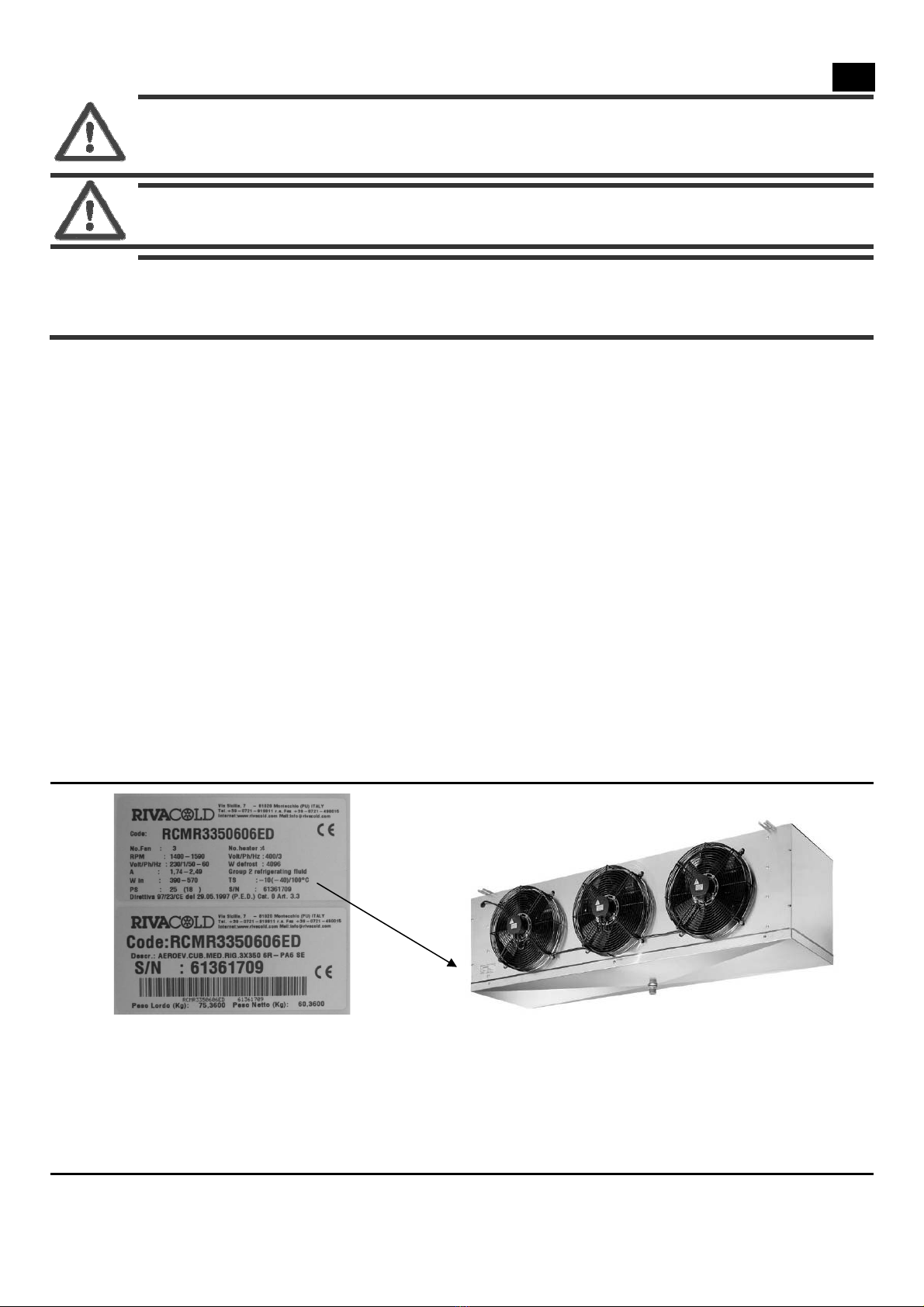

RCMR Pag. 32 Rev. 02 02 13

UK

G

Be careful for sharp cutting parts and when cleaning the air-cooled evaporator

3.5 Proper and improper use of the partly completed machinery

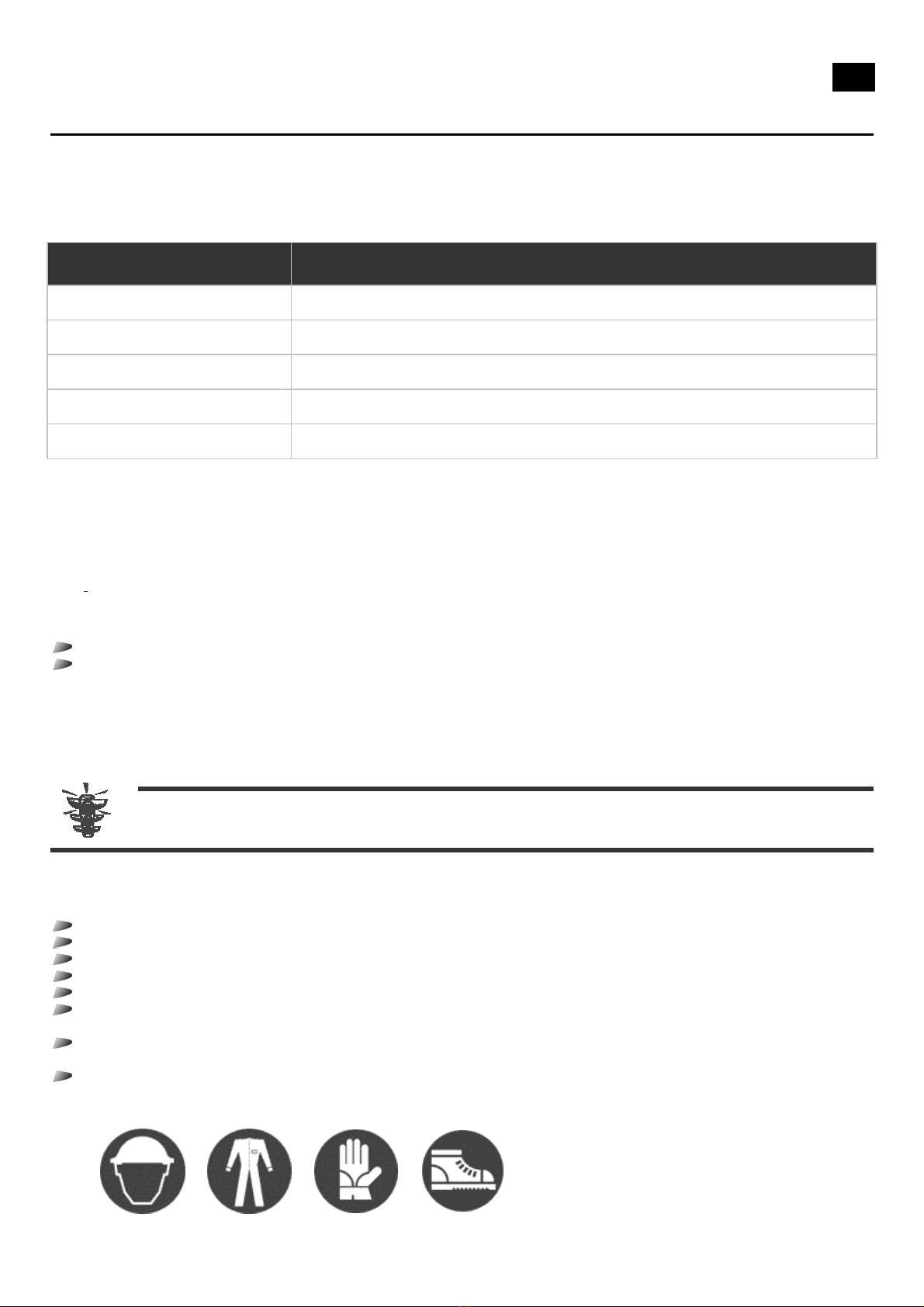

The

PARTLY COMPLETED MACHINERY

is designed and built to be inserted in a refrigerating circuit that can be used in the field of industrial

and commercial refrigeration in a permanent site.

Each model of the

PARTLY COMPLETED MACHINERY

can make use of the refrigerant gas specifically foreseen and indicated on its plate.

The

PARTLY COMPLETED MACHINERY

has been designed and built to work in environments that do not have a potentially explosive

atmosphere.

It is a sound cautionary norm to place powder extinguishers near the

PARTLY COMPLETED MACHINERY

. To prevent the possibility of a fire

outbreak, it is necessary to keep the

PARTLY COMPLETED MACHINERY

clean of pieces of plastic, oils, solvents, paper, and rags.

The use of the

PARTLY COMPLETED MACHINERY

for different operations or the use of a refrigerant gas different from the one indicated on

the plate could cause damages to persons or to the

PARTLY COMPLETED MACHINERY

itself, and are therefore considered improper uses for

which the Manufacturer does not deem itself responsible.

ATTENTION: in case of a different intended use, it is essential to first consult the Technical Office of the Manufacturer.

3.6 General Warnings and Behavioral Norms

In order to avoid any condition of risk to persons or of damages to the

PARTLY COMPLETED MACHINERY

, we recommend that you diligently

follow the general warnings and behavioral norms reported herein.

DANGER: the Manufacturer rejects any responsibility for possible damages to things and/or persons

stemming from improper interventions performed by unqualified, untrained, or unauthorized

personnel.

The operators appointed to manage the

PARTLY COMPLETED MACHINERY

must be duly instructed on how to best use it risk-free, and must

operate in a comfortable environment that can ensure the best possible conditions of safety and hygiene.

DANGER: prevent that the

PARTLY COMPLETED MACHINERY

be used by unauthorized or uninstructed personnel

without surveillance: in fact, before starting to work, each operator must be perfectly

knowledgeable of the characteristics of the

PARTLY COMPLETED MACHINERY

; he must, moreover, have

FULLY

read these instructions.

Before using the

PARTLY COMPLETED MACHINERY

, make sure that any condition dangerous to safety has been duly eliminated and

that there are no operators in the dangerous areas near the

PARTLY COMPLETED MACHINERY

.

Before using the

PARTLY COMPLETED MACHINERY

, make sure that all the guards or other protections are in their place and that all the

safety devices are present and efficient.

After having removed the packing, make sure that all the parts of the machine are intact; if they are not, contact the retailer.

Carefully read the labels on the

PARTLY COMPLETED MACHINERY

, do not cover them for any reason, and immediately replace them if

they get damaged.

Do not lay liquid containers on the

PARTLY COMPLETED MACHINERY

.

Consult these instructions with regard to the safety provisions in force and to the specific IPD to be adopted for personal safety;

more specifically, at any rate, the personnel appointed to the

PARTLY COMPLETED MACHINERY

must wear suitable clothing, avoiding or

paying the necessary attention to:

flapping clothing,

loose sleeves,

dangling neckties or scarves,

necklaces, bracelets, and rings.

The personnel appointed to maintenance on the

PARTLY COMPLETED MACHINERY

must be knowledgeable of all the procedures

reported in Chapter 5 - Maintenance and Demolition and have adequate technical preparation to correctly interpret the

instructions and annexed diagrams and to intervene on the

PARTLY COMPLETED MACHINERY

.

The area where the maintenance operations are performed must always be clean, dry, and with the suitable equipment always

available and efficient.

In case it were necessary to perform interventions near electrical components, operate with thoroughly dried hands and use

dielectric gloves (operating on electrical components with wet hands may lead to a near certain danger of electrical shock):