RKC INSTRUMENT SR Mini System Assembly Instructions

SR Mini SYSTEM

IMSRM02-E6

High-performance Multi-point

Control System

SR Mini SYSTEM

Hardware

Instruction Manual

RKC INSTRUMENT INC.

®

All Rights Reserved, Copyright 1994, RKC INSTRUMENT INC.

IMSRM02-E6 i-1

Thank you for purchasing the RKC instrument. In order to achieve maximum performance and ensure

proper operation of your new instrument, carefully read all the instructions in this manual. Please

place this manual in a convenient location for easy reference.

SYMBOLS

: This mark indicates important information on installation, handling and operating

procedures.

: This mark indicates supplemental information on installation, handling and

operating procedures.

: This mark indicates where additional information may be located.

z

An external protection device must be installed if failure of this instrument

could result in damage to the instrument, equipment or injury to personnel.

z

All wiring must be completed before power is turned on to prevent electric

shock, fire or damage to instrument and equipment.

z

This instrument must be used in accordance with the specifications to prevent

fire or damage to instrument and equipment.

z

This instrument is not intended for use in locations subject to flammable or

explosive gases.

z

Do not touch high-voltage connections such as power supply terminals, etc.

to avoid electric shock.

z

RKC is not responsible if this instrument is repaired, modified or

disassembled by other than factory-approved personnel. Malfunction can

occur and warranty is void under these conditions.

CAUTION

: This mark indicates precautions that must be taken if there is danger of electric

shock, fire, etc., which could result in loss of life or injury.

: This mark indicates that if these precautions and operating procedures are not

taken, damage to the instrument may result.

: This mark indicates that all precautions should be taken for safe usage.

WARNING

!

WARNING

!

IMSRM02-E6

i-2

zThis is a Class A instrument. In a domestic environment, this instrument may cause radio

interference, in which case the user may be required to take adequate measures.

zThis instrument is protected from electric shock by reinforced insulation. Provide

reinforced insulation between the wire for the input signal and the wires for instrument

power supply, source of power and loads.

zThis instrument is designed for installation in an enclosed instrumentation panel. All high-

voltage connections such as power supply terminals must be enclosed in the

instrumentation panel to avoid electric shock by operating personnel.

zAll precautions described in this manual should be taken to avoid damage to the

instrument or equipment.

zAll wiring must be in accordance with local codes and regulations.

zAll wiring must be completed before power is turned on to prevent electric shock,

instrument failure, or incorrect action. The power must be turned off before repairing work

for input break and output failure including replacement of sensor, contactor or SSR, and

all wiring must be completed before power is turned on again.

zTo prevent instrument damage or failure, protect the power line and the input/output lines

from high currents with a protection device such as fuse, circuit breaker, etc.

zPrevent metal fragments or lead wire scraps from falling inside instrument case to avoid

electric shock, fire or malfunction.

zTighten each terminal screw to the specified torque found in the manual to avoid electric

shock, fire or malfunction.

zFor proper operation of this instrument, provide adequate ventilation for heat dispensation.

zDo not connect wires to unused terminals as this will interfere with proper operation of the

instrument.

zTurn off the power supply before cleaning the instrument.

zDo not use a volatile solvent such as paint thinner to clean the instrument. Deformation or

discoloration will occur. Use a soft, dry cloth to remove stains from the instrument.

zTo avoid damage to instrument display, do not rub with an abrasive material or push front

panel with a hard object.

NOTICE

zThis manual assumes that the reader has a fundamental knowledge of the principles of electricity,

process control, computer technology and communications.

zThe figures, diagrams and numeric values used in this manual are only for purpose of illustration.

zRKC is not responsible for any damage or injury that is caused as a result of using this instrument,

instrument failure or indirect damage.

zPeriodic maintenance is required for safe and proper operation of this instrument. Some

components have a limited service life, or characteristics that change over time.

zEvery effort has been made to ensure accuracy of all information contained herein. RKC makes no

warranty expressed or implied, with respect to the accuracy of the information. The information in

this manual is subject to change without prior notice.

zNo portion of this document may be reprinted, modified, copied, transmitted, digitized, stored,

processed or retrieved through any mechanical, electronic, optical or other means without prior

written approval from RKC.

CAUTION

IMSRM02-E6 i-3

CONTENTS

Page

1. OUTLINE ...............................................................................1

1.1 Handling Procedures.......................................................................................1

1.2 Confirmation of the Products...........................................................................2

1.3 Confirmation of the Model Code......................................................................3

2. SYSTEM CONFIGURATION............................................... 12

2.1 Basic Configuration .......................................................................................12

2.2 Precautions for System Configuration...........................................................13

3. DESCRIPTION OF EACH MODULES ................................19

3.1 Basic Configuration .......................................................................................19

3.2 Common Items of Each Module ....................................................................20

3.3 PCP Module ..................................................................................................25

3.4 TIO Module....................................................................................................33

3.5 CT Module.....................................................................................................42

3.6 DI Module ......................................................................................................44

3.7 DO Module ....................................................................................................46

4. MOUNTING .........................................................................51

4.1 Mounting Environment ..................................................................................51

4.2 Mounting Position within Panel......................................................................52

4.3 Dimensions....................................................................................................54

4.4 Mounting the Mother Block............................................................................56

4.5 Mounting the Module Mainframe...................................................................58

4.6 Removing the Module Mainframe..................................................................59

4.7 Terminal Covers ............................................................................................59

5. WIRING ...............................................................................60

5.1 Wiring Precautions ........................................................................................60

5.2 Wiring of Each Modules ................................................................................62

IMSRM02-E6

i-4

Page

6. IN CASE OF TROUBLE ......................................................64

6.1 Troubleshooting.............................................................................................64

6.2 Module Replacement Procedure...................................................................71

7. FUNCTIONS........................................................................75

7.1 Inputs.............................................................................................................75

7.2 Settings .........................................................................................................77

7.3 Controls .........................................................................................................78

7.4 Alarms ...........................................................................................................83

7.5 Contact Inputs ...............................................................................................90

8. SPECIFICATIONS...............................................................92

8.1 PCP Module ..................................................................................................92

8.2 TIO Module....................................................................................................95

8.3 CT Module.....................................................................................................99

8.4 DI Module ....................................................................................................100

8.5 DO Module ..................................................................................................101

8.6 Common Specifications...............................................................................103

IMSRM02-E6 1

1. OUTLINE

1.1 Handling Procedures

For proper operation of your new instrument, follow the procedures and precautions listed below.

When the operation panel is . . .

Confirmation of

the Products

Confirmation of

the Model Code

Mounting and Wiring

See 1.2 Confirmation of the Products (P. 2)

See 1.3 Confirmation of the Model Code (P. 3)

See 3. DESCRIPTION OF EACH MODULES (P. 19)

See 4. MOUNTING (P. 51)

Setting of all data

Operation

Generation of the host

communications program

Setting of all data

Operation

See Operation Panel Instruction

Manual (OPL, OPM, OPM-H)

See Communication Instruction

Manual (IMSRM04-E)

See Operation Panel Instruction

Manual (OPL, OPM, OPM-H)

See Communication Instruction

Manual (IMSRM04-E)

Conduct operation according to the operating

procedure of equipment on which this

product is mounted.

Used

Not used

See 5. WIRING (P. 60)

1. OUTLINE

IMSRM02-E6

2

1.2 Confirmation of the Products

When unpacking your new instrument, please confirm that the following products are included. If any

of the products are missing, damaged, or if your manual is incomplete, please contact RKC sales

office or the agent.

SR Mini HG SYSTEM control unit: Required number of sets

Hardware Instruction Manual (IMSRM02-E

): 1 copy

Communication Instruction Manual (IMSRM04-J

)*: 1 copy

DIN rail holding clips: 2 clips/unit

* See this instruction manual when the control unit is directly connected to the host computer

(Personal computer). This instruction manual may not be attached depending on the system

configuration of the purchased products.

Modules for the SR Mini HG SYSTEM cannot be mixed with those for the SR Mini

SYSTEM.

1. OUTLINE

IMSRM02-E6 3

1.3 Confirmation of the Model Code

The model code for the instrument you received is listed below. Please confirm that you have received

the correct instrument by checking the model code label, located on the left side of the module, with

this list. If the product you received is not the one ordered, please contact RKC sales office or the

agent.

RKC INSTRUMENT INC. MADE IN JAPAN

INPUT OUTPUT

0TO400℃RELAY

K (250V AC 3A)

MODEL H-TIO-B-FK02-M*NN

NO. 95C01011

SUPPLY

RKC INSTRUMENT INC. MADE IN JAPAN

SYSTEM NO. UNIT NO.

F0000203 01

MODEL H-PCP-A-14N-M*AB

NO. 95C01010

SUPPLY 100 TO 120V AC,50/60 Hz

20VA MAX

Model code label

If the product conforming to CE/UL/CSA is selected, “/CE” is entered in the serial number

section.

Model code

label

PCP module Single type function module

Model code

label

PCP module

Single type function module

Double type function module

Serial number

column

1. OUTLINE

IMSRM02-E6

4

PCP module (Power/CPU module) model code

(1) Type

A: DO 4 points type

B: DO 2 points type with DI function

(2) Power supply voltage

1: 100 to 120 V AC

2: 200 to 240 V AC

3: 24 V DC

(3) Communication interface

1: RS-232C

4: RS-422A

Alarm Code Table

The selected function will be common for all the modules with alarm functions in the

control unit.

When the communication interface of PCP module is RS-232C, only one control unit can be

connected.

A: Deviation High B: Deviation Low

C: Deviation High and Low D: Deviation Band

E: Deviation High (with alarm hold) F: Deviation Low (with alarm hold)

G: Deviation High and Low (with alarm hold) H: Process High

J: Process Low K: Process High (with alarm hold)

L: Process Low (with alarm hold)

A special alarm function

Q: Deviation High (with alarm re-hold) R: Deviation Low (with alarm re-hold)

T: Deviation High and Low (with alarm re-hold)

M-PCP-

-

N -

∗

∗∗

∗

(1) (2) (3) (4) (5) (6)

(4) DO signal

M: Relay contact output

D: Open collector output

(5) First alarm function

N: No alarm function

: See Alarm Code Table

(6) Second alarm function

N: No alarm function

: See Alarm Code Table

1. OUTLINE

IMSRM02-E6 5

For the contents of the DO, four functions can be selected out of the six functions ; first

alarm, second alarm, heater break alarm, burnout alarm, temperature rise completion and

loop break alarm.

For details on the DO Allocation, see the following Initial Code Table.

Initial Code Table

DO function can be allocated by the customer on the operation panel. The customer who do not have

the operation panel needs to add this settings to the customer's host communication program.

-

DO1 to DO4 is not possible to overlap allocation . Excluding the case of “N.”

For type B, only DO1 or DO2 can be selected. For DO3 or DO4, set “N.”

DO4

DO3

DO2

DO1

DO allocation code

N: Unused

1: Temperature first alarm

2: Temperature second alarm

3: Heater break alarm

4: Burnout alarm

5: Temperature rise completion

8: Loop break alarm

1. OUTLINE

IMSRM02-E6

6

TIO module (Temperature control module) model code

z

zz

z

1 channel control type

(1) Type

A: 1 channel type (Temperature input)

C: 1 channel heat/cool type (Temperature input)

(2) Control action

A: ON/OFF control (Reverse action) 1

C: ON/OFF control (Direct action) 1

F: PID control with autotuning function

(Reverse action)

D: PID control with autotuning function

(Direct action)

B: Heat/ cool PID control with autotuning

function (Air cooling) 2

W:Heat/ cool PID control with autotuning

function (Water cooling) 2

(3) Input type

:See Input Range Table (P. 9)

(4) Range

:See Input Range Table (P. 9)

(5) Control output (Heat-side) 3

M: Relay contact output

V: Voltage pulse output for SSR drivers

D: Open collector output

T: Triac output

:Continuous current output

(See Output Code Table)

:Continuous voltage output

(See Output Code Table)

Output Code Table

3: 0 to 1 V DC 4: 0 to 5 V DC 5: 0 to 10 V DC 6: 1 to 5 V DC

7: 0 to 20 mA DC 8: 4 to 20 mA DC 9: Others

M-TIO-

-

-

∗

∗∗

∗

(1) (2) (3) (4) (5) (6) (7) (8)

(6) Control output (Cool-side) 3

None: No function

M: Relay contact output

V: Voltage pulse output

D: Open collector output

T: Triac output

:Current output

(See Output Code Table)

:Voltage output

(See Output Code Table)

(7) Alarm output 4

N: No function

1: Fast alarm output 5

2: Second alarm output 5

3: Heater break alarm output 1

4: Loop break alarm output 1

(8) Current transformer input 6

N: No function

1: CT input: CTL-6-P-N

2: CT input: CTL-12-S56-10L-N

1. OUTLINE

IMSRM02-E6 7

1Only possible to select for type A.

2Only possible to select for type C.

3Both heat-side and cool-side outputs can be selected by using the heat/cool control type (C, G).

For other types, “No function” is selected for cool-side control output, and only heat-side control

output can be selected.

4Output type is relay contact output.

5First/second alarm types are those selected by the PCP module.

6Current transformer input can be designated when the type of control output (heat-side) is relay

contact output, voltage pulse output, open collector output, or triac output.

1. OUTLINE

IMSRM02-E6

8

z

zz

z

2 channels control type

(1) Type 1

B: 2 channels type (Temperature input)

D: 2 channels heat/cool type (Temperature input)

P: 2 channels fuzzy control type

(Temperature input)

(2) Control action

A: ON/OFF control (Reverse action) 2

C: ON/OFF control (Direct action) 2

F: PID control with autotuning function

(Reverse action)

D: PID control with autotuning function

(Direct action)

B: Heat/cool PID control with autotuning

function (Air cooling) 3

W:Heat/cool PID control with autotuning

function (Water cooling) 3

(3) Input type

:See Input Range Table (P. 9)

(4) Range

:See Input Range Table (P. 9)

Output Code Table

3: 0 to 1 V DC 4: 0 to 5 V DC 5: 0 to 10 V DC 6: 1 to 5 V DC

7: 0 to 20 mA DC 8: 4 to 20 mA DC 9: Others

1In two channels type, the inputs, ranges and outputs should be identical.

2Only possible to select for type B.

3Only possible to select for type D.

4Both heat-side and cool-side outputs can be selected by using the heat/cool control type (D).

For other types, “No function” is selected for cool-side control output, and only heat-side control

output can be selected.

5Current transformer input can be designated when the input belongs to type D, as well as the type of

control output (heat-side) is relay contact output, voltage pulse output, open collector output, or

triac output.

M-TIO-

-

-

∗

∗∗

∗N

(1) (2) (3) (4) (5) (6) (7)

(5) Control output (Heat-side) 4

M: Relay contact output

V: Voltage pulse output for SSR drivers

D: Open collector output

T: Triac output

:Current output

(See Output Code Table)

:Voltage output

(See Output Code Table)

(6) Control output (Cool-side) 4

None: No function

M: Relay contact output

V: Voltage pulse output

D: Open collector output

T: Triac output

:Current output

(See Output Code Table)

:Voltage output

(See Output Code Table)

(7) Current transformer input 5

N: No function

1: CT input: CTL-6-P-N

2: CT input: CTL-12-S56-10L-N

1. OUTLINE

IMSRM02-E6 9

Input Range Table

Inpu

t

type C

o

de Range C

o

de Range C

o

de Range

Input Range Input Range Input Range

K 02 0 to 400 °C K 04 0 to 800 °C K 11 0 to 1300 °C

K (JIS/IEC) K 09 0.0 to 400.0 °C K 10 0.0 to 800.0 °C

KA1 0 to 800 °F K A4 0.0 to 800.0 °FK A5 0 to 2400 °F

J 02 0 to 400 °C J 04 0 to 800 °C J 006 0 to 1200 °C

J (JIS/IEC) J 08 0.0 to 400.0 °C J 09 0.0 to 800.0 °C

JA2 0 to 1600 °F J A4 0 to 700 °F J A5 0 to 2100 °F

R (JIS/IEC) R 03 0 to 1700 °C

R A3 0 to 3000 °F

S (JIS/IEC) S 03 0 to 1700 °C

S A3 0 to 3000 °F

Thermo- B (JIS/IEC) * B 03 0 to 1800 °C

couple B A5 0 to 3000 °F

(TC) E (JIS/IEC) E 04 0 to 400 °C E 02 0 to 1000 °C E 03 0.0 to 700.0 °C

EA3 0 to 1800 °F

T09 0~200 °CT08 0~400 °CT10 -200~+200 °C

T (JIS/IEC) T 08 0.0~400.0 °C

T A7 0.0 to 700.0 °F T A9 0 to 700 °F

T B1 -300 to +400 °F

N (IEC) N 02 0 to 1300 °C

N A1 0 to 2300 °F

PLII (NBS) A 03 0~1200 °C

W 03 0 to 2300 °C

W5Re/

W26Re

(ASTM) W A3 0 to 3000 °F

U (DIN) U 05 0 to 400 °C U 06 -200 to +200 °C U 04 0.0 to 600.0 °C

UA5 0 to 700 °F U A6 -300 to +400 °F

L01 0~400 °CL05 0~900 °CL03 0.0~400.0 °C

L (DIN) L 04 0.0~900.0 °C

LA1 0 to 800 °FL A2 0 to 1600 °F

P17 0~400 °CP18 -200~+200 °CP21

-200.0~+200.0 °C

JPt 100 P16 0.0~400.0 °C

RTD (JIS) P B3 0 to 800 °F P B4 -300 to +900 °F P B7 0.0 to 800.0 °F

Pt 100 D 17 0~400 °CD18 -200~+200 °CD21

-200.0~+200.0 °C

(JIS/IEC) D16 0.0~400.0 °C

DB4 0 to 800 °F D B5 -300 to +1200 °F D B7 0.0 to 800.0 °F

* Accuracy is not guaranteed between 0 to 399 °C (0 to 799 °F) for type B thermocouple input.

1. OUTLINE

IMSRM02-E6

10

CT module (Current transformer input module) model code

(1) Type

A: CT input 6 points type (Each 2 points together are common)

(2) CT type

P: CTL-6-P-N is used for 0 to 30 A

S: CTL-12-S56-10L-N is used for 0 to 100 A

CT (current transformer) is sold separately.

Initial Code Table

Each temperature control channel corresponding to each CT module can be allocated by the customer

through operation panel. But those who do not have operation panel are necessary to add this settings

to the customer's host communication program.

- - -

CT6

CT5

CT4

CT3

CT2

CT1

Note on allocation

• Specify the temperature control channels corresponding to each CT channel.

Channel No. Unused 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Code No. N 1 2 3 4 5 6 7 8 9 A B C D E F G H J

• The overlapping of temperature control channels is possible.

• The unused channel is to be specified as “N.”

M-CT-

-

(1) (2)

CT channels

1. OUTLINE

IMSRM02-E6 11

DI module (Digital input module) model code

(1) Type

A: 24 V DC 8 points input type (4 points/common)

If the type A without the memory area selection input terminal is requested, the special

model code of “Z-186” is added to the end of PCP module model code.

DO module (Digital output module) model code

(1) Type

A: 8 points output type

B: 4 points output type (Open collector output can not be selected.)

(2) Output signal

M: Relay contact output (Type A: 4 points/common, Type B: Independent common)

D: Open collector output (8 points/common)

Initial Code Table

DO function can be allocated by the customer through operation panel. But those who do not have

operation panel are necessary to add this settings to the customer's host communication program.

-

Block 2 (Lower 4 points of terminal)

Block 1 (Upper 4 points of terminal)

- N

Block 1 (All points of terminal)

Above initial codes are for DO-A and DO-B type module.

M-DI-

(1)

H-DO-

-

(1) (2)

DO-A

DO-B

DO module function allocation

code list

N: Unused

1: Temperature first alarm

2: Temperature second alarm

3: Heater break alarm

4: Burnout alarm

7: Loop break alarm

12 IMSRM02-E6

2. SYSTEM CONFIGURATION

2.1 Basic Configuration

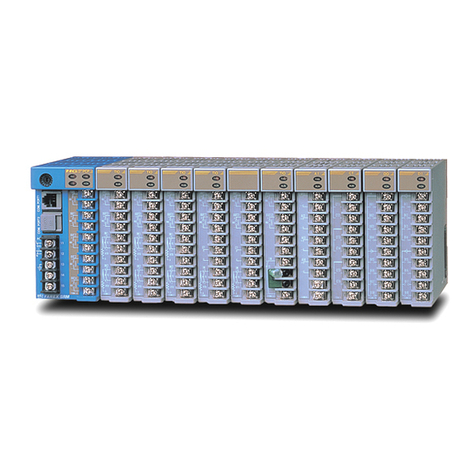

The basic system consists of control units containing the PCP module connected with the function

modules of the desired type, and the dedicated operation panel for display and setting or the host

computer.

z

zz

z

Example 1 (Connection with host computer)

z

zz

z

Example 2 (Connection with RKC operation panel OPM)

PCP module

Host computer

Function modules (10 modules max.)

Control unit

Up to 16 units (RS-422A)

RKC standard

communication

RS-232C

RS-422A

Host computer

RKC standard

communication

RS-232C

RS-422A

PCP module Function modules (10 modules max.)

Control unit

Up to 16 units *

(RS-422A)

RS-422A

Operation panel OPM

RKC standard

communication

* Up to eight units when the OPM [Z-191 specifications] or

the OPM-H [Z-191 specifications] is connected.

2. SYSTEM CONFIGURATION

IMSRM02-E6 13

2.2 Precautions for System Configuration

When configuring or extending the system, observe the following precautions.

When any function module is extended or removed, as it is necessary to store the new

function module configuration in the PCP module, always initialize the module.

For details on how to initialize the module, see the Operation Panel Instruction Manual

(OPM: IMSRM03-E

, OPL-A: IMSRM11-E

, OPM [Z-191 specifications]:

IMSRM21-E

, OPM-H [Z-191 specifications]: IMSRM26-E

), and the

Communication Instruction Manual Supplementary Information Initialize Settings

(Extended Communications) (IMSRM07-E

).

(1) When connecting modules

• The maximum number of function modules which can be connected to one control unit is 10,

excluding the PCP module. However, in this case, one TIO-D module corresponds to two function

modules. The number of function modules that can be connected is restricted depending on the

module type.

( See P. 15)

Function modules

10 modules max.

PCP module

One TIO-D corresponds to

two function modules.

2. SYSTEM CONFIGURATION

IMSRM02-E6

14

• If two or more control units are multi-drop connected, the communication specification of all PCP

modules must be RS-422A. In addition, the maximum number of control units that can be connected

is 16.

(When connected to the OPM [Z-191 specifications] or the OPM-H [Z-191 specifications] : Up to 8

units)

RS-422A

RS-422A

Up to 16 control units *

*Up to eight units when the OPM [Z-191 specifications] or

the OPM-H [Z-191 specifications] is connected.

Other manuals for SR Mini System

1

Table of contents

Other RKC INSTRUMENT Control System manuals

RKC INSTRUMENT

RKC INSTRUMENT SR Mini System Owner's manual

RKC INSTRUMENT

RKC INSTRUMENT FAREX SR MINI SYSTEM Use and care manual

RKC INSTRUMENT

RKC INSTRUMENT Z-COM User manual

RKC INSTRUMENT

RKC INSTRUMENT SR Mini HG Assembly Instructions

RKC INSTRUMENT

RKC INSTRUMENT SR Mini HG Use and care manual

RKC INSTRUMENT

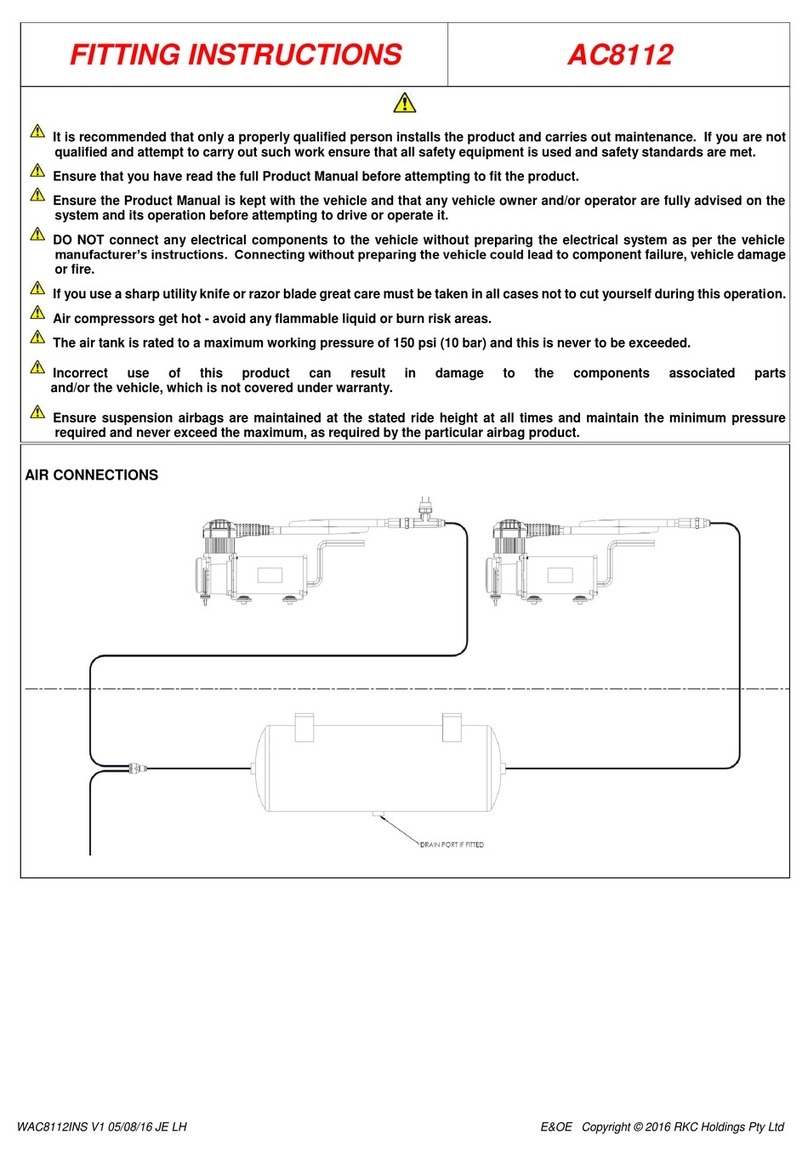

RKC INSTRUMENT AC8112 User manual