Rinnai Sensei RU199i User manual

Other Rinnai Water Heater manuals

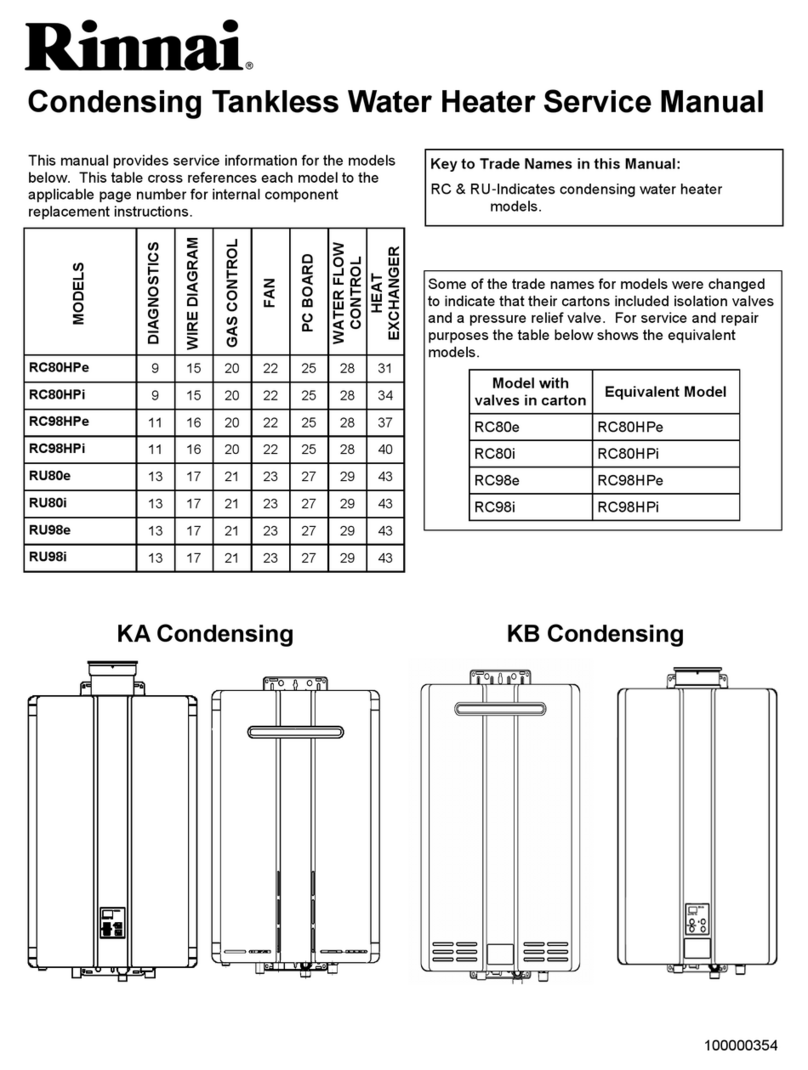

Rinnai

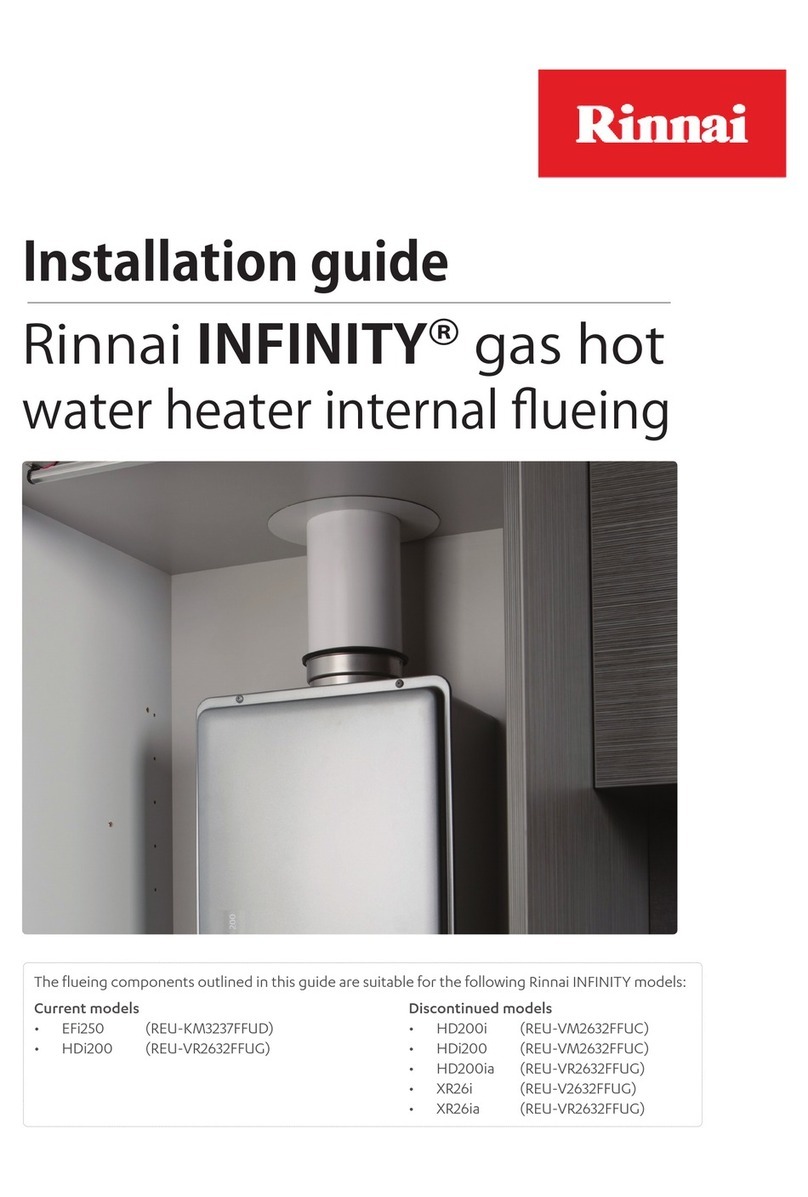

Rinnai INFINITY User manual

Rinnai

Rinnai INFINITY 32 User manual

Rinnai

Rinnai VC Series User manual

Rinnai

Rinnai Continuum Series User manual

Rinnai

Rinnai Circ-Logic RU80i User manual

Rinnai

Rinnai Continuous Flow Water Heaters User manual

Rinnai

Rinnai RUS-51FT User manual

Rinnai

Rinnai V75i User manual

Rinnai

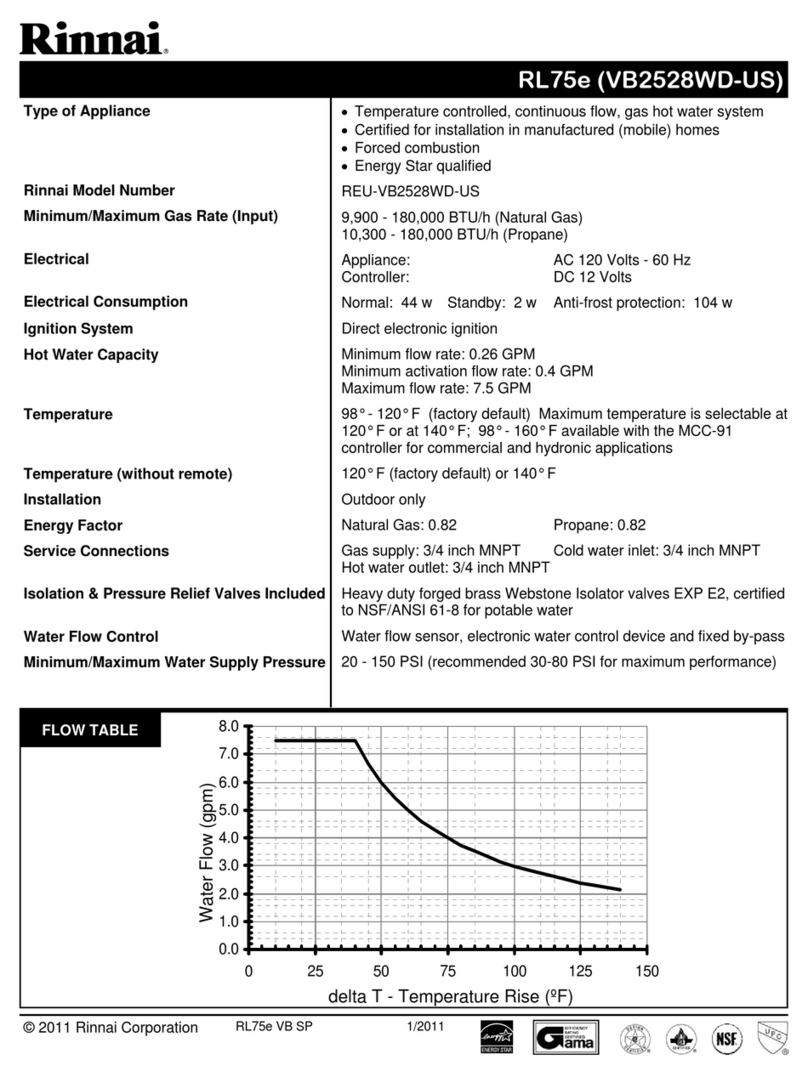

Rinnai REU-VB2528WD-US User manual

Rinnai

Rinnai Infinity 16F User manual

Rinnai

Rinnai RV53I Specification sheet

Rinnai

Rinnai Infinity 24e User manual

Rinnai

Rinnai Circ-Logic RL75i User manual

Rinnai

Rinnai infinity 32 HD 250 E User manual

Rinnai

Rinnai REU-KA2530FFUD-US User manual

Rinnai

Rinnai Infinity XR26ia User manual

Rinnai

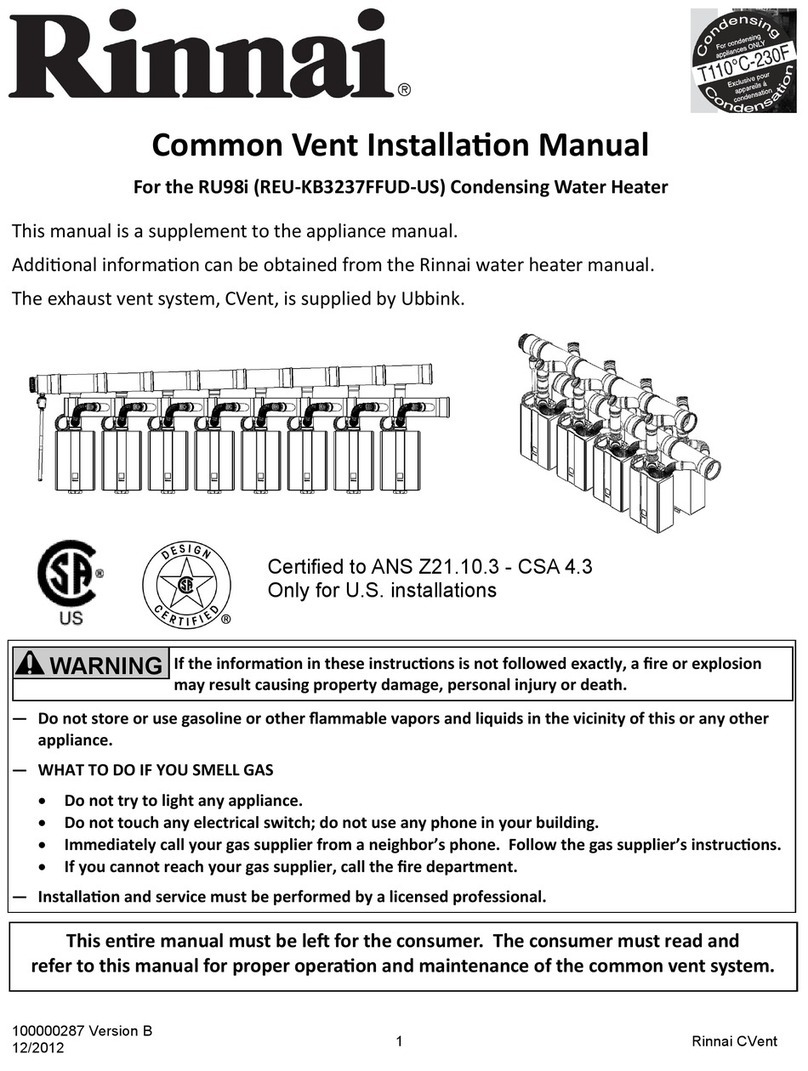

Rinnai Circ-Logic RU98i User manual

Rinnai

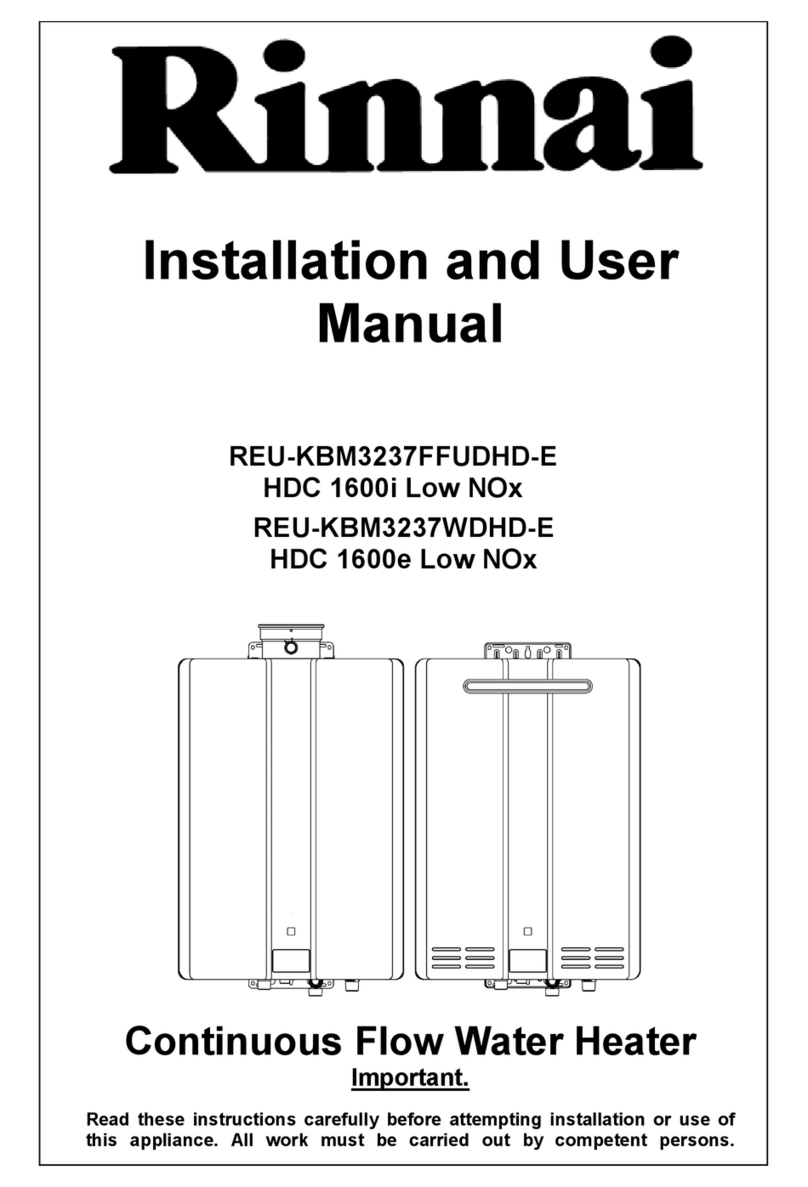

Rinnai HDC 1600i Low NOX User manual

Rinnai

Rinnai RIN25E24P User manual

Rinnai

Rinnai One 11i Specification sheet

Popular Water Heater manuals by other brands

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

A.O. Smith

A.O. Smith Gphe 50 instruction manual

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions

Koryo

Koryo KWHZF15Y user manual

Pentair

Pentair PSC-14-4-02 Installation and operation manual

GE

GE 40M06AAG Energy guide