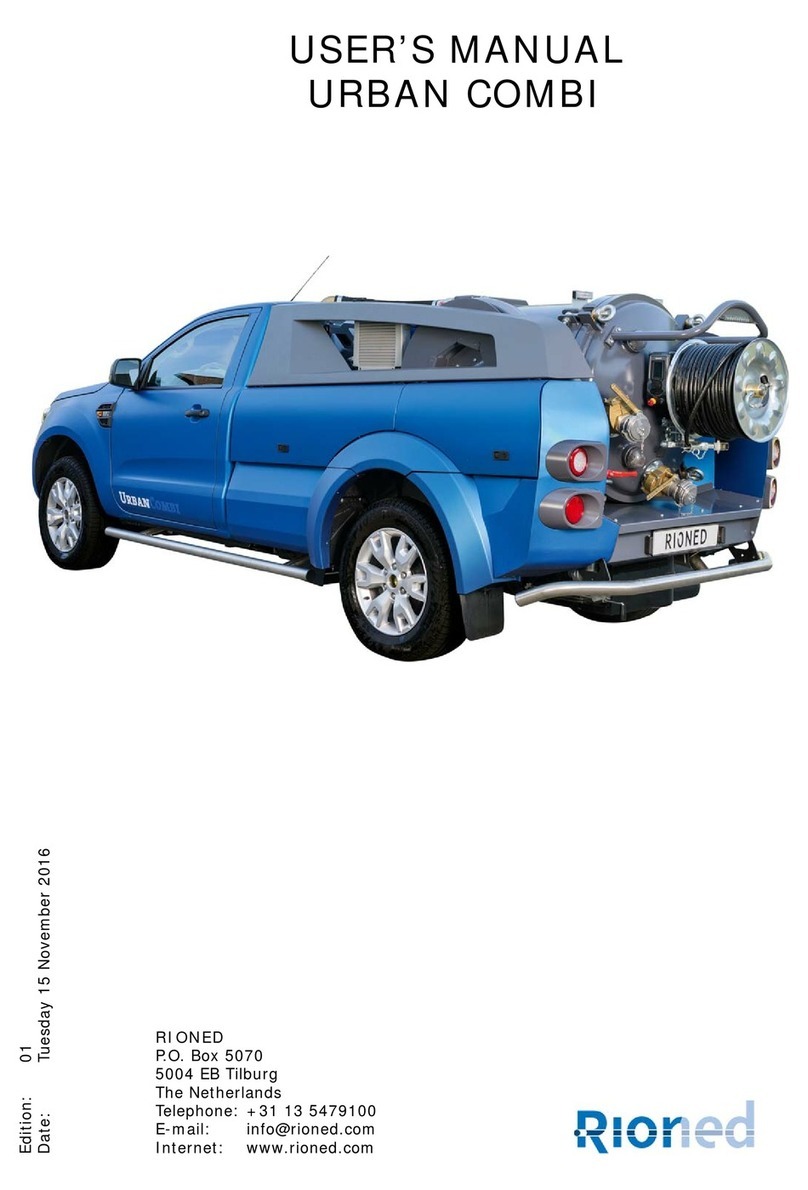

Rioned AquaJet User manual

AquaJet

user manual

2

Operating and maintenance manual

Identification number: vo . . . . .

Serial number: . . . . . . . . . . . . .

Type AquaJet

Year of manufacture: . . . .

Manufacturer:

Rioned

Centaurusweg 45

5015 TC Tilburg

P.O. Box 5070

NL-5004 EB Tilburg

Tel. no.: +31 13-5479100

Email: [email protected]

Internet: www.rioned.com

For information about adjustments, maintenance or repairs not contained in this user manual,

contact Rioned.

Original user manual

Publication date: 16/4/19

Version: 08

All rights reserved. No part of this publication may be reproduced and/or made public by

means of printing, photocopying, microfilm or any other means whatsoever without the prior

written permission of Rioned.

Rioned reserves the right to make changes to parts at any time, without providing prior or direct

notification to the buyer. The content of this user manual may also be changed without prior

notification.

3

Preface

This user manual is intended for the professional user. It is intended to enable the user to

operate the machine and must always be kept with the machine.

The photographs and drawings in the manual are intended to support the text.

In this user manual you will first find an introduction that describes, among other things, the

intended purpose of the machine. Then there is an explanation of how the machine is

constructed and how it works in general. This is followed by an overview of the most important

safety aspects.

Then the best way to start up and operate the machine is explained. The standard functions and

additional functions are described separately. The information in the Maintenance section

allows you to perform simple maintenance work yourself. Troubleshooting tips to help you

correct minor malfunctions yourself are also provided.

Finally, at the end of this user manual you will find an index to help you quickly find information

and a number of annexes containing, among other things, Rioned's contact details.

4

5

Table of contents

4 Introduction .......................................9

5 Description and principle of

operation............................................ 11

5.1 Introduction............................................................ 11

5.2 Machine.................................................................. 11

5.2.1 Design and principle of operation......................... 11

5.2.2 Symbols on pressure gauge, pressure regulator

and valve controls ..................................................19

5.2.3 Accessories.............................................................19

6 Safety..................................................21

6.1 Introduction............................................................ 21

6.2 General danger symbol..........................................21

6.3 Working safely ........................................................ 21

6.4 Dangers of non-compliance with safety

instructions............................................................. 21

6.5 Use only by authorized personnel .........................22

6.6 Bystanders ..............................................................22

6.7 Restrictions on use.................................................22

6.8 Thunderstorm ........................................................22

6.9 Spraying..................................................................23

6.10 Spray break .............................................................23

6.11 Sewer gases ............................................................23

6.12 Water tank ..............................................................23

6.13 Emergency stop......................................................23

6.14 Levers and valves ...................................................23

6.15 Personal protective equipment............................. 24

6.16 Water discharge..................................................... 24

6.17 Other machine safety provisions.......................... 24

6.17.1 Introduction........................................................... 24

6.17.2 Pressure regulator ................................................. 24

6.17.3 Protective guards .................................................. 24

6.18 Safety sticker...........................................................25

7 Operation: standard functions........ 27

7.1 Introduction............................................................27

7.2 Checks before departure ........................................27

7.3 Preparations at the workplace ...............................28

7.3.1 Preparing the vehicle..............................................28

7.3.2 Before starting........................................................28

7.3.3 Workstations ..........................................................30

7.3.4 Starting the engine.................................................32

7.3.5 Starting engine type Honda GX630.......................32

7.3.6 Starting engine type Honda GX690 with the

control box:.............................................................34

7.3.7 Starting the engine with the eControl ................... 35

7.3.8 Starting the engine with the eControl+ .................36

7.3.9 Starting the engine with the Riomote control

(eControl) ...............................................................38

7.3.10 Starting the engine with the Riomote control

(eControl+).............................................................38

7.3.11 Starting Honda GX690 with the 5-channel

cable reel ............................................................... 40

7.4 Unblocking a sewer................................................ 41

7.4.1 Spray nozzle warning............................................. 41

7.4.2 Preparations for spraying ...................................... 41

7.4.3 Starting spraying.................................................... 41

7.4.4 Stopping spraying .................................................. 45

7.5 Handling the high pressure hose..........................46

7.6 Cleaning a wall, terrace or floor.............................47

7.6.1 Warnings for spray gun .........................................47

7.6.2 Preparations for spraying ......................................47

7.6.3 Pressurizing the system.........................................47

7.6.4 Starting spraying....................................................49

7.6.5 Depressurizing the system....................................49

7.6.6 Stopping the engine................................................51

7.7 Ending the work ..................................................... 53

7.7.1 Cleaning up, securing and draining ...................... 53

7.7.2 Additional steps during freezing temperatures.... 53

8 Operation: extra functions .............. 59

8.1 Introduction ........................................................... 59

8.1.1 Location of extra functions:...................................59

8.2 eControl.................................................................. 61

8.2.1 Design and principle of operation ........................ 61

8.2.2 eControl.................................................................. 61

8.3 eControl+ ...............................................................62

8.3.1 Design and principle of operation ........................62

8.3.2 eControl+ ...............................................................63

8.3.3 Lightbar ..................................................................64

8.3.4 Navigation bullets..................................................64

8.3.5 Functions and symbols..........................................68

8.3.6 Tachometer ............................................................69

8.4 Riomote control (option) ......................................70

8.4.1 Introduction ...........................................................70

8.4.2 Preparation for use ................................................70

8.4.3 Replacing the battery ............................................. 73

8.4.4 5-channel Riomote control (eControl) ..................74

8.4.5 5-channel Riomote control (eControl+) ................ 75

8.4.6 7-channel Riomote control ....................................76

8.5 Functions 5-channel wired remote control ........... 77

8.6 Pulsator .................................................................. 78

8.6.1 Introduction ........................................................... 78

8.6.2 Manual operation pulsator....................................79

8.6.3 Starting the pulsator with the eControl+ ..............79

8.6.4 Stopping the pulsator with the eControl+ ............80

8.6.5 Setting the speed with the eControl+ when the

pulsator is switched on.......................................... 81

8.6.6 Starting the pulsator with the Riomote control ....82

8.6.7 Stopping the pulsator with the Riomote control ..82

8.7 Reel......................................................................... 83

8.7.1 Safety ...................................................................... 83

8.7.2 Hydraulically reeling high pressure hose in/out... 83

8.7.3 Manually reeling high pressure hose out..............84

6

8.7.4 Hose guide ............................................................ 84

8.7.5 Reeling high pressure hose in/out with the

eControl+................................................................85

8.7.6 Manually reeling out high pressure hose

controlled by eControl+ ........................................87

8.7.7 Reeling in/out with the Riomote control.............. 89

8.7.8 Hose meter counter eControl+.............................90

8.7.9 Activating the eControl+ ....................................... 90

8.7.10 Switching the hose counter on and off................. 90

8.7.11 Resetting hose counter to 0 metres ..................... 90

8.7.12 Switching between ‘metres’ and ‘feet’...................91

8.8 Electronic water level control.................................91

8.9 Dry running protection ......................................... 92

8.10 Suction venturi .......................................................93

8.11 Second HP reel instead of supply reel.................. 94

8.12 Non-return valve in supply line ............................ 94

8.13 Hour counter..........................................................95

8.14 Work light ...............................................................95

8.15 Rotating beacon .....................................................95

8.16 Additional steps during freezing temperatures

with antifreeze tank................................................95

8.16.1 Removing antifreeze ............................................. 97

8.17 Eco mode eControl+ ............................................. 97

8.17.1 Introduction........................................................... 97

8.17.2 Switching eco mode on and off ............................ 97

8.17.3 ECO Start/Stop...................................................... 99

8.17.4 ECO Stop ............................................................. 100

8.18 Management function eControl+ ....................... 100

9 Maintenance....................................103

9.1 Safety instructions................................................103

9.2 Making changes to the machine .........................103

9.3 Maintenance schedule .........................................103

9.4 Removal/installation of protective covers........... 105

9.5 Maintenance before the work.............................. 105

9.5.1 Check oil levels..................................................... 105

9.5.2 Clean water filter .................................................. 105

9.5.3 Check high pressure hose and other hoses........106

9.5.4 Maintenance of remote control...........................106

9.6 Weekly maintenance............................................106

9.7 Maintenance every 50 hours of operation ..........106

9.8 Maintenance every 250 hours of operation

or at least once every six months ........................ 107

9.8.1 Lubricate moving parts........................................ 107

9.8.2 Clean pressure regulator ..................................... 107

9.9 Maintenance every 1000 hours of operation

or at least once a year .......................................... 107

9.9.1 Change hydraulic oil ............................................ 107

9.9.2 Clean suction valves of high pressure pump...... 107

9.9.3 Clean pressure valves of high pressure pump.... 108

9.9.4 Major scheduled maintenance............................108

10 Malfunctions .................................. 109

10.1 Fault messages eControl+...................................109

10.1.1 Emergency stop ...................................................109

10.1.2 Engine temperature too high ..............................109

10.1.3 Heat exchanger temperature too high ................ 110

10.1.4 Hydraulic oil temperature too high..................... 110

10.1.5 Hydraulic oil level too low ................................... 110

10.1.6 Coolant level too low ............................................ 111

10.1.7 Battery voltage too low ......................................... 111

10.1.8 Water level too low ...............................................112

10.1.9 Water level too high..............................................112

10.2 Troubleshooting.................................................... 113

11 Index ................................................ 119

12 Attachments .................................... 123

7

8

INTRODUCTION

9

4 Introduction

Congratulations on the purchase of the AquaJet! The AquaJet is intended for unblocking sewers

and cleaning walls, terraces and floors. With correct use, this machine will serve you well for

years to come.

Read this user manual carefully before putting the machine in service, and always use the

machine in accordance with the instructions. If problems occur, consult Rioned.

This user manual contains all the information about operation and maintenance. If the

machine is set up and operated correctly and regularly maintained, we provide the warranty

specified in the general terms and conditions of delivery. The warranty is void and your safety

and that of people in the vicinity cannot be guaranteed if the operating and maintenance

instructions are not followed or are not followed correctly.

The following requirements must be met when working with the machine:

Use in enclosed spaces:

> When working in an enclosed space, the space must be well ventilated.

> Make sure the combustion gases are properly discharged. Prevent CO poisoning!

Spray site:

ALWAYS follow the instructions below for the spray site:

> Demarcate the site clearly. The minimum distance between the spray site and the

demarcation is six metres.

> Remove anything within the demarcation that is not firmly anchored.

> NEVER spray from an unstable location. Examples: ladder, boat, or hanging scaffolding.

> If it is necessary to use artificial lighting, ALWAYS use waterproof light fixtures.

INTRODUCTION

10

DESCRIPTION AND PRINCIPLE OF OPERATION

11

5 Description and principle of operation

5.1 Introduction

In this chapter we first briefly describe the operation, the main components and the symbols

used for the machine and the accompanying accessories. You will then find a description of the

machine's control units in chapter ‘Control’, sections ‘eControl+’, ‘Riomote control’, ‘Control

box’ and ‘5-channel remote control’.

5.2 Machine

5.2.1 Design and principle of operation

The engine drives the high-pressure pump via a V-belt The high pressure pump draws water

from the water tank via the water filter and pressurizes it. The water then exits the machine at

high pressure via the high pressure hose on the reel.

The machine consists of the following parts:

1. High pressure hose on reel

2. Filling reel

3. Securing end of filling hose

4. Drip tray

5. Handle, reel

6. Locks, covers

7. Pressure gauge

8. Pressure regulator

9. Connection, drain hose

10. Drain valve, water filter

11. Water filter

12. Supply valve, water filter

13. Fuel tank

14. Reel latch

15. Button, emergency stop

16. High pressure pump

17. Supply valve, filling reel

18. Water tank

19. Spray nozzles on holders

20. Battery

21. Pump oil drain

22. Engine oil drain

23. High pressure valve

24. Drainage point drip tray

25. Engine

26. Hose holder

27. Control box

28. Throttle lever

29. Choke

(petrol engine only)

30. Expansion tank, coolant

(diesel engine only)

31. Air filter

(diesel engine only)

32. Indicator, water level

DESCRIPTION AND PRINCIPLE OF OPERATION

17

The following is a brief explanation of parts from the illustrations above that are not discussed

further in the manual.

Securing end of filling hose (3)

The end of the filling hose is attached to this connection.

Drip tray (4)

The drip tray is designed to collect any water that drips off the hoses.

This drip tray can be removed to access the engine, pump and battery for maintenance and

service.

Handle, reel (5)

The reel handle is designed to turn the reel and reel the hose on or off.

Locks, covers (6)

The pump and engine cover are held in place with these locks.

Connection, drain hose (9)

Connect the drain hose here and place the end of the hose outside the vehicle when you want

to empty the water tanks. Then the vehicle will remain dry inside.

Drain valve, water filter (10)

Opening this tap allows the water to flow out of the water filter. If the water filter supply tap is

also opened, the water tank will also empty.

Water filter (11)

Protects the high pressure pump and pressure regulator from dirt.

First fold the handle out, and then release the reel latch.

After use, latch the reel again and fold the handle back in.

DESCRIPTION AND PRINCIPLE OF OPERATION

18

Supply valve, water filter (11)

This valve is normally open. It is only closed when cleaning the water filter and servicing the

high pressure pump.

Reel latch (14)

This latch prevents the reel from turning. It is operated by twisting the wings.

Supply valve, filling reel (17)

Open this valve when the water tanks are filled through the filling hose.

Spray nozzles on holders (19)

Screw the spray nozzles onto the nozzle holders.

Battery (20)

The battery supplies the machine with power.

High pressure valve (23)

This valve regulates the supply of water to the high pressure hose. If the Riomote control

(option) is installed, the high pressure valve is always open. The water supply is then controlled

by the valve on the actuator. The high pressure valve acts as a safety valve in an emergency: this

allows you to immediately interrupt the supply of water to the high pressure hose.

Drainage point drip tray (24)

The drainage point is intended to drain water that lies in the drip tray.

By removing the plug, the collected water flows out.

Indicator, water level (32)

This indicates the water level in the water tank.

This sight glass can be hung anywhere in the vehicle.

DESCRIPTION AND PRINCIPLE OF OPERATION

19

5.2.2 Symbols on pressure gauge, pressure regulator and valve controls

5.2.3 Accessories

Pressure gauge (7)

The maximum operating pressure is indicated on a sticker near the

pressure gauge.

Reduce the operating pressure with the handwheel of the pressure

regulator until the indicator of the pressure gauge is halfway between 0

and the maximum operating pressure.

Pressure regulator (8)

Operation of high pressure valve (23)

Move the lever up to open the high pressure valve. Move the lever down

to close the high pressure valve.

The following are included as standard with the machine:

1. Two nozzles for unblocking sewers: ‘Open nozzle’ and ‘Blind nozzle’,

which are fitted on the end of the high pressure hose.

2. One spray gun with lance for cleaning façades, terraces and floors.

The spray gun is attached to the end of the high pressure hose using

the open-end spanners. These open-end spanners are also supplied

as standard.

Operating range Danger zone

Maximum allowable pressure

Less pressure More pressure

Spray nozzle, open

Spray nozzle, blind

Spray gun with lance

DESCRIPTION AND PRINCIPLE OF OPERATION

20

3. Two open-end spanners for tightening and loosening the spray gun.

4. This user manual

5. Engine documentation

6. One suction hose with strainer.

7. Attachment: high pressure pump

8. Attachment: exploded view drawings and diagrams.

Open-end spanners

Table of contents

Other Rioned Water Pump manuals

Popular Water Pump manuals by other brands

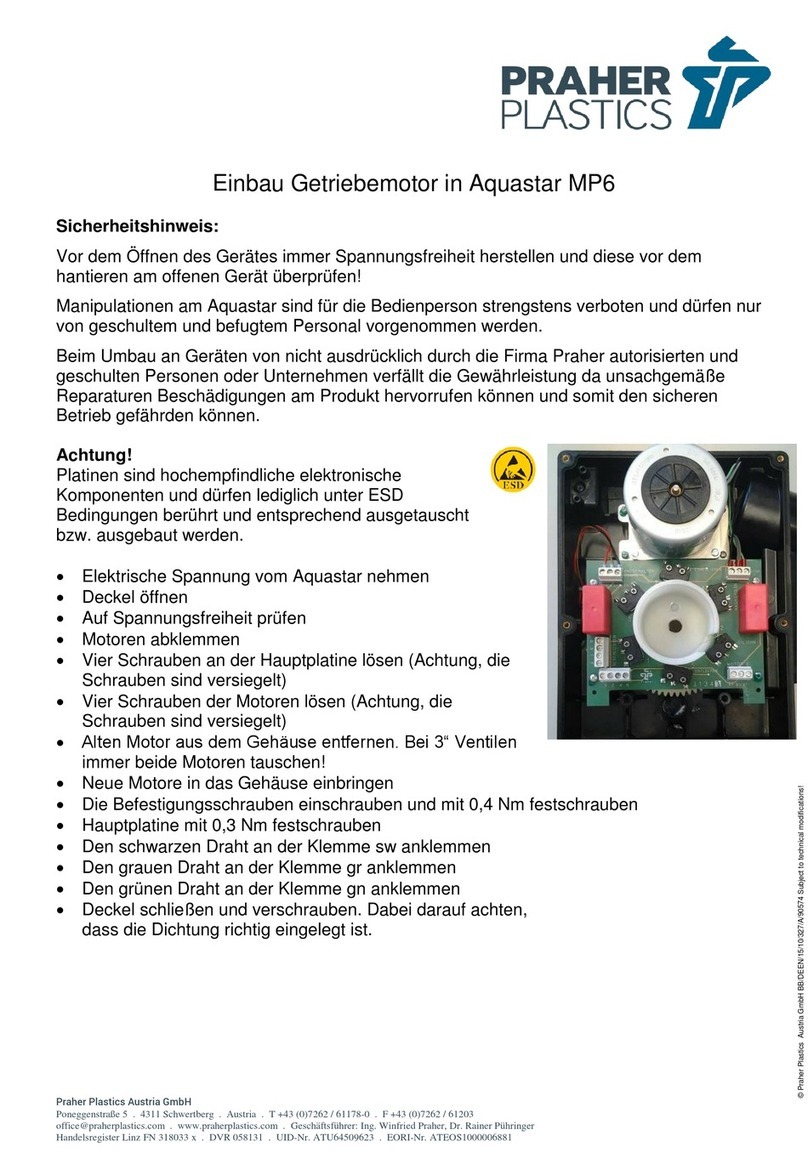

Praher Plastics

Praher Plastics Aquastar MP6 installation instructions

SKC

SKC AirLite 110-100 operating instructions

Champion Power Equipment

Champion Power Equipment C40940 manual

SPX FLOW

SPX FLOW Universal TS Series instruction manual

EBARA

EBARA GSD Series Translation of the original instructions

Little Giant

Little Giant BSC33 owner's manual