RJX Hobby x800 ep User manual

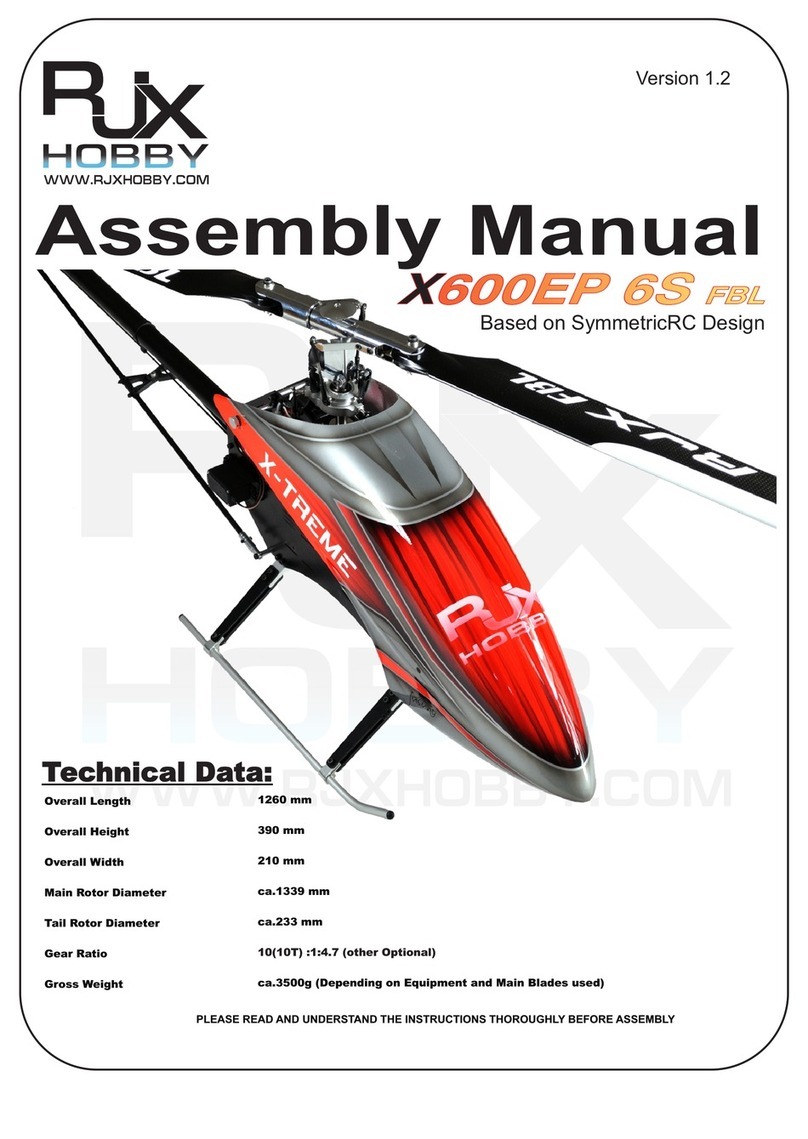

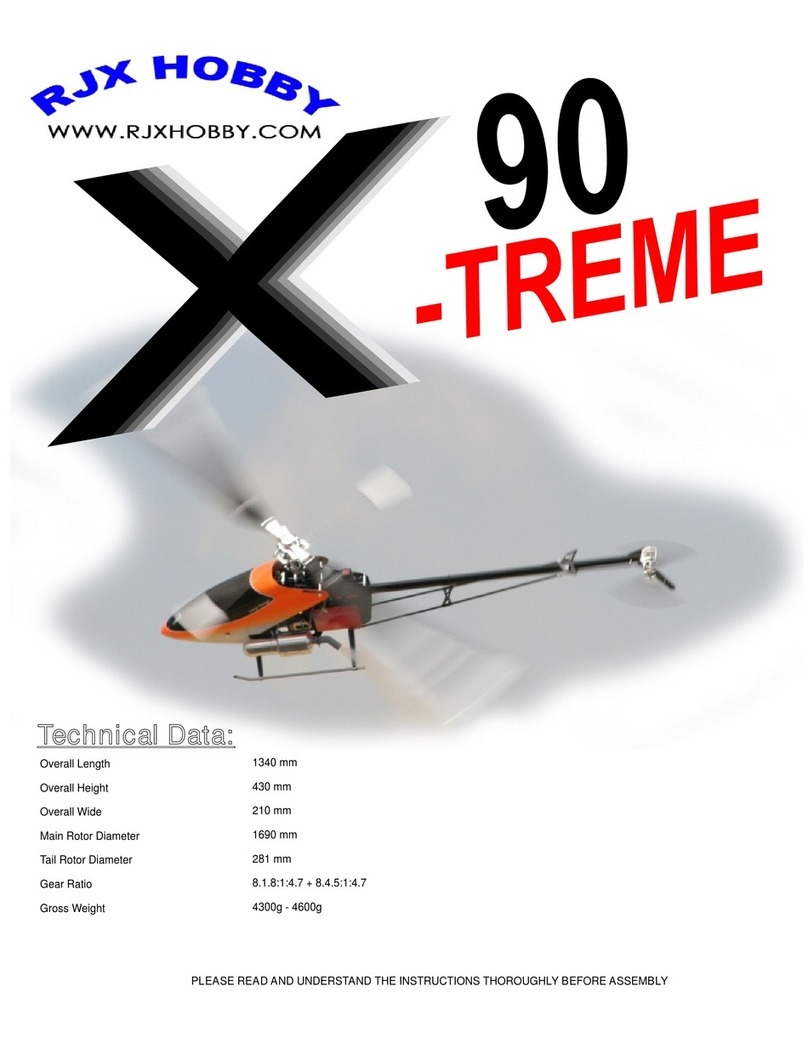

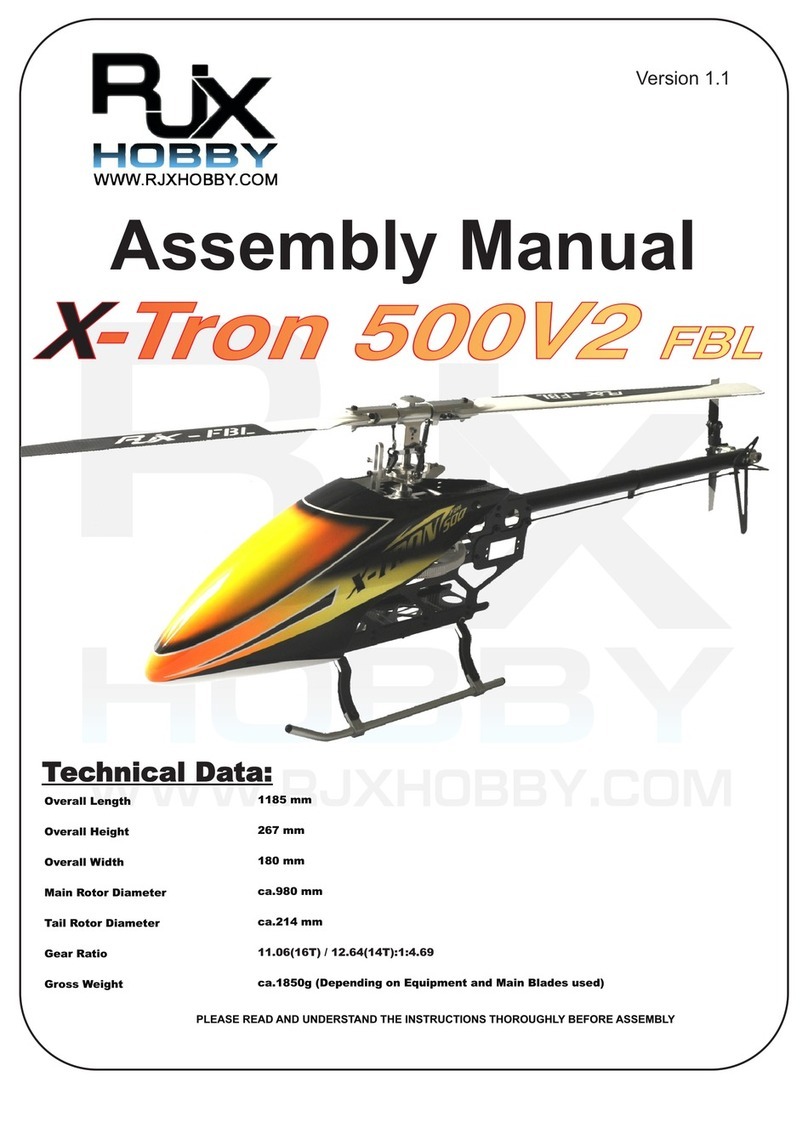

Technical Data:

Overall Length

Overall Height

Overall Wide

Main Rotor Diameter

Tail Rotor Diameter

Gear Ratio

Gross Weight

ca.2000 mm

430 mm

210 mm

ca.1800 mm

ca.301 mm

5200g - 5600g (Depending on Equipment and Main Blades used)

10:1:4.7 (others Optional)

PLEASE READ AND UNDERSTAND THE INSTRUCTIONS THOROUGHLY BEFORE ASSEMBLY

Version 1.0

800

INTRODUCTION

Please read this manual carefully. It is essential for the correct assembly of the

For the correct assembly and safe flying, this manual uses this symbol where special attention is required in the assembly of

your model. It is very important that you follow the instructions at these points in the manual. Failure to do so can lead to the loss of

control of the model without warning and the possibility of serious accidents or injury.

NOTE Failing to carry out the instructions at this point in the assembly manual will

probably result in an electronic or mechanical failure occurring without warning..

IMPORTANT Means that special care is required at this point for correct assembly.

Disclaimer:

Whilst every effort has been made to supply the correct information in this manual, The Manufacturer and Distributor

cannot guarantee that the purchaser will interpret or follow these instructions as intended and therefore the

Manufacture and Distributor assumes no liability for damage or claims that may occur from the use/misuse of this

product.

Do not be fooled it is NOT easy to fly R/C Helicopters

It may look easy when watching an experienced pilot flying his model, but perseverance and hours of practice will needed before you

will be able to fly and opperate the model safely. RJX HOBBY suggests you join a club or seek help from an experienced pilot to help

you in your first hops off the ground and then as with all things the more you practice the better you will become. Who knows you could

be the next world champion.

WARNING

The fuel used in model helicopter engines is highly inflammable and poisonous to human beings. For your own safety and that of

others, you should exercise care when handling and storing it. Always read the label on the container and please note the cautions

below.

1. Model helicopter fuel is highly inflammable. Do not smoke or light fires near your fuel.

2. We recommend that you keep your fuel in metal cans or plastic bottles and to store it where there is no risk of fire.

3. Please keep fuel away from the starter battery. It only needs one spark and…..!!!

4. Wipe up spilt fuel immediately. Do not take any chances.

5. Do not leave fuel in the sun or in you car on a hot day.

6. Before refuelling, shut off the engine and wait until it cools down.

7. Always drain the fuel tank of you helicopter at the end of a flying session. It is good practice.

I1

800

I2

TABLE OF CONTENTS

1. Introducion

2. Table of contents

3. Additional Items Required

4. Tools Required

5. Assembly

6. Servo Installation

7. Servo Adjustment

8. Rotor Head Setup

9. Final Servo and Radio Setup

10. Please read before flight

11. Spare Parts List

I1

I2

I3

I4

A1 - A29

S1-S4

S5-S6

A17

R1-R5

Pf1

SP1 - SP7

This manual contains the detailed instructions to build and set up the . Please follow it to ensure that you

achieve the best performance and mechanical integrity from your finished kit. For those of you who already have

experience of model helicopters, we still suggest that you assemble and adjust your model according to these

instructions for the best results. Please keep your copy of this manual in a safe place and refer to it when replacing

spare parts or upgrading.

Remove oil and grease then apply threadlock. (This applies throughout the manual)

Remove oil and grease. (This applies throughout the manual)

Please refer to the list at the end of this instruction manual when you need spare parts.

Regardless how tight the nuts, bolts and screws are tightened, they will still slowly come loose over a period of time

due to vibration from the helicopter. Should this happen the helicopter will become out of control or severely damaged

causing a very potential dangerouse situation.

We strongly recommend that you apply threadlock to any nuts, bolts or screws that are indicated by these signs.

There are two types of threadlock, blue (soft) and red (hard) . Use blue threadlock on screws

that have to be removed regularly and red threadlock for screws that should be fixed permanently. Clean them

with Alcohol (or similar) before you apply the threadlock.

TO PREVENT LOOSE SCREWS AND BOLTS

HOW TO USE THIS INSTRUCTION MANUAL

Use CA (Superglue or similar) at this point

CA

800

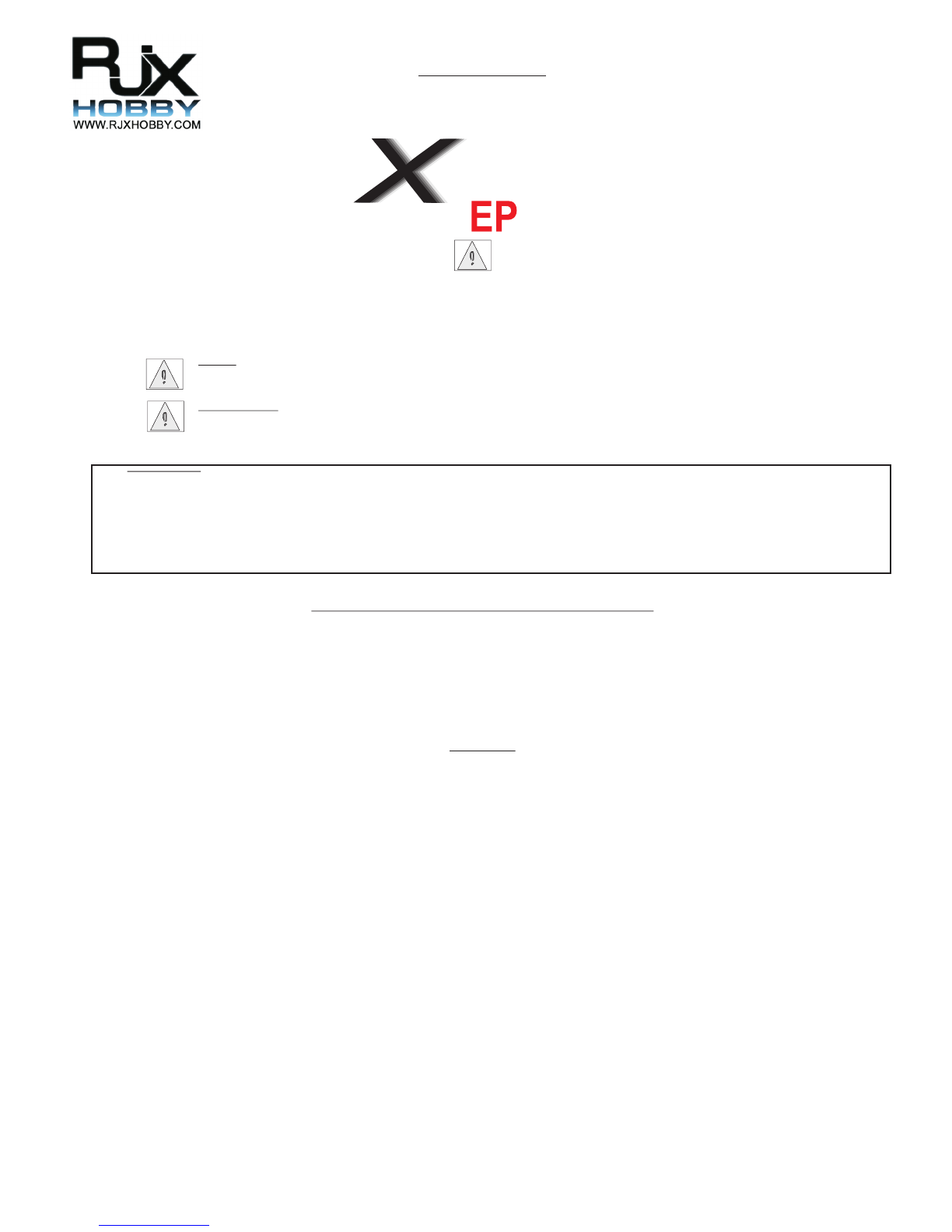

ADDITIONAL ITEMS REQUIRED TO COMPLETE THE

I3

Choose a CCPM compatible PCM Radio System for

Helicopters with a minimum of 6 channels.

Gyro system with

Heading Hold Three large and two small disks or

arms are required

1x Servo extension 100 mm

(depending on Servos) Brushless Motor (Outrunner)

300KV-450KV(10S-12S) 10-12S Li-Po Batterie Pack

Li-po/Ion Charger 120A-180A Brushless Motor ESC

for 10S-12S 800mm - 820mm Main Blades (for kits without Blades)

800

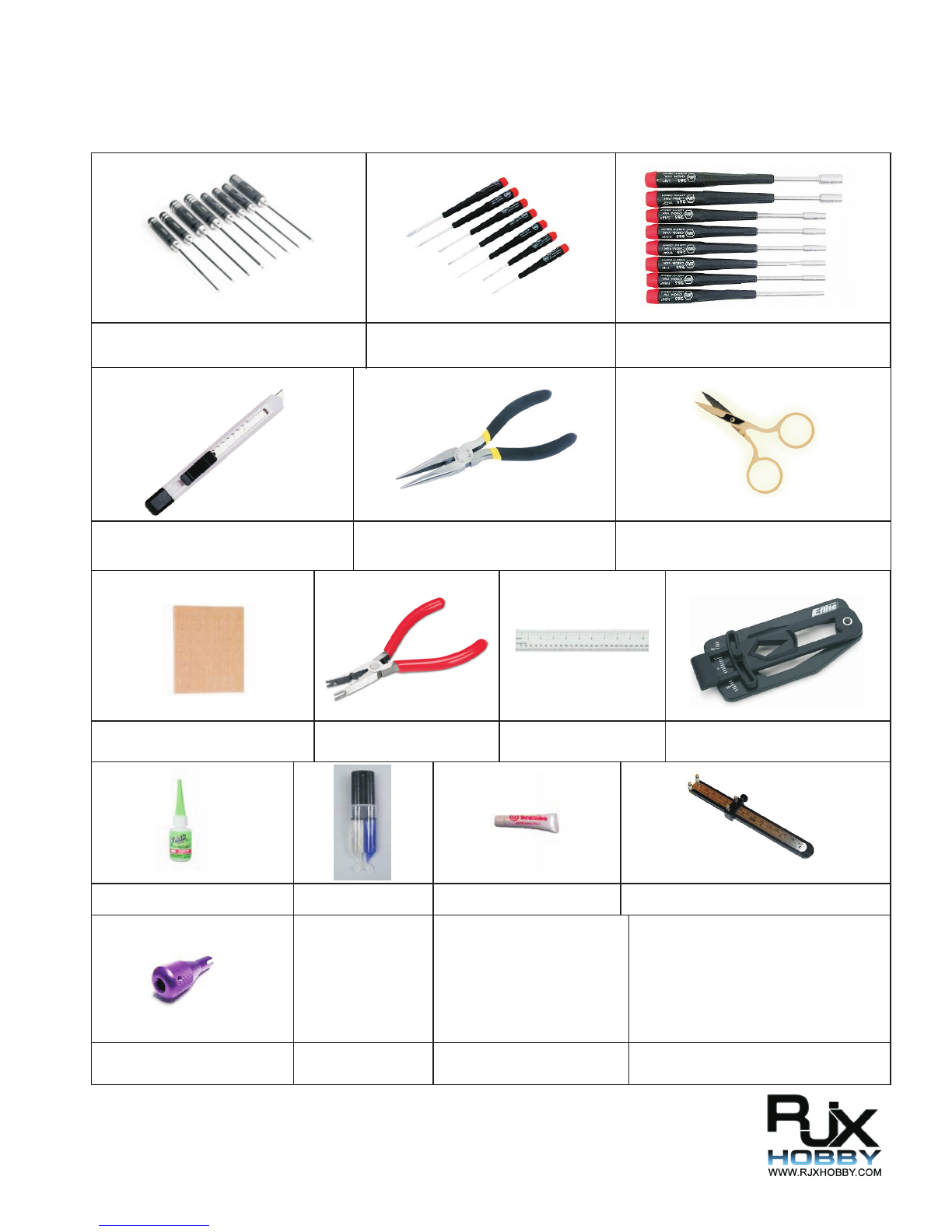

TOOLS REQUIRED (NOT INCLUDED)

I4

Allen Drivers 1,5mm - 2mm - 3mm - 4mm Phillips Drivers Large,Middle, Small Nut Drivers 4,5mm - 5,5mm - 7mm

Cutter Universal Pliers Scissors

Sandpaper Ball Link Plier Metric Ruler Pitch Gauge

Cyanoacrylate (CA/Superglue) Epoxy 30 Minutes Grease

Ball Link Driver

Ball Link Tool

A1

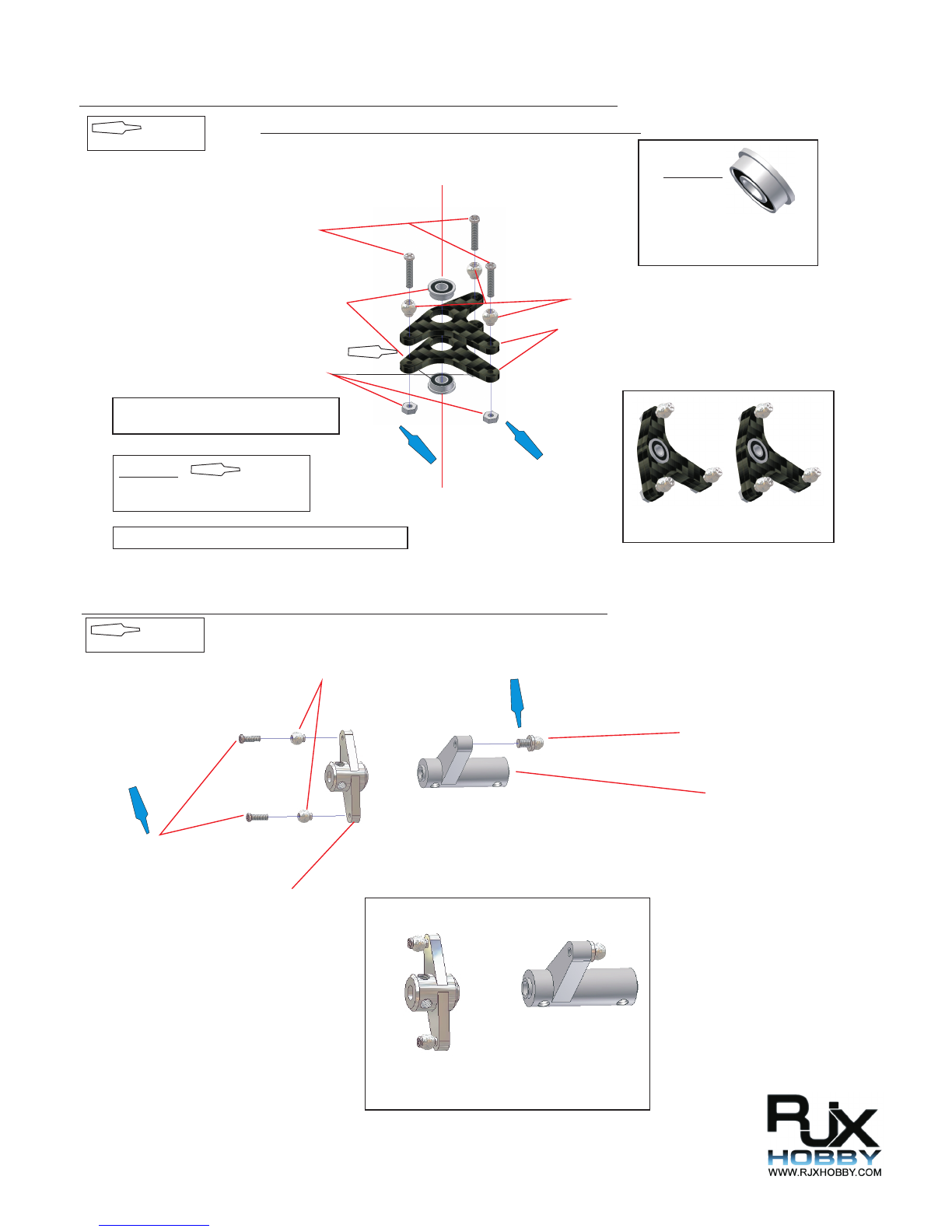

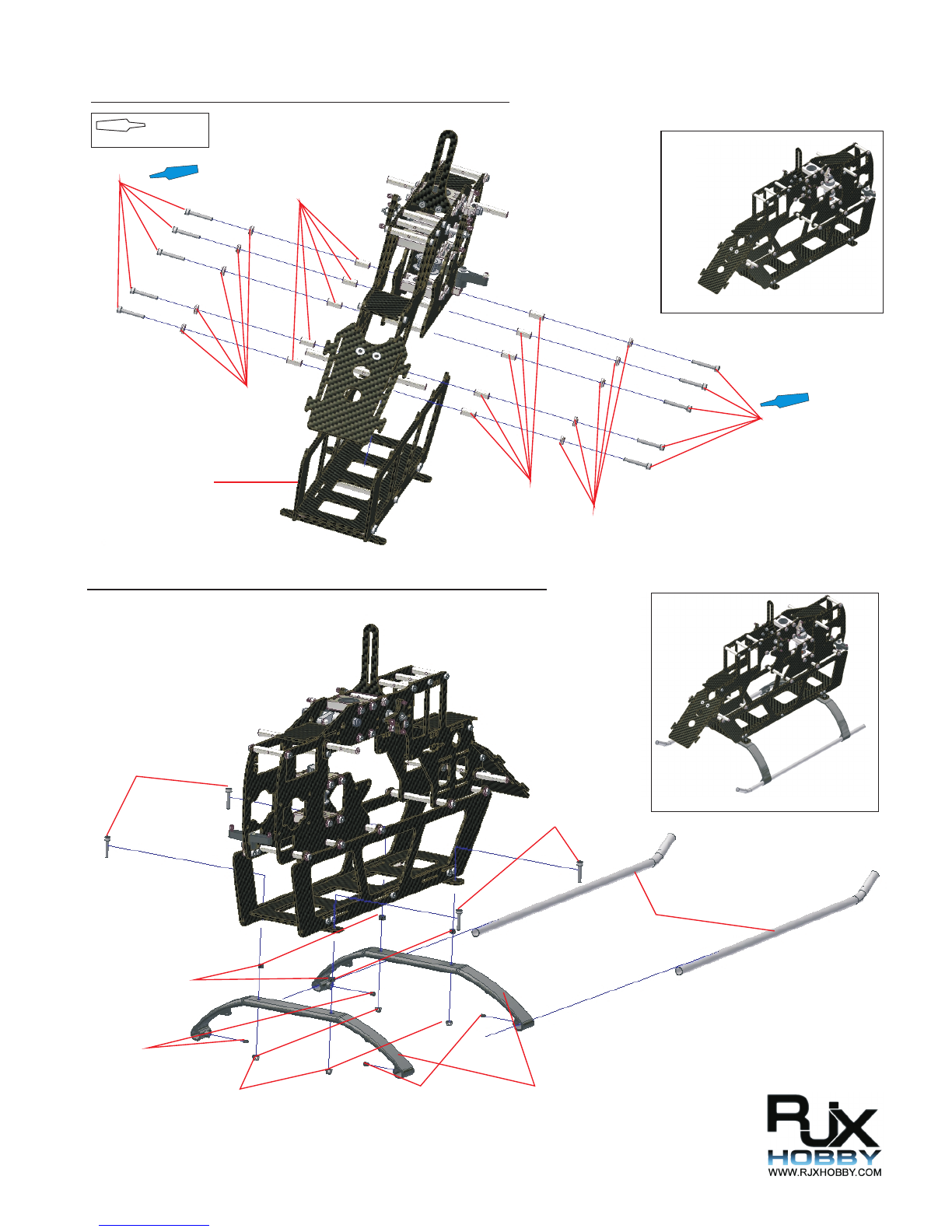

STEP 1-1 Landing Skid Support Assembly

View of the complete Assembly.

.

USE THREADLOCK

M3x12

Landing Skid Mount A

Landing Skid Mount B

NOTE:Assemble 2 units.

Bottom Plate Mounting Block

LANDING SKID MOUNTS inside the bag of the MAIN FRAME

STEP 1-2TT Tail Drive Pinion Gear Assembly (TT Version)

Tail Drive Pinion

M3 Washer

M3x6 Socket Head Bolt

M3x4 Setscrew

12mm Pin

Output Shaft

19T Delrin Bevel Gear

19T Delrin Bevel Gear

M3x4 Setscrew

5x7x1 Washer

5x7x1 Washer

(if needed)

TT Gear Box

View of the complete Assembly.

Check that the gearmesh is correctly

(if necesary add a 0.2mm Nylon Washer) and

the assembly rotated freely but without play.

USE THREADLOCK IMPORTANT: Start assembly with the OUTPUT SHAFT.

IMPORTANT:

Add 0,2mm Nylon washer to

reach a PLAYLESS Gear mesh.

Check that the two gears are

perfectly aligned (shown in the

picture on the right).Stay on the

tight side of the gear mesh.

A ecssesive play can strip the

Delrin gear.

Lub the Bevel Gears regulary.

This step is preassembled.PLEASE CHECK AND ADD THREAD LOCK

Aligned

A2

STEP 1-3 Drive Gear Assembly

M3x8 Socket Head Bolt

93T Helical Main Gear

M3x6 Counter Socket Head Bolt

80T Tail Drive Gear

Tail Drive Gear Housing

Autorotation Shaft

Autorotation Spacer

IMPORTANT:

Stepped side facing downward

and entering completly inside

the bearing.

View of complete Assembly

CAUTION:

Clean off any dust on drive gears.

Add grease to the one way bearing,

to ensure smooth opperation.

Don´t fix the four M3x6 bolts before

having all four in place.

USE THREADLOCK

Autorotacion Unit

OPTIONAL:

93T Helical Main Gear

STEP 1-4 Canopy Stands

32mm Crossmember

M3x8 Socket Head Bolt

Breakoff

View of the completed Assembly

NOTE: Assemble 4 sets

BREAKOFF are inside the bag of the MAIN FRAME

USE THREADLOCK

A3

STEP 1-5 Swash Control Lever Assembly

M2x8 Socket Head Bolt

F3x6x2.5 Bearing with Flange

M2 Nut

Jointball

Control Lever

CA

View of the completed Assembly

CAUTION:

the two Control Lever parts.

Add a small amount of CA between

CA

CAUTION:

Control the correct fit of

the Flanged Bearings.

Flange facing upward

Flange facing downward

NOTE: Assembly 2 sets of this lever

USE THREADLOCK

CONTROL LEVER inside the bag of the MAIN FRAME

Add a 0.2mm Shim between the bearings if necesary

STEP 1-6 Rear Swash Control Assembly

USE THREADLOCK

M2x6 Socket Head Bolt

Joinball

4mm Ball Arm

Nick Arm

Rear Swash Lever

View of the completed Assembly

A4

STEP 1-7 Front Tail Arm Assembly

USE THREADLOCK

M2x10 Socket Head Bolt

M3x20 Socket Head Bolt

Joinball

Control Lever

Washer 3x5x1

Leverblock

View of the completed Assembly

CAUTION:

Do NOT over tighten the M3x20 bolts

to avoid breaking the bearings.

STEP 1-8 Battery Tray Assembly

USE THREADLOCK

M3x8 Countersunk Head Bolt

Battery Tray

View of the completed Assembly from both side

Special Crossmember

BATTERY TRAY inside the bag of the MAIN FRAME

A6

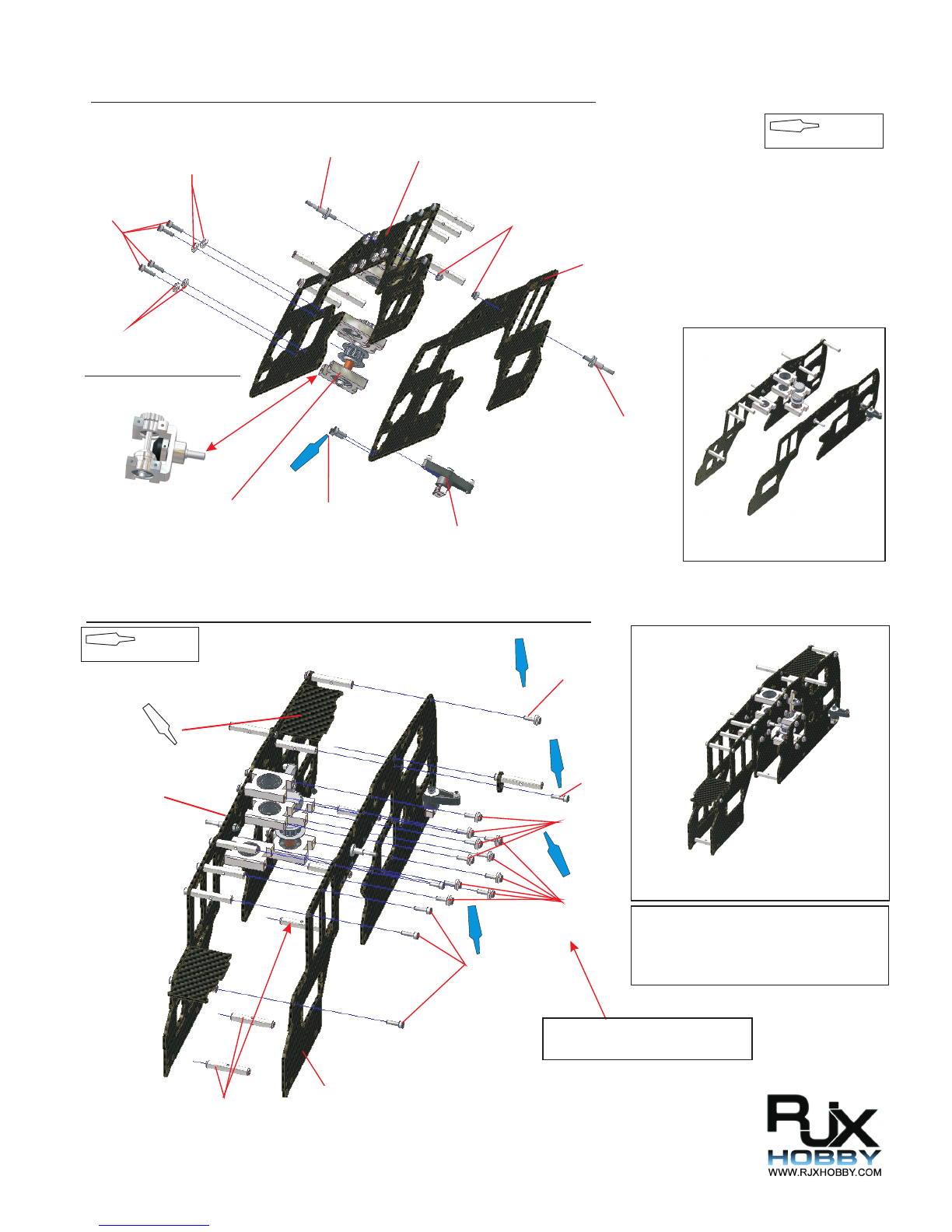

STEP 2-1 Lower Main Frame Assembly

USE THREADLOCK

Assambled in Step 1-1

M3x8

M3x10

M3x10

M3x8

M3x8

M3x8

60mm Crossmenber

Lower Frame

Lower Frame

Bottom Plate

View of the completed Assembly

CAUTION:

The upper main frame sides are NOT the same.

Look at the X50-EP writing cutout on the frame

sides to ensure that you have the correct sides.

STEP 2-2 Upper Main Frame Assembly

USE THREADLOCK

View of the completed Assembly

BB Block

(Flange Down)

BB Block Pinion

(Flange Down)

BB Block

(Flange Up)

32mm Crossmember

32mm Crossmember

M3x10

Finish Cap

Right Upper Frame

Assembled in Step 1-4

M3x10

Flange

M3x10

(NO Threadlock

BB Block Pinion)

A7

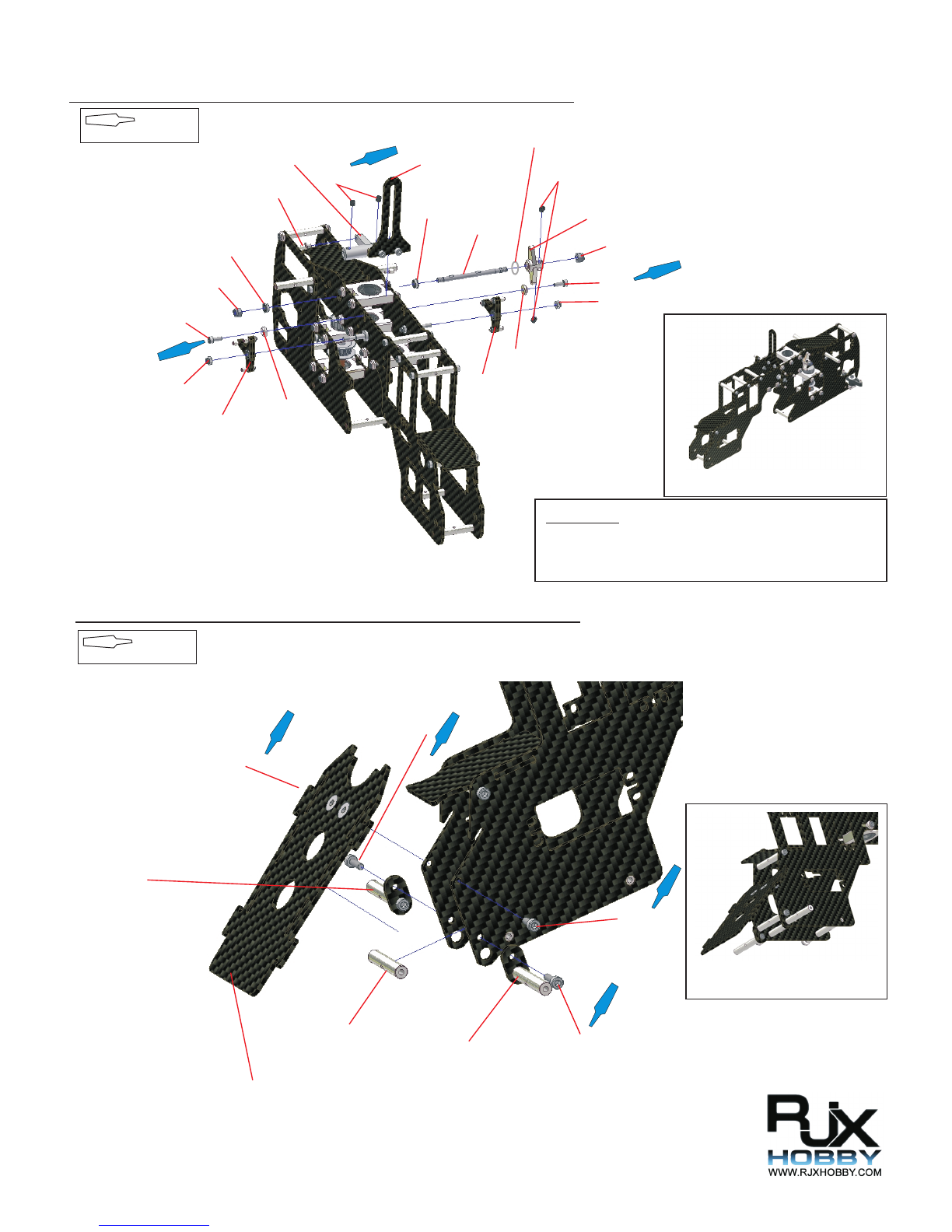

STEP 2-3 Upper Main Frame Assembly

USE THREADLOCK

STEP 2-4 Upper Main Frame Assembly

USE THREADLOCK

View of the completed Assembly

View of the completed Assembly

M3x10

Finish Cap

Finish Cap

Standoff

Standoff

M3 Lock Nut

Assembled in Step1-2B

Assembled in Step2-2

Left Upper Frame

Gyro Mount

Assembled in Step 2-3

M3x10

M3x10

Finish Cap

Canopy Mount

Stepped Crossmember(5pcs.)

M3x8 (2)

Assembled in Step1-1

Note:

To ensure a perfect fit of the Gyro Mounts

use CA to fix them.

CA

Assembled

in Step 2-3

TT VERSION available only

Use the Assembly from

STEP1-2TT

M3x10

Do not use threadlock here to be able

attaching the belt in a later Step

M3x10

Finish Cap

M3x10

A8

View of the completed Assembly

STEP 2-5 Upper Main Frame Assembly

USE THREADLOCK

STEP 2-6 Upper Main Frame Assembly

USE THREADLOCK

View of the completed Assembly

Nick Arm

M4x4

Set Screw ( Do not use Threadlock for later adjustment)

Swashguide

F4x8x3 Bearing

CCPM Shaft

M4x4

Set Screw

CCPM Arm

M3 Lock Nut

M3x8

Front CCPM Arm

F4x8x3 Bearing

M4 Lock Nut M3x8

M4 Lock Nut

M3 Lock Nut

Finish Cap

Finish Cap

Front CCPM Arm

M3x8

M3x10

Canopy Mount

Canopy Mount

M3x10

M3x8

32mm Crossmember

Assembled in Step 1-8

IMPORTANT:

Do NOT over thighten the M4 Lock Nut to ensure the smooth

opperation of the assembly.

4x6x1 Washer

A9

STEP 2-7 Main Frame Assembly

STEP 2-8 Landing Skid Attachment

Assempled in Step2-1

USE THREADLOCK

M3x25

Finish Cap

12mm Spacer

12mm Spacer

Finish Cap

M3x25

View of the completed Assembly

View of the completed Assembly

3x5x3 Plastic Washer(4)

M3x4 Set Screw

M3x4 Set Screw

M3 Lock Nut

M3x18

M3x18

Skids

Landing Skid Brace

A10

STEP 3-1 Drive Gear Instalation

USE THREADLOCK

Pinion

M4x4 Set Screw

M4x10 Motor Mount

Brushless Motor

M4x10

View of the completed Assembly

STEP 3-2 Drive Gear Installation

Note:

Do not tighten the two M4x10 screws.

On some motors you can use up to 4

Set Screws to fix the Pinion.

Depending on the KV of the Brushless

Motor the Pinion and/or the Maingear

must be changed to reach a good ratio.

View of the completed Assembly

USE THREADLOCK

M3x10

Finish Cap

M3x10

Finish Cap

Important:

Ensure that the Pinion is inside

the bearing.

A11

STEP 3-3 Drive Gear Instalation

IMPORTANT:

When securing the main shaft, pull it upwards through

the main bearings to eliminate any freeplay. Next press

the main shaft collar firmly onto the upper bearing block

and fix with threadlock the four M4x4 set screws.

NOTE:

DO NOT tighten the Jesus Bolt too much.

If tigthen to much the Tail Gear Housing

could deform.

NOTE:

Insure the bigger hole is

inserted.

M2,5x12 M4x10

4mm Hole Main Shaft

Main Shaft Collar

M2,5x10

Assembled in Step 1-3

M2,5x12

M4x10

USE THREADLOCK

View of the completed Assembly

NOTE:

Depending on Motor and Ratiu selected the distance between main gear and motor position will change.

Ensure to archive a perfect gear mesh.On high power setups, please leave the backslash as samll as possible

without beeing to tight.

A12

STEP 4-1 SWASHPLATE ASSEMBLY

STEP 4-2 WASHOUT ASSEMBLY

NOTE:

There are two position to mount the Jointball.

The outer hole is for faster response.The

inner for less.

View of the completed Assembly

View of the completed Assembly

USE THREADLOCK

USE THREADLOCK

4mm Ballarm (4)

Swash Guide Pin

Washout Base Washout Arm

M2x10 Socket Head Bolt

Jointball

M3x12 Socket Head Bolt

Washer 3x5x1

Washout Arm

NOTE:

Do NOT over tighten the M3x12 Bolts to avoid damge

to the bearings.

9mm Ballarm (3)

STEP 4-3 SWASHPLATE / WASHOUT INSTALLATION

STEP 4-4 SEESAW INSTALLATION

TOP

BOTTOM

IMPORTANT:

Insure the correct direction

View of the completed Assembly

View of the completed Assembly

NOTE:

Attach the two Washoutlinks to the swash plate.

M3x10 Socket Head Bolt

Rotor Stopper

Centerhub

Seesaw

M4x6 Socket Head Bolt

M4x6 Socket Head Bolt

USE THREADLOCK

IMPORTANT:

Do NOT over tighten the M4x6 Socket Head Bolt to fix the

Seesaw.Hard type of thread lock is necessary.

A13

NOTE:

Apply the threadlock inside the Seasaw.

On this way the fix of the screws is enured.

A14

STEP 4-5 MAIN BLADE HOLDER ASSEMBLY

STEP 4-6 MIXER ARM ASSEMBLY

View of the completed Assembly

View of the completed Assembly

Main Blade Holder

M3x6 Socket Head Bolt

Pitch Arm

Mixer Arm

Ball Arm 4mm

NOTE: Assemble 2 sets of the Main Blade Holder.

Detailed adjustments in Step 4-13.

NOTE: Assemble 2 sets of this mixer arm

NOTE:

Don´t use in this step threadlock to fix the Ball arm.

IMPORTANT:

Mixer settings are explained in Step 4-13 more detailed.

A15

STEP 4-7 MAIN ROTOR HEAD ASSEMBLY

STEP 4-8 MAIN ROTOR HEAD ASSEMBLY

View of the completed Assembly

Spindle

Damper

Spindle Collar

Thrust Washer

Washer 5mm

M5x12 Socket Head Bolt

Thrust Bearing

smaller ID

bigger ID

IMPORTANT:

Check the correct size and way

of installing the Thrust Bearing.

Add grease to the bearing.

USE THREADLOCK NOTE:

Use silicon grease for the dampers.

This also needs to be reaplied as part

of your on going maintenace (after

about 30 to 40 flights) to ensure that

the dampers not getting dry.

View of the completed Assembly

4mm Flybar (550mm)

Washer 3x5x2

Ball Arm 9mm

M3x16 Socket Head Bolt

Assembled in Step 4-6

Washer 3x5x1

Flybar Arm

Rotorhead Assembly

NOTE:

Assemble both sides of the Rotor head the same way.

Do NOT use threadlock for later adjustments.

M4x4 Set Screw

GREASE

A16

STEP 4-9 MAIN ROTOR HEAD ASSEMBLY

Phase Ring

Set Screw M3x4

Jesus Bolt M4x8

View of the completed Assembly

M3x14 Socket Head Bolt

Jesus Bolt M4x8

M3x14 Socket Head Bolt

Set Screw M3x4

NOTE:

The size of the linkage rod can variate depending

on the head setup. In the STEP 7-2 will be an

example of setup with the acording sizes of the

linkage rods.

By looking closely, you will notice on the universal

links the letters RJX (on the small) and RJXHOBBY

on the large links. ensure this are always pointed

outside from the ball as shown in the diagram below.

RJX or RJXHOBBY

Link A

Link B

Link C

Use four short links

and two 2x20mm rod

Use four long links and

two 2x25 mm rod

Use four long XL links

and two 2,6x75mm rod

STEP 4-10 CONTROL ROD INSTALLATION

USE THREADLOCK

Other RJX Hobby Toy manuals

Popular Toy manuals by other brands

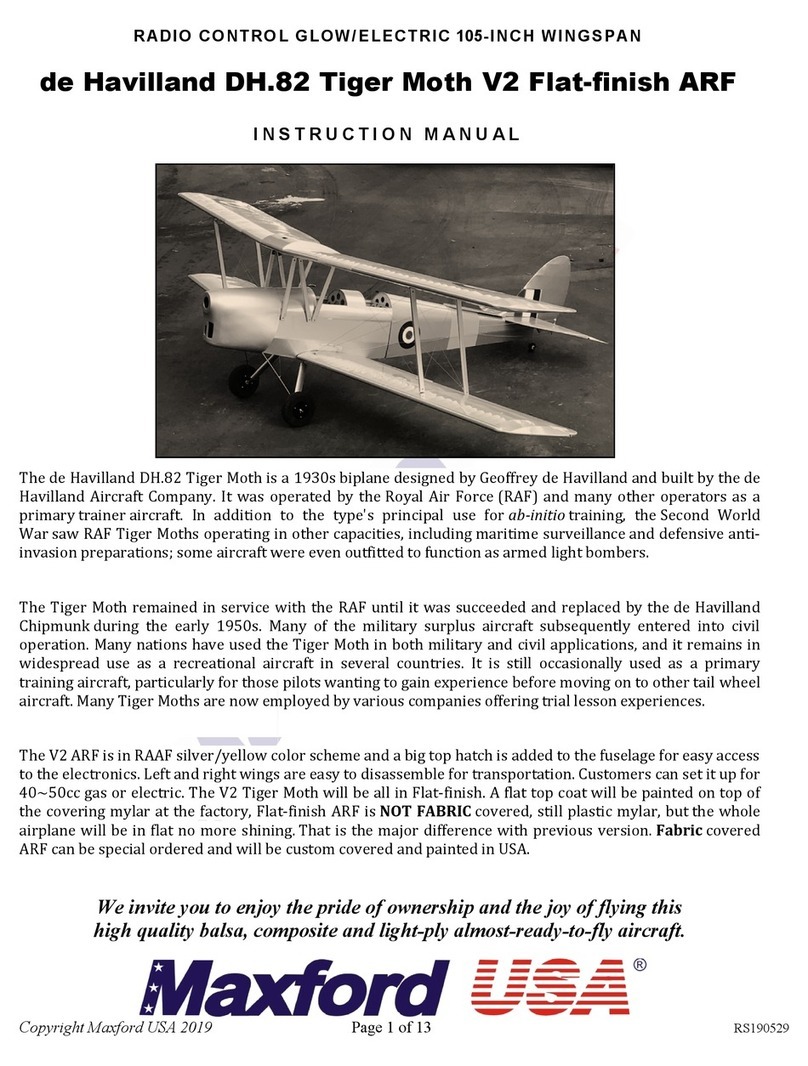

Maxford USA

Maxford USA de Havilland DH.82 Tiger Moth V2 instruction manual

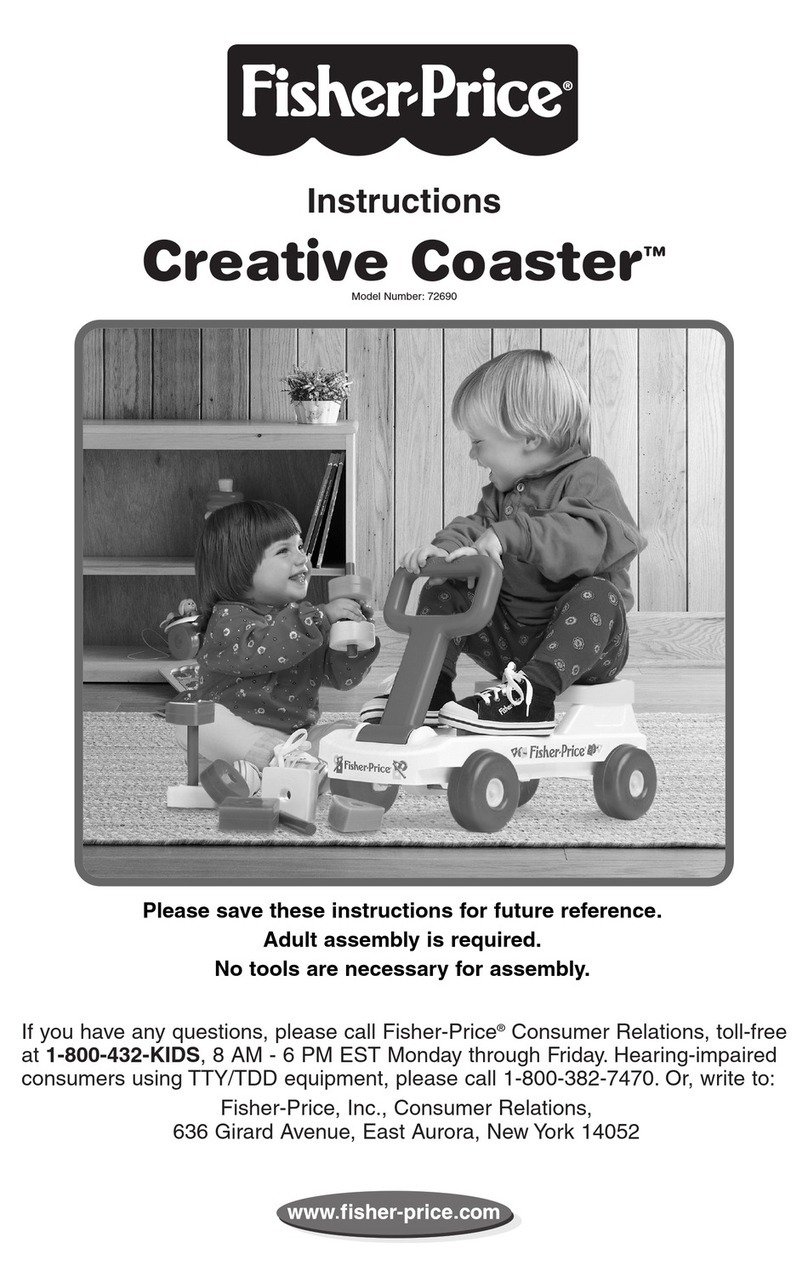

Fisher-Price

Fisher-Price X7673 instructions

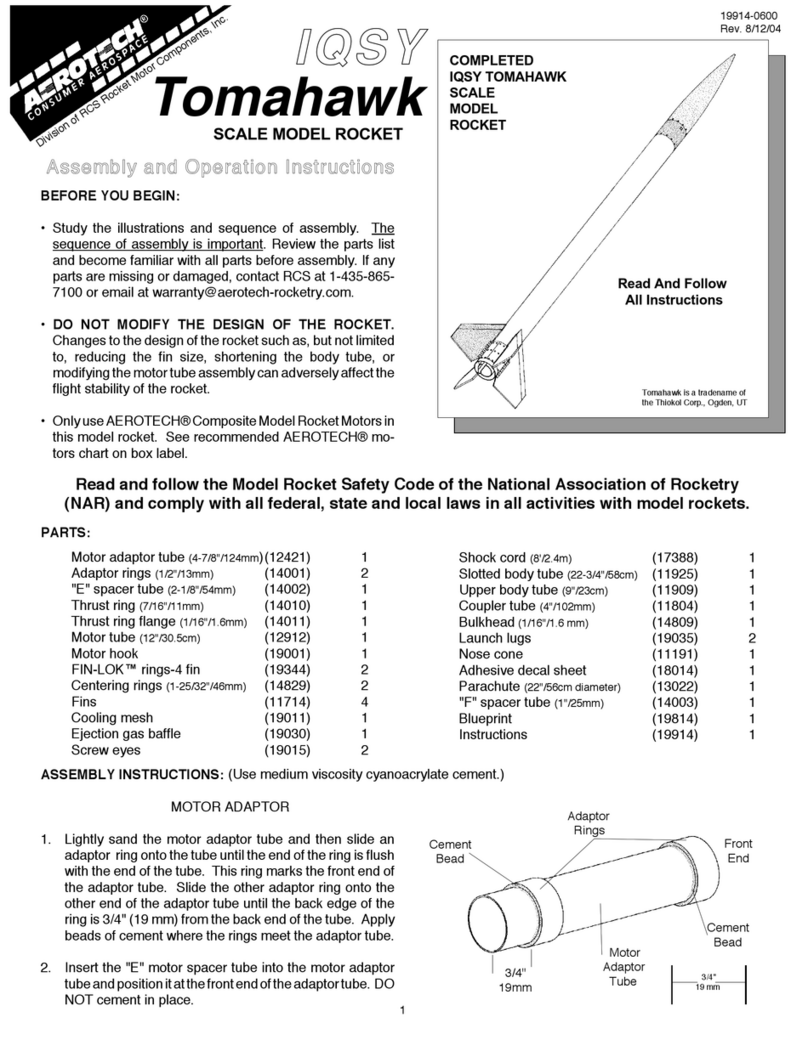

Aerotech

Aerotech tomahawk Assembly and operation instructions

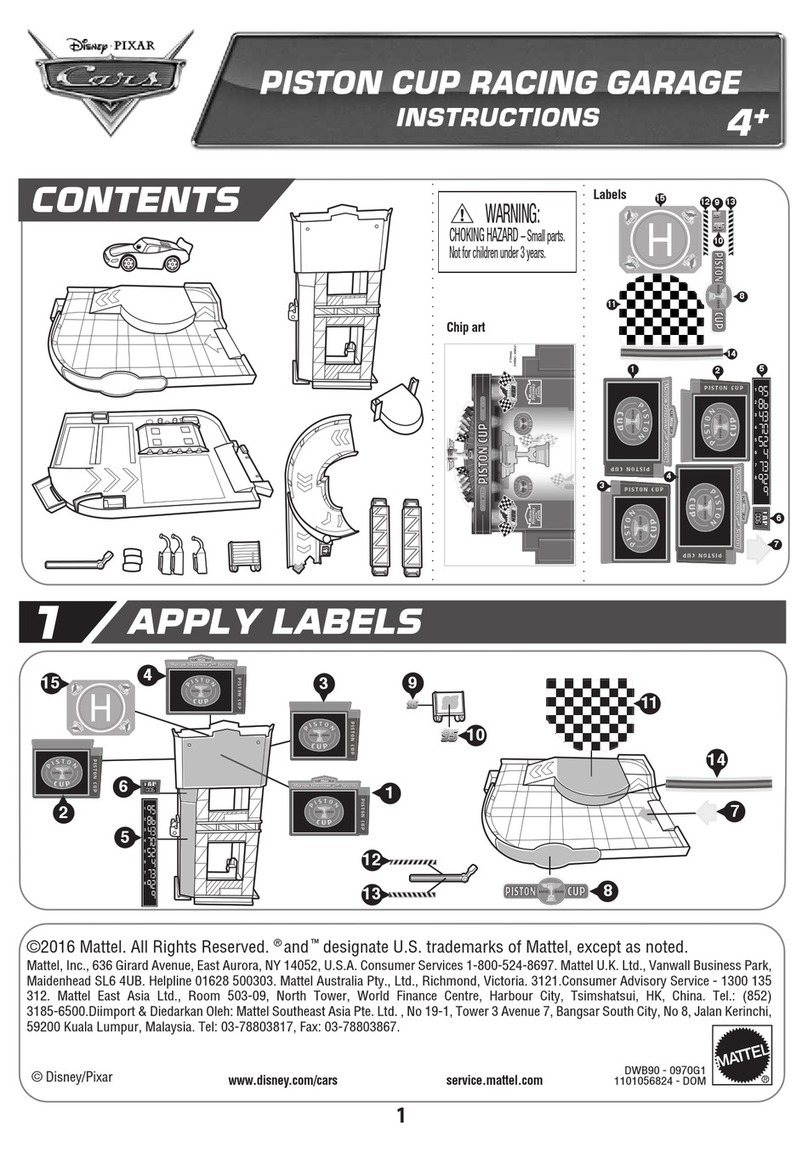

Mattel

Mattel FBT08 instructions

Little Tikes

Little Tikes CRAZY BLENDER 645129 quick start guide

Gigo

Gigo EXPERIMENTS 7335RR manual

Hasbro

Hasbro Transformers Titans Return Titan Master Decepticon Necro & Full-Tilt &... Assembly instructions

Fisher-Price

Fisher-Price CREATIVE COASTER 72690 instructions

Faller

Faller SERVICING AREA ACCESSORIES manual

LEGO

LEGO Home Alone 21330 manual

Compass

Compass 7hv Wiring Tips

Easy-Bake

Easy-Bake Blueberry Muffin Tops Mixes instructions