vi

Contents

Outline......................................................................................................... 1

NC-72A Main Unit External View ............................................................... 2

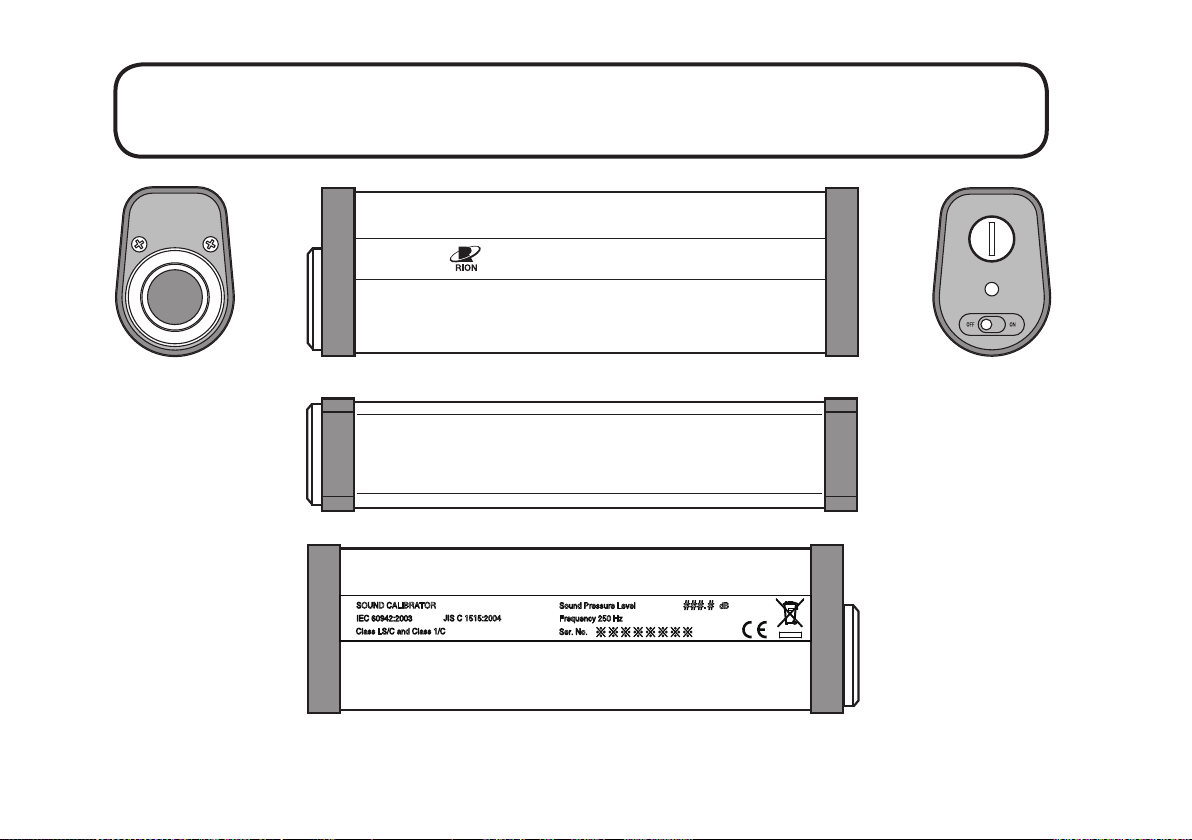

Accessories External View........................................................................... 3

Names of Parts and Functions...................................................................... 5

Coupler ................................................................................................... 5

Power supply section............................................................................... 6

Side view and top view ........................................................................... 7

Operation ..................................................................................................... 8

Inserting the batteries ............................................................................. 8

Checking the battery voltage ................................................................ 10

Sound pressure measurement system (sound level meter) calibration .... 11

Using the microphone adapters ............................................................. 15

Reference ................................................................................................... 16

Output sound pressure level compensation............................................ 16

Electromagnetic Compatibility ............................................................. 26

Specications ............................................................................................. 29