Rinnai REU-24 W-A User manual

Other Rinnai Water Heater manuals

Rinnai

Rinnai RLX94i User manual

Rinnai

Rinnai Sensei RU199i User manual

Rinnai

Rinnai Demand Duo R Series User manual

Rinnai

Rinnai QRESS315L348 User manual

Rinnai

Rinnai Infinity N1600i Specification sheet

Rinnai

Rinnai Circ-Logic RU98i User manual

Rinnai

Rinnai HOTFLO EHFA Series User manual

Rinnai

Rinnai Multi-Point 11i Low NOx User manual

Rinnai

Rinnai REU-V2520FFU series User manual

Rinnai

Rinnai INFINITY N Series User manual

Rinnai

Rinnai R50LSI Specification sheet

Rinnai

Rinnai Infi nity Solar 20 Specification sheet

Rinnai

Rinnai REU-VA3237W User manual

Rinnai

Rinnai Infinity 20e User manual

Rinnai

Rinnai Smart Cylinders Series Instructions for use

Rinnai

Rinnai SPLIT SOLAR User manual

Rinnai

Rinnai Circ-Logic RL75i User manual

Rinnai

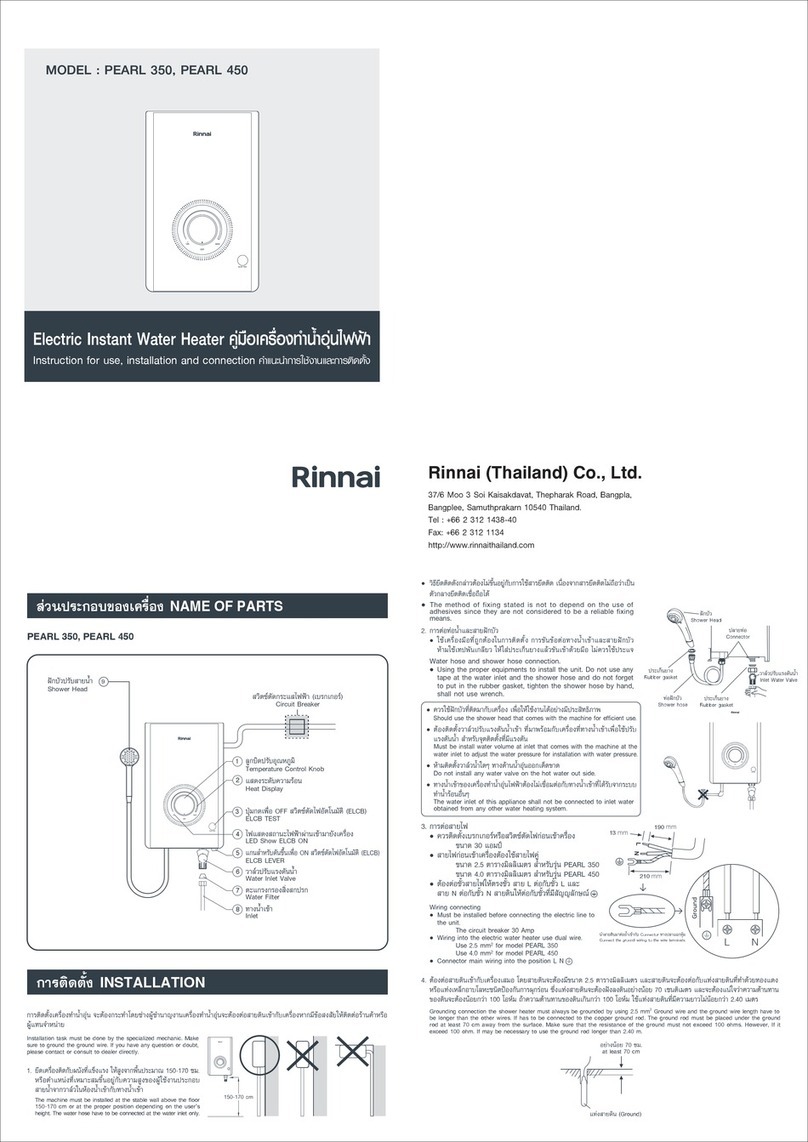

Rinnai PEARL 350 User manual

Rinnai

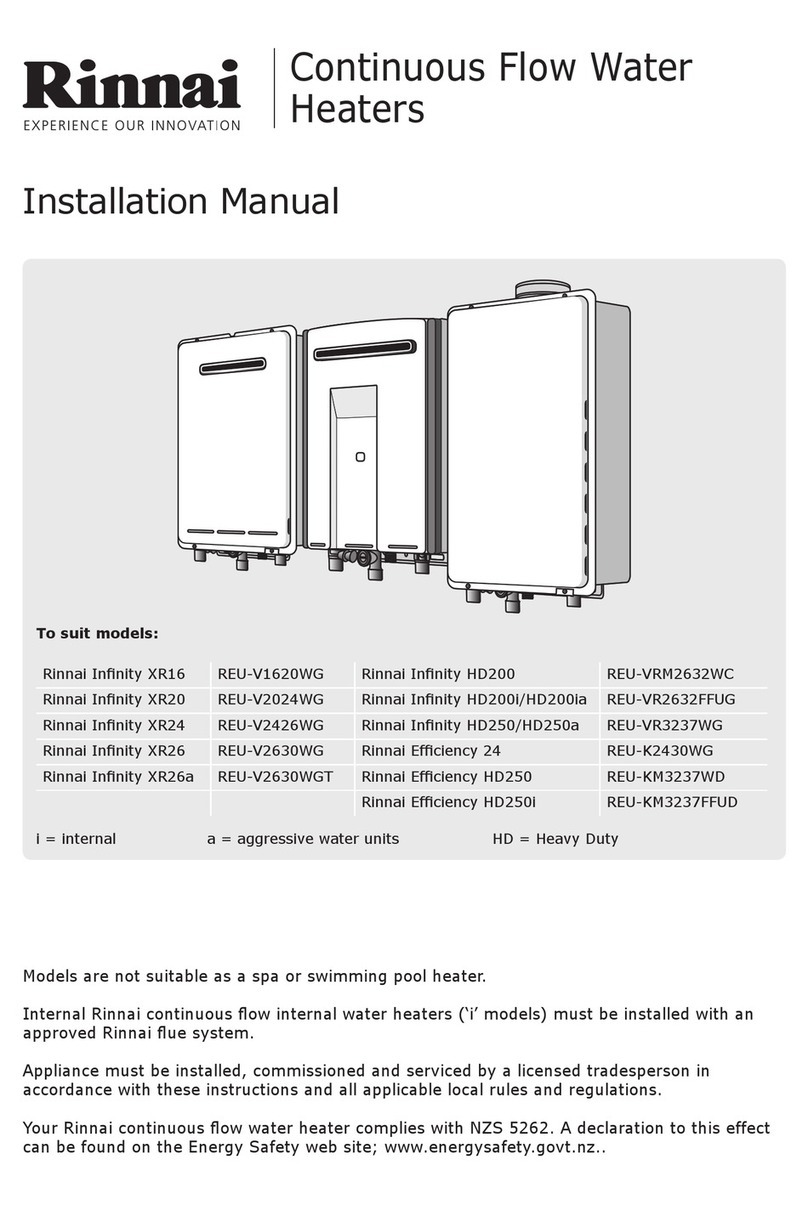

Rinnai Infinity XR16 User manual

Rinnai

Rinnai REU-1110FFU-E User manual

Popular Water Heater manuals by other brands

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

A.O. Smith

A.O. Smith Gphe 50 instruction manual

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions

Koryo

Koryo KWHZF15Y user manual

Pentair

Pentair PSC-14-4-02 Installation and operation manual

GE

GE 40M06AAG Energy guide