RLS Wacon LIMES PLUS User manual

Safety reliably produced.

Operating instructions

LIMES

Hardness control device for automated monitoring

of total hardness in the process water

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

3

Foreword 5

General 6

Brief description .......................................................................................................................................................................................... 6

Scope of delivery ....................................................................................................................................................................................... 6

Overview: LIMESBase and LIMESPlus.................................................................................................................................................. 8

Safety instructions and symbols used ................................................................................................................................................... 9

Transport..................................................................................................................................................................................................... 9

Storage......................................................................................................................................................................................................... 9

Disposal note.............................................................................................................................................................................................. 9

Performance features 10

Specifications 12

General specifications.............................................................................................................................................................................12

Signal input and outputs ........................................................................................................................................................................12

Technical data ..........................................................................................................................................................................................13

Analysis properties..................................................................................................................................................................................13

Maintenance intervals ............................................................................................................................................................................13

Installation 14

Installation requirements .......................................................................................................................................................................14

Wall mounting LIMES.............................................................................................................................................................................15

Wall-mounted junction box (optional) ................................................................................................................................................16

Establish supply line to the sample water and to the canal ............................................................................................................17

Device overview 18

Displays and front panel ........................................................................................................................................................................20

Overview of the configuration elements............................................................................................................................................21

Upgrade Kit from LIMESBase to LIMESPlus......................................................................................................................................21

Electrical installation 22

Overview of the electrical connections (main board): .....................................................................................................................22

Overview of the electrical connections (cables): ..............................................................................................................................24

Overview of the electrical connections (junction box): ...................................................................................................................25

Establishing the supply voltage (with junction box): ........................................................................................................................26

Establishing the supply voltage (without junction box): ..................................................................................................................26

Connecting the relay outputs................................................................................................................................................................27

Connection input contact ......................................................................................................................................................................29

Wiring example 1: Connection to control room (LIMESPlus only)................................................................................................30

Wiring example 2: Connection to a reverse osmosis system (connection potential free switch, LIMESPlus) .....................31

Wiring Example 3: Connection to external control (LIMESPlus only) ..........................................................................................32

Wiring example 4 and 5: Input contact INPUT (LIMESPlus only)..................................................................................................33

Wiring Example 6: LIMESBase..............................................................................................................................................................34

Operation and handling 35

Key functions ...........................................................................................................................................................................................35

Operating principle..................................................................................................................................................................................36

Analysis process.......................................................................................................................................................................................36

Before commissioning ............................................................................................................................................................................38

Device settings.........................................................................................................................................................................................39

Setting the flushing time LIMESPlus....................................................................................................................................................40

Setting the flushing time LIMESBase ..................................................................................................................................................40

Analysis interval LIMESPlus depending on the input contact INPUT...........................................................................................41

Analysis interval LIMESBase .................................................................................................................................................................42

Input contact LIMESPlus (INPUT, start or stop analysis interval)..................................................................................................42

Input contact LIMESBase.......................................................................................................................................................................44

First value suppression...........................................................................................................................................................................45

Trigger conditions for an analysis start ...............................................................................................................................................45

Commissioning.........................................................................................................................................................................................46

LED indicators ..........................................................................................................................................................................................47

LED display reagent level.......................................................................................................................................................................51

Content

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

4

Maintenance and service 52

Inserting a full reagent bottle................................................................................................................................................................53

Install maintenance set / clean measuring chamber ........................................................................................................................54

Change peristaltic pump cash register ................................................................................................................................................55

Component exchange.............................................................................................................................................................................56

Diagnostic functions LIMESPlus...........................................................................................................................................................59

Diagnostic functions LIMESBase..........................................................................................................................................................64

Spare parts 65

Maintenance sets and accessories 67

Maintenance sets.....................................................................................................................................................................................67

Accessories ...............................................................................................................................................................................................68

Reagents 69

Reagents for monitoring total hardness .............................................................................................................................................69

Interesting facts about the reagents....................................................................................................................................................69

Troubleshooting 70

Notes 71

Appendix 72

Maintenance and service .......................................................................................................................................................................72

Setting en ..................................................................................................................................................................................................73

Document changes..................................................................................................................................................................................73

EU Declaration of Conformity 74

Content

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

5

Foreword

Thank you for purchasing a LIMES analyser for online monitoring of water hardness.

•The LIMES analyser for monitoring water quality is part of the water treatment plant.

•This manual is intended for the manufacturer and the operator of such a unit. It contains

instructions for the installation and operation of the unit.

•Please read this manual carefully before operating the unit.

•We recommend that you always keep the manual close at hand during operation.

•Operate the unit only in accordance with the instructions in this manual.

•Under no circumstances will we be liable for any damage caused by operating errors or

failure to follow the instructions in this manual.

•Some details and instructions in this manual may differ from your actual purchased unit.

We reserve the right to make technical changes without prior notice.

On our website www.rls-wacon.de you will always find the latest version of our documentation.

The LIMES analyser automatically detects hardness breakthroughs in a water treatment

system and issues a message when the limit value is exceeded. This message can be

used, for example, to trigger regeneration of the water softener.

The LIMES analyser is not a device that prevents hardness breakthroughs.

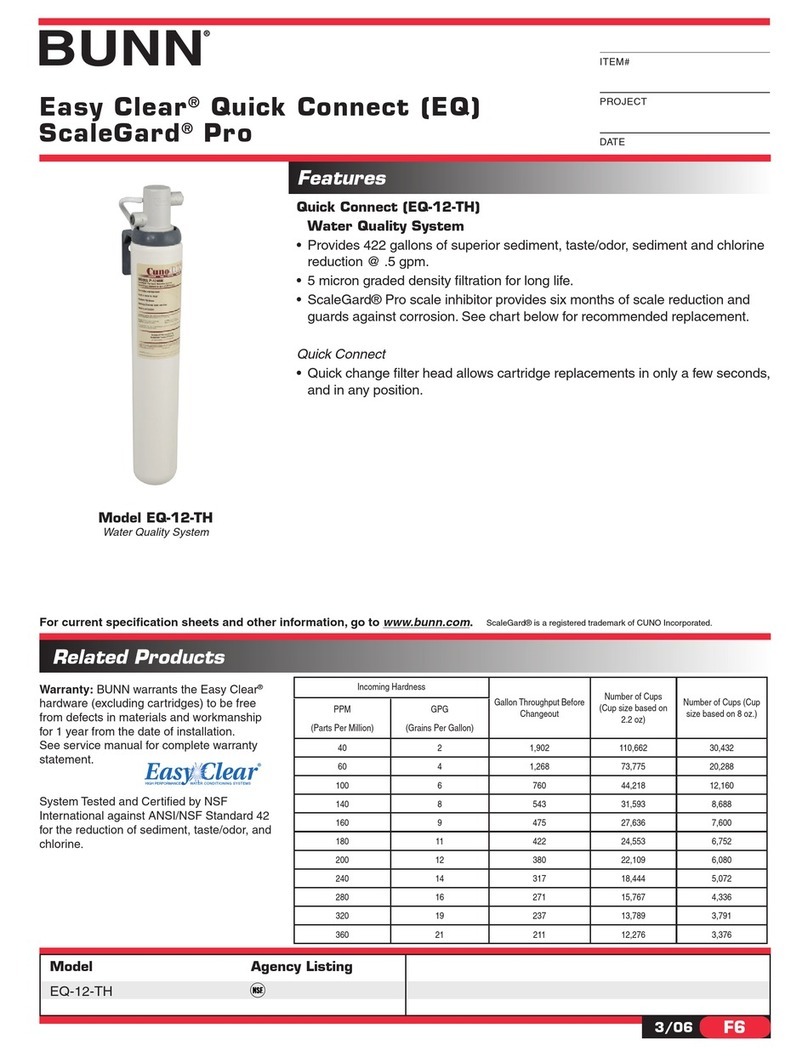

Conversion for the units of water hardness

°dH

°e

°fH

ppm

mval/l

mmol/l

German degrees

1 °dH =

1

1,253

1,78

17,8

0,357

0,1783

English degrees

1 °e =

0,798

1

1,43

14,3

0,285

0,142

French degrees

1 °fH =

0,56

0,702

1

10

0,2

0,1

ppm CaCO3(USA)

1 ppm =

0,056

0,07

0,1

1

0,02

0,01

mval/l Alkaline earth

ions

1 mval/l =

2,8

3,51

5

50

1

0,5

mmol/l Alkaline earth

ions

1 mmol/l =

5,6

7,02

10

100

2

1

The unit 1 ppm is used here contrary to the actual literal sense in the sense of 1 mg/l CaCO .3

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

6

General

Brief description

With the LIMES analyser, RLS Wacon offers a compact and very easy-to-use analyser for the

automatic online monitoring of water treatment plants.

The measuring device works on the principle of "limit value monitoring with colour change" and

provides all important functionalities for reliable field use.

The LIMES analyser automatically carries out water analyses at regular intervals to determine the

total hardness.

Based on the reagent type used, a limit value is specified by the user. There are 4 reagents

available for monitoring the total hardness.

If the limit value is exceeded, the unit outputs a message on a potential-free relay output. This

message can be further processed by a softening control. In this way, functions such as

automatic regeneration triggering can be realised.

The LIMES analyser is characterised by low maintenance costs. Up to 10,000 analyses can be

carried out with a 750 ml reagent bottle. The input contact of the device can additionally be

used to connect a flow monitor to the device. In this way, the LIMES interrupts the analysis

interval during downtimes of the water softener and automatically resumes the analysis when

the unit is put back into operation.

To prevent disturbances due to the counter ion effect, a first value suppression is available. If the

limit value is exceeded, this first carries out another control measurement before a hard water

message is issued.

You will find in-depth and much more information about your new LIMES analyser in this

manual.

Scope of delivery

The scope of delivery for a new unit includes the following items:

•LIMES analyser with 1.75m connection cables

•Operating instructions

Optional accessories:

•Front cover for analyser (transparent)

•Junction box (for electrical installation)

•LIMES connection set (for water supply)

•Stopcock

Further information on accessories can be found from page 65.

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

7

General

These operating instructions describe the installation and operation of the LIMES on-line

analyser. Installation and commissioning may only be carried out by an authorised specialist.

The unit may only be operated under the conditions described in these operating instructions.

The unit may only be used for the specified purpose. When installing and operating the analyser,

all locally applicable regulations (such as EN, DIN, VDE, UVV) must be observed.

The analyser is used for the automatic determination of the total water hardness in the process

water. Proper operation can only be guaranteed if the reagents and spare parts recommended by

us are used.

Changes to the electrical wiring and programming may only be carried out by a designated

specialist.

The water connection lines to the unit should be kept as short as possible and should not be laid

together with mains lines or in their immediate vicinity. In the vicinity of strong electromagnetic

radiators, interference with the analysis may occur; in this case, separate interference

suppression measures must be taken, in particular the EMC guidelines must be observed.

It is recommended to always have access to the analyser when familiarising oneself with the help

of these operating instructions in order to be able to understand the explained correlations and

functions immediately. Since certain areas build on each other, it makes sense to work through

the chapters in the given order.

If you have any questions about the use of the analyser, you will receive support from our

partners or from us. You can reach us by telephone during normal business hours or by e-mail.

The contact details of our technicians and our partners can be found on our website.

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

8

General

Quick overview: LIMESBase and LIMESPlus

LIMESBase

LIMESPlus

Parameters:

Limit value reagents Total hardness

0.1 / 0.5 / 3.0 / 7.0 °dH

Bottle size reagent

750 ml

750 ml

Shelf-life reagent in months

24

24

Contacts:

Input contact

(INPUT, start or stop analysis interval)

Relay output 1

(Boundary value alarm)

Relay output 2

(Unit fault or reagent message BoB)

Functions:

Adjustable flushing time

Fixed 50 sec.

First value suppression

Adjustable analysis interval

Available analysis intervals

10 min

5 / 10 / 20 / 30 min

Diagnosis mode

Technical data:

IP protection class without front cover

IP43

IP43

IP protection class with optional front cover

IP54

IP54

Protection class

SKII

SKII

- Available

- Not available

For more information, see page 21 and 68.

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

9

Safety instructions and symbols used

In this operating manual you will find various safety instructions that point out possible risks

when handling the analyser. This concerns in detail dangers for

•People,

•this product or associated equipment and installations,

•the working environment.

Various symbols in these operating instructions indicate special dangers to prevent personal

injury and damage to the appliance. Please read the entire text completely before starting work.

This symbol draws your attention to useful tips that contribute to a better

understanding of the unit.

This symbol is a general warning that indicates circumstances that must be

observed.

Pressure

This symbol is a warning that you must expect pipes under pressure.

Irritant

This symbol indicates the danger of harmful as well as irritating chemicals.

Avoid direct skin contact.

Voltage

This symbol indicates the danger of electric current and the danger to persons

and electronic components and assemblies.

Transport

Immediately after receipt, check that the unit is complete and has no transport

damage. The analyser is delivered in a transport-safe condition. Nevertheless,

damage may occur during transport. Immediately inform the delivery person

of any transport damage.

Protect the analyser from possible damage during transport. Remove any

liquids still in it beforehand. Remove the reagent bottle and close it to prevent

the reagent from leaking.

Storage

Store the analyser in a dry place at temperatures between 0 - 45 °C and out of

direct sunlight.

Disposal notes

The appliance must not be disposed of with residual waste. Take the appliance to a collection

point.

Alternatively, you can return the analyser to your dealer or to us for disposal.

General

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

10

Performance features

Fully automatic

The unit detects hardness breakthroughs fully automatically when

the limit value of the reagent used is exceeded.

The analysis process is more reliable than manual methods and

more sustainable than other measurement methods. Compared to

swelling resin sensors or electrodes, no regeneration, calibration or

replacement of the sensor element is necessary.

Intelligent and self-sufficient

The device does not need to be calibrated. Due to the integrated

measurement technology and a two-stage analysis procedure with

zero-point measurement, external measurement influences due to

contamination of the measurement chamber, turbidity of the

sample and extraneous light influences is detected and eliminated

during the evaluation of the analysis.

The integrated full colour sensor is one of the central components

for the self-sufficient operation of the unit and does not need to be

maintained or replaced.

Selectable interval time (LIMESPlus)

The interval time between two measurements can be set in 4 steps:

Interval times of 5 / 10 / 20 / 30 minutes can be selected. The

analysis can also be started via an external switch or paused when

the system is at a standstill.

Self-calibrating

Hardness breakthroughs are reliably detected by using LHV limit

reagents. Our reagents are calibrated to a fixed limit value in

production. You choose the reagent to suit your requirements. No

further configuration or calibration is necessary.

First value suppression

After a bad measurement, a reference measurement is taken every

4 minutes to evaluate the result. This prevents false alarms due to

the counter ion effect after a system shutdown.

Extensive alarm functions

If the limit value is exceeded, an alarm is issued by switching a

potential-free relay. This alarm output can be connected to a

control room for signalling or used to activate a horn, close a valve

or control a programme for regeneration of a softening system.

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

11

Performance features

Diagnostic programme (LIMESPlus)

If technical problems occur at the unit, a fault message is output by

switching a potential-free relay. The detailed diagnostic programme

in LIMESPlus enables step-by-step testing of all unit functions. In

this way, the unit is thoroughly checked, and the cause of the error

message is clearly identified.

Minimal maintenance effort

Depending on the set measuring interval or the frequency of the

measurements, the measuring chamber must be cleaned. The hose

pump cassette and sealing rings typically only need to be replaced

every 24 months.

Efficient reagent consumption

The reagent bottle is easy to replace. A freshly inserted 750 ml

bottle allows up to 10,000 analyses.

Digital input contact (INPUT, start or stop analysis interval) only with LIMESPlus

The potential-free switch of a flow monitor, a timer or another

status switch can be connected to this input, for example. When

the contact is open, no analyses are carried out in the programmed

interval.

Alternatively, this input can be used as a start input for analyses.

Two potential-free relay outputs

The potential-free relay outputs can be used to signal a limit value

alarm, a device fault or a reagent message BoB, e.g., to a control

room. Alternatively, signalling devices or service valves can be

switched.

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

12

Specifications

General specifications

Parameter

Value / Range

Power supply

100 - 240 VAC (50/60 Hz)

Protection class

II

Power consumption

15 VA (in operation)

Load capacity of the relay

outputs

2.5 A per relay

IP protection class

without front cover

IP43

with optional front cover

IP54

Storage temperature

0 °C - 45 °C

Ambient temperature

10 °C - 45 °C

Measured water temperature

5 °C - 40 °C

Humidity

20 - 90 % RF (without ice or condensation)

Inlet water pressure

min: 0.5 bar - max: 5 bar / recommended 1 - 2 bar

Inlet water in general

clear, colourless, free of solids, without gas bubbles

Water quality requirements for

the measurement of water

hardness

pH:

4 - 10

Iron:

< 3 ppm

Copper:

< 0.2 ppm

Aluminium:

< 0.1 ppm

Manganese:

< 0.2 ppm

Acid capacity:

KS 4.3 < 5 mmol/l

Note on oxidising agents:

Oxidising agents such as calcium hypochlorite, chlorine, chlorine dioxide, sodium hypochlorite or

ozone above the limits permitted in "TrinkwV 2012" attack the dye contained in the reagent and

interfere with the measurement. This means that an exact determination of the water hardness is

no longer guaranteed. An activated carbon filter connected upstream of the analyser can remove

these oxidants from the sample water and thus enable the correct determination of the water

hardness.

The capacity of an activated carbon filter is consumed during operation. Therefore, the activated

carbon filter must be replaced at regular intervals. The effectiveness of the activated carbon filter

can be checked with the help of Caldur® test sets.

Signal input and outputs

Parameter

Value / Range

Relay outputs

2 Relay

2.5 A / 250 VAC

2.5 A / 100 VDC

as potential-free outputs NC/NO

The relays provide the following functions:

•Limit value alarm (relay output 1)

•Device fault or reagent message BoB (relay output 2)

Input contact

(INPUT, start or stop

analysis interval)

only with LIMESPlus

Galvanically isolated input contact for connection of a potential-

free contact

•Start analyses (external analysis interval)

•Flow monitor (analysis interval interruption during system

standstill)

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

13

Specifications

Technical data

Parameter

Value / Range

Installation

Wall mounting in closed rooms

Dimensions

without lid:

250 x 330 x 60 mm (W x H x

D)

with lid:

250 x 330 x 90 mm (W x H x

D)

Weight

without lid:

approx. 1.8 kg

with lid:

approx. 2.1 kg

Inlet/outlet connection

Plastic hose with 1/4-inch outer diameter

Analysis properties

Parameter

Value / Range

Measuring principle

Colorimetric method

The limit value alarm is

defined by the reagent

used

•Total hardness limit reagents:

Reagent Limit value

LHV - 0.1 0.1 °dH

LHV - 0.5 0.5 °dH

LHV - 3 3 °dH

LHV - 77 °dH

For more information, see page 69

Reagent consumption

•< 0.10 ml / analysis

•Up to 10,000 analyses per 750 ml reagent bottle

Accuracy

Measurement accuracy:

•± 10 % of the limit value of the respective reagent used

Durability of the reagents

24 months from date of manufacture

Water consumption

•Approx. 2 L / analysis

•The water consumption varies depending on the inlet

pressure and the set flushing time

Maintenance intervals

Interval

Maintenance work

every 6 months

Cleaning the measuring chamber

In case of high ambient and water temperatures or water with a

high organic load, the cleaning intervals may have to be

shortened.

After 24 months of

operation

Installation Maintenance kit: Changing the hose pump cassette

and the seals

Further information can be found on pages 52 and 67

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

14

Installation

Installation requirements

The LIMES analyser may only be used for determining the total hardness in water.

Changes to the electrical wiring and parameterisation may only be carried out by an

authorised and experienced specialist.

The installation to be monitored must fulfil the following conditions:

•The maximum permissible load capacity of the relay outputs and the total power of the

system must not be exceeded by the connected load.

•All inductive loads (valves, motors, contactors, transformers) in the system must be

equipped with suitable overvoltage protection (e.g., RC element, varistor, diode, etc.).

•If there are external devices with a high mains interference level in the vicinity of the

control unit, these must be reduced with suitable measures, or appropriate external

interference suppression measures (mains filters) must be taken at the supply voltage

input of the control unit.

Voltage

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

15

Installation

Wall mounting LIMES

The LIMES analyser can be mounted directly. An additional front cover is optionally available for

protection against dirt and dust.

Illustration 1: LIMES - rear and side view (dimensions are in mm)

The unit is attached to a wall or suitable supporting structure using 3 screws (max. Ø 5 mm).

1. Select a suitable mounting location

2. First pre-mount a screw (A) on the wall.

3. Suspend the analyser, align

4. Finally, fix to the wall from the front with two screws (B).

Do not install the analyser under dripping pipes.

Voltage

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

16

Installation

Wall-mounted junction box (optional)

The junction box is attached to a wall or suitable supporting structure using 4 screws (max. Ø 6

mm).

1. Select a suitable mounting location

2. First pre-mount on the wall with two screws (A).

3. Align junction box

4. Finally, fix it to the wall with two screws (B).

Do not install the junction box under dripping pipes.

Illustration 2: LIMES junction box - front and side view (dimensions are in mm)

Voltage

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

17

Installation

Establish supply line to the sample water and to the canal

The connections for inlet and outlet are designed for flexible plastic hose with 1/4-inch

outer diameter.

A manual shut-off valve must be provided between the preparation unit and the analyser. A

suitable valve can be found in the product catalogue or in the spare parts list. When connecting

to a drinking water pipe, the installation must take EN 1717 into account. The drain must lead

into an open channel via a short connection. The drainpipe must remain depressurised.

Make sure that the inlet and outlet are not interchanged. The inlet is located on the left

side of the inlet filter.

Pressure

The inlet pressure of the water sample must be between 0.5 and 5.0 bar.

The recommended inlet pressure of the water sample should be between

1 and 2 bar.

The hose length of the water drain must not be longer than 2 m and must

lead away vertically downwards. The system must be able to relax freely

against the atmospheric pressure (no counterpressure). The water drain is

pressureless into an open funnel or drain.

Water inlet

(Water inlet)

open hopper

Hand valve

(Install on site)

Softening

Water drainage

(Water outlet)

Illustration 3: Connecting the water inlet and outlet

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

18

Device overview

Position

Description

A

Control

B

LED display

C

Operating buttons

D

Cable gland

E

Dosing pump (peristaltic pump cassette)

F

Measuring chamber

G

Filter

H

Pressure regulator

I

Reagent bottle 750 ml

J

Solenoid valve

K

Water inlet / sample water

Push-in connection for plastic hoses

with 1/4-inch outer diameter

L

Water drainage

M

Measuring chamber drain

N

Measuring chamber inlet

In the housing / not visible

O

Magnetic stirrer

P

Stirrer blade

Q

Injector

R

Optical measuring path

S

Actuator board (LED)

T

RGB sensor

Illustration 4: LIMES analyzer with indicator bottle installed (l.),

schematic representation of the measuring chamber (r.)

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

19

Device overview

Observe the correct placement and flow direction when replacing components or

performing other work on the analyser.

Illustration 5: LIMES exploded view - assembling the components

Safety reliably produced.

info@rls-wacon.de

Subject to change without notice

20

Device overview

Displays and front panel

On the front of the LIMES analyser there are 4 LEDs to indicate the operating status and 4 keys

to operate the unit.

Illustration 6: LIMES - Unit overview / front foil

The LED display shows the operating status:

LED

Colour

Information

A

Green (two-colour LED)

Limit value undershot

A

Red (two-colour LED)

Limit value exceeded

B

Yellow

Analysis active

B

Yellow flashing

Input contact open, e.g., by flow monitor

C

Blue

Provide reagent

C

Flashing blue

BoB message

D

Red

Device fault

Further information can be found from page 35 and 47.

This manual suits for next models

8

Table of contents

Popular Water System manuals by other brands

Taco Comfort Solutions

Taco Comfort Solutions 00e VT2218 Series instruction sheet

Grundfos

Grundfos rmq-a Installation and operating instructions

H20 Distributors

H20 Distributors USRO4-100-QC-38 Installation and service guide

Sears

Sears CRAFTSMAN 390.252157 owner's manual

BWT

BWT Rondomat Duo Series Installation and operating manual

Technosmart

Technosmart Atmopure 320 manual

Julabo

Julabo Corio C Original operating manual

IMI PNEUMATEX

IMI PNEUMATEX Pleno PI Series Installation

Kenmore

Kenmore 625.3845 owner's manual

Graf

Graf EcoBloc maxx Series manual

Wave Home Solutions

Wave Home Solutions HYDROCARE DUAL ACTION installation manual

Everpure

Everpure Exubera CGCC-1 Specifications