V. DUCT TEMPERATURE OPTIMIZER (DTO)

FOR MONITORING LEAVING AIR TEMPERATURE

As Zone Perfect Two-Zone System operates through a heating or

cooling cycle, the zone demands will change. This changes the

actual load that is applied to the HVAC equipment. If the zone

airflow decreases, the cooling equipment will tend to lower

supply-air temperatures which could tend to exceed the LAT trip

limits. Conversely, the heating equipment will tend to raise

supply-air temperatures which could exceed high trip limits. In

cooling, when the LAT reaches the non-adjustable low tempera-

ture trip limit (50°F) the LAT algorithm begins operating, closed

dampers are initially opened 3 positions, then 1 position every 20

sec there after until full open. Zone Perfect Two-Zone will not shut

down second-stage cooling (if used); however, if temperature

continues to drop to 45°F, the zoning system will turn off both

stages of cooling. If the temperature improves, the system will stay

in the duct temperature optimizer mode until the LAT reaches

55°F or higher. At 55°F the LAT algorithm will reset and return

dampers to their original position. In the heating mode, Zone

Perfect Two-Zone will perform the same duct temperature opti-

mization. The trip limits will be determined by the jumper setting.

(See Fig. 12.) This will continue until the LAT problem is

corrected.

This control helps Zone Perfect Two-Zone System cope with

installations where the air conditioning system may suffer from

poor ductwork, improperly sized heating or cooling equipment,

and/or improper settings of the barometric bypass damper. This

control is especially useful in retrofit applications where the size

and routing of the ductwork may not be entirely known or

satisfactory.

The duct temperature optimizer works by controlling how cold or

hot the air inside the supply-air duct gets by monitoring the

temperature of the air inside the supply-air system.

Whenever Zone Perfect Two-Zone is providing heating or cooling,

the zone within the home that is asking for conditioned air will

always have its damper fully open. The other zone in the system

may or may not have an open damper depending upon its

particular needs. If the ductwork is too small (or the air

conditioner/heater is too large), then the zone requiring condi-

tioned air may not be able to take enough air to allow your

equipment to operate properly. Zone Perfect Two-Zone will detect

this, and open up the closed damper allowing the equipment to

continue to operate.

CAUTION: The duct temperature optimizer may be

disabled on the control center. A 10k resistor can be

installed in place of the duct sensor at the terminal block.

By disabling the duct temperature optimizer, the LAT

safety algorithm is removed from the system.

It is highly recommended that you use this control option. The

heating LAT is adjustable for the duct sensor. In this Installation

Instruction, you will find the section showing an adjustment for the

heating LAT. (See Fig. 12.) It is very important that this tempera-

ture is properly set. For gas or oil furnaces, the temperature limit

will be in the higher temperature range. For heat pumps the

temperature setting should always be in the lower temperature

range.

If you encounter a situation where 1 zone seems to have poor

ductwork, then the Zone Perfect Two-Zone system is capable of

reverting back to a fully open, constant-volume system. If this

condition persists, it should always be looked upon as an indication

of a HVAC problem, not a Zone Perfect Two-Zone problem.

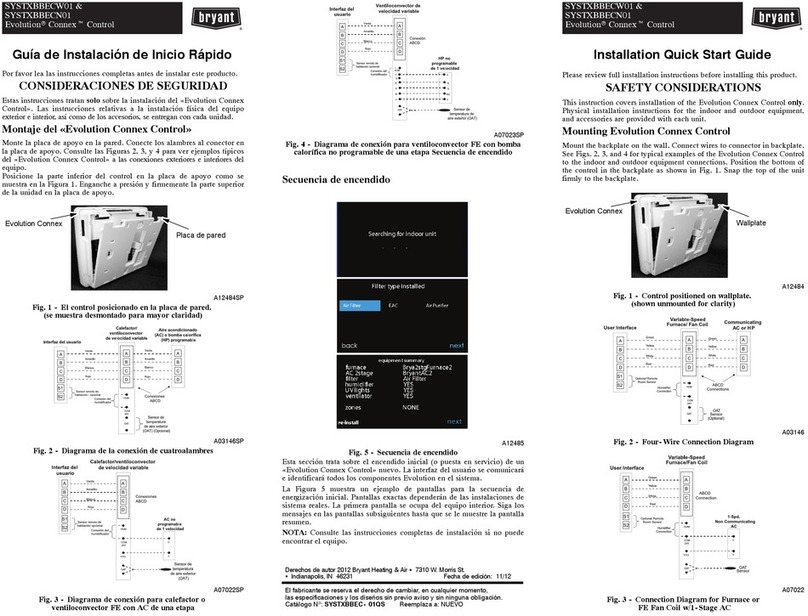

VI. ELECTRONIC THERMOSTAT CONNECTION WITH

ZONE PERFECT TWO-ZONE CONTROL

Bryant electronic non-programmable and programmable thermo-

stats can be connected to the Zone Perfect Two-Zone. See pre-sale

literature for thermostat part numbers.

NOTE: The zone control board is only capable of 2-stage heat

and 2-stage cool operation. Fig. 13 and 14 will reflect these

applications only. Review and understand the following items

before installing.

A. Thermostat Setup

1. Thermostat will not operate unless both R and C are

connected to zone module input.

2. If selected thermostat is a heat pump (HP) or 2-speed (2S)

model, convert thermostat to air conditioning operation.

This will assure that Y signals are generated for cooling,

and W signals are generated for heating from thermostat to

zone module input. The thermostat O/W2 output will now

be the second-stage heat call. If installation is a heat pump

system, the zone control board will provide proper output

signal to heat pump.

3. Select "Zoning" option on thermostat. This will disable the

Timeguard and 4-cycle per hr (cph) protection built into

thermostat. Let zone control board perform the Timeguard

and cycle protection. Refer to thermostat Installation In-

struction under Zoning for more detail.

4. The zone 1 thermostat is the only thermostat that can

control continuous fan operation with zoning. Connect G

between zone 1 thermostat and zone 1 input on zone control

module.

5. Follow all safety and installation considerations outlined in

the thermostat Installation Instructions.

B. Zone Control Board Setup

1. Configure zone control board jumper for Tstat (thermostat)

Fnc option only. Do not use Tstat HP option. When Tstat

Fnc is selected this will setup control inputs to recognize Y1

and Y2 for first- and second-stage cooling, W1 and W2 for

first- and second-stage heating.

2. Configure zone control board for either Equipmt (equip-

ment), HP or Fnc. When a heat pump system is used,

Equipmt HP mode should be selected. The zone control

board will provide the proper output signal to the heat

pump. When a gas/electric furnace is used, Equipmt Fnc

mode should be selected for proper output signal.

3. Configure zone control board for either Fnc Ht, w/f (with

fan), or w/of (without fan). With Fan mode should be

selected when a heat pump is installed and fan is needed to

come on immediately with demand. Without Fan mode

should be selected when fan is controlled by gas/electric

furnace.

4. Configure zone control board for either DTO On or Off.

When DTO On is selected (Factory default) and if a LAT

trip occurs, closed dampers will begin opening to try and

keep equipment running by maintaining proper air tempera-

tures. However, if LAT temperatures exceed their limits,

equipment will start staging down. When DTO Off is

selected, equipment will stage down. Closed dampers will

not open on initial trip, however if LAT temperatures

exceed their limits, control will lock out and damper will

open.

NOTE: An HP temperature sensor must be used with a heat pump

application using electric strip heat. This is necessary in case the

DTO is set to the Off position.

—5—

→

→