Rittal RiLine SV 9635.400 User manual

Assembly and operating instructions

RiLine Compact

Motor Controller

SV 9635.400

SV 9635.410

SV 9635.420

2RiLine Compact Motor Controller Assembly and operating instructions

Contents

Page

1. Technical specifications, overview 3

2. Notes on documentation 4

2.1 CE labelling 4

2.2 Storing the documents 4

2.3 Symbols used 4

2.4 Associated documents 4

3. Safety provisions / set-up instructions 4—5

4. Brief description 5

5. Assembly / dismantling 6—8

6. Protection of the load circuit from short circuits 9—10

6.1 Protection to IEC 9

6.2 Protection to UL (SCCR) 10

7. Function 10—13

7.1 Status and diagnosis display 10

7.2 Diagnosis function 11—12

7.3 Parameterisation – Setting the rated current 12—13

8. Application instructions 14

8.1 Motor with brake 14

8.2 Connection of auxiliary relays 14

9. Technical specifications 14—16

10. Appendix 17—18

11. Servicing 18

12. Storage 18

13. Warranty 19

14. Customer service addresses 19

3RiLine Compact Motor Controller Assembly and operating instructions

1. Technical specifications,

overview

Model No. 9635.400 9635.410 9635.420

Max. rated current A 0.6 2.4 9

Rated operating voltage V AC 500 500 500

Rated frequency Hz 50/60 50/60 50/60

Heat loss W 2.8 5.5 12

Adjustable current monitoring A 0.075 – 0.6 0.18 – 2.4 1.5 – 9

Number of poles 3-pole 3-pole 3-pole

Height mm 160 160 160

Width mm 22.5 22.5 22.5

Depth mm 114 114 114

Application area IEC/UL ¹ IEC/UL ¹ IEC/UL ¹

1 The technical specifications provided may vary for UL applications. See 9. Technical specifications.

4RiLine Compact Motor Controller Assembly and operating instructions

2. Notes on documentation

The assembly instructions are aimed at personnel who are suitably trained and qualified to configure enclosures with electrical,

electronic, mechanical and pneumatic equipment in accordance with applicable standards and to erect, assemble and connect

such enclosures at the place of use.

The operating instructions are aimed at operating personnel and suitably trained electrical and mechanical maintenance special-

ists.

2.1 CE labelling

The declaration of conformity is available for downloading at www.rittal.com.

2.2 Storing the documents

The safety instructions constitute part of the product, and must be handed to the plant operator. The operator is responsible for

suitable storage of the documents so they are readily available when needed.

2.3 Symbols used

Please observe the following safety instructions and other notes in these instructions:

2.4. Associated documents

These installation and operating instructions for the busbar components described here can be downloaded from www.rittal.com.

Rittal cannot accept any liability for damages associated with the failure to observe these instructions. The instructions for any

accessories used also apply.

Danger!

Immediate danger to life and limb.

Caution!

Potential threat to the product and the environment.

Note!

Useful information and special features.

3. Safety provisions / set-up instructions

• The national safety and accident prevention regulations must be observed whenever working on the device. Failure to observe

these regulations may result in death, serious injury or considerable material damage.

• The product documentation / instructions for use must be kept in a safe place.

• If using "automatic RESET" mode, the drive will be reactivated once the cooldown period has elapsed, provided a control signal

is still present. The cooldown period is 20 minutes.

• Installation should be performed in accordance with the operating instructions provided. Access to the circuits inside the appli-

ance is inadmissible.

• Opening or modifying the appliance and carrying out repairs yourself will invalidate the warranty. The device will be replaced

under warranty with an equivalent appliance. Repairs may only be carried out by the manufacturer. The manufacturer will not be

liable for any damages caused by a contravention of this provision.

• The safety data can be taken from this documentation and the certificates.

• When the drive is switched on and/or in the deactivated state, the device performs a function diagnosis. Additionally, an electri-

cian or specialist who is familiar with the relevant standards may carry out a test of the "motor protection" safety function. For

this test, the drive must be operated in counter-clockwise or clockwise mode and the flow of electricity interrupted in one con-

ductor (e.g. by removing a fuse in phase L1 or L3). The motor controller will then switch o the drive within 1.5 .. 2 s. The LEDs

for counter-clockwise or clockwise rotation will be extinguished and the ERR-LED and checkback output will be set.

• Only power packs with reliable disconnection with SELV/PELV voltage to EN50178/ VDE 0160 (SELV/ PELV) should be used.

5RiLine Compact Motor Controller Assembly and operating instructions

These are designed to prevent short-circuits between the primary and secondary side.

• The motor controller is a product designed for Environment A (industry). In Environment B (households), this device may cause

unwanted malfunctions. In such cases, the operator may be required to take appropriate action.

4. Brief description

The three-phase motor controller with reversing function and current monitoring combines four functions in one:

• Contactor, clockwise rotation

• Contactor, counter-clockwise rotation

• Motor protection relay

• Short-circuit protection

The internal load and interlock circuit reduces wiring eort to a minimum. The device may only be operated in combination with

3-phase motors.

14

16

OPEN

2/ T 1 4/T26/T 3

S et/

Re s e t

P W R

Err

L

R

ma x.

2,4 A

0,18

0,87

1,63

2,4

U

s

Τ

R L

MAN R ES AUT

97 9 6 95

97 9 6 95

MA N R E S AU T

Us R L

T

R itta l G m bH & C o. K G

Au f d em S tütze lber g

357 45 Herbo rn

Germa ny

SV 9635 .4 10

XX /X X

13

12

11

10

9

8

7

6

5

4

2

1

15

3

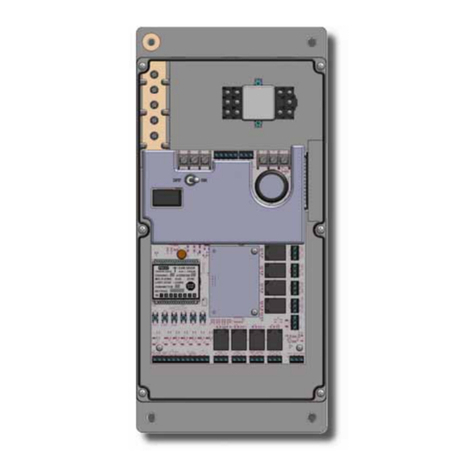

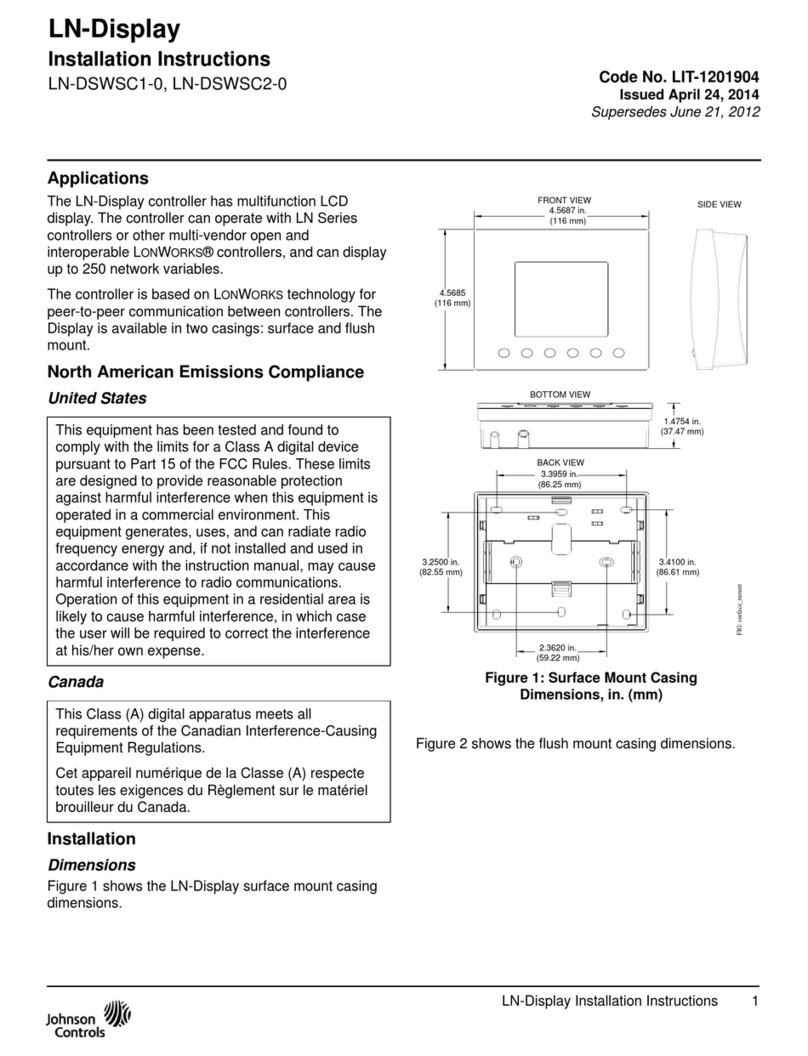

Connection, operating and display elements

[1] Input: Control supply voltage [Us]

[2] Control input clockwise/counter-clockwise rotation [R / L]

[3] Reference point for control supply voltage and clockwise/

counter-clockwise rotation [ ]

[4] Acknowledgement inputs [MAN / RES / AUT]

[5] Check-back contacts [97 / 96 / 95]

[6] Potentiometer for rated current parameterisation

[7] LED PWR: Control supply voltage

[8] LED ERR: Status display / error

[9] LED L: Counter-clockwise rotation

[10] LED R: Clockwise rotation

[11] Reset/set button

[12] 3-phase output voltage [2/T1, 4/T2, 6/T3]

[13] Fuse box

[14] Locating lug

[15] Guide pin for attaching to RiLine Compact Board

[16] Contact springs for 3-phase incoming voltage

MAN

RES

AUT

T

Us

L

R

Reset2

Reset

Auto-

Reset

24

VDC

24VDC

97

2/T1

96 4/T2

95

6/T3

Logic

µP

L1 L2 L3

& Error

reset

Block diagram

3. Safety provisions / set-up instructions

6RiLine Compact Motor Controller Assembly and operating instructions

5. Assembly / dismantling

Caution!

Never work with live current!

Danger to life!

• The hybrid motor controller snaps onto the RiLine Compact Board. It is automatically connected to the 3-phase network via the

integral device contacts.

Click

Assembly

Note!

The device is installed in a vertical position. The coding tab must not be removed to rotate the device.

7RiLine Compact Motor Controller Assembly and operating instructions

Danger from electric shock and risk of fire!

An open fuse box [13] may indicate an interrupted fault current. To reduce the risk of fire and electric shock, current-

carrying parts and other components in the controller must be checked and replaced if damaged. Failure to observe

these instructions can result in death, serious injury or considerable material damage.

5. Assembly / dismantling

Dismantling

1

2

8RiLine Compact Motor Controller Assembly and operating instructions

5. Assembly / dismantling

Mains connection and line protection

• When connecting the 3-phase RiLine Compact Board, it is essential to ensure the correct phase position.

• The control supply voltage and control voltage inputs must only be operated with power supply modules that comply with IEC

61131-2 (max. 5% residual ripple).

• With long pilot wires, to avoid the inductive / capacitive coupling of interference pulses, we recommend the use of shielded

lines.

• Copper lines with 75 °C approval for use with a low-voltage, limited energy, isolated power supply should be used.

Electrical safety

When connecting double conductors, only conductors with an identical conductor cross-section should be connected

to the same terminal.

Replacing fuses

• Remove the motor controller from the RiLine Compact Board.

• Remove the outgoing motor cables ►Pull the 3-phase output voltage terminal block from the device [12].

• After opening the cover of the fuse box [13], the fuses can be removed.

• Insert new fuses. Replace all fuses at the same time.

• Only fuses listed in the tables for this device under point 6 should be used.

• After closing the fuse box cover, re-connect the outgoing motor cables (3-phase output voltage terminal block [12]) and snap

the device onto the Riline Compact Board.

L1

L2

L3

L1

L2

L3

9RiLine Compact Motor Controller Assembly and operating instructions

P E PE

MM

33

3x F 2 3x F2

3x F 1

L1

L2

L3

9635.400

9635.410

9635.420

9635.400

9635.410

9635.420

Busbar system

RiLine Compact

6. Protection of the load circuit from short circuits

* F1= External fuse

* F2= Internal fuse

* F2 in the supplied state

9635.400 Motor controller 0.6 A Mersen FR10GR69V16 (16 A)

9635.410 Motor controller 2.4 A Mersen FR10GR69V16 (16 A)

9635.420 Motor controller 9.0 A Mersen FR10GR69V20 (20 A)

6.1 Protection to IEC

For device size Icw Ue * F1 * F2 Allocation type 1)

0.6 A/2.4 A/9.0 A

5 kA 400 V - 20 A gR (10 x 38 mm) 2

10 kA 500 V - 16 A gR (10 x 38 mm) 2

30 kA 500 V - 30 A gR (10 x 38 mm) 1

50 kA 500 V - 16 A gR (10 x 38mm) 1

50 kA 500 V - 20 A gR (10 x 38 mm) 1

1) Allocation type 1 = System protection

Allocation type 2 = Device protection

...

10 RiLine Compact Motor Controller Assembly and operating instructions

6.2 Protection to UL (SCCR)

For device size SCCR Ue * F1 * F2 Allocation type 1)

0.6 A/2.4 A

5 kA 500 V 20 A RK5 Mersen

FR10GR69V16 (16 A) 1

100 kA 500 V 30 A Class J /

Class CC

Mersen

FR10GR69V16 (16 A) 1

100 kA 500 V - Littlefuse CCMR30 1

6.5 A

5 kA 500 V 20 A RK5 Mersen

FR10GR69V20 (20 A) 1

100 kA 500 V 30 A Class J /

Class CC

Mersen

FR10GR69V20 (20 A) 1

100 kA 500 V - Littlefuse CCMR30 1

6. Protection of the load circuit from short circuits

7. Function

1) Allocation type 1 = System protection Allocation type 2 = Device protection

7.1 Status and diagnosis display

The device visualises operating statuses with a total of 4 LEDs.

After applying the control supply voltage, all LEDs are initially illuminated as an LED test.

LED PWR Green Device status

LED L Yellow Counter-clockwise rotation

LED R Yellow Clockwise rotation

LED ERR Red Internal or external error

Process error: Overcurrent, asymmetry, phase failure

WARNING: Danger from electric shock and risk of fire

Opening the safety device in the branch circuit may indicate an interrupted fault current.

To reduce the risk of fire and electric shock, current-carrying parts and other components in the controller must be checked and

replaced if damaged.

Failure to observe these instructions can result in death, serious injury or considerable material damage.

NOTE: Please use copper lines approved for use with at least 75 °C and a low-voltage, limited energy, isolated power supply.

The device is designed for use with a low-voltage, limited energy, isolated power supply.

SCCR (individual and group installation)

Suitable for use in circuits with maximum 5 kA e. symmetrical current and ≤ 500 V, with 20 A, class RK5 fuses (allocation type 1).

Suitable for use in circuits with maximum 100 kA e. symmetrical current and ≤ 500 V, with 30 A, class J or class CC fuses

(allocation type 1).

FLA 0.6 A (500 V AC) / 2.4 A (500 V AC) / 6.5 A (500 V AC)

11RiLine Compact Motor Controller Assembly and operating instructions

7. Function

Status Description

PWR ERR L R 96

97

95

96

Error

acknowl-

edgement

Green Red Yellow

O No supply voltage present A A A A 0 1 -

Operational Supply voltage present E A A A 0 1 -

Drive activated

Counter-clockwise rotation (L) E A E A 0 1 -

Clockwise rotation (R) E A A E 0 1 -

Internal error Internal device error -

Replacement unit required E E A A 1 0 Nm

External fault in

the actuator or

peripherals (servic-

ing required, power

transmission path

deactivated)

Motor protection function:

Motor current > rated motor

current requirement: Cool-down

time in progress (20 min)

Trip class: 10 A

1 0

Fault with counter-clockwise

rotation E B E A 1 0 Aut

Fault with clockwise rotation E B A E 1 0 Aut

After 2 minutes have expired "L"

or "R" will flash: manual reset

possible 1 0

Fault with counter-clockwise

rotation E B B A 1 0 Man

Fault with clockwise rotation E B A B 1 0 Man

Fault restoring the system

status: Manual acknowledge-

ment possible after 2 min E B B B 1 0 Man

Symmetry: The two motor cur-

rents deviate from one another by

more than 33% E B A A 1 0 Man

Blockage: The maximum meas-

urable motor current is exceeded

for more than 2 s. 1 0

Fault with counter-clockwise

rotation E B B A 1 0 Man

Fault with clockwise rotation E B A B 1 0 Man

Message (power

transmission path

remains connected)

Message with control signal

applied:

- 2 or more phases missing

- No motor connected

- Motor current on at least 2

phases below the minimum cur-

rent value setting for > 2 s

1 0

Message with counter-clockwise

rotation B B E A 1 0 Aut

Message with clockwise rotation B B A E 1 0 Aut

7.2 Diagnosis function

Explanation:

A ►LED deactivated

E ►LED permanently illuminated

B ►LED flashing approx. (2 Hz)

Aut ►Automatic

Man ►Manual

Nm ►Not possible

12 RiLine Compact Motor Controller Assembly and operating instructions

• Various diagnosis functions allow the motor controller to detect internal and external errors (error in the peripherals).

When a fault is detected, the device is in a safely deactivated state.

• Flashing or steady illumination of the ERR-LED indicates an error.

• Internal errors cannot be acknowledged. They are stored in the device. The device will need to be replaced.

• External errors can be acknowledged once the cause has been rectified.

• With external errors, an error acknowledgement is needed in order to be able to exit the safely deactivated state.

• Flashing of the PWR LED indicates a message. With a message, the power transmission path remains connected.

An acknowledgement is not required.

• Symmetry detection: The motor currents are measured at phases L1 and L3 and monitored for symmetry. If there

is a deviation in the motor currents of ≥ 33%, the motor will switch o within 2 minutes. If there is a deviation in the

motor currents of ≥ 67%, the motor will switch o within 2 seconds.

7. Function

Error acknowledgement

• The RES terminal provides the voltage for the reset. At the rated control supply voltage of 24 V DC, this is 24 V DC.

• Maximum 30 m long cables may be connected to the MAN, RES and AUT terminals.

Manual reset button

Manual reset occurs by pressing the reset button (< 2 s) on the front of the device.

If pressed for longer than 2 s, the unit will resume error status. If pressed for longer than 6 s, the unit will switch to "Parameterisa-

tion" mode (see point 7.3 Parameterisation, rated current setting).

Manual - remote acknowledgement button

For remote acknowledgement, a button (normally open contact) is connected between the MAN and RES terminals.

Acknowledgement is triggered as soon as a positive edge is detected at the MAN input. If no negative edge is detected after

approximately 2 s, the unit will return to error status, because manipulation or a defect in the acknowledgement circuit cannot be

excluded.

Automatic

For automatic acknowledgement, an electrical connection is made between the RES and AUT terminals. The unit performs an

automatic reset after motor protection monitoring and subsequent cooling has been initiated.

The cooldown period is 20 minutes.

Check-back relay

As soon as the unit detects an error or signals a message, the check-back relay is activated. In other words, the normally open

contact is closed or the normally closed contact is opened. This response is equivalent to that of a motor circuit-breaker or motor

protection relay.

7.3 Parameterisation – Setting the rated current

• To enter "Parameterisation" mode, press the reset button on the front of the device for more than 6 s. The green LED PWR

flashes once.

• The rated current of the drive is set using the 240° potentiometer. There are 16 rated current settings. The four LEDs indicate

the set rated current. Refer to the following table under point 7.3 Parameterisation – Setting the rated current.

• The value is set by pressing the reset button again (non-volatile part of the data memory)

• Pressing the reset button for > 2 s (and < 6 s) will display the set current for 3 s. This function is only possible if the device is not

being controlled and there is no error on the device.

• To distinguish it from other operating states, in "parameterisation" mode, the LEDs are switched o for 0.3 s at 2 s

intervals.

• From a motor current of 45 A, blockage monitoring is activated (see point 10 in the Annex - Tripping characteristic

and derating curve).

13RiLine Compact Motor Controller Assembly and operating instructions

7. Function

Explanation:

A ►LED deactivated

E ►LED permanently illuminated

Code Rated current (mA)

Variants:

PWR ERR L R 0.6 A 2.4 A 9 A

A A A A 75 180 1500

A A A E 110 250 2000

A A E A 145 410 2500

A A E E 180 560 3000

A E A A 215 710 3500

A E A E 250 870 4000

A E E A 285 1020 4500

A E E E 320 1170 5000

E A A A 355 1330 5500

E A A E 390 1480 6000

E A E A 425 1630 6500

E A E E 460 1790 7000

E E A A 495 1940 7500

E E A E 530 2090 8000

E E E A 565 2250 8500

E E E E 600 2400 9000

• If the 9 A motor controller is used in UL applications, the maximum admissible rated current is 6500 mA.

7.3 Parameterisation – Setting the rated current

14 RiLine Compact Motor Controller Assembly and operating instructions

8. Application instructions

8.1 Motor with brake

When using a motor with brake (connection to motor terminal board), the 400 V AC brake is connected to 2/T1 and 6/T3. A 230 V

AC brake should be connected to 4/T2 and the motor neutral point.

Motor current monitoring should be increased by the rated current of the brake, and set accordingly on the motor control-

ler.

8.2 Connection of auxiliary relays

Auxiliary relays to control external brakes or check-back signals, e.g. to the SPC, are connected to 4/T2 and N of the system.

Switching o the control supply voltage while the motor is being controlled always leads to wear and tear on the motor

controller. Consequently, this circuit should only be used if no more than 10,000 deactivations are anticipated over the

entire service life of the system.

9. Technical specifications

Model No. Description

9635.400

9635.410

9635.420

Motor controller 0.6 A

Motor controller 2.4 A

Motor controller 9.0 A

Incoming data

Rated control

supply voltage Us

to IEC 60947-1 / UL 508 24V DC

Control supply voltage range 19.2 ... 30 V DC

Rated control supply voltage Is to IEC 60947-1 ≤ 40 mA

Control input L, R: Switching level "Low"

Switching level "High"

Input current

-3 ... 9.6 V DC

19.2 ... 30 V DC

5 mA

Typical break time < 30 ms

Output data, load side 9635.400 9635.410 9635.420

Switching principle Safety output stage with bypass, three-phase isolated switch o

Rated operating voltage Ueto IEC 60947-1 500 V AC (50/60 Hz)

Operating voltage range to IEC 60947-1

to UL 508

42 ... 550 V AC (50/60 Hz)

42 ... 500 V AC (50/60 Hz)

Load current at 20 °C (see 10. Appendix. Derating curve) 0.075 ... 0.6 A 0.18 ... 2.4 A 1.5 ... 9.0 A

Rated operating current Ie

AC-51

AC-53a

(see 10. Appendix. Derating curve)

to IEC 60947-1

to IEC 60947-4-3

to IEC 60947-4-2

to UL 508

0 6 A

0.6 A

0.6 A

2.4 A

2.4 A

2.4 A

9 A

6.5 A

6.5 A

Rated switching capacity

to UL 508

Full Load (power factor = 0.4)

Full Load (power factor = 0.8)

0.3 kW (0.4 HP)

0.5 kW (0.6 HP)

0.9 kW (1.2 HP)

1.7 kW (2.2 HP)

2.3 kW (3.0 HP)

4.6 kW (6.1 HP)

15RiLine Compact Motor Controller Assembly and operating instructions

9. Technical specifications

9635.400 9635.410 9635.420

Leakage current (input, output) 0 mA 0 mA 0 mA

Residual voltage at Ie < 300 mV < 400 mV < 600 mV

Surge current 100 A (t = 10 ms)

Input protection circuit Varistors, slow fuses

Short circuit current rating SCCR to UL 508A With Littlefuse CCMR 30A fuse, suitable for use in circuits that

supply no more than 100 kAe symmetrical current, max.

500 V. (see 6. Protection of the load circuit from short circuits).

Checkback output

Contact version Single contact, 1 changeover contact

Switching capacity to IEC 60947 -5-1 3 A (230 V, AC 15)

2 A (24 V, DC 13)

Measurement system 9635.400 9635.410 9635.420

Two-phase current measurement

Range 0.075 ... 0.6 A 0.18 ... 2.4 A 1.5 ... 9.0 A

Symmetry monitoring

Amount Imax > Irated => (Imax - Imin / Imax)

Amount Imax < Irated => (Imax - Imin / Irated)≥ 33% / ≥ 67% ≥ 33% / ≥ 67% ≥ 33% / ≥ 67%

≥ 33% / ≥ 67% ≥ 33% / ≥ 67% ≥ 33% / ≥ 67%

Response time 2 min / 1.8 s 2 min / 1.8 s 2 min / 1.8 s

Phase failure monitoring

I(L1), I(L3) typ.

(Angle (L1, L3) > 75 mA > 150 mA > 1200 mA

170° ... 190° 170° ... 190° 170° ... 190°

Response time < 1.8 s < 1.8 s < 1.8 s

Blocking protection

I(L1) or I(L3) - - > 45 A

Response time - - 2 s

Trigger characteristic (see 10. Appendix) to IEC 60947-4-2 Class 10 A

Cool-down time - - 20 min

16 RiLine Compact Motor Controller Assembly and operating instructions

9. Technical specifications

Display and operating elements 9635.400 9635.410 9635.420

Operating voltage display LED PWR (green)

Device and process error display LED ERR (red)

Control display counter-clockwise/clock-

wise LED L (yellow) / LED R (yellow)

Reset button Error acknowledgement/parameterisation

Potentiometer for setting the rated motor current 240°

General specifications

Heat loss 0.88 W / 2.8 W 0.88 W / 5.5 W 0.88 W / 12 W

Max. switching frequency (pulse/pause times 50:50) 2 Hz

Rated surge voltage between control input, control supply and

switching voltage 6 kV

- Mains rated voltage (≤ 500 V AC)

- Mains rated voltage (≤ 300 V AC,

e.g. 230/400 V AC, 277/480 V AC)

- Mains rated voltage (300 ... 500 V AC)

Reliable disconnection (EN 50178)

Reliable disconnection (IEC 60947-1)

Basic insulation (IEC 60947-1)

Control input, control supply voltage and checkback output.

Checkback output and switching voltage Safe isolation (IEC 60947-1)

- Mains rated voltage (≤ 500 V AC)

- Mains rated voltage (≤ 300 V AC,

e.g. 230/400 V AC, 277/480 V AC)

- Mains rated voltage (300 ... 500 V AC)

Safe isolation (EN 50178)

Safe isolation (IEC 60947-1)

Basic insulation (IEC 60947-1)

Ambient temperature range Operation

Transportation, storage -25 °C ... +70 °C

-40 °C ... +80 °C

Overvoltage category III

Level of contamination 2

Standards / provisions IEC 60947-4-2 / IEC 61508-1 /

EN 954-1 / ISO 13849-1 / UL 508

Service life 3 x 107switching cycles

Protection category IP20

Installation position Vertical

Installation (see derating curve) Bayable without or with a distance of ≥ 22.5 mm

Case: Material

Dimensions (W / H / D) PA 66

(22.5 / 160 / 114.5) mm

Connection data (conductor cross-section)

Screw terminals (rigid / flexible)

Thread M3, recommended torque

Insulation stripping length

See connection instructions

0.14 ... 2.5 mm2(AWG 26 ... 14)

0.5 ... 0.6 Nm

8 mm

Weight Motor controller approx. 325 g

17RiLine Compact Motor Controller Assembly and operating instructions

10. Appendix

Trigger characteristic at 20 °C

30 40 50 60 70 90

20 80

6

8

0,1

4

2

9

7

5

3

1

0,6

100 110 120

30 40 50 60 70 90

20 80

6

8

0,1

4

2

9

7

5

3

1

0,6

100 110 120

t [°C]

S

I

[A]

L

I

[A]

L

t [°C]

S

t=80 °C

U

t=60 °C

U

t=40 °C

U

t=20 °C

U

t=

60 °C

U

t=

40 °C

U

t=

20 °C

U

Derating curve of busbar

IL= Load current [A]

tU= Ambient temperature [°C]

tS = Temperature of busbar [°C]

IA= Start-up current [A]

The adjustment factors described here refer to motor controllers with a max. load current of 9 A. The max. admissible

rated current of the motor can be calculated using the load current, the overcurrent factor (see data sheet for the respec-

tive motor) and the 9 A derating curve.

9 A derating curve

Overcurrent factor IA/IN1 2 3 4 5 6 7 8 9 10

Adjustment factor K 1 1 1 1 1 0.96 0.83 0.72 0.64 0.58

Example 1 (motor controller 9 A)

Motor with overcurrent factor IA/IN(from motor data sheet) 8

Adjustment factor K 0.72

Maximum admissible load current ILat tS30 °C and tU 20 °C, at a distance of 22.5 mm (see de-

rating curve ) 9 A

Maximum admissible rating current INof motor = ILx K 6.5 A

Bayed at a distance of 22.5 mm

Bayed with no distance

123456789 10

0,5

2

5

10

3

1

20

50

100

30

200

I/I

N

t [s]

=

=Min

=

=Max

I>45A=>t<2s

Class 10 A

Trigger time

Overcurrent factor

(The ratio between the actual current and the parameterised rated current)

9 A

9 A

2.4 A

0.6 A

9 A

9 A

2.4 A

0.6 A

Derating curves at 100% duty cycle

9 A

18 RiLine Compact Motor Controller Assembly and operating instructions

11. Servicing

As a general principle, manufacturers of electrical plant and equipment must set out, in writing, the required installation, commis-

sioning and maintenance measures, and present these to the operator.

Once commissioned and signed o, all electrical plant and equipment must be re-inspected at suitable intervals. This is the opera-

tor's responsibility.

These intervals are generally based on the use, installation and ambient conditions of the electrical plant and equipment. In particu-

lar, requirements relating to stationary or mobile use must be observed.

For electrical plant and equipment subject to particular loads and special types of facilities such as:

• Campsites

• Medical environments

• Vehicles

• Wet rooms and outdoors

• Agricultural and horticultural facilities

special conditions apply.

Inspection and testing must normally be carried out by a trained, qualified electrician with suitable knowledge and experience

• of the particular environment

• of the relevant standards and regulations

• of the work involved

• in the identification of risks.

Testing e.g. of RCDs may also be carried out by sta who have received appropriate instruction using suitable measurement and

test equipment.

Alongside the relevant standards and regulations, depending on the installation site, the applicable national/regional regulations

and laws must also be observed.

For Rittal power distribution components, we recommend inspections at least every year.

Further information on the topic of servicing, testing and personnel requirements may be found in the following standards:

• IEC 60364-7 Group 700, DIN VDE 0100 Group 700, VDE 0100 Group 700

• DIN VDE 0105-100

• VDE 1000-10

• DGU V3

12. Storage

When storing components, please ensure that

• The ambient temperature is no higher than +80 °C

• The ambient temperature is no lower than -40 °C

• The relative humidity is between 10% and 95%, non-condensing.

10. Appendix

Example 2 (motor controller 2.4 A)

Motor with overcurrent factor IA/IN(from motor data sheet) -

Adjustment factor -

Maximum admissible load current ILat tS65 °C and tU 60 °C, bayed (see derating curve ) 2.2 A

19RiLine Compact Motor Controller Assembly and operating instructions

13. Warranty

The terms of sale and delivery of the individual Rittal sales agencies and subsidiaries apply.

14. Customer service address

Germany headquarters

RITTAL GmbH & Co. KG

Auf dem Stützelberg

35745 Herborn

Germany

Phone +49(0)2772 505-1855

Fax +49(0)2772 505-1850

E-mail: [email protected]

◾ Enclosures

◾ Power Distribution

◾ Climate Control

◾ IT Infrastructure

◾ Software & Services

www.rittal.com/contact

You can find the contact details of all

Rittal companies throughout the world here.

RITTAL GmbH & Co. KG

Postfach 1662 · D-35726 Herborn

Phone +49(0)2772 505-0 · Fax +49(0)2772 505-2319

07.2018/339962/D-0000-00001352Rev01

This manual suits for next models

2

Table of contents

Other Rittal Controllers manuals

Popular Controllers manuals by other brands

Flexit

Flexit ProNordic CS2500 quick guide

Alcor Micro

Alcor Micro AU9216 Technical reference manual

Distech Controls

Distech Controls ECLYPSE ECY-VAV installation guide

Honeywell

Honeywell N20 Series instructions

Barber-Colman

Barber-Colman DYN1-10704 Series Service information

HID

HID Mercury LP1502 Installations and specifications

Growatt

Growatt GroBoost Quick installation guide

Emerson

Emerson Advantage 2.1 Installation, operation and maintenance manual

Hornby

Hornby R8238 quick start guide

Bosch

Bosch Rexroth ctrl CORE operating manual

AMERITRON

AMERITRON SDC-103 instruction manual

Johnson Controls

Johnson Controls LN-DSWSC1-0 installation instructions