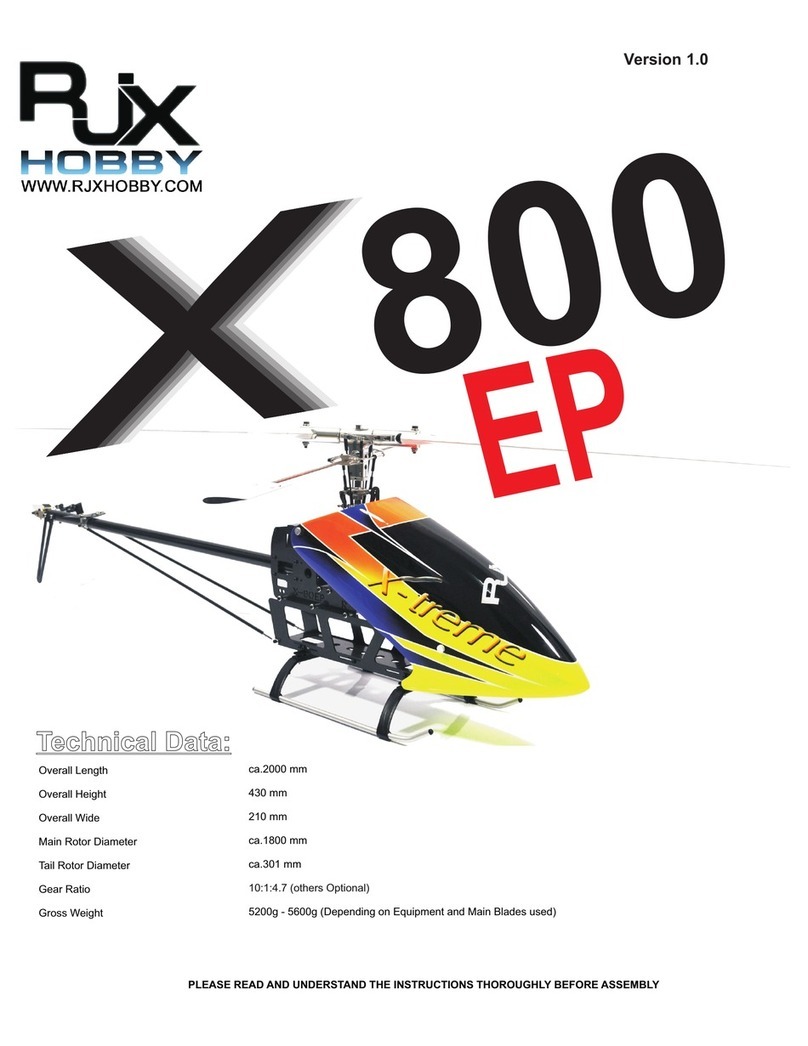

RJX Hobby X-Tron 500V2 FBL User manual

Overall Length

Overall Height

Overall Width

Main Rotor Diameter

Tail Rotor Diameter

Gear Ratio

Gross Weight

1185 mm

267 mm

180 mm

ca.980 mm

ca.214 mm

11.06(16T) / 12.64(14T):1:4.69

ca.1850g (Depending on Equipment and Main Blades used)

PLEASE READ AND UNDERSTAND THE INSTRUCTIONS THOROUGHLY BEFORE ASSEMBLY

Technical Data:

Assembly Manual

X

-Tron 500V2 FBL

-Tron 500V2 FBL

Version 1.1

INTRODUCTION

Please read this manual carefully. It is essential for the correct assembly of the

For the correct assembly and safe flying, this manual uses this symbol where special attention is required in the assembly of

your model. It is very important that you follow the instructions at these points in the manual. Failure to do so can lead to the loss of

control of the model without warning and the possibility of serious accidents or injury.

NOTE Failing to carry out the instructions at this point in the assembly manual will

probably result in an Electronics or mechanical failure occurring without warning..

IMPORTANT Means that special care is required at this point for correct assembly.

Disclaimer:

While every effort has been made to supply the correct information in this manual, The Manufacturer and Distributor

cannot guarantee that the purchaser will interpret or follow these instructions as intended and therefore the

Manufacture and Distributor assumes no liability for damage or claims that may occur from the use/misuse of this

product.

Do not be fooled it is NOT easy to fly R/C Helicopters

It may look easy when watching an experienced pilot flying his model, but perseverance and hours of practice will be needed before

you will be able to fly and opperate the model safely. RJX HOBBY suggests you join a club or seek help from an experienced pilot to

assist you in your first test flights and then as with all things the more you practice the better you will become. We encourage you to

practice often and enjoy the experience of RC rotary flight!

WARNING

LiPo batteries need special care. Improper handeling or charging can cause fire and damage to your Helicopter and yourself. Contact

your dealer or supplier for more information.

1. Check your charger settings before charging your LiPo battery to insure they are correct for the specifications of the battery.

2. We recommend storing and charging LiPo batteries in a lipo sack or porcelain container." If kept in a metal container or ammo

case, explosion could occur if these cases are sealed and gases are not allowed to vent. We recommand to use the original

LipoSack from the USA since it has been actually designed and tested by a firefighter to contain the jet flames discharged from

a failing lipo battery.

3. Please keep LiPo Batteries away from sources of heat..

4. Never store LiPo Batteries fully charged. Check the information on your batteries.

5. NEVER SHORT OUT LiPo Battery wires.

6. Before conecting your LiPo battery to the Helicopter,make sure your transmitter is turned ON and all sticks and switches are

set properly.

X

-Tron 500 FBL

-Tron 500 FBL

I1

TABLE OF CONTENTS

1. Introducion

2. Table of contents

3. Additional Items Required

4. Tools Required

5. Assembly

6. Servo Installation

7. Servo Adjustment

8. Final Servo and Radio Setup

9. Please read before flight

10. Spare Parts List

I1

I2

I3

I4

A1 - A16

S1-S4

S5-S9

R1-R5

Pf1

SP1 - SP5

This manual contains the detailed instructions to build and set up the X-Tron 500FBL. Please follow it to ensure that you

achieve the best performance and mechanical integrity from your finished kit. For those of you who already have

experience with model helicopters, we still suggest that you assemble and adjust your model according to these

instructions for the best results. Please keep your copy of this manual in a safe place and refer to it when replacing

spare parts or upgrading.

Remove oil and grease then apply threadlock. (This applies throughout the manual)

Remove oil and grease. (This applies throughout the manual)

Please refer to the list at the end of this instruction manual when you need spare parts.

Regardless how tight the nuts, bolts and screws are tightened, they will still slowly come loose over a period of time

due to vibration from the helicopter. Should this happen the helicopter will become out of control or severely damaged

causing a very potential dangerouse situation.

We strongly recommend that you apply threadlock to any nuts, bolts or screws that are indicated by these signs.

There are two types of threadlock, blue (medium) and red (hard) . Use blue threadlock on screws

that have to be removed regularly and red threadlock for screws that should be fixed permanently. Clean them

with Alcohol (or similar) before you apply the threadlock.

TO PREVENT LOOSE SCREWS AND BOLTS

HOW TO USE THIS INSTRUCTION MANUAL

Use CA (Superglue or similar) at this point

CA

I2

ADDITIONAL ITEMS REQUIRED TO COMPLETE THE

CCPM compatible PCM or 2,4Ghz Radio System

with 3 or 4 Mid Servos (Tail can be Standard or Mid) 3 Axis Virtual Flybar Sytem Three large and one small

servo arm are required

3226-1600kv(6S) Brushless Motor

(if not delivered) Lipo Pack from 4S-8S (Depending on setup) 80A ESC (if not delivered)

430mm CF Main Blades

(if not delivered)

X

-Tron 500 FBL

-Tron 500 FBL

20mm

3X

1X

13mm

I1

TOOLS REQUIRED (NOT INCLUDED)

Allen Drivers 1,5mm - 2mm - 3mm - 4mm Phillips Drivers Large,Middle, Small Nut Drivers 4,5mm - 5,5mm - 7mm

Cutter Universal Pliers Scissors

Sandpaper Ball Link Plier Metric Ruler Pitch Gauge

Cyanoacrylate (CA/Superglue) Epoxy 30 Minutes Grease

Ball Link Driver

Ball Link Tool

I1

STEP 1 MAIN DRIVE

Bag Content:

1x 177T Main Gear

1x 155T Taildrive Gear

1x Auto Shaft

1x Autorotation Unit

1x Tail Drive Hub

8x M3x6 Counter Sunk Hex Screws

M3X6(4)

155T

M3X6(4)

AUTO SHAFT

177T

AUTOROTATION UNIT

TAIL DRIVE HUB

A1

STEP 2 LANDING GEAR

Bag Contend:

2x Skid Brace

8x Landing Skid Struts

4x Skidholder

2x Skids

1x Canopy Mount

8x M2,5x10 Socket Head Screws

2x M2,5x8 Socket Head Screws

4x M3x12 Socket Head Screws

4x M3 Lock Nut

8x M2,5 Lock nut

M2,5x8(2) M2,5x10(8)

M2,5 Lock Nut(8)

M3 Lock Nut(4)

Landing Skid(2)

Skid Holder(4)

M3x12(4)

Struts(8)

Lower Canopy

Standoff

Canopy Support

Skid Brace(2)

A2

STEP 3-1 MAIN FRAME

Bag Contend:

2x Main Frame

2x Battery Tray Guides

10x M2x5 Socket Head Screws

M2x5(10)

Main Frame

Battery Tray Guide

CA

Add CA to the M2x5 Screws to

improve their hold in the Guides

A3

STEP 3-2 MAIN FRAME

Bag Contend:

1x Upper Bearing Block

1x Lower Bearing Block

2x Boom Holder

12x M2,5x8 Socket Head Bolt

1x Frame Stiffener

Check for the correct

mounting of the Bearing

Blocks.

M2,5x8(12)

Boom Holder

Lower Bearing Block

Upper Bearing Block

Frame Stiffener

A4

STEP 3-3 MAIN FRAME

Bag Contend:

2x 50mm Crossmember

17x M2,5x8 Socked Head Bolt

1x ESC Mount

2x Canopy Breakoff

1x Electronics Mount

2x Canopy Mount

1x Frame Stiffer 2

M2,5x8(13)

M2,5x8(4)

50mm Crossmember

ESC Mount

Electronics Mount

50mm Crossmember

Canopy Mount(2)

Secure the ESC Mount, Electronics Mount and the Frame Stiffener with CA.

Check position for hole

A5

NO SCREWS (will be

fixed in STEP 6-2)

Frame Stiffer 2

STEP 3-4 MAIN FRAME

Bag Contend:

1x Swash Guide

1x 33T Tail Gear Pinion

1x 16T S3M Pulley

1x Lower Tail Gear Mount

1x M3x6 Socket Head Bolt

1x M3x8 Socket Head Bolt

1x 3x8x1 Washer

3x M2,5x8 Socket Head Bolt

Swash Guide

M2,5x8

M3x6

16T S3M

Pulley

M2,5x8

Lower Tail Gear Mount

(Flange downwards)

33T Tail Pinion

M3x8

3x8x1 Washer

A6

STEP 3-5 MAIN FRAME

Bag Contend:

1x Main Shaft

1x Main Shaft Collar

1x M2,5x10 Socket Head Bolt

2x M3x8 Socket Head Bolt

Main Shaft

Hole closer to end of the

shaft goes down

Main Shaft Collar M2,5x10

M3x8

M3x8

After affixing the 2 M3x8 Socket Head Bolts, pull up on the main Shaft

and tighten the M2,5x12 Socket Head Bolt.

Do not overtighten the M3x8 main shaft bolts so as not to distort the gears.

Bolts should be snug.

A7

STEP 3-6 MAIN FRAME

Bag Contend:

4x M2,5x8 Socket Head Bolt

4x 2,6x7x1 Washer

2,6x7x1 Washer

M2,5x8

M2,5x8

2,6x7x1 Washer

DO NOT use thread lock on the Landing Gear's M2.5x8 bolts. This allows the

landing gear to slip out of the frame in the event of a crash.

A8

STEP 4-1 Rotor Head

Bag Contend:

1x Center Hub

1x Spindle

2x Blade Holder

2x Pitcharm

2x 90º Dampener

2x Collar

2x Thrust Bearing

2x Thrust Washer

2x Swashlock Arm

4x M2,5x8 Socket Head Bolt

2x M3x10 Socket Head Bolt

1x M2x8 Socket Head Bolt

2x M3x20 Socket Head Bolt

2x 3x5x1 Washer

Blade Holder

Center Hub

Spindle

90º Dampener

Collar

Thrust Washer

Thrust Bearing

(Bigger ID inside

Smaller ID outside)

3x8x1 Washer

M3x10

M2x8

Stopper

M2,5x8

Pitcharm

4mm Joint Ball

3x5x1 Washer

Swashlock Arm

M3x20

Apply grease to the Thrust Bearings

and Dampeners!

A9

STEP 4-2 Swashplate

Bag Contend:

1x Swashplate

3x 9mm Joint Ball

4x 4mm Joint Ball

4mm Joint Ball

9mm Joint Ball

A10

STEP 4-3 Installation

Bag Contend:

1x M3x16 Socked Head Bolt

1x Delrin Guide

1x M2,5x17 Socked Head Bolt

1x M2,5 Lock Nut

M3x16

Delrin Guide

M2,5 Lock Nut

M2,5x17

Tighten the M3x16 Socket Head Bolt to allow the Delrin guide to move smoothly

in the Swash Guide.

Clip the two Swashlock Links onto the corresponding balls.

There are 3 different adjustments for

center hub height. Use the Standard

position in the middle hole of the

center hub.

A11

STEP 5-1 Tail Section

Bag Contend:

1x Tailcase

1x 16T S3M Pulley

1x 14mm Pin

1x Tail Shaft

1x M3x4 Set Screw

1x Tail Control Arm Support

1x Tail Control Arm

2x M2,5x6 Socket Head Bolt

1x M2x5 Socket Head Bolt

1x M3x25 Socket Head Bolt

2x 3x5x2 Washer

1x Joint Ball

16T S3M Pulley

14mm Pin

Tail Shaft

Tail Case

M3x4

To remove the tail shaft, heat the

14mm pin with the tip of a

soldering iron and press out with

a small screwdriver or use a draft

pin and arbor press.

M2,5x6

3x5x2 Washer

Tail Control Arm

3x5x2 Washer

M3x25

Tail Control Arm Support

M2x5

Joint Ball

A12

STEP 5-2 Tail Section

Bag Contend:

2x Tail Blade Holder

1x Tail Center Hub

1x Copper Sleeve

1x Slide Ring

1x Pitch Fork

3x Joint Ball

2x M2x8 Socket Head Bolt

1x M2x5 Socket Head Bolt

2x Thrust Bearings

2x Thrust Washer

2x M3x10 Socket Head Bolt

2x 3x8x1 Washer

Tail Hub

M2x8

Joint Ball

Tail Blade Holder

Thrust Washer

Larger OD Thrust Ring

Thrust Ball Ring

Small ID Thrust Ring

M3x10

3x8x1 Washer

Use grease on the Thrust Bearing!

Copper Sleeve

Slide Ring

Joint Ball

M2x5

Pitch Fork

A13

STEP 5-3 Tail Section

Bag Contend:

2x 70mm Tail Blades

2x M3x20 Socket Head Bolt

2x M3 Lock Nut

2x M4x4 Set Screw

4x 3x10x1,5 Washer

M4x4

70mm CF Tail Blade

M3x20 M3 Lock Nut

3x10x1,5 Washer

A14

STEP 5-4 Tail Section

Bag Contend:

1x Tail Fin Set

1x S3M 1119 Belt

1x Tailboom

2x M3x6 Socket Head Bolt

2x M3x8 Socket Head Bolt

CA

Tail Boom

S3M Belt

M3x6

M3x8

A15

Table of contents

Other RJX Hobby Toy manuals

Popular Toy manuals by other brands

Chicco

Chicco HELICO MUSICAL manual

Hasbro

Hasbro Fur Real Friends Cuddles My Giggly Monkey manual

Little Tikes

Little Tikes Slammin' Racers Runaway Railroad quick guide

Faller

Faller 191794 manual

ROBBE

ROBBE Air Beaver Assembly and operating instructions

Finwing Technology

Finwing Technology Traveler 1400MM user manual

Rapido Trains

Rapido Trains F40PH-2D manual

Freewing

Freewing Spacewalker instruction manual

Eduard

Eduard Leopard 2A6 Assembly instructions

REVELL

REVELL Bristol F.2B Fighter Assembly instructions

Parkside

Parkside PP 1500 A1 Operation and safety notes

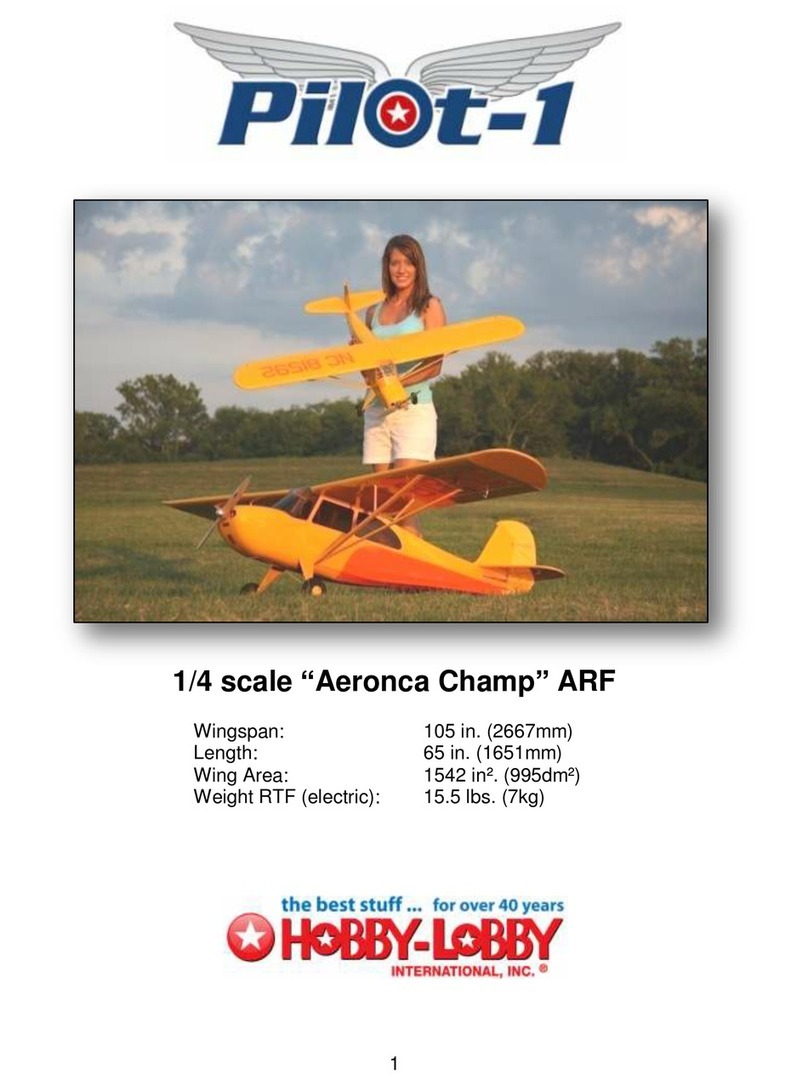

Pilot-1

Pilot-1 Aeronca Champ Assembly instructions & owner's manual