IMSRM15-E5

i-2

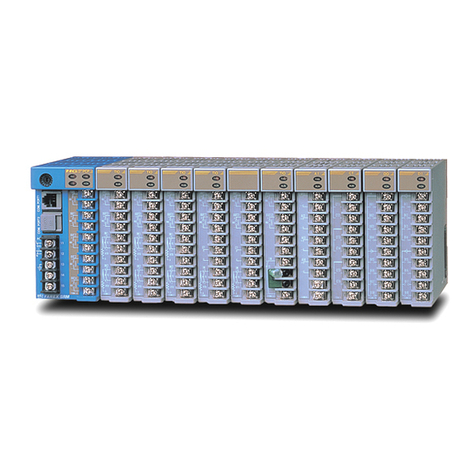

This product is intended for use with industrial machines, test and measuring equipment.

(It is not designed for use with medical equipment and nuclear energy.)

This is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take additional measures.

This instrument is protected from electric shock by reinforced insulation. Provide reinforced

insulation between the wire for the input signal and the wires for instrument power supply,

source of power and loads.

Be sure to provide an appropriate surge control circuit respectively for the following:

- If input/output or signal lines within the building are longer than 30 meters.

- If input/output or signal lines leave the building, regardless the length.

This instrument is designed for installation in an enclosed instrumentation panel. All

high-voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

All precautions described in this manual should be taken to avoid damage to the instrument or

equipment.

All wiring must be in accordance with local codes and regulations.

All wiring must be completed before power is turned on to prevent electric shock, instrument

failure, or incorrect action.

The power must be turned off before repairing work for input break and output failure including

replacement of sensor, contactor or SSR, and all wiring must be completed before power is

turned on again.

To prevent instrument damage or failure, protect the power line and the input/output lines from

high currents with a protection device such as fuse, circuit breaker, etc.

Prevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

Tighten each terminal screw to the specified torque found in the manual to avoid electric shock,

fire or malfunction.

For proper operation of this instrument, provide adequate ventilation for heat dispensation.

Do not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

Turn off the power supply before cleaning the instrument.

Do not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

To avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

Do not connect modular connectors to telephone line.

When high alarm with hold action/re-hold action is used for Alarm function, alarm does not turn

on while hold action is in operation. Take measures to prevent overheating which may occur if

the control device fails.

NOTICE

This manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

The figures, diagrams and numeric values used in this manual are only for purpose of illustration.

RKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

RKC is not responsible for any damage and/or injury resulting from the use of instruments made by

imitating this instrument.

Periodic maintenance is required for safe and proper operation of this instrument. Some components

have a limited service life, or characteristics that change over time.

Every effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in this

manual is subject to change without prior notice.

No portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior written

approval from RKC.

CAUTION