08/13 5

TABLE OF CONTENTS

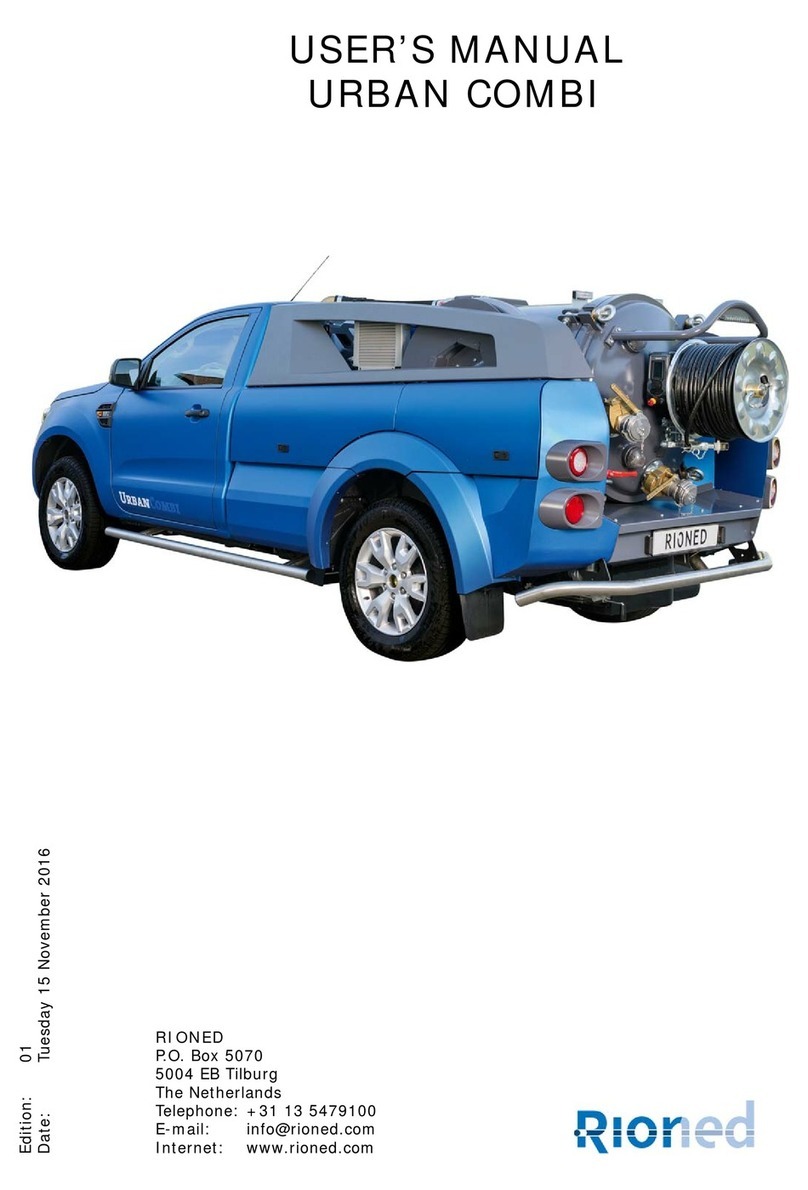

1 INTRODUCTION ...............................................................................................................7

1.1 Use...............................................................................................................................7

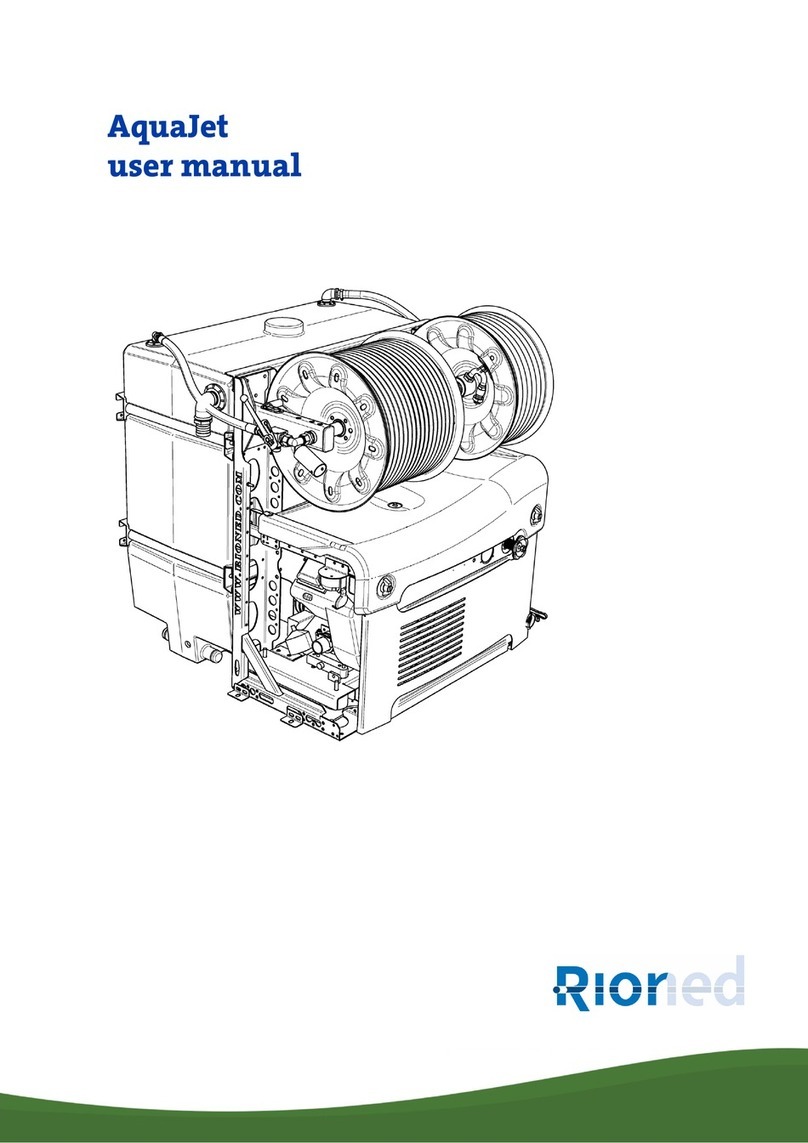

2 SECURITY...........................................................................................................................9

2.1 Instruction indications in this manual..........................................................................9

2.2 Descriptions security measures ...................................................................................9

2.3 Personnel protection outfit ..........................................................................................9

2.4 Warnings......................................................................................................................9

2.5 Personnel qualification and education.......................................................................10

2.6 Danger that can occur if the security regulations aren’t observed ............................10

2.7 Working safely...........................................................................................................10

2.8 Security regulations for the user and technical service.............................................10

2.9 Security regulations for maintenance, inspection and mounting activities...............10

2.10 Making changes and fabricate spare parts.................................................................10

2.11 Improper use..............................................................................................................10

3 TECHNICAL SPECIFICATIONS ..................................................................................13

3.1 General .....................................................................................................................13

3.2 Motor........................................................................................................................13

4 CONSTRUCTION.............................................................................................................15

5 CONTROL.........................................................................................................................17

5.1 Transport....................................................................................................................17

5.2 Controls .....................................................................................................................17

5.3 Before unblocking.....................................................................................................20

5.4 Unblocking................................................................................................................23

5.5 Unclogging a highly placed hole...............................................................................26

6 OPTIONS ...........................................................................................................................27

6.1 Foot switch ................................................................................................................27

7 MAINTENANCE...............................................................................................................29

7.1 General ......................................................................................................................29

7.2 Cleaning the feed unit................................................................................................29

7.3 Lubrication ................................................................................................................33

7.4 Extensive periodical maintenance.............................................................................33

7.5 Maintenance schedule ...............................................................................................34

8 ACCESSORIES.................................................................................................................35

8.1 Supplies .....................................................................................................................35

8.2 Auxiliaries that can be coupled:................................................................................36

9 EXPLODED VIEW

EXPLOSIONSZEICHNUNG UND ERSATZTEILLISTE

DESSIN ET LISTE DE RECHANGE ........................................................................................39

9.1 Exploded view...........................................................................................................40