Rinnai Continuum HV Series 1 User manual

Other Rinnai Boiler manuals

Rinnai

Rinnai E75CN Release note

Rinnai

Rinnai Q175C User manual

Rinnai

Rinnai E85SRN Release note

Rinnai

Rinnai M Series User manual

Rinnai

Rinnai i Series User manual

Rinnai

Rinnai REB-KBI2424FF Operating manual

Rinnai

Rinnai QP85N Guide

Rinnai

Rinnai E50CRN Release note

Rinnai

Rinnai E32S Release note

Rinnai

Rinnai Q130SN Release note

Rinnai

Rinnai E75CN Guide

Rinnai

Rinnai E50CRN Guide

Rinnai

Rinnai Mirai 24 User manual

Rinnai

Rinnai CHS199100 User manual

Rinnai

Rinnai E60SRN Installation and maintenance instructions

Rinnai

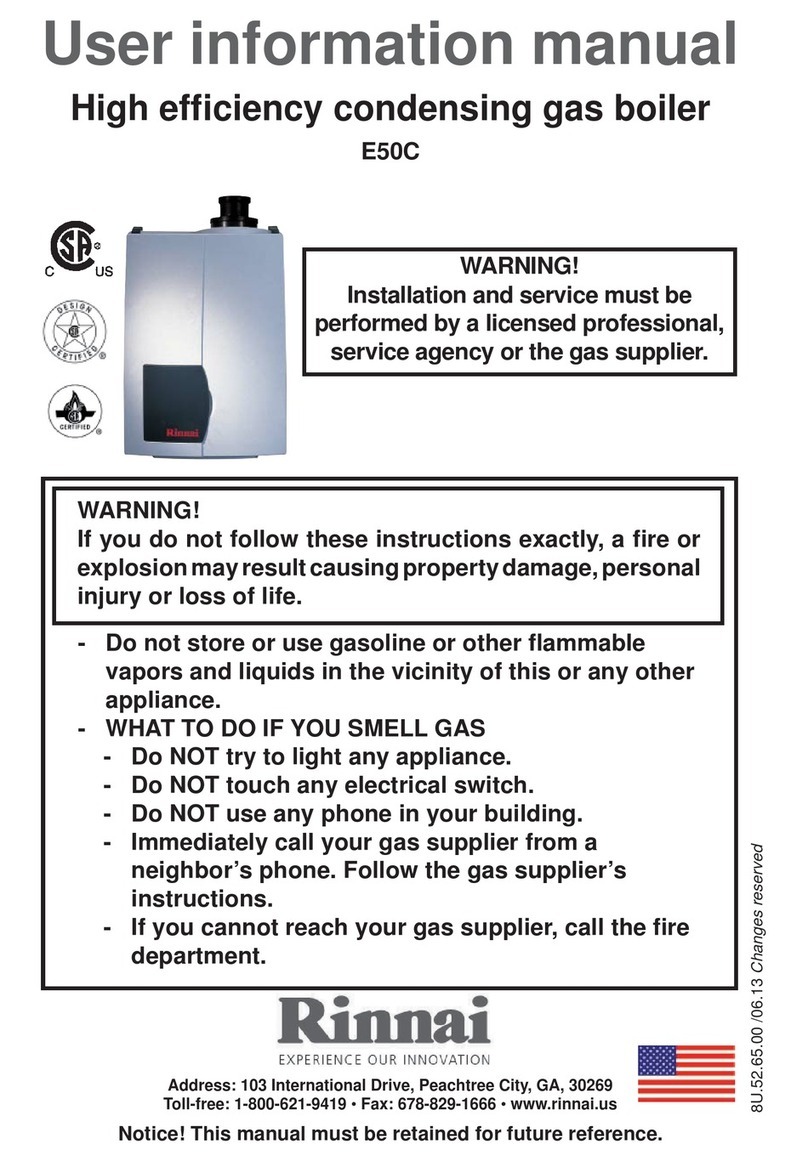

Rinnai E50C Guide

Rinnai

Rinnai WF-100W_EU User manual

Rinnai

Rinnai Q85SN Release note

Rinnai

Rinnai E50C Guide

Rinnai

Rinnai M060S User manual

Popular Boiler manuals by other brands

Ferroli

Ferroli DOMIcompact F 30 D null

Vaillant

Vaillant uniSTOR VIH SW GB 500 BES operating instructions

Radijator

Radijator BIO max 23.1 instruction manual

Brunner

Brunner BSV 20 Instructions for use

Buderus

Buderus Logamax GB062-24 KDE H V2 Service manual

Potterton

Potterton 50e Installation and Servicing Manual

UTICA BOILERS

UTICA BOILERS TriFire Assembly instructions

Joannes

Joannes LADY Series Installation and maintenance manual

ECR International

ECR International UB90-125 Installation, operation & maintenance manual

Froling

Froling P4 Pellet 8 - 105 installation instructions

Froling

Froling FHG Turbo 3000 operating instructions

U.S. Boiler Company

U.S. Boiler Company K2 operating instructions