Southwestern Industries ProtoTRAK Plus Service manual

ProtoTRAK®Plus

Programming, Operating & Service Manual

Southwestern Industries, Inc.

2615 Homestead Place

Rancho Dominguez, CA 90220 USA

T | 310.608.4422 |F | 310. 764.2668

Service Department: 800.367.3165

e-mail: sales@southwesternindustries.com | service@southwesternindustries.com | web: southwesternindustries.com

Document: P/N 15692

Version: 070390

Copyright © 2008, Southwestern Industries, Inc. All rights are reserved. No part of this

publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by

any means, mechanical, photocopying, recording or otherwise, without the prior written

permission of Southwestern Industries, Inc.

While every effort has been made to include all the information required for the purposes of this

guide, Southwestern Industries, Inc. assumes no responsibility for inaccuracies or omission and

accepts no liability for damages resulting from the use of the information contained in this guide.

All brand names and products are trademarks or registered trademarks of their respective

holders.

Southwestern Industries, Inc.

2615 Homestead Place

Rancho Dominguez, CA 90220-5610

Phn 310/608-4422 Fax 310/764-2668

Service Department

Phn 800/367-3165 Fax 310/886-8029

ProtoTRAK

Pl1r.s

Progrnmming.

Operaring

&

Cure Manual

Table

of

Contents

1

-0

Introduction

.............................................

1

2.0

Description

..............................................

2

Keyboard

............................................................

-2

..............................................................

Displays

3

Pendant Back Panel

................................................

-3

Power Control Cabinet

.............................................

-3

.............................................................

2.5

Encoders

-3

........................................................

2.6

ServoMotors

-4

...............................................

2.7

Ball

Screw Assembly

-4

................................................

2.8

Tape Cassette Deck -4

3.0

Definitions.

Terms.

and

Concepts

....................

5

.....................................

3.1 ProtoTRAK Axis Conventions

5

...............................

3.2

Absolute

&

Incremental Reference

-5

...........................

3.3

Referenced and Non-Referenced

Data

-6

.....................................

3.4

Tool

Diameter Compensation

-6

..................................................

3.5

Connective Events 10

..............................

...................

3.6

CONRAD

....

-10

4.0

DRO.

JOG.

POWER

FEED

Operation

..............

12

..........................................................

4.1

Clear

Entry

12

4.2

IN

to

MM

or

MM

to

IN

............................................

12

.....................................................

4.3 Reset One Axis

12

................................................................

4.4 Preset

12

4.5 Reset Absolute Reference

.........................................

12

.........................................

4.6 Preset Absolute Reference

12

............................

4.7 Recall Absolute Position of

All

Axes

12

4.8 Recall Absolute Position on One Axis

...........................

13

..................................................

4.9 Feedrate Ovemde 13

4-10

JOG

..................................................................

13

.........................................................

4.1

1

Power Feed 14

5.0

Programming

&

Program

Run

........................

15

.

.

...................................

.

5

!

Incremental

Reference

120sltion

15

...........................................................

5.2

CONRAD

15

..................

5.3 POSITION

or

DR[L,I..

(POSN/DRII,

L)

Events

16

...............................................

5.4

BOLT

HOLE

Events

17

........................................................

5.5

MILI, Events

18

........................................................

5.6

ARC Events

-20

.....................................................

5.7

CIRCLE

Events

22

ProloTR,.lK

Pll~s

Progratnrning. Oporurit1y

&

Care

Mnnuul

...................................................

5.8

POCKET Events -24

....................................................

5.9

REPEAT

Events

26

...........................

5.10

Start,

Stop

and Running Several Parts 28

5.11 Editing

..............................................................

29

..........................................

5.12 Tape CassetteOperation 34

...........................................

5.13 RS232 Communications 37

..................................................

5.14 Program Sample

-39

6.0

DO

ONE

Operation

.

Program

&

Run

..............

42

...................................

6.1 Incremental Reference Position

42

........................................

6.2

DO

ONE

Program

&

Run

-42

.....................................................

6.3 Cutting Comers

43

6.4

DO

ONE Editing

..................................................

-44

7.0

Math

Help

...............................................

45

...........................................................

7.1

Procedure -45

..................................................

7.2

Math

Help

Types

-46

8.0

Care

&

Service

.........................................

54

..............................................

8.1

General System Care -54

...............................................

8.2

Data Error Messages

54

....................................................

8.3 Fault Messages

-56

....................................

8.4 ProtoTRAK

Limited

Warranty

57

Section

1

Introduction

1

I

1.0

Introduction

Congratulations! Your ProtoTRAK is a unique, one-of-a-kind, control system which

combines the simplicity of manual machining with the contouring capability of CNC

controls.

The ProtoTRAK has been designed to maximize the interplay between manual and

automatic machining.

o

It

acts like an advanced digital readout in manual machine

operation.

o It acts like

a

CNC when programmed to do complex contouring

jobs.

o And it acts with the best qualities of each when your job is best

done

by

transitioning back and forth between manual and contouring

CNC

operations with the powerful

DO

ONE

routines.

Section

2

provides a brief description of the ProtoTRAK.

Section

3

defines some terms and concepts useful in learning to program and operate

the ProtoTRAK.

Section

4

describes the digital readout (DRO), jog, and power

feed

operation of the

ProtoTRAK.

Section

5

describes general programming and program run.

Section

6

describes programming and running DO ONE routines.

Section

7

describes the Math Help features built into the ProtoTRAK.

Section

8

provides some suggestions for the proper care and maintenance as well as

error messages.

Secrion

2

Descriprio~r

1

2

2

-0

Description

2.1

Keyboard

(Figure

1)

All of the data required to properly program and operate the ProtoTRAK is input

through

the

keyboard. This sealed polycarbonate front panellkeyboard

will

beep when

proper contact has been made with

each

key.

X,

Y,

Z:

selects axis for subsequent commands.

DO

ONE:

calls up single cycle routines.

POSN

DRILL:

callsup the positionldrill routine.

BOLT

HOLE:

calls

up

bolt hole routine.

MILL:

calls up the straight line

mill

routine.

ARC:

calls up the arc mill routine.

CIRCLE:

calls

up

circular pocket or frame routines.

REPEAT: calls up programming of subroutines.

POCKET:

calls up rectangular pocket or frame routines.

START: initiates the start of a program or

DO

ONE.

PWR

FEED:

activates power feed routines.

FEED?:

feedrate override to increase feedrate.

FEED&

:

feedrate override to decrease feedrate.

INC

SET: loads incremental dimensions and general data.

ABS

SET:

loads absolute dimensions and general data.

INIMM: causes English to Metric or Metric to English conversion of displayed data.

TAPElRS232: calls

up

read or write cassette tape program storage and

CAD/CAM

interface routines.

INCIABS:

switches all or one axis from incremental readout to absolute or absolute

to

incremental

.

RESTORE:

clears an entry, aborts

a

keying

procedure, restores

;l

failure or warning

indication, and aborts Math

Help.

STOP:

halts motion during program or

DO

ONE

run.

GO:

continues rnotion after

STOP,

actuates

jog

routine.

MATH

HELP:

calls up Math Help routines.

EDIT: calls up recall, add event, delete event, and special mode routines.

RECALL DATA: cycles readout through programmed data.

*

:

not used.

0-9,

+I-,

.

:

inputs numeric data with floating point format. Data

is

automatically

+

unless

+I-

key is pressed. All input data

automatically rounded to the system's resolution.

2.2

Displays

(Figure

1)

X,

Y,

Z:

shows current position or data being entered during

program or

DO ONE

input. Non-dimensional program or DO

ONE

input will always be displayed in

2.

A red dot above the

+/-

display indicates absolute dimensions are being displayed.

EVENT:

shows event number and type being programmed or run.

D

indicates a position/drill event; B for Bolt Hole;

M

for Mill;

A

for Arc;

R

for

Repeat,

C for Circle, and P for Pocket.

CONVERSATION: shows prompting messages for the operation during program and

Nn.

SERVOS ON: indicates that the

DC

servo motors and amplifiers are turned on.

IN

POSITION: indicates that the tablelsaddle have stopped moving

and the ProtoTRAK awaits further input.

2.3

Pendant

Back

Panel (Figure

2)

See Figure

2

for

a

description of the fuses, switches, and

connectors

on

the pendant back panel.

2.4

Power

Control Cabinet

(Figure

3)

The power control cabinet contains the unique SWI digital servo

amplifiers which drive the

DC

servo motors. See Figure

3

for

a

description of the

connectors located on the side.

2.5

Encoders

The encoders

used

to provide dircct table

and

quill position

feedback to

the

I'roto'I'RAK are sealed

against

typical shop environ-

men

ts and utilize the time proven gage-wheel principal. Model

M250C

is

used

all

axes.

Section

2

Description

1

4

2.6

Servo Motors

The servo motors are rated 280 in-oz maximum continuous torque which are sufficient

for

the heaviest cuts.

2.7

Ball Screw Assembly

The normal acme leadscrews are replaced with zero backlash ball bearing leadscrews to

provide accurate positioning and precise contouring.

2.8

Tape

Cassette

Deck

(optional)

The cassette deck allows all programs to be saved on tape for future run. The deck is

held in a separateenclosure which

can

be easily moved from one ProtoTRAK to another

or

used

with a

TRAK

CNC

or

TRAK CNC

2.

Additional tapes may be obtained by contacting:

SouthwesternIndustries,

Inc.

2605

Homestead Place

Rancho Dominguez,

CA

90220

2131608-4422

FAX

2

131764-2668

L

0

+'

U

U

U

N

W

Ill

LOU

ms

cvr

w.rr

NC

nr

3mr

VJO

roo

000

rro

I-U

ado

POWER

CONTROL

CABINET

(Side

View)

X

Motor

Connector

.(im).

d

Pendant

Logic

Connector

I

Switch

FIGURE

3

1

Section

3

Deiinjtions,

Terms.

and

Concepts

1

5

3.0

Definitions, Terms,

and

Concepts

3.1

ProtaTRAK

Axis

Conventions

X

Axis

-

Positive

X

axis

motion

is

defined

as

the

table

moving

to

the

left

when

facing

the

mill.

Consequently, measurement to

the

right

is

positive

on

the workpiece.

Y

Axis

-

Positive

Y

axis

motion

is

dehed

as

the

table

moving

toward the

operator. Measurement toward

the

machine

(away

from

operator)

is

positive

on the workpiece.

Z

Axis

-

Positive

Z

axis

motion is defined

as

moving

the

quill

up.

Measurement

up

is also

positive on the workpiece.

3.2

Absolute

&

Incremental

Reference

The

ProtoTRAK

may

be programmed

and

operated

in

either (or

in

a

combination)

of

absolute or incremental dimensions.

An

absolute reference

from

which all absolute dimensions

are

measured

(in

DRO,

DO

ONE

and

program operation) can be set

at

any point on or

even

off the workpiece.

To help understand the difference

between

absolute

and incremental

position

consider

the

example below:

1

Absol

ute

Dimensions

A.bsolute

Reference

Iricremental Diinension5

3.3

Referenced

arid

Non-Referenced

Data

Data is always loaded into the ProtoTR4.K by using the

INC

SET

or

US

SET

key.

In

entering

any

X,

Y,

or

Z

position

data

the operator

must note whether it is an incremental or absolute dimension and

enter it accordingly.

All

other information,

such

as

tool diameter,

feedrate, etc. is not

a

position

and

may,

therefore, be loaded

with

either

the

INC

SET

or

ABS

SET

key.

3.4

Tool

Diameter

Compensation

Tool

diameter compensation allows the machined edges

shown

direct-

ly on

the

print to be programmed instead

of

the center of the tool.

The

ProtoTRA.K

then

automatically compensates for the programmed

geometry so that the desired results are obtained.

If

the

cutter

in

the

sketch

above is moving

from

left

to

right

from

point

XI,

Y1

to

X2,

Y2

and on to

X3,

Y3

then

these

actual

points

can

be programmed instead

of

the

center of the

cutter.

Section

3

Definibbns,

Terms,

and

Concepts

1

7

Or

for

the

sketch

above

the

actual desired circle

with

radius

R

can

be

programmed instead

of

the

radius

of

the

center

at

the

cutter Rc.

Tool

cutter

compensation

is

always

specsed

as

the

tool

either

right or

left

of

the

workpiece

while

looking

in

the

direction

of

the

tool

motion.

Below are

examples

of

tool

right:

Examples

of

tool

left

are:

Tool

center

means

no compensation

either

right

or left.

That

is,

the

centerline of the

tool

will

be

moved to the programmed

points.

3.4.1

Special Small Step

Milling

Situation

Ln

cases

where tool diameter compensation is to

be

used to

mill

a connective

step

whose length

is

less than

the

tool radius,

an

offset distance must

be

calculated

and

used to adjust the

beginning or ending point (depending on the direction of

the

milling

cut)

of the event.

-

7

'3

X4,

Y4

XI,

Y1

In

the

figure

above, to mill from

XI,

Y1

to X2,

Y2

to

X3,

Y3

to

X4, Y4

when the

length

of the step

from

X2,

Y2

to

X3,

Y3

is

less than

the

radius

(R)

of the tool, point

X2,

Y2

would have to

be offket toward point

XI,

Y1

by

a distance equal to d.

d

can

be

calculated using the following formula:

where

R

=

tool radius

L

=

length of step

from

X2,

Y2

to

X3,

Y3

(2)

For rough machining d

may

be estimated quickly

by

multiplying the tool diameter

by

0.15.

CAUTION:

Using

this

method may result in larger than necessary

offsets

when

the step

is

very

small and the tool

diameter

is

very

large.

The

following examples show

how

d

map be calculated and

estimated. Example

2

iilustrates

how

a

larger than necessary

offset

results when

a

large tool is used

and

d is estimated.

Section

3

Definirions

Terms,.

and

Concepts

1

,9

EXAMPLE

1

Let

XI

=

0"

ABS

Using

Formula

1

to

calculate

d:

Y1

=

0"

AB

*

=

1,~

d

ABS

!.r,ri!z

d

=

(.125-.050)

(4~)

Y2

=

0"

ABS

2(.125)-.050

X3

=

1.500"

ABS

d

=

(.075)

Y3

=

0.050"

ABS

(m)

X4

=

3.000" ABS

d

=

(-075)

(G)

Y4

=

0.050"

ABS

Tool

Diameter

=

.250"

d

=

(.075)(.5)

Using

(2)

to

estimate

d:

By

using

d

calculated

X2

would

d

=

(.25)(.15)

be

adjusted

to

1.462"

ABS

for

d

=

.038

programming

EXAMPLE

2

Let

X1

=

0"

ABS

Using

Formula

1

to

calculate

d:

-

Y1

=

0"

ms

X2

=

1.500" ABS

d

=

(-375-.010)

(-)

Y2

=

0"

ABS

X3

=

1.500" ABS

d

=

(.365)

(m)

Y3

=

0.010"

ABS

X4

=

3.000" ABS

d

=

(.365)

(F)

Y4

=

0.010"

ABS

\

/

Tool Diameter

=

,750"

d

=

(.365)(.116)

Using

(2)

to

estimate

d:

3.5

Connective

Events

Connective events occur between two milling events (either

MILL

or

ARC,

but not

CIRCLE)

when

the

X,

Y,

and

Z

ending points of

the

first

event are

in

the

same location

as

the

X,

Y,

and

Z

starting points of

the

next

event.

In

addition,

the

tool ofFset-s and tool number of

both

events

must

be

the

same.

3.6

CONRAD

CONRAD

is

a

unique

feature of

the

ProtoTRAK in

that

it allows

the

operator to program

a

tangentially co~ectingradius

between

connec-

tive events

or

tangentially connecting

radii

for the corners of

pockets

and

kames

without

the

necessity of complex calculations.

A

few typical

examples

of

CONRAD

applications are described below.

For

the

figure below, the operator

simply

programs

a

MILL

event from

XI,

Y1

to

,W,

Y2

with

tool right offset

and

another

MILL

event from

X2,

Y2

to

X3,

Y3

also

with

tool right offset. During

the

programming

of

the first

MILL

event

the

system will

prompt

for

CONRAD

at which time

the

operator

inputs

the

numerical

value

of

the

tangentially

connecting

radius (r=k).

The

system will calculate the tangent

points

TI

and

TZ

and

direct

the

tool

cutter

to

move

continuously from

XI,

Y1

through

TI,

r=k,

T2

to

X3,

Y3.

kction

3

Def?njh'ons

Terms,

and

Concepts

I

11

For the

figure

below,

the

operator simply programs

an

ARC

MILL

event

from

XI,

Y1

to

X2,

Y2

with

tool

offset

left

and another

ARC

MILL

event

from

X2,

Y2

to

X3,

Y3

also

with

tool ofFset left. During

the

programming

of

the first

ARC

MILL

event the system will prompt for

CONRAD

at

which

time the operator

inputs

the

numerical value

of

the

tangentially co~ectingradius r=K3.

The

system will calculate the tangent

points

TI

and

T2

and

direct

the tool cutter

to

move continuously from

XI,

Y1

through

TI,

r==,

T2

to

X3,

Y3.

NOTE:

CONRAD

must

always

be

the same or larger

than

the

tool radius

for inside corners.

Lf

CONRAD

is less

than

the tool radius

and

an

inside

corner

is

machined,

the

ProtoTRAK

will

ignore

the

CONRAD.

Secrion

4

DRO,

JOG,

POWER

FEED

Operation

1

12

4.0

DRO,

JOG,

POWER

FEED

Operation

The ProtoTRAK operates in manual operation as a sophisticatedthree-axis

digital readout

(DRO)

with jog and power

feed

capability.

4.1

Clear

Entry

Press

RESTORE,

then re-enter

all

keys.

Press

WIMM

and observe position of decimal point

to

determine

measurement mode.

4.3

Reset

One

Axis

Press

X

or

Y

or

2,

INC

SET.

This zeros the incrementalposition in the

selected axis.

4.4

Preset

Press

X

or

Y

or

2,

numeric data,

INC

SET

to preset selected axis.

4.5

Reset

Absolute

Reference

Press

X

or

Y

or

2,

ABS

SET

to set selected axis absolute to zero at the

current position. See

4.7

and

4.8

to display this data.

NOTE:

This

will

also reset the incremental dimension

if

the

absolute

position is being displayed when it is reset.

4.6

Preset

Absolute

Reference

Press

X

or

Y

or

2,

numeric data,

ABS

SET

to set the selected axis

absolute to

a

preset location for the current machine position.

See

4.7

and

4.8

to display this data.

NOTE:

This will also reset the incremental dimension

if

the absolute

position

is

being displayed when it is preset.

4.7

Recall Absolute

Position

of

All

Axes

Press

TWC/ABS.

Note presence of red dot above each

+I-

to

determine

if

the axis is reading incremental (no red dot) or absolute data

(red

dot).

Press

INC/ABS

again to revert to the original reading.

4.8

Recall

Absolute

Position on

One

Axis

Press

X

or

Y

or

Z,

INCJABS.

Note presence of red dot above selected

axis

+I-

to determine if the axis is reading incremental data (no red dot)

or absolute data (red dot). Repeat to get selected axis back to original

reading.

4.9

Feedrate

Override

The feedrate may be modified during any program run (including while the

table

is

moving), during Jog operation, and during Power

Feed

operation

(see

4.10 and 4-11below).

Pressing and holding the

FEED&

key will slow the feed down. The

FEED

key increases the feed

in

the same

way.

The

limits are 10percent to

150

percent of the programmed rate, but not faster than the

100

inches

per minute rapid speed. The feedrate change will always stop as it passes

100%. Release the key and press again to continue the change.

While the

Feed?,

or

Feed\Lkey

is pressed, and for one second following

release, thepercent feedrate (or actual feedrate for power feed) will be

shown in the conversation display.

4.10

JOG

The servo motors can be used to jog the table. To jog at rapid

(100

ipm):

a) Press and hold for

3

seconds the

GO

key.

b) The conversation display will flash "JOG+"or "JOG-" and the Servo On

display will be lit.

c)

Press the

X

key to move at rapid speed in the

X

direction shown.

d)

Press the

Y

key to move at rapid speed in the

Y

direction shown.

e) Press

+/-

key to switch between

"

+"

and

"-"

jog direction.

f) Press

FEED?,

or FEEDbkey to change feedrate. The conversation

display will show the percentage feedrate override.

g) Press

RESTORE

to cancel jog operation.

For slower jog speeds:

Use

the same procedure as above except press a two-digit feedrate

(2

7

means to feed at

27

ipm) prior to pressing

X

or

Y.

The

new

feedrate

(27

in

the above example) can now be modified by the feedrate override.

The feedrate can be changed at any time by releasing

X

or Y, inputting a

new

two-digit rate, and re-pressing

X

or Y.

Table of contents

Other Southwestern Industries Control System manuals

Popular Control System manuals by other brands

Crestron Electronics

Crestron Electronics 4 Series product manual

HIK VISION

HIK VISION DS-K3B530X Series user manual

HydroQuip

HydroQuip Universal Air Series installation instructions

Spraying Systems

Spraying Systems TeeJet TECHNOLOGIES BoomPilot installation manual

I-Tech

I-Tech IT8700P+ Series user manual

CYPRES

CYPRES S6AL211A94 manual

Carlin

Carlin EZ-Temp 90000B instruction manual

J.R. Clancy

J.R. Clancy SceneControl 500 operating manual

Woodward

Woodward SECM112 installation manual

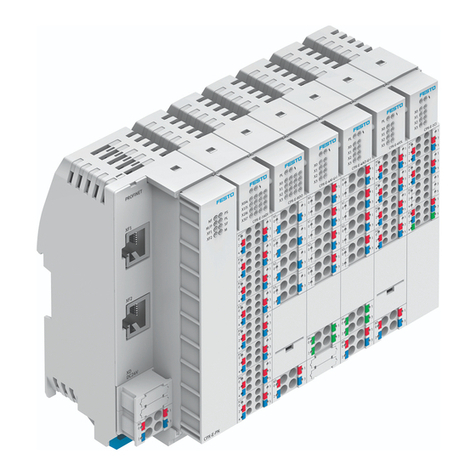

Festo

Festo CPX-E Instructions & Operating

SALUPO

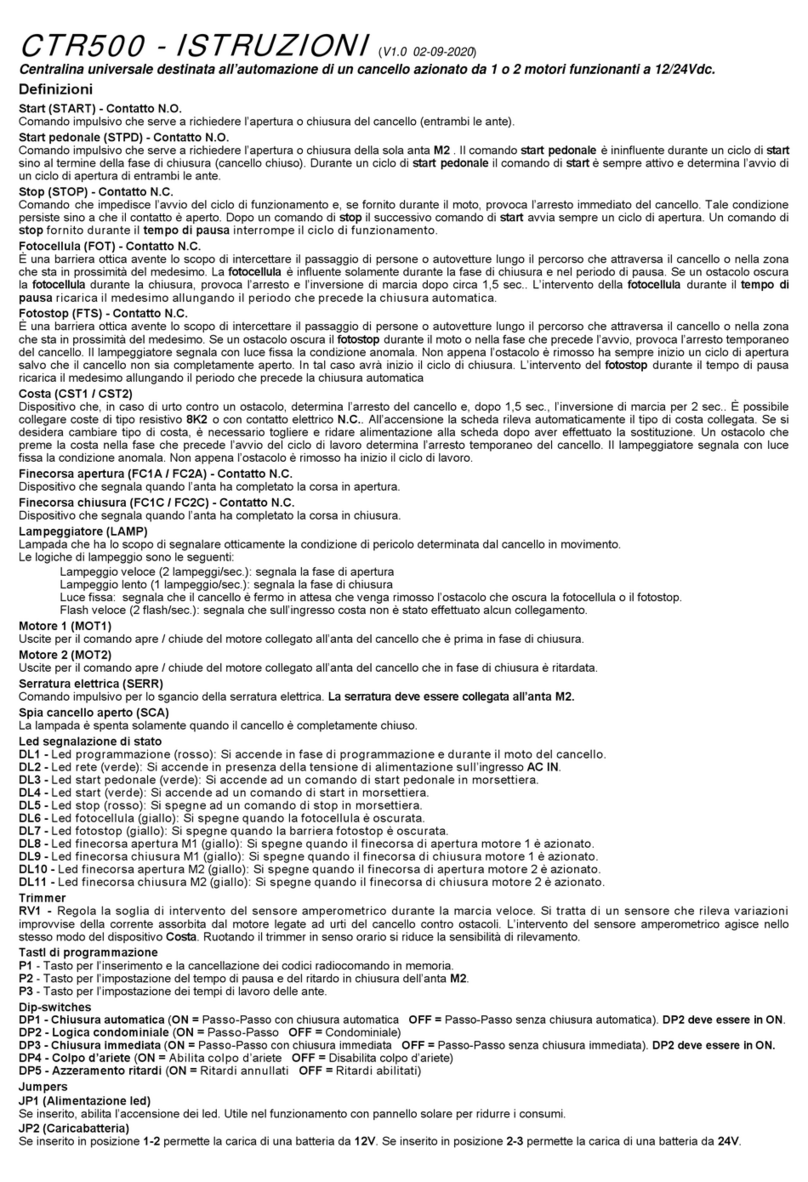

SALUPO IMPEDANCE 1 SQ701. Series Instruction and installation manual

Leb Electronics

Leb Electronics CTR500 instructions