* For clearances not specified in ANSI Z223.1 / NFPA 54 or CAN/CGA-

B149, please use clearances in accordance with local installation codes

and the requirement of the gas supplier.

** 4 feet for units other than Direct-Vent Appliance.

1

10) Thread the cable through the access hole at the base of the unit and

connect the wires to the controller terminals on the right hand side

bottom of the PCB.

11) Secure the controller cable using the clamp provided.

12) Replace plastic cover over PCB and then replace the front cover of the

Rinnai Water Heater.

Suggested temperatures are:

Kitchen 120°F - 130°F, Shower 98°F - 110°F, Bath fill 102°F - 114°F

These temperatures are suggestions only. You may find higher or lower

temperatures more comfortable. Maintaining lower temperatures helps

save energy. To obtain water temperatures lower than 98°F, simply add

cold water.

Deluxe Controllers are an optional extra. ‘Controller’ and ‘Deluxe’

Controllers can be installed together. Controllers allow temperature

selection only. ‘Deluxe’Controllers have temperature selection, bath fill and

clock functions.

Controllers allow the water temperature to be set from the various

locations where they are installed. The temperature selected will be

available to all outlets. Below are the combination of Controllers that are

offered by Rinnai:

Controllers Combination Pattern

**See controller manual in controller carton box for more infomation detail.

Water Smart / Bath FillTemperature Table

2

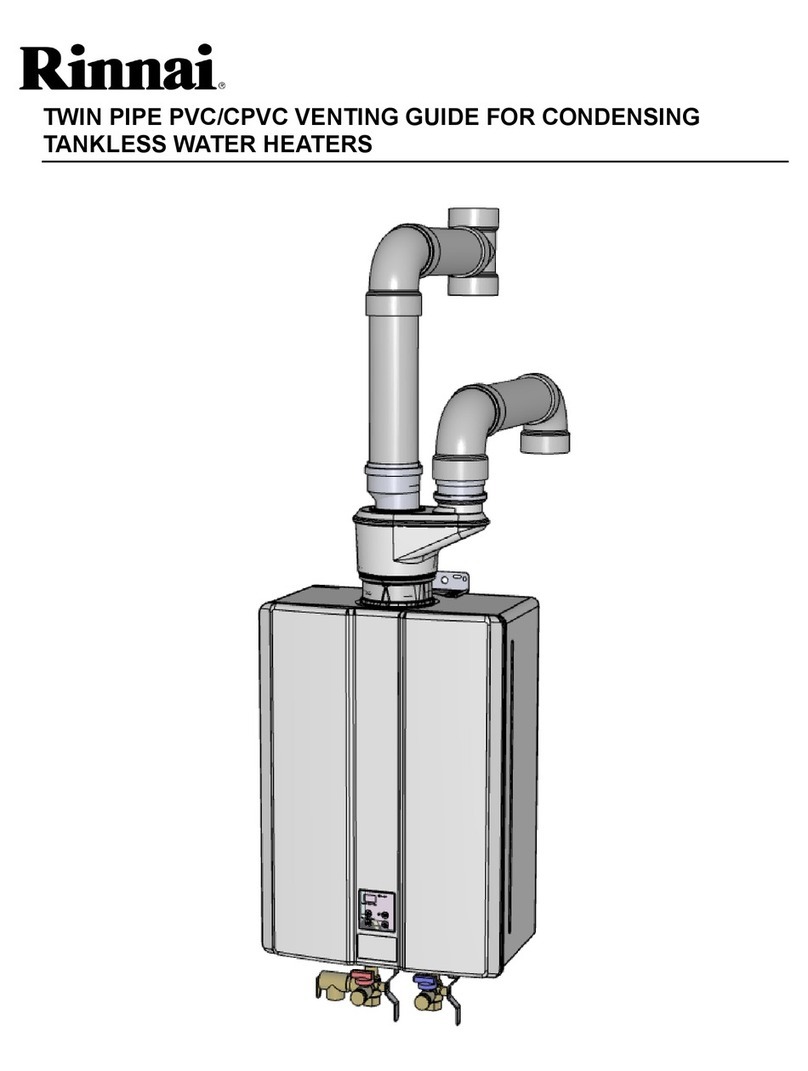

□The vent pipe has a negative slope/grade to the outside of three

degrees (3°) or 5/8" per foot of vent pipe.If the vent pipe is sloped back

towards the appliance as some code may require, provisions SHALL

be made to collect all condensation to drain off and away from the

appliance to a proper drain source.See local code for details.

□You have no more than three bends in your vent system and the length

does not exceed Rinnai specifications.

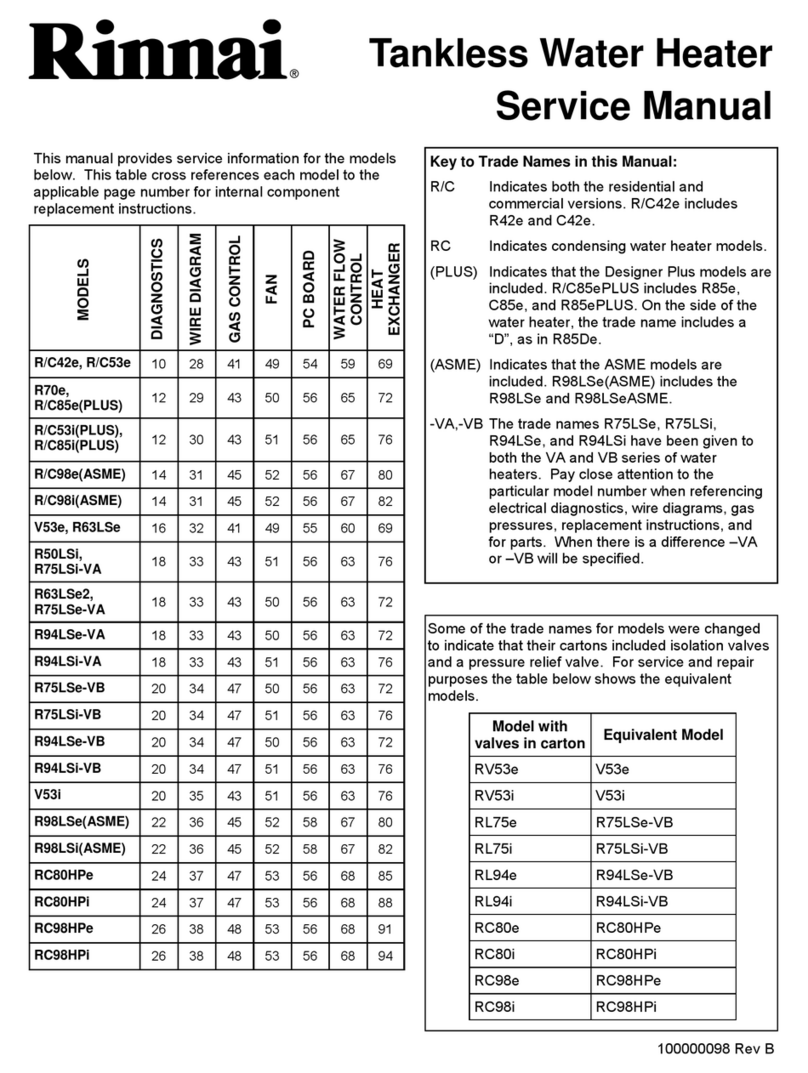

Thesettingsbelowarefactorydefaultsettings.Pleaseensurethemodel

numberandgastypeoftheunityouhave,matchesthemodelnumber

and gas type listed below; before settings any switches. If you need

assistance,contactRinnaiat(800)621-9419beforeproceeding.

WARNING

In appropriate Dip Switch setting can damage the Rinnai water heater and

may void the warranty of this unit

9. Set the Infinity to‘Forced Low’combustion by setting No.7 dip switch of

the (SW1) set of dip switches to‘ON’.(Fig.3).

10. Check the burner test point pressure.

11. Remove rubber access plug and adjust the regulator screw on the

modulating valve (Fig.4) as required inTable 1.Replace rubber access

plug.

12. Set the RinnaiWater Heater to ‘Forced High’combustion by setting

both No.7 and No. 8 dip switches of the bottom (SW1) set to‘ON’.

(Fig.5). Ensure maximum water flow !

13. Check the burner test point pressure.

14. Adjust the high pressure Potentiometer (POT) on the Printed Circuit

Board (PCB) as required to the pressure shown in Table 1.

IMPORTANT: Set dip switches 7 and 8 on the bottom (SW1) to‘OFF’

to return the appliance to 'Normal' combustion. (Fig.6).

15. Close hot water tap.

16.Turn ‘OFF’the gas supply and 120V power supply.

17. Remove pressure gauge & replacing sealing screw.

18.Turn ‘ON’the gas supply and 120V power supply.

19. Operate unit and check for gas leaks at test point.

20. Replace the front cover of the appliance.

34

Top of Heater

Back of Heater

Front of Heater

Sides of Heater

Floor

Vent/Air Intake

6 inches

0 inch

6 inches

2 inches

12 inches

0 inch

INSTALLER'S INSTALLATION INSTRUCTIONS

Remote Controllers- General

The remote controls for the Rinnai Water Heater allow the customer to

control the functions of the water heater and to diagnose certain fault

conditions.

Before installing the remote controllers, determine the most convenient

location(s).

When deciding on the best location for the remote controllers, please

consider the

following items:

1) Place the controllers out of reach of small children.

2) Avoid locations where the controller(s) will become hot.(over the stove,

near the oven or a radiant heater.

3) Avoid direct sunlight.(The digital monitor can be difficult to read in

direct sunlight)

4) Avoid areas where the remote can be splashed with cooking water, oil

or sauce.

5) The remote controller cables carry low voltage, 12VDC digital.

The controllers can be wired in series or in parallel depending on the

distance from the Rinnai Water Heater to the controllers.

Every installation is different

REMOTE CONTROLLER OPERATION

GENERAL CONTROLLER INFORMATION

DIAGNOSTIC USE OF CONTROLLER

1. To Display Maintenance Codes: Press ‘On/Off’ button. To sequence

through stored maintenance codes, press‘On/Off’ followed by the

thermostat button.

2. To DisplayWater Flow through water heater: Press thermostat

button, hold for 2 seconds and simultaneously press‘On/Off’button.

3. To display OutletWaterTemperature: Press ‘thermostat button’,

hold for 2 seconds and simultaneously press‘On/Off’ button.

TO CHANGETEMPERATURES FROM °F to °C

1. Press and hold‘On/Off’button for 5 seconds while water heater is OFF.

2.To change back from °C to °F, please repeat step 1.

MUTE

To eliminate the beeping sound, press and hold and button

simultaneously until a‘beep’is heard (approximately 5 seconds).

Temperature controllers allows precise temperature control by the user.

When used correctly, the hot water unit will deliver the selected

temperature, even when the water flow is varied, or more than one tap is in

use. Each Temperature Controller can be individually programmed,

however the water heater unit can only deliver one set temperature at any

time.The available temperatures (°F) are as follows:

TemperatureTable by Models

□▲

□▲

□▼

□▲ □▼

GAS PRESSURE SETTING AND DIAGNOSTICS

INFORMATION

NOTE:For additional installation and commissioning

information refer to Operation / Installation Manual

APPLIANCE OPERATING PRESSURES

COMMISSIONING

With all gas appliances in operation at maximum gas rate, the flowing

inlet pressure at the incoming test point on the Rinnai Water Heater

should read 6"W.C. - 10.5"W.C.on Natural Gas and 10"W.C. - 13.5"W.C.

on Propane Gas. If the pressure is lower, the gas supply is inadequate

and the appliance unit will not operate to specification. Check gas meter,

regulator and pipework for correct operation/sizing and rectify as

required.

GAS PRESSURE SETTING

(Ensure gas pressure check under Commissioning above has been

completed first !)

The regulator is electronically controlled and factory pre-set. Under

normal circumstances it does not require adjustment during

installation. Make adjustments only if the unit is not operating

correctly and all other possible causes for incorrect operation have

been eliminated.

1.Turn ‘OFF’the gas supply.

2.Turn ‘OFF’120V power supply.

3. Remove the front cover from the appliance.

4. Check gas type switches (Fig.1) are in the correct position

(dip switch 1 of SW2‘ON’= NG,‘OFF’= LPG)

Note:‘ON’towards front,‘OFF’towards rear.

5. Attach pressure gauge to burner test point, located on the gas control.

(Fig.2).

6.Turn ‘ON’the gas supply.

7.Turn ‘ON’120V power supply.

8. If remote controllers are fitted, turn the unit‘ON’at the kitchen controller,

select the maximum delivery temperature and open all available hot

water taps full including the shower.

(CAUTION: Ensure building occupants do not have access to hot water

outlets during this procedure).

THIS APPLIANCE MUST BE INSTALLED, SERVICED

AND REMOVED BY ANAUTHORISED PERSON

DURING PRESSURE TESTING OF THE CONSUMER PIPING

ENSURE GAS COCK SITUATED BEFORE UNIT IS SHUT-OFF.

FAILURE TO DO SO MAY RESULT IN SERIOUS

DAMAGE TO THE APPLIANCEAND POSSIBLE INJURY.

WARNING

Nat.G Prop.G Nat.G Prop.G Nat.G Prop.G

REU-V2532FFUD

REU-V2532FFUCD

REU-V2520FFUD

REU-V2520FFUCD

150PSI

6"W.C.

10.5"W.C. 10"W.C.

13.5"W.C. 0.77"W.C. 0.93"W.C.

3.7"W.C. 4.2"W.C.

Table 1.

Water

Inlet Min.

Gas Inlet

Min./ Max. Forced Low Forced High

No code or

blank

display Nothing happens when water

flows through water heater.

Clean inlet filter screen and ensure you have at least the

minimum flow rate required to fire unit. Check for pipe dope

inside water flow control turbine.

On new installations, ensure hot and cold water lines are not

crossed.

Check for bleed over.Isolate unit from building by turning off

hot water line to building.Then open your pressure relief

valve, if unit fires, thereís a bleed over in your plumbing.

If a circulating system is in use, it must be isolated also.

Remote control does not light up but you have 12VDC at the

terminals for controls:

Disconnect water flow control motor, then turn on hot water,

if unit fires replace water flow control assembly.

Code

Displayed

00

Fault

When checking maintenance code history,

“00” is substituted for“LC” Build up of lime scale in heat exchanger - needs to be

flushed.

03

Power interruption during Water Smart/Bath Fill

(Hot water will not flow when power returns)

Turn off all hot water taps.Press ON/OFF twice.

33 Heat exchanger outlet water temperature

faulty Check H.E.outlet sensor or wiring. Measure resistance of

sensor.Clean sensor of scale build-up

34

52 Modulating Solenoid Valve signal abnormal Check gas control wiring harness and measure resistance of

valve coil in ohms.

61 Combustion Fan Failure Combustion fan or wiring harness faulty. Make sure

motor/fan turns freely. Measure resistance of motor winding.

71 SV0, SV1, SV2 or SV3

Solenoid Valve Circuit Faulty Check all gas solenoid wiring harness and connections.

Measure resistance of each solenoid valve coil.

LC Scale build-up in Heat Exchanger Build up of lime scale in heat exchanger ñ needs to be

flushed.

02 No burner operation during freeze

protection mode

Verify that gas supply is turned on to the water heater and

valve at meter or tank is open.Verify proper gas type and

supply pressure. Bleed air from gas line.Verify all ignition

component/wires are connected.

10 Air intake supply or exhaust blockage Check for a restriction in exhaust or intake vent, verify proper

dip switch settings.Ensure only Rinnai approved venting

components are used.

14 Thermal Fuse Ensure high and low fire manifold gas pressures are properly

set.Verify dip switch settings are correct.Measure

resistance in ohms of safety circuit.

11 No Ignition Verify that gas supply is turned on to the water heater and at

meter or tank.Verify proper gas type and supply pressure.

Bleed air from gas line.Verify all ignition component/wires

are connected.

32 Outlet water temperature sensor reading

out of expected range Check outlet temperature sensor or wiring for damage.

Measure resistance of sensor.Clean sensor of scale build -

up.

65 Water Flow Servo Faulty

(Does not stop flow properly) Water Flow Servo or wiring faulty. Check Water Flow Servo

wiring harness conection.

Measure resistance of Water Flow Servo wiring.

16 Over Temperature Warning Verify dip switch settings, check manifold pressure and verify

gas type for water heater. Check for clogged heat

exchanger.Check for low water flow in a circulating system

causing short-cycling.

72 Flame Sensing Device Faulty Check flame rod and wiring harness connections. Measure

micro amp output of sensor circuit with flame present. Clean

flame sensor of any build-up.Check for debris in burner

chamber that may block flame from sensor.

12 Flame Failure, poor ground connection Make sure gas is turned on at the water heater; check for

obstructions in exhaust vent.Ensure only Rinnai approved

venting components are used.Verify proper grounding.

Check for debris or moisture in burner area.

Items to Inspect

INSTALLER'S INSTALLATION INSTRUCTIONS

-Warnings-

This manual must be followed exactly.

The Rinnai Water Heater is not suitable for use in pool or spa applications.

Installer must install a Pressure relief valve. Pipe pressure relief discharge to

a drain or outside environment.

Maintain proper space around the unit for proper servicing and operation.

Minimum clearances from combustible materials are listed below.

RECOMMENDEDVENT/AIR INTAKE TERMINAL POSITION

Terminals should be so positioned as to avoid products of combustion

entering openings into buildings or other flues or vents.

REF U.S. Installations Candadian

Installations

DESCRIPTION

K 3 feet 6 feetClearance to a forced air inlet into a building

N 2 feet 2 feetVent FIue from wall (FIat or Pitched Roof)

P 1 foot 1 footClearance between two vertical flue on the same pIane

Q 1 foot 1 footHorizontal between two terminals on the same wall

S 4 feet 4 feetClearance from terminal facing a terminal

R 5 feet 5 feet

Clearance between two Vertical flue on pitched roof above

each other

O 5 feet 5 feet

Vertical between two terminals on the same wall above each

other

M3 feet 3 feetClearance under deck, veranda, porch, or balcony

(open on 3 sides)

L * 7 feet

Clearance above paved sidewalk or paved driveway located on

public property

J **1 foot 1 foot

Clearance to nonmechanical air supply inlet to building or the

combustion air inlet to any other appliance

INSTALLER'S INSTALLATION INSTRUCTIONS

Locating the vent terminal

REF U.S. Installations Canadian

Installations

DESCRIPTION

A 1 foot 1 footClearance above grade, veranda, porch, deck, or balcony

B **1 foot 1 foot

**

Clearance to window or door that may be opened

C Clearance to permanently closed window

D 3 feet 3 feetVertical clearance to ventilated soffit, eaves or overhang

E 3 feet 3 feetClearance to unventilated soffit, eaves or overhang

F 1 foot 1 footClearance to outside corner

G 2 feet 2 feetCIearance to inside corner

I * 3 feetClearance to service regulator vent outlet

H*

3 feet within a height

15 feet.above the

meter/reguIator

assembly

Clearance to each side of center line extended above

meter/regulator assembly

INSTALLER'S INSTALLATION INSTRUCTIONS

Remote Controllers - Installation

1) Determine a suitable location for the

controller.

2) Make three holes on the wall as

shown.

3) Run the cable between the controller

and the Rinnai Water Heater or the

controller and the other controller.

4) Remove the face plate from the remote controller.

5) Connect the cable to the remote controller.

6) Mount the controller to the wall using the holes drilled in step 2.

7) Disconnect the power from the Rinnai Water Heater.

8) Remove the cover of the Rinnai Water Heater.

9) Remove the plastic cover from the PCB and electrical connections.

DO NOT ATTEMPT TO CONNECT THE REMOTE CONTROLLERS WITH

THE POWER ON, THERE'S 120 VOLT POTENTIAL, NEXT TO THE

REMOTE CONTROLLER CONNECTIONS INSIDE THE UNIT. All service

and wiring should be performed by a certified installer.

111

32"

35

16"

model

REU-V2532FFUD

REU-V2520FFUD(°F)

REU-V2520FFUCD(°F)

REU-V2532FFUCD(°F) 98

98

100

100

102

102

104

104

106

106

108

108

110

110

115

115

120

120

120

125

125

125

130

130

130

135

135

135

140

140

140

150

150

160

160

185

Approx.

temperature(°C) 37 38 39 40 41 42 43 46 49 52 54 57 60 66 71 85

185

temperature

water smart/

bath fill temperature (°F)

Approx.

temperature (°C) 49

120

48

118

47

116

46

114

44

112

43

110

42

108

41

106

40

104

39

102

38

100

37

98

temperature

1+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

+

MC-91-1US

MC-91-1US

MC-91-1US

MC-91-1US

MC-91-1US

MC-91-1US MC-91-1US BC-100V MC-100V

MC-100V

MC-91-1US **MC-91-1US

MC-91-1US

BC-100V

MC-91-1US

MC-91-1US

MC-91-1US2

3

4

5

6

Remote and Deluxe Controllers

(M)Water Flow Control Device Servo or Geared Motor:

NOTE:The grey wire listed above turns to black at B connector on the PCB,the orange wire turns to red.

(QS)Water Flow Sensor:

By-pass Flow Control: (REU-V2532FFU/FFUC ONLY)

(IG) Ignition System:

(FM) Combustion Fan Motor:

Set your meter to the hertz scale. Reading across the red and yellow wires at terminals 2 and 3

you should read between 60 and 350 hertz.

Thermal Fuse:

Overheat Switch:

Flame Rod:

Place one lead of your meter to the flame rod and the other to earth or ground. With the unit

running you should read between 5 ~ 150 VAC. Set your meter to the µamp scale, series your

meter in line with the flame rod. You should read 1µor greater for proper flame circuit. In the

event of low flame circuit remove the flame rod and check for carbon and/or damage.

Heat Exchanger, AirTemperature, and Outgoing WaterTemperature Thermistors:

Check all thermistors by inserting meter leads into each end of the thermistor plug. Set your

meter to the 20K scale and read resistance.You should be able to apply heat to the thermistor

bulb and see the resistance decrease.Then apply some ice to the thermistor and the resistance

should increase. See below for examples of temperatures and resistance reading at those

temperatures.

Example: 59°F = 11.4 ~ 14K

86°F = 6.4 ~ 7.8K

113°F = 3.6 ~ 4.5K

140°F = 2.2 ~ 2.7K

221°F = 0.6 ~ 0.8K

OutgoingWaterThermistor:

Heat ExchangerTemperatureThermistor:

Surge Protector:

With the power off you can check the continuity through the surge protector. Place one meter

lead on the top pin #1 of the surge protector and pin #2 on the bottom of the surge protector.

Then check across top pin #3 and bottom pin #1, if you read continuity across these two points

the surge protector is good. If you do not get continuity, replace the surge protector.

Remote Controls:

Frost Protection:

This unit has four frost protection heaters mounted at different points inside the unit, to protect

the water heater from freeze ups. There are two heaters located on the outlet hot water line

next to the thermistor.

Using a voltage meter set on the 200 ohm scale, you should have a resistance reading of 26 ~

30 ohms through each of these heaters. The heater located on the heat exchanger piping

should have a resistance reading of 81 ~ 86 ohms and the one located in the water flow sensor

valve has a resistance reading of 16 ~ 19 ohms.Voltage throughout this circuit should be 120

VAC.

Amp Fuses:

This unit has two inline (3) amp glass fuses. Remove the fuse and check continuity through it.If

you have Continuity through the fuse, it is good. If you can not read continuity, the fuse is blown

and must be replaced.

SERVICEMAN'STROUBLESHOOTING INFORMATION

for the RINNAIWATER HEATERS

IMPORTANT SAFETY NOTES:

There are a number of (live) tests that are required when fault finding this

product. Extreme care should be used at all times to avoid contact with

energized components inside the water heater. Only trained and qualified

service agencies should attempt to repair this product. Remember,

before checking for resistance readings, you should disconnect the power

source to the unit and isolate the item to be checked from the circuit (unplug it).

(TR)Transformer:

(SV1, SV2,SV3 and POV) Gas valve and Modulating solenoids: (Set meter above 2K)

Wire color

Black ~ White

Blue ~ Brown

Voltage

90 ~ 100 VAC

108 ~ 132 VAC

Resistance

51 ~ 63 ohms

51 ~ 63 ohms

Connector #

F9

F7

Pin #'s

1 ~ 2

1 ~ 3

Red ~ Black

White ~ Black

Yellow ~ Black

6 ~ 45 VDC

5 ~ 10 VDC

11 ~ 13 VDC

N/A

9.2K ~ 9.4K

3.5K ~ 3.9K

A1

A1

A1

1 ~ 2

2 ~ 4

2 ~ 3

(Main) Pink ~ Black

(SV1) Black ~Yellow

(SV2) Black ~ Blue

80 ~ 100 VDC

80 ~ 100 VDC

80 ~ 100 VDC

1.7K ~ 2K ohms

1.7K ~ 2K ohms

1.7K ~ 2K ohms

E1

E2

E3

1 ~ 2

2 ~ 3

2 ~ 4

(SV3) Black ~ Brown 80 ~ 100 VDC 1.7K ~ 2K ohms E4 2 ~ 5

(POV) Pink ~ Pink 2 ~ 15 VDC 67 ~ 81 ohms C2 3 ~ 4

Grey ~ Grey 90 ~ 100 VAC N/A A1 1 ~ 2

Red ~ Red 12 VDC Below 1 ohm B ~ C B6 ~ C1

Red ~ Red 12 VDC Below 1 ohm B ~ C B6 ~ C1

White ~ White N/A See example above B B3 ~ B4

White ~ White N/A See example above B B3 ~ B12

Terminals D1, D210 ~ 13 VDC digital 1.5K ~ 1.9K ohms H 1 ~ 3

Black ~ White

Blue ~ Brown 108 ~ 132 VAC

108 ~ 132 VAC N/A

N/A

Surge Protector D1

Surge Protector D2

1 ~ 3

1 ~ 2

Brown ~ White

Orange ~ White

Yellow ~ White

Red ~ White/ Ground

2 ~ 6 VDC

Unit in operating

mode

15 ~ 35K

G4 ~ G5

G2 ~ G5 4 ~ 5

2 ~ 5

G1 ~ G5

G3 ~ G5 1 ~ 5

3 ~ 5

Red ~ Blue

Grey ~ Brown

Grey ~Yellow

11 ~ 13 VDC

4 ~ 6 VDC

N / A

22 ~ 26 ohms

N / A

N / A

B2

B2

B2

9 ~ 10

5 ~ 7

Black ~ Red

Yellow ~ Black 11 ~ 13VDC

4 ~ 7 VDC 5.5K ~ 6.2K

1 meg ~ 1.4 meg B4

B4 5 ~ 6

1 ~ 5

5 ~ 8

Grey ~ Orange 11 ~ 14VDC N / A B2 5 ~ 6

REU-V2532FFUD-US

REU-V2532FFUCD-US

REU-V2520FFUD-US

REU-V2520FFUCD-US

U245-3245(00)

In Use Indicator

Indicates that a hot water tap

is open and that control of the

temperature has been taken at

another controller.

Digital Monitor

Indicates the selected

water temperature.

Error messages flash

in the event of a failure.

Thermostat

Increases or decreases

the desired water

temperature.

Priority Indicator

Indicates whether this

controller has priority

control over the water

temperature

Priority

Pressing takes control

of the water temperature

by this controller.

ON/OFF

Used to switch the

water heater on and off

Attention Installer! - HaveYou Checked Everything?

For full details - Always Refer to Rinnai Installation Instructions

□HOT (outlet) and COLD (inlet) water lines are not crossed to the unit

and are leak free.

□You have installed isolating valves, unions, and drain down vales on the

cold water inlet line and hot water outlet lines.(These components are

used for servicing and/or removing the appliance quickly).

□COLD water inlet filter was cleaned after installation.(The filter MUST

be cleaned after installing the unit)

□A pressure relief valve is installed and is rated for 200,000 Btu's at 150

PSI per local code.

□120 VOLTS A.C. is connected to the unit, it is properly GROUNDED

and circuit is turned on.

□Gas supply system is properly sized. All gas meters, regulators, gas

line types, tanks, etc.have a BTU value.Please confirm that all

components meet the gas requirements at this location.Verify the

system is functioning correctly by connecting your manometer to the

gas pressure test port on the Rinnai unit. Operate all gas appliances in

the facility.The inlet gas pressure must not drop below that listed in the

ownerís manual specification sheet or appliance rating plate.

□Proper gas type and pressure is supplied to the unit. (See owner's

manual for correct inlet gas pressures in the specification section.

Normal inlet gas pressures are 7" to 10" of water column for natural

gas, and 11" to 13" of water column for propane gas).

□Gas supply pipe is purged of foreign material before connection.

□Proper model controllers are used, connected and functioning.

□Instructed the customer how to operate the Controllers.

□Verify proper clearances around the unit and all vents and air intakes.

(See owner's manual for all clearance requirements.)

□Explained to the customer to never store anything around the vent

terminals or block the air and/or exhaust ports to the unit.

For Internal models only

□Ensure you used the proper venting materials for the unit you have

installed.

RinnaiWater Heaters

Dip Switch Default Settings

Fig. 3

Fig. 5 Fig. 6

ON

ON

SW1

ON

SW1

Fig. 2Fig. 1

Fig. 4

Regulator adjustment

screw access plug

Burner test point

GAS

COLD water inlet filter

inlet GAS test port

WATER INLET

(COLD)

WATER OUTLET

(HOT)

CLAMP

REMOTE

CONTROL CABLE

REMOTE CONTROL

CONNECTION TERMINALS

Water Smart / Bath Fill temperature cannot exceed 120°F for the following

commercial models with no by-pass :REU-V2520FFUCD

◆REU−V2532FFUD

◆REU−V2532FFUCD

NAT.GLPG LPG NAT.G NAT.GLPG LPG NAT.G

◆REU−V2520FFUD

◆REU−V2520FFUCD

Residential Units Commercial Units

Dip Switch Settings Dip Switch Settings

Residential Units

Dip Switch Settings

Commercial Units

Dip Switch Settings

1

O

F

F

2

3

4

5

6

7

8

ON

→

O

F

F

2

3

4

1

→

ON

1

O

F

F

2

3

4

5

6

7

8

→

ON

O

F

F

2

3

4

1

→

ON

1

O

F

F

2

3

4

5

6

7

8

→

ON

O

F

F

2

3

4

1

→

ON

1

O

F

F

2

3

4

5

6

7

8

→

ON

O

F

F

2

3

4

1

→

ON

1

O

F

F

2

3

4

5

6

7

8

ON

→

O

F

F

2

3

4

1

→

ON

1

O

F

F

2

3

4

5

6

7

8

→

ON

O

F

F

2

3

4

1

→

ON

1

O

F

F

2

3

4

5

6

7

8

→

ON

O

F

F

2

3

4

1

→

ON

1

O

F

F

2

3

4

5

6

7

8

→

ON

O

F

F

2

3

4

1

→

ON

Sensor or wiring faulty.Verify fan blade is mounted securely

to shaft. Check for airflow restrictions in venting system.

(Indoor Units Only) Combustion air sensor

reading out of expected range

OFF/ON

Vent/air intake

piping length

See Owner's manual for more in informd detail.

12345678

070 00012 31445 7