Rishabh Rish Master 3444i User manual

This manual suits for next models

1

Table of contents

Popular Touch Panel manuals by other brands

Extron electronics

Extron electronics TouchLink TLP Pro 725C Series Setup guide

JETWAY

JETWAY HPC150C-DCP1135G7 user manual

Lippert Components

Lippert Components OCTP owner's manual

Avalue Technology

Avalue Technology APC-2132 Quick reference guide

AMX

AMX Modero NXD-1000Vi Operation/reference guide

Beijer Electronics

Beijer Electronics X2 marine 15-B2 SC installation manual

Crestron

Crestron MiniTouch MT-1000C Operation guide

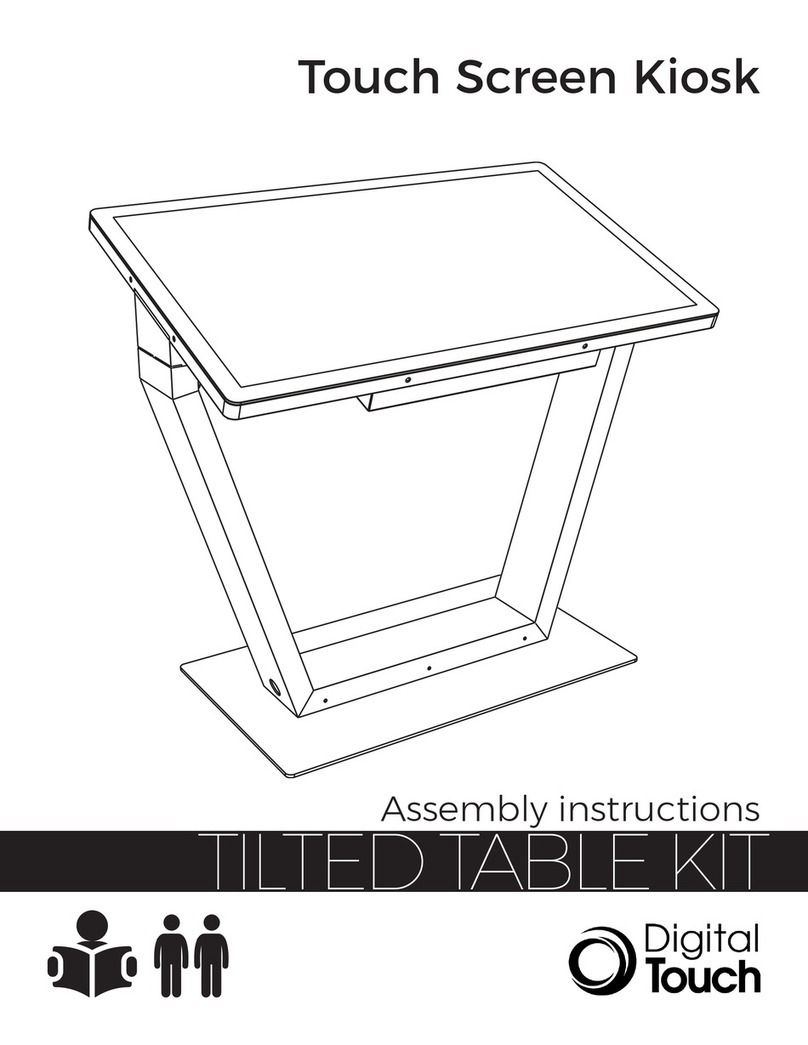

Digital Touch Systems

Digital Touch Systems TILTED TABLE KIT Assembly instructions

Grossenbacher Systeme

Grossenbacher Systeme WebPanel WP-284 Series operating instructions

AMX

AMX MXT-701 Operation/reference guide

Advantech

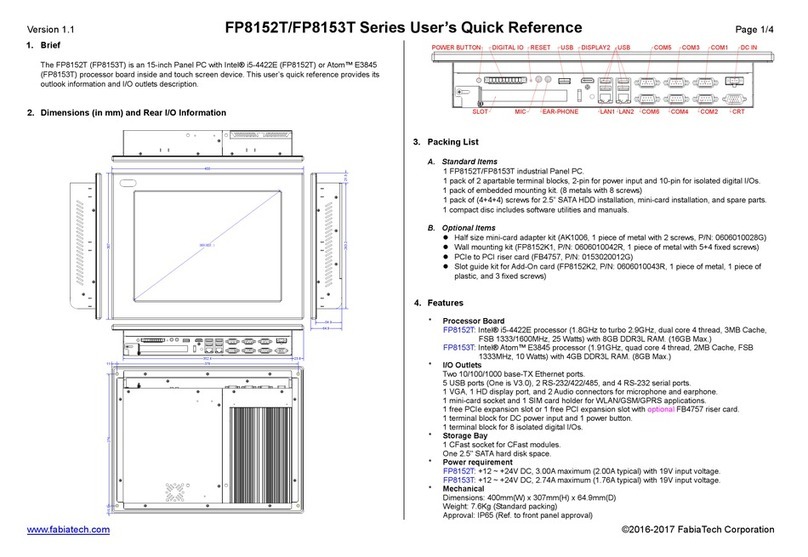

Advantech PPC-153 user manual

Avalue Technology

Avalue Technology SID-21W04 Quick reference guide