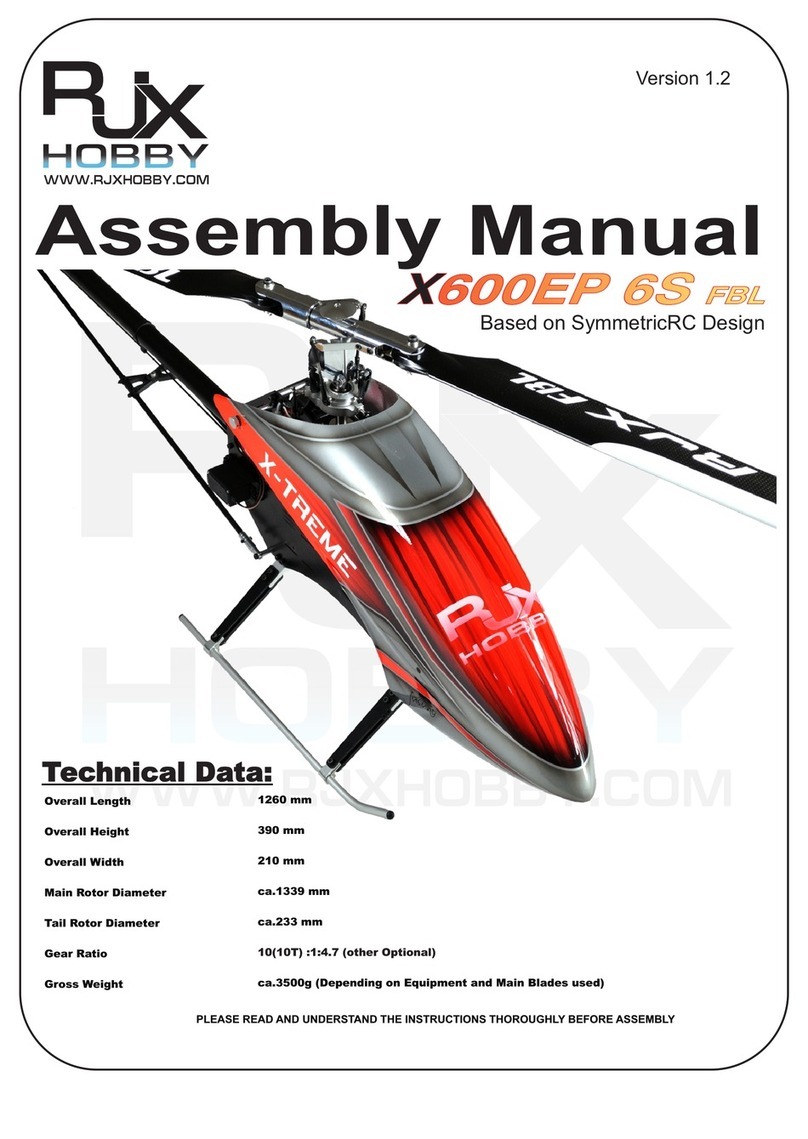

RJX Hobby X-Treme 90 User manual

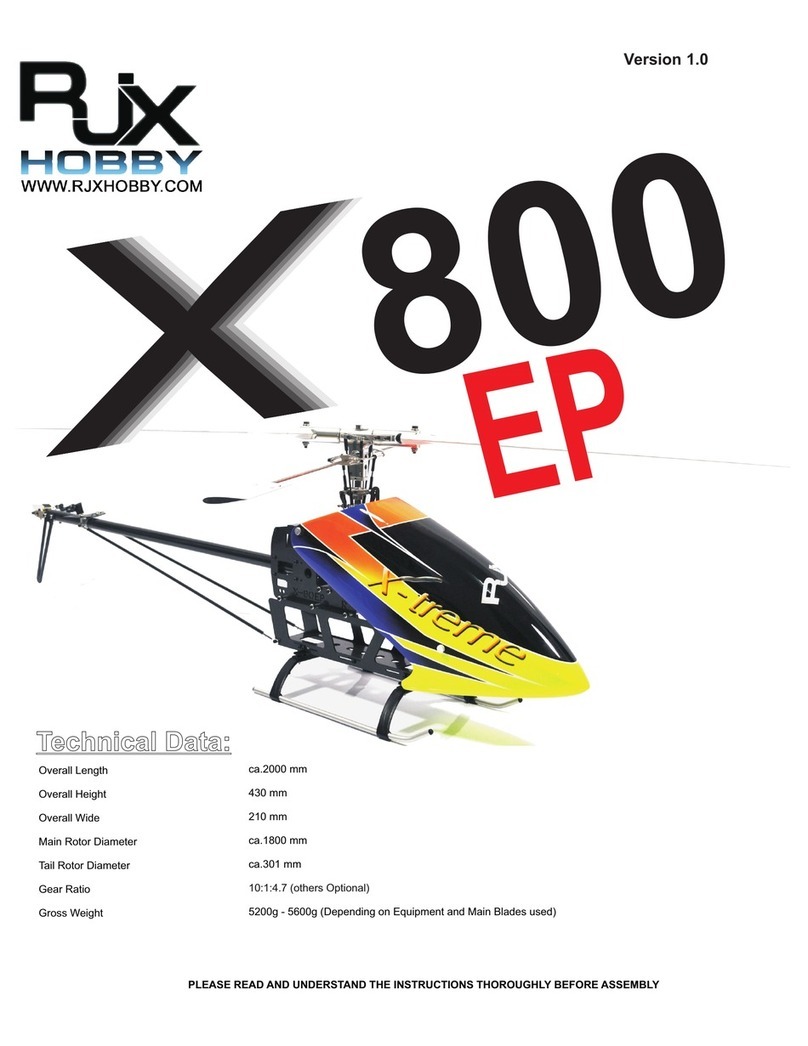

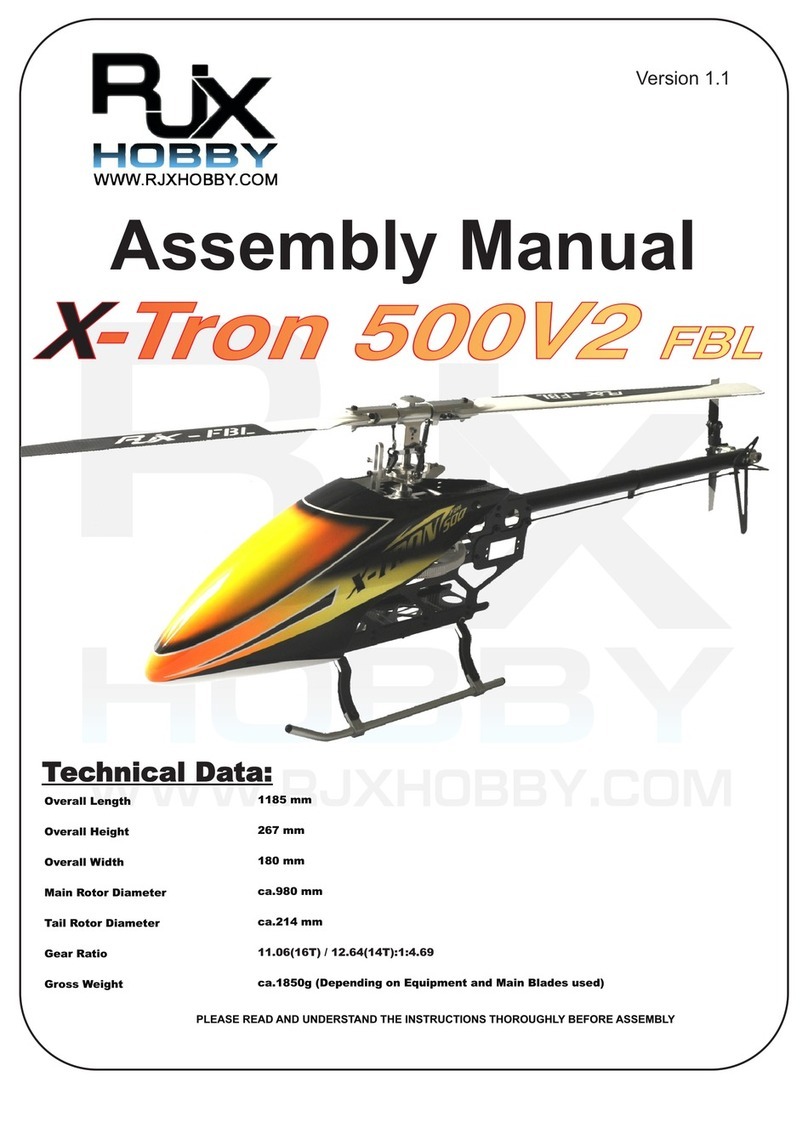

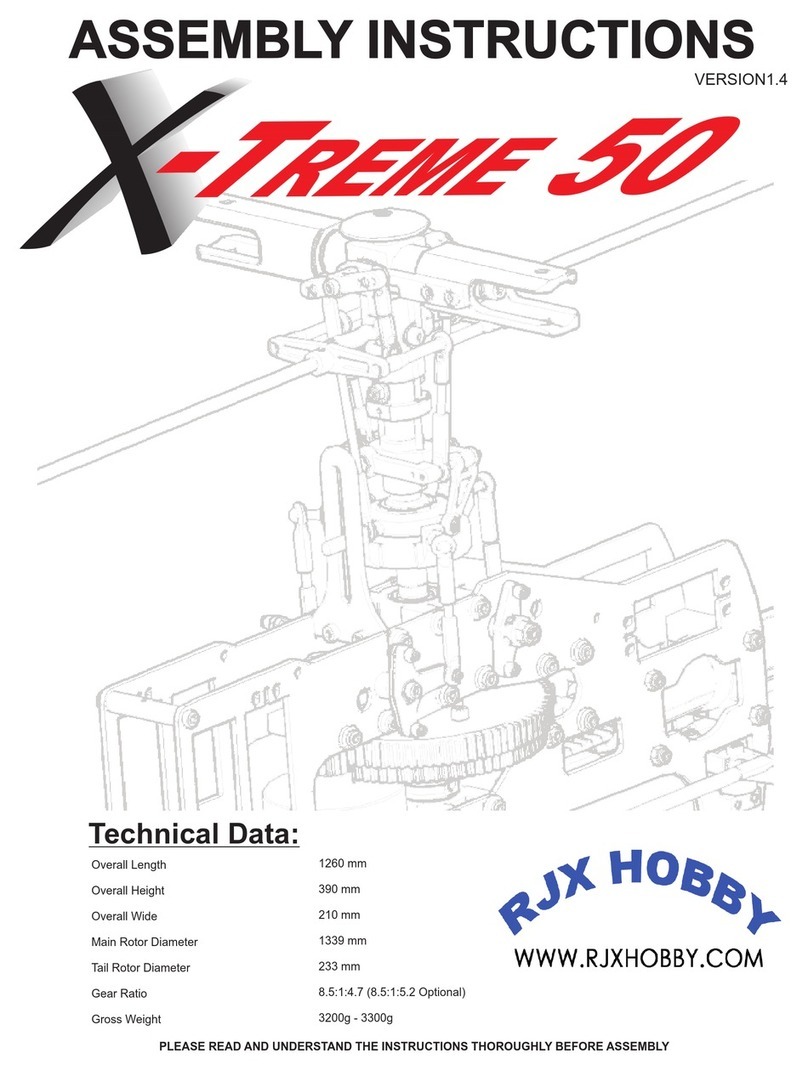

Technical Data:

Overall Length

Overall Height

Overall Wide

Main Rotor Diameter

Tail Rotor Diameter

Gear Ratio

Gross Weight

1340 mm

430 mm

210 mm

1690 mm

281 mm

8.1.8:1:4.7 + 8.4.5:1:4.7

4300g - 4600g

PLEASE READ AND UNDERSTAND THE INSTRUCTIONS THOROUGHLY BEFORE ASSEMBLY

INTRODUCTION

Please read this manual carefully. It is essential for the correct assembly of the

For the correct assembly and safe flying, this manual uses this symbol where special attention is required in the assembly of

your model. It is very important that you follow the instructions at these points in the manual. Failure to do so can lead to the loss of

control of the model without warning and the possibility of serious accidents or injury.

NOTE Failing to carry out the instructions at this point in the assembly manual will

probably result in an electronic or mechanical failure occurring without warning..

IMPORTANT Means that special care is required at this point for correct assembly.

Disclaimer:

Whilst every effort has been made to supply the correct information in this manual, The Manufacturer and Distributor

cannot guarantee that the purchaser will interpret or follow these instructions as intended and therefore the

Manufacture and Distributor assumes no liability for damage or claims that may occur from the use/misuse of this

product.

Do not be fooled it is NOT easy to fly R/C Helicopters

It may look easy when watching an experienced pilot flying his model, but perseverance and hours of practice will needed before you

will be able to fly and opperate the model safely. RJX HOBBY suggests you join a club or seek help from an experienced pilot to help

you in your first hops off the ground and then as with all things the more you practice the better you will become. Who knows you could

be the next world champion.

WARNING

The fuel used in model helicopter engines is highly inflammable and poisonous to human beings. For your own safety and that of

others, you should exercise care when handling and storing it. Always read the label on the container and please note the cautions

below.

1. Model helicopter fuel is highly inflammable. Do not smoke or light fires near your fuel.

2. We recommend that you keep your fuel in metal cans or plastic bottles and to store it where there is no risk of fire.

3. Please keep fuel away from the starter battery. It only needs one spark and…..!!!

4. Wipe up spilt fuel immediately. Do not take any chances.

5. Do not leave fuel in the sun or in you car on a hot day.

6. Before refuelling, shut off the engine and wait until it cools down.

7. Always drain the fuel tank of you helicopter at the end of a flying session. It is good practice.

I1

I2

TABLE OF CONTENTS

1. Introducion

2. Table of contents

3. Additional Items Required

4. Tools Required

5. Assembly

6. Servo Installation

7. Servo Adjustment

8. Rotor Head Setup

9. Final Servo and Radio Setup

10. Please read before flight

11. Spare Parts List

I1

I2

I3

I4

A1 - A33

S1-S4

S5-S6

A24

R1-R5

Pf1

SP1 - SP6

This manual contains the detailed instructions to build and set up the . Please follow it to ensure that you

achieve the best performance and mechanical integrity from your finished kit. For those of you who already have

experience of model helicopters, we still suggest that you assemble and adjust your model according to these

instructions for the best results. Please keep your copy of this manual in a safe place and refer to it when replacing

spare parts or upgrading.

Remove oil and grease then apply threadlock. (This applies throughout the manual)

Remove oil and grease. (This applies throughout the manual)

Please refer to the list at the end of this instruction manual when you need spare parts.

Regardless how tight the nuts, bolts and screws are tightened, they will still slowly come loose over a period of time

due to vibration from the helicopter. Should this happen the helicopter will become out of control or severely damaged

causing a very potential dangerouse situation.

We strongly recommend that you apply threadlock to any nuts, bolts or screws that are indicated by these signs.

There are two types of threadlock, blue (soft) and red (hard) . Use blue threadlock on screws

that have to be removed regularly and red threadlock for screws that should be fixed permanently. Clean them

with Alcohol (or similar) before you apply the threadlock.

TO PREVENT LOOSE SCREWS AND BOLTS

HOW TO USE THIS INSTRUCTION MANUAL

Use CA (Superglue or similar) at this point

CA

ADDITIONAL ITEMS REQUIRED TO COMPLETE THE

Choose a CCPM compatible PCM Radio System for

Helicopters with a minimum of 6 channels. Gyro system with

Heading Hold Three large and two small disks or

arms are required

90 Size glow engine,OS 91, YS91 90 Size Muffler (for kits without Muffler)

Helicopter fuel:

15% - 30% Nitro,18% - 23% Oil 1,5V Glow Plug Battery

and glow plug conector Fuel Pumb 12V Electric Starter

Starter Extension Fuel Filter 690mm - 710mm Main Blades (for kits without Blades)

I3

Allen Drivers 1,5mm - 2mm - 3mm - 4mm Phillips Drivers Large,Middle, Small Nut Drivers 4,5mm - 5,5mm - 7mm

Cutter Universal Pliers Scissors

Sandpaper Ball Link Plier Metric Ruler Pitch Gauge

Cyanoacrylate (CA/Superglue) Epoxy 30 Minutes Grease

Ball Link Driver Universal RC Cross Wrench Ball Link Tool

TOOLS REQUIRED (NOT INCLUDED)

I4

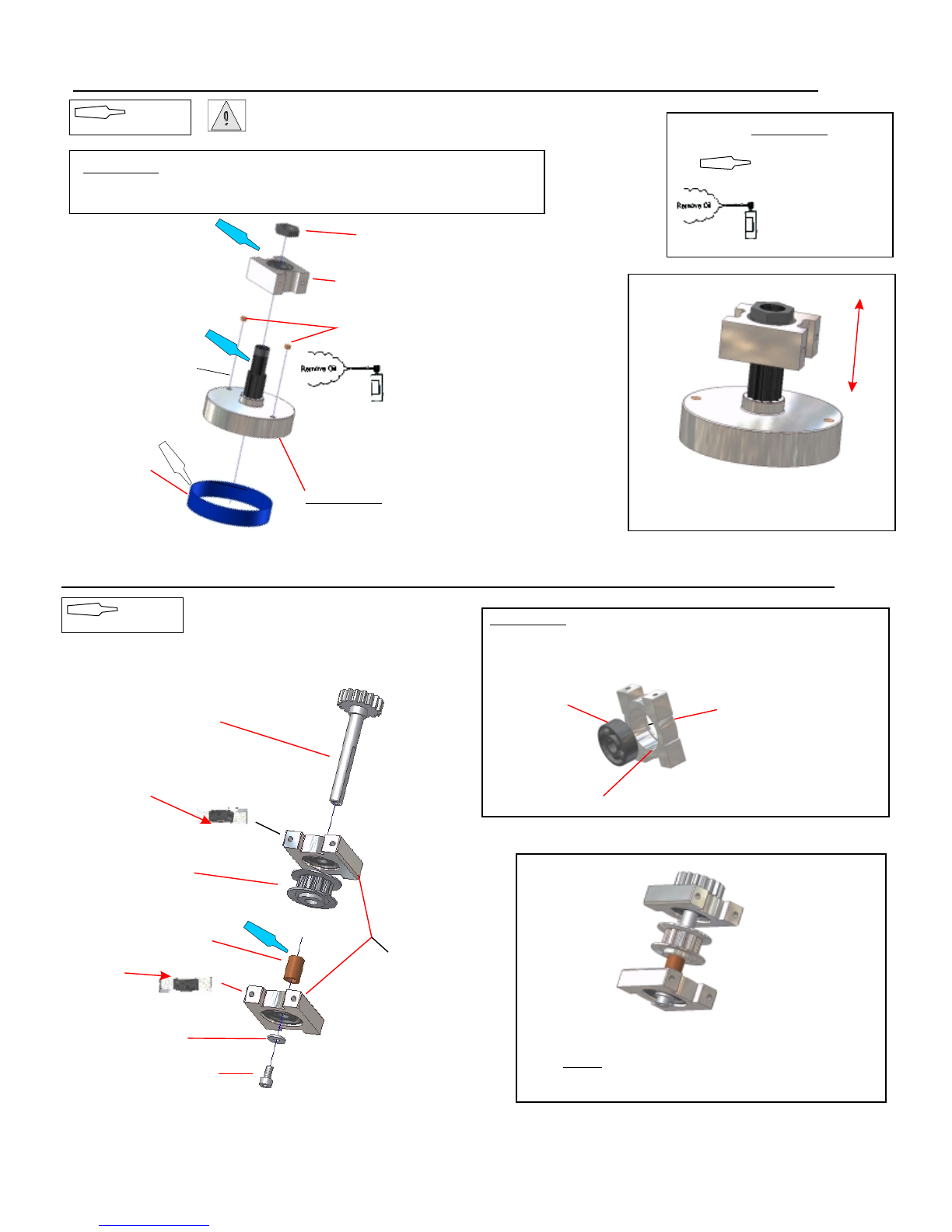

STEP 1-2B Tail Drive Pinion Gear Assembly (Belt Version)

STEP 1-1 Clutch Bell / Starter Shaft BB Block Assembly

A1

Clutch Bell Assembly

Starter Shaft BB Block

IMPORTANT:

Sand the inside before glueing the clutch liner.

View of the completeAssembly.

Check that there is no exessive movement

up and down and the assembly rotated freely.

Apply threadlock to the pinion gear and

install in place until the threadlock has

completely set.

USE THREADLOCK

CLEAN FROM OIL

AND GREASE

IMPORTANT:

Flange

Without Flange

Bearing

IMPORTANT:

One end of the BB Block is machined with a flange to retain the

Bearing. Assemble it as shown in the diagramm below.

With Flange facing downwards

Tail Drive Pinion BB Block

Tail Drive Pinion

M3 Washer

M3x6 Socket Head Bolt

Front Tail Pulley

View of the completed assembly

USE THREADLOCK

IMPORTANT: Before assembling sand the inner side of the clutch bell and the side

from the clutch liner you will glue in.Use 30 minutes EPOXY to glue the liner in the

clutch bell and fix them with some clips to ensure a good and thight fit of the liner.

Magnet´s for Governor:

Install them by using 30 minute

EPOXY.

Special Nut

Clutch Liner

With Flange facing upwards

NOTE: DON´T use threadlock for the M3x6 Screw

for later attach the belt.

Copper Spacer

USE THREADLOCK

EPOXY

STEP 1-2TT Tail Drive Pinion Gear Assembly (TT Version)

Tail Drive Pinion

M3 Washer

M3x6 Socket Head Bolt

M3x4 Setscrew

12mm Pin

Output Shaft

19TAlloy Beevel Gear

19T Delrin Beevel Gear

M3x4 Setscrew

5x7x1 Washer

5x7x1 Washer

(if needed)

TT Gear Box

View of the completeAssembly.

Check that the gearmesh is correctly

(if necesary add a 0.2mm Nylon Washer) and

the assembly rotated freely but without play.

USE THREADLOCK

STEP 1-3 Drive Gear Assembly

M3x6 Socket Head Bolt

90/93T Helical Main Gear

M3x6 Counter Socket Head Bolt

80T Tail Drive Gear

Tail Drive Gear Housing

Autorotation Shaft

Autorotation Spacer

IMPORTANT:

Stepped side facing downward

and entering completly inside

the bearing.

View of completeAssembly

CAUTION:

Clean off any dust on drive gears.

Add grease to the one way bearing,

to ensure smooth opperation.

Don´t fix the four M3x6 bolts before

having all four in place.

USE THREADLOCK

IMPORTANT: Start assembly with the OUTPUT SHAFT.

A2

NOTE:

Use the 90T main gear for OS91 and YS91SR.

The 93T is for use with YS91ST.

IMPORTANT:

Add 0,2mm Nylon washer to

reach a PLAYLESS Gear mesh.

Check that the two gears are

perfectly aligned (shown in the

picture on the right).Stay on the

tide side of the gear mesh.

A exesive play can strip the

Delrin gear.

STEP 1-4 Fuel Tank and AUX Tank Assembly

Main Tank

Fuel Clunk

Silicon Tube ca.87mmTank Grommet

Tank Nipple

Tank Nipple

Tank Grommet

Silicon Tube 40mm

Fuel Clunk

AUX Tank

To Main Tank

Exhaust pressure nipple

IMPORTANT:

Make sure that the Fuel Clunk can move freely inside the tank.

Be sure to replace the silicon fuel tubing inside the Main

and AUX Tank regularly.

NOTE:

Cut the fuel tubing to length using a hobby knife.

So there is a clean cut.

M5 Special Nut

NOTE:

For easy assambling of the Exhaust Pressure Nipple

use a thin cable binder passing it throug the nipple.

STEP 1-5 Swash Control Lever Assembly

M2x8 Socket Head Bolt

Jointball

Control Lever

View of the completedAssembly

Flange facing downward

NOTE: Assembly 2 sets of this lever

USE THREADLOCK

A3

A4

STEP 1-6 Swash Control Assembly

USE THREADLOCK

M2x6 Socket Head Bolt

Joinball

4mm Ball Arm

Nick Arm

Swash Lever

View of the completedAssembly

STEP 1-7 Front Tail Arm Assembly

USE THREADLOCK

M2x10 Socket Head Bolt

M3x20 Socket Head Bolt

Joinball

Control Lever

Washer 3x5x1

Leverblock

CAUTION:

Do NOT over tighten the M3x20 bolts

to avoid breaking the bearings.

M4x4 Setscrew

View of the completedAssembly

A5

STEP 1-8 Battery Tray Assembly

USE THREADLOCK

M3x6 Countersunk Head Bolt

Battery Tray

View of the completedAssembly from both side

Special Crossmember

BATTERY TRAY inside the bag of the MAIN FRAME

STEP 1-9 Canopy Stands

32mm Crossmember

M3x8 Socket Head Bolt

Breakoff

View of the completedAssembly

NOTE: Assemble 4 sets

BREAKOFF are inside the bag of the MAIN FRAME

USE THREADLOCK

A6

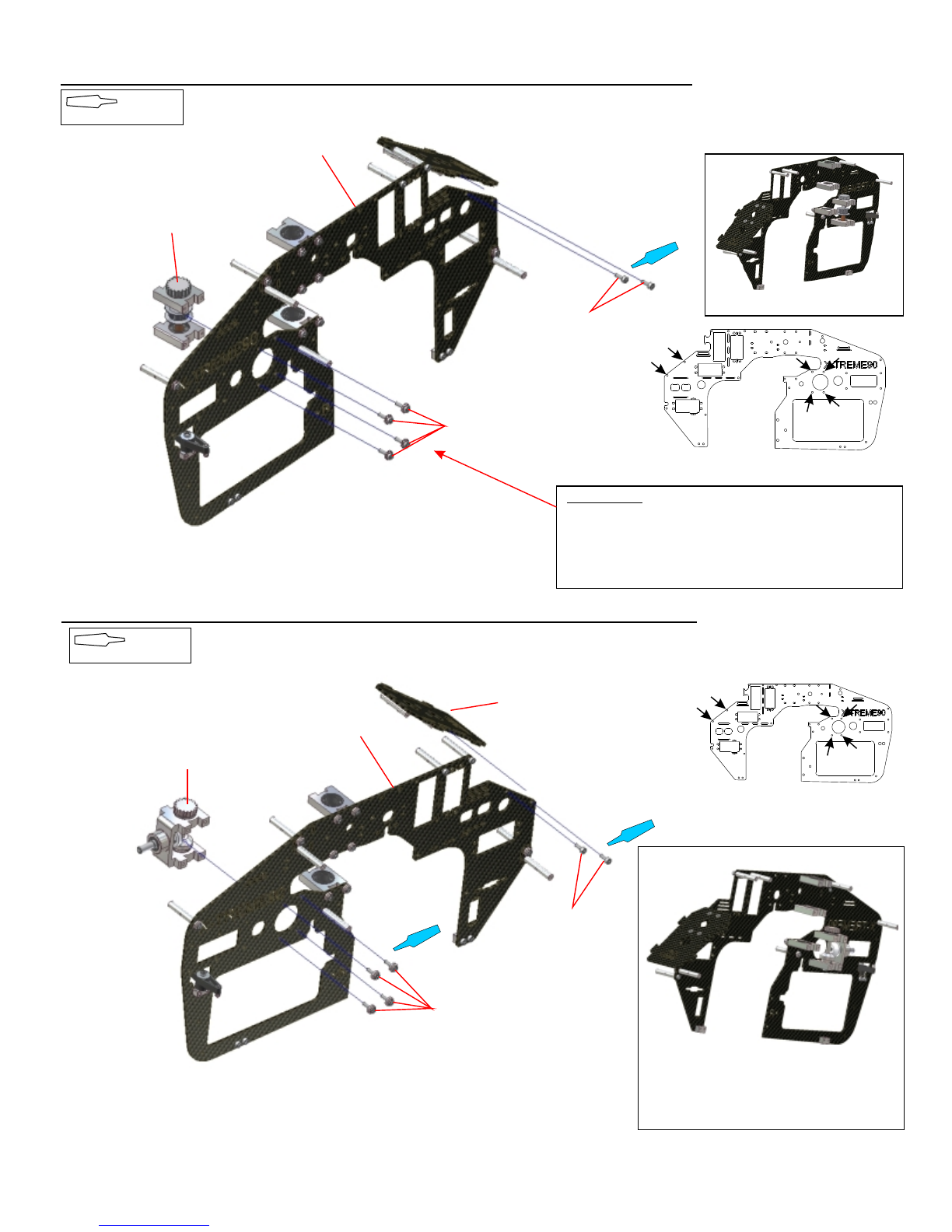

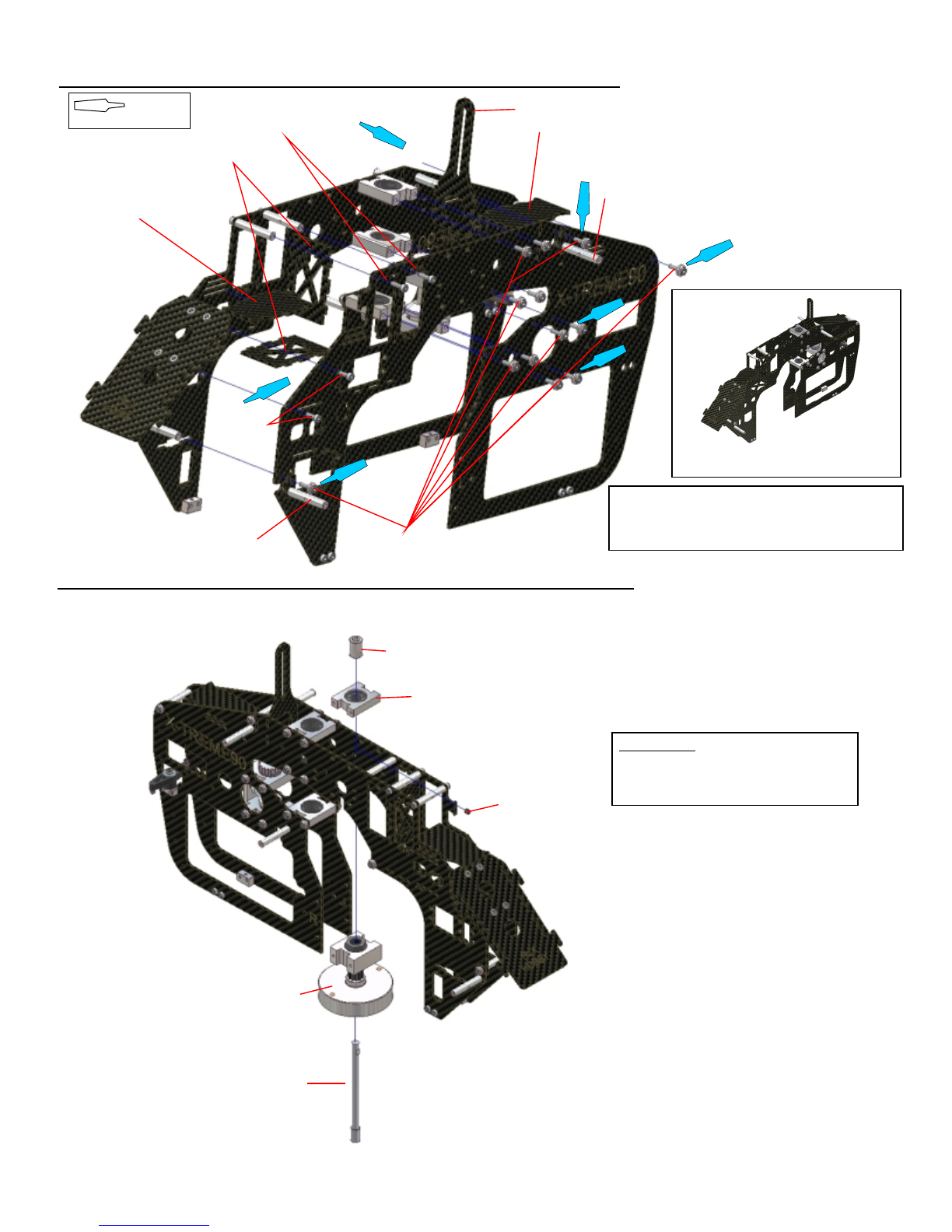

STEP 2-1 Main Frame Assembly (TT+Belt)

Main Frame Right

Bottomplate Mounting Block M3x8 Socket Head Bolt

Main Frame Left

M3x8 Socket Head Bolt

Bottomplate Mounting Block CAUTION:

The main frame sides are NOT the same. Look at

the L and R writing cutout on the frame sides to

ensure that you have the correct sides.Assemble

both sides like shown in the diagram.

USE THREADLOCK

STEP 2-2 Main Frame Assembly (TT+Belt)

Main Shaft Bearing Block

Assembled in Step 1-9

M3x8 Socket Head Bolt

Assembled in Step 1-9

M3x10 Socket Head Bolt

with Finish Cap´s

M3x10 Socket Head Bolt

32mmCrossmember

Main Frame Right

(Assembled in STEP 2-1)

NOTE:

Place the Frame on a flat surface to mount the Bearing Blocks

and the Crossmember.

IMPORTANT:

DO NOT use Threadlock in this stage for the Bearing Blocks

for later adjustment. It will be indicated when Threadlock

should be used.

USE THREADLOCK

TOP

Flange face

downward

Flange face

downward

Flange face

upward

IMPORTANT:

Holes to be used

Bottomplate Mounting Block

M3x8 Socket Head Bolt

M3x8 Socket Head Bolt

Holes to be used

Assembled in Step 1-7

M3x10 Socket Head Bolt

with Finish Cap

32mmCrossmember

32mmCrossmember

R

L

A7

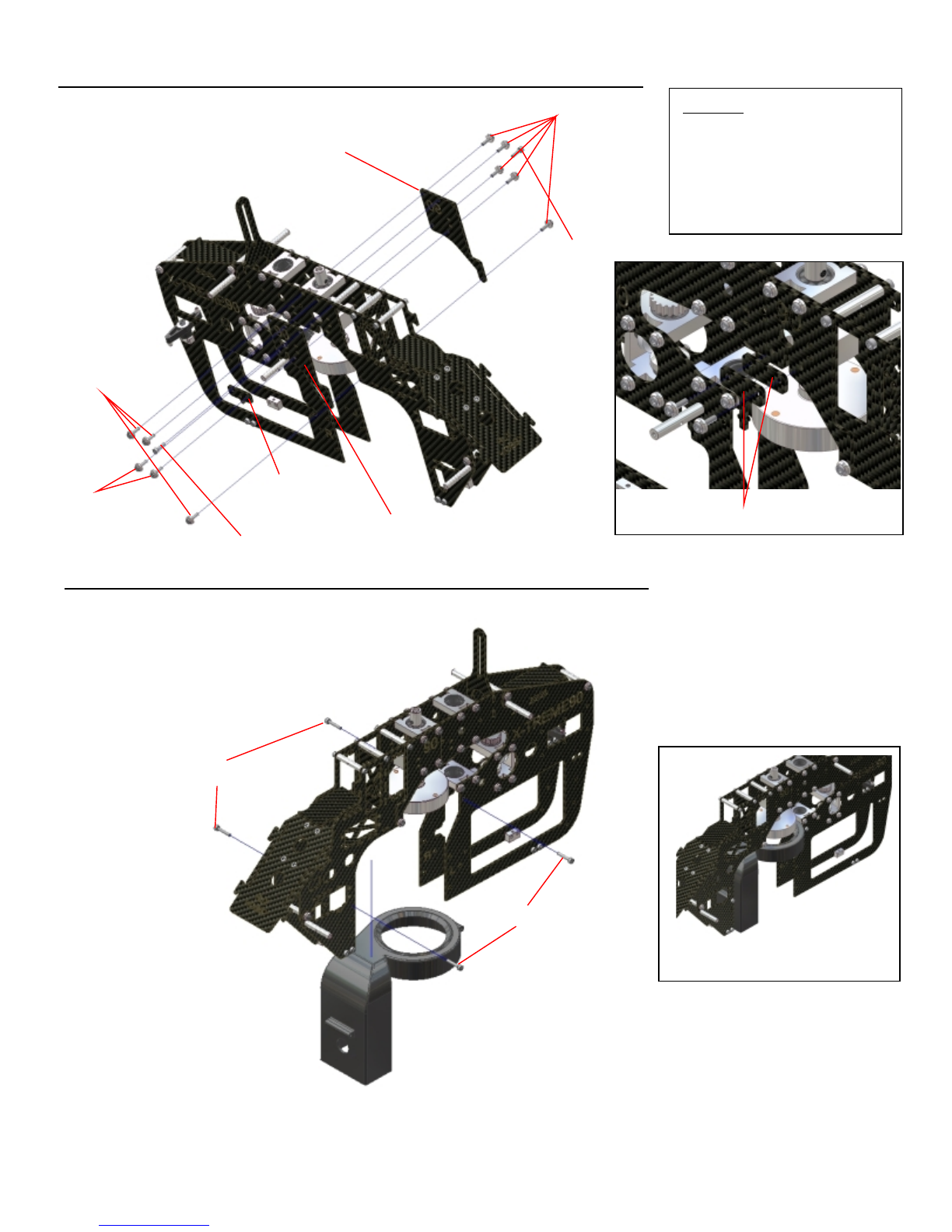

STEP 2-3B Main Frame Assembly (Belt Version)

M3x10 Socket Head Bolt

with Finish Cap´s

IMPORTANT:

DO NOT use Threadlock in this stage for the Bearing Blocks,

for later adjustment. It will be indicated when Threadlock

should be used.

M3x8 Socket

Head Bolt

Main Frame Right (Assembled in Step 2-2)

View of the completedAssembly

USE THREADLOCK

STEP 2-3TT Main Frame Assembly (TT Version)

USE THREADLOCK

View of the completedAssembly

M3x8 Socket head Bolt

Holes to be used

Tail Drive (Assembled in Step 1-2B)

Battery Tray

(Assambled in Step 1-8)

M3x10 Socket Head Bolt

with Finish Cap´s

TT Tail Drive (Assembled in Step 1-2TT)

Main Frame Right (Assembled in Step 2-2)

Holes to be used

A8

STEP 2-4 Main Frame Assembly (TT+Belt)

USE THREADLOCK

STEP 2-5/1 Main Frame Assembly (TT+Belt)

M3x10 Socket Head Bolt with Finishcup

Front Gyro Mount

Rear Gyro Mount

Starter Shaft

Assembled in Step 1-2

6mm Bearing Block

IMPORTANT:

DO NOT tiden the M4x4 Set Screw..

View of the completedAssembly

Canopy Mount

Canopy Standoff

M3x8 Socket

Head Bolt

Frame Stiffner

M3x10 Socket Head Bolt

NOTE:

DO NOT use thread lock on the Bolts for the Main

Shaft BB Blocks. Will be indicated in later step.

Hex Starter Coppler

M4x4 Set Screw

Swash Guide

A9

STEP 2-5/2 Main Frame Assembly (TT+Belt)

STEP 2-6 Clutch Sytem Assembly (TT+Belt)

M3x10 Socket Head Bolt

Standoff

CAUTION:

Depending on witch Engine Type used

must be selected diferent Ratio Mounts.

For Os91 Types and YS 91 SR must be

used the Mount with 90 indicated for a

8,18 Ratio.

For a YS 91 ST Engine the 93 one for a

Ratio from 8,45.

3x16 Special Spckegt Head Bolt

M4 Lock Nut

Fan Shroud

View of the completedAssembly

M3 Lock Nut

M3x10 Socket Head Bolt with Finishcup

Ratio Modul Right

(90T Main Gear)

Mount for Sensor

(Gv1 FUTABA)

M3x10 Socket Head Bolt

M3x14 Socket Head

Bolt with Finishcup

Ratio Modul Left

(90T Main Gear)

Use this mounts for other Type

of Governors

3x16 Special Spckegt Head Bolt

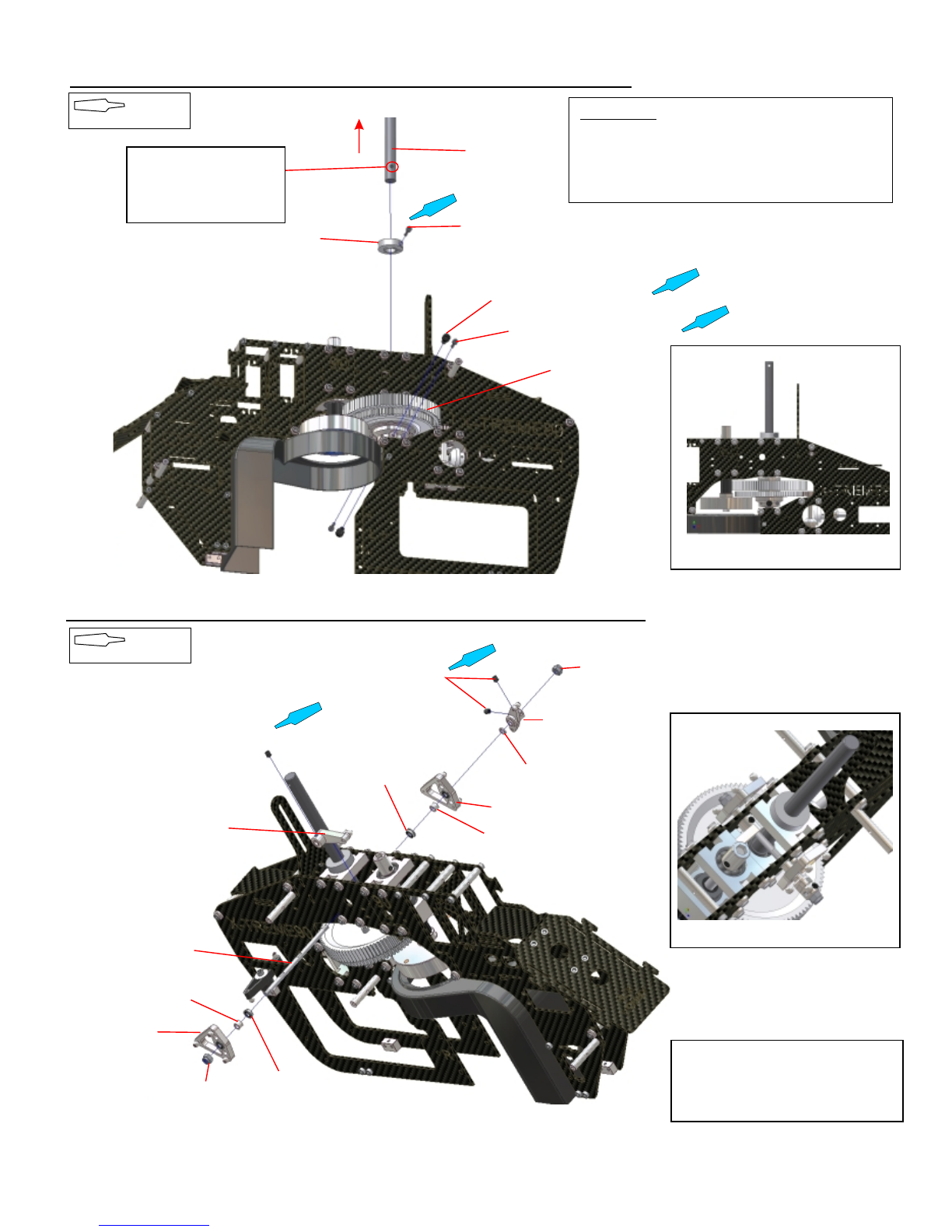

STEP 2-7 Main Frame Assembly (TT+Belt)

USE THREADLOCK

Main Shaft

M2,5x10 Socket Head Bolt

Main Shaft Collar

M4x8 Socket Head Bolt (2)

M2,5x10 Socket Head Bolt (2)

Autorotacion Unit

View of the completedAssembly

STEP 2-8 CCPM Sytem Assembly (TT+Belt)

M4x4 Set Screw

M4x4 Set Screw

M4 Lock Nut

M4 Lock Nut

Washer 4x6x1

Nick Lever

CCPM Ballcrank

Spacer 4x6x4

Bearing F4x8x3

Bearing F4x8x3

CCPM Ballcrank

Spacer 4x6x4

CCPM Shaft

Nick Arm

View of the completedAssembly

USE THREADLOCK

NOTE:

DO NOT overtiden the M4 Lock Nut.

Check the Armes work smooth and

without play.

NOTE:

Ensure the correct way

of the main shaft.Hole with

larger distance to the end

first inside.

IMPORTANT:

When securing the main shaft, pull it upwards through

the main bearings to eliminate any freeplay. Next press

the main shaft collar firmly onto the upper bearing block

and fix with threadlock the four M4x4 set screws.

A10

STEP 2-9 Main Tank (Engine WITHOUT Tank Preasure)

USE THREADLOCK

Main Tank

M3x10 Socket Head Bolt

with Finishcap

Main Shaft Collar

32mm Crossmember

Tank Rubber

View of the completedAssembly

View of the completedAssembly

NOTE:

DO NOT overtiden the M4 Lock Nut.

Check the Armes work smooth and

without play.

CA

CA

Tank Rubber

M3x10 Socket Head Bolt

with Finishcap

STEP 2-9/1 Main Tank (Engine WITH Tank Preasure)

USE THREADLOCK

Tank Rubber

M3x40 Socket Head Bolt

Finishcap

32mm CrossmemberM3x10 Socket Head Bolt

with Finishcap

Tank Plate

25mm Spacer

NOTE:

Use CA to fix the Tank Rubbers

in the corners of the Main Frame.

NOTE:

Use CA to fix the Tank Rubbers

in the corners of the Main Frame.

CA

Tank Rubber

CA

A11

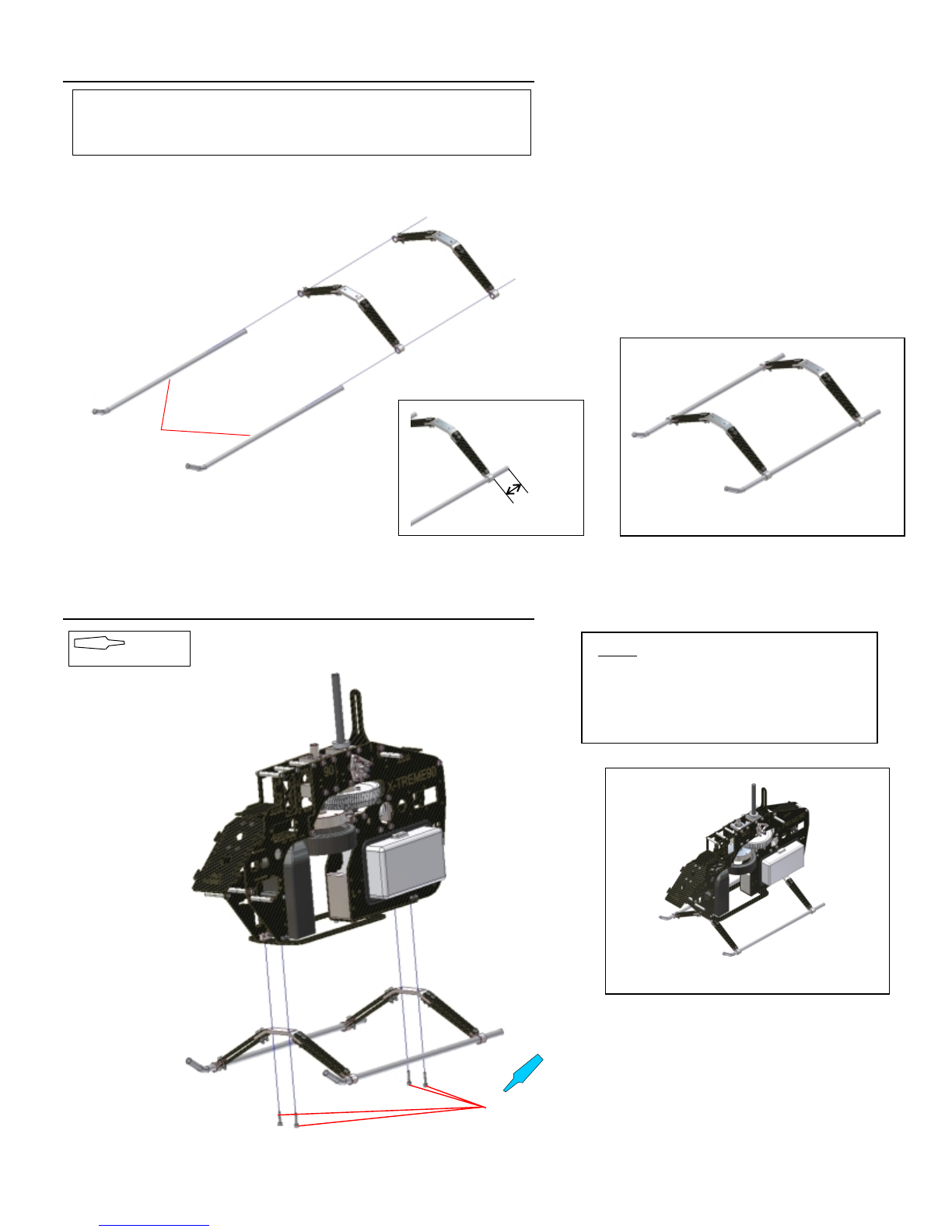

STEP 2-10 Main Frame Assembly (TT+Belt Version)

USE THREADLOCK

M3x14 Socket Head Bolt

Landing Strut

Landing Skid Brace

M3 Lock Nut

Skid Holder

NOTE:

Assemble two sets.Do NOT tighten the screws for later adjustment.

Landing Strut

STEP 2-11 Landing Skid Assembly

Note:

For extra strength place a second Landing Strut.On the

top of both sides and the other on the lower part of the

other set. As shown in the diagram below..

To be used in back To be used in front

View of the completedAssembly

Bottom Plate

Engine Mount (Middle)

M3x10 Socket Head Bolt

with Finish caps

A12

A13

STEP 2-13 Landing Gear Assembly

View of the completedAssembly

Landing Skids

NOTE:

Place the complete assembly on a flat surface.Do NOT tighten the screws yet

ca. 20mm

View of the completedAssembly

M3x14 Socket Head Bolt

STEP 2-12 Landing Gear Assembly

NOTE:

Place the complete frame after assembling on a

flat surface and tighten the screws from the

Landingskid assembly.Insure that the the skids

are flat on the surface.

USE THREADLOCK

A14

STEP 3-1 CLUTCH/COOLING FAN ASSEMBLY

Drive Nut

( incl. with OS Engine)

Cooling Fan Hub

Cooling Fan

M3x6 Socket Head Bolt

Engine Washer

(incl. with OS Engine)

USE THREADLOCK

NOTE:

If a drive washer is included with the engine you willl need

to remove this. (Contact your dealer for information). For

OS Engines, the thin black washer supplied will be used

under the bottom collet.

The Fanhub may be a little tight on the crankshaft

so a good push may needed.

Note that the black washer goes on first if you are

using a OS Engine.

Assemble as shown in the diagram and secure

the engine nut tightly. It is suggested that you

use a piece of towel or cloth wrapped around

the engine and the fan hub so that you can

hold them tightly when doing this operation.

After tiden the Engine Nut tide the two

M2,5x10 Socket Head Bolts.

IMPORTANT:

Be sure to keep the clutch shoe square to the fan hub

when tightening the securing bolts.

Tighten each bolt a little at time and keep checking as you proceed.

Clutch

M4x10 Socket Head Bolt

M2,5x10 Socket Head Bolt

IMPORTANT:

For OS 91 and YS 91 SR use the 90T Main Gear and Ratio Mounts.

For YS 91 ST use the 93T Main Gear and 93 Ratio Mounts.

A15

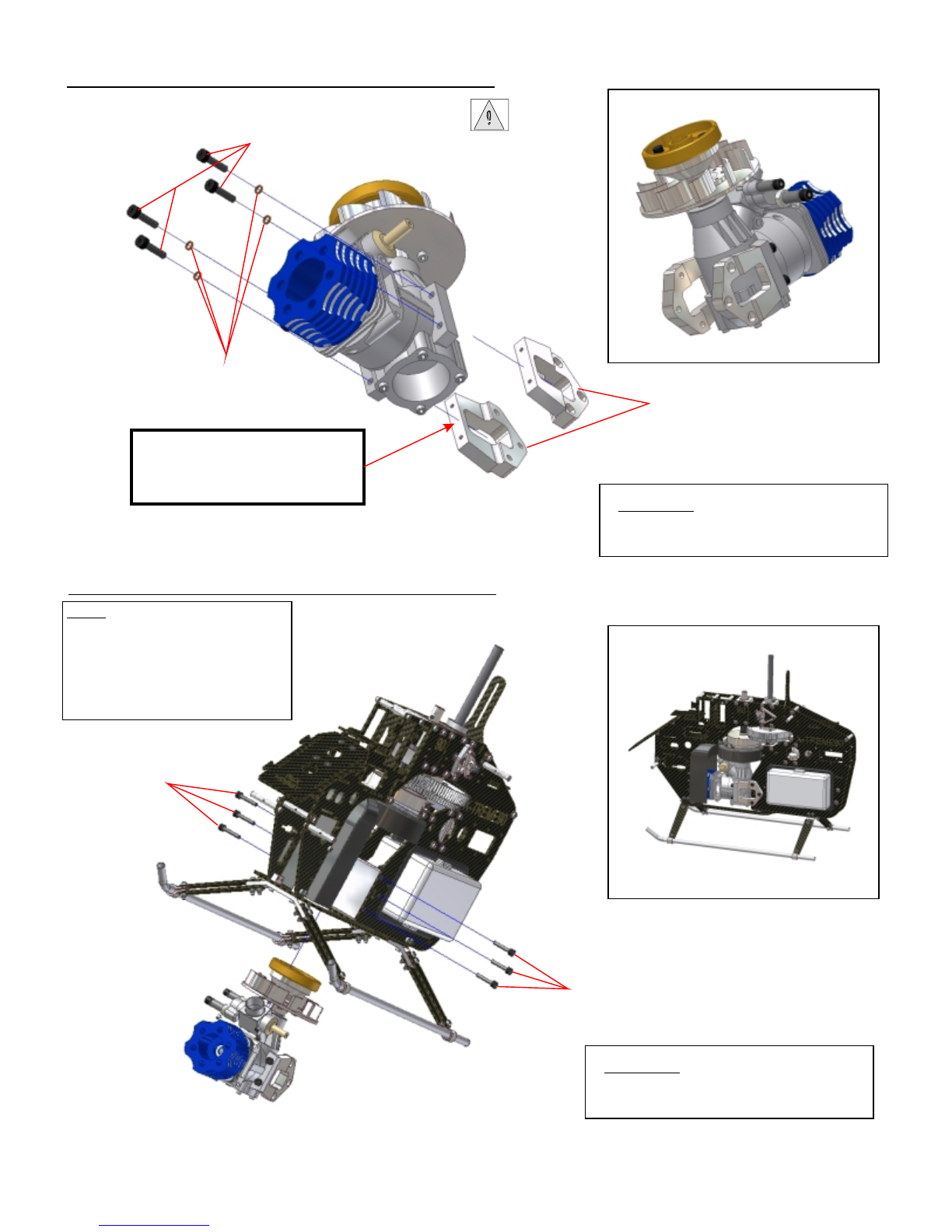

STEP 3-2 ENGINE INSTALATION

STEP 3-3 ENGINE INSTALATION

M4x16 Socket Head Bolt

IMPORTANT:

Do NOT tighten the srews for later alignment.

Spring Washer

Engine Mount L/R

View of the completedAssembly

IMPORTANT:

For the 8,45 Ratio you need to add the

two delivered 1.5mm Spacers between

the Engine and the Engine Mount

View of the completedAssembly

M4x20 Socket Head Bolt

M4x20 Socket Head Bolt

IMPORTANT:

Do NOT tighten the srews for later alignment.

NOTE:

It is possible that you may have to

remove the carburator to insert the

engine.After the engine has passed

through the bottom plate reinstall the

carburator before inserting the engine

completly.

Table of contents

Other RJX Hobby Toy manuals

Popular Toy manuals by other brands

HOMCOM

HOMCOM 350-081 manual

Fisher-Price

Fisher-Price Ford MUSTANG J4390 Owner's manual & assembly instructions

Multiplex

Multiplex ParkMaster 3D Building instructions

THE WORLD MODELS

THE WORLD MODELS Extra 300 EP instruction manual

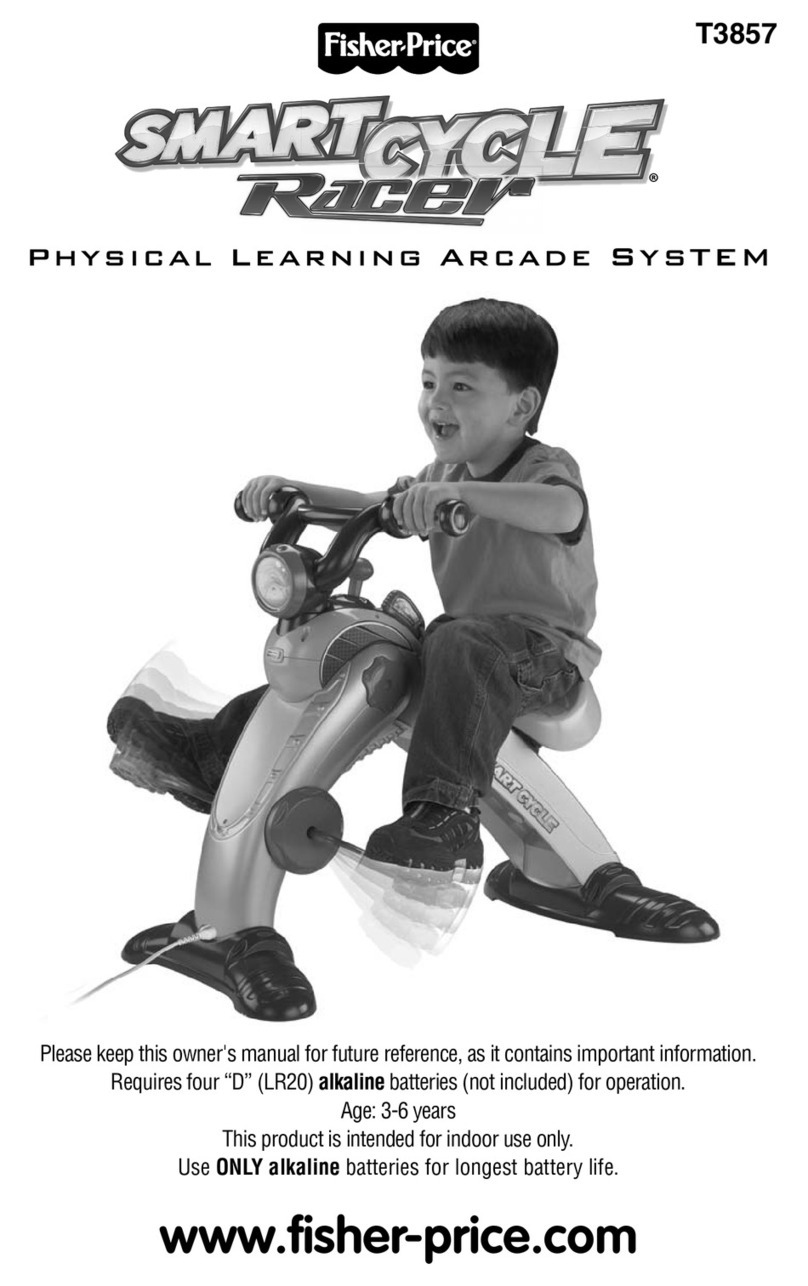

Fisher-Price

Fisher-Price 71997 instructions

TILLIG BAHN

TILLIG BAHN 03940 manual