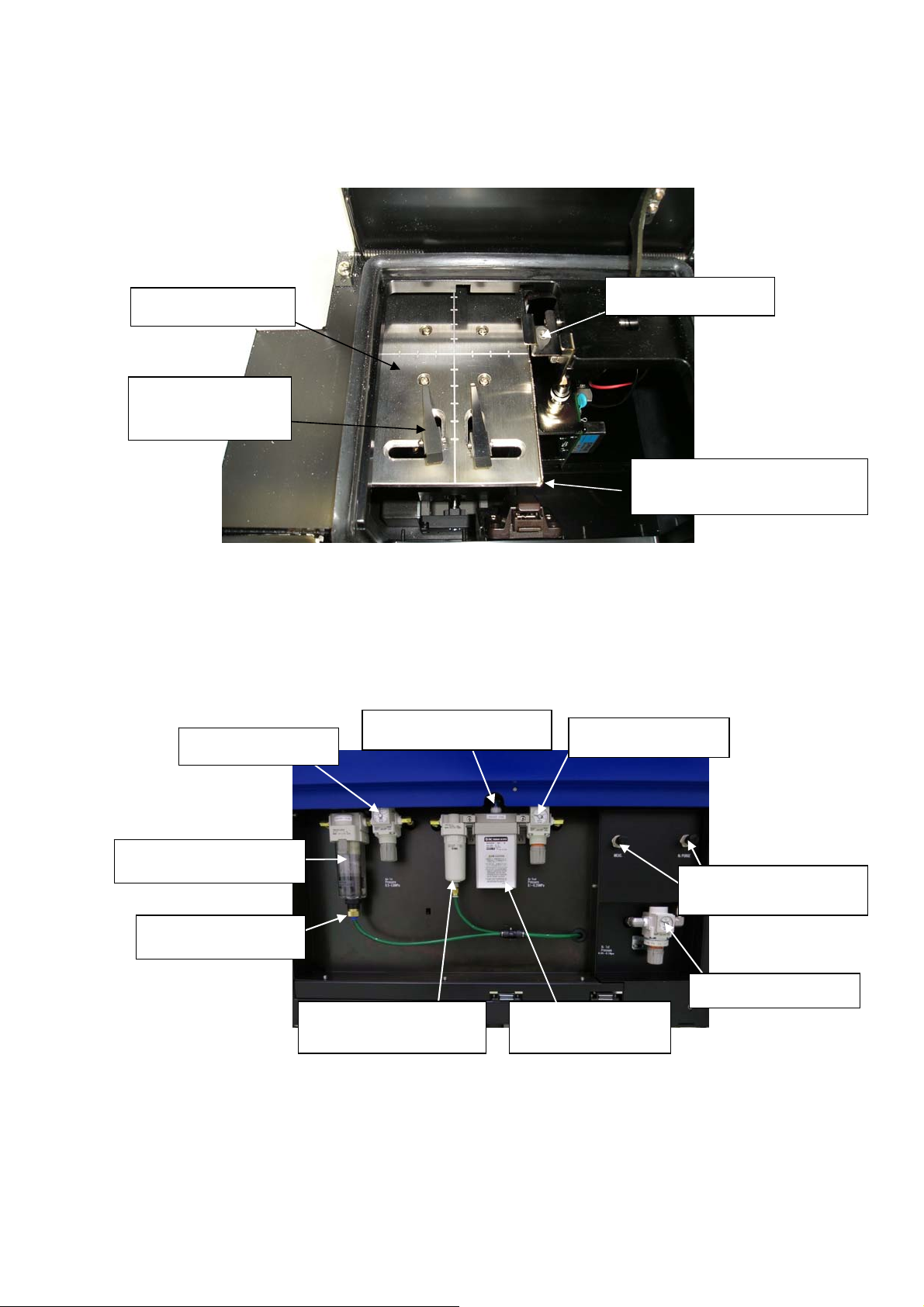

The caution for compressed air

When the following material is contained in the compressed air, it may deteriorate the

detector and dry air generating conditioner and there is possibility for damage.

Kind Materials which should not contain

Solvent

Acetone, Benzene, Phenol, Toluene, Trichloroethylene, Xylene, Cresol,

Thinner, Aniline, Chloroform, Alcohol, Dioxane, Tetrahydrofuran, Methylene

chloride, Cyclohexanone, Carbon tetrachloride etc

Acid Sulfuric acid, Nitric acid, Hydrochloric acid, Acetic acid, Lactic acid,

Chromic acid etc

Gas Chlorine, Sulfur dioxide, Hydrogen sulfide, Bromine, Semiconductor

processing gas etc

Oil Hydraulic fluid (Phosphatic Ester), Fuel oil, Water soluble cutting

fluid(Alkaline), Kerosene etc

・

When use at more than given pressure, it may damage the dry air generating system.

・

When induct liquid such as water from the compressed air pipe, it may damage the system.

・ When induct other gas such as N2 gas, oxygen, inert gas than air from compressed air pipe,

it may damage the system.