RMS 1S20-FAB User manual

rms

1S20

1S20 | W11 |09/03/2017

Arc Flash Protection

High speed arc fault protection for metal clad air Insulated

switchgear utilizing optical sensors.

>

Compact, economic design

>

Simple panel mounting for retrofit applications

>

Two or three arc sensor inputs

>

Made in Australia

www.rmspl.com.au

rms

Functional Description

1S20

2

Figure 1: 1S20 surface mount version front panel

Application

Utilised in either new installations or as a simple retrofit in

existing installations, the

1S20

provides high speed detection and

signalling of arc flash hazards for application in air insulated

metalclad switchgear.

Arc fault p

rotection schemes may be implemented on an arc

only

basis, or alternatively a current check may be employed where

additional security is warranted.

A current

checked scheme may be implemented by making use

of available protection relay logic and a fast acting instantaneous

overcurrent element.

Some typical application examples are shown on the Application

page together with an example s

chematic.

For further

application information refer to the 1S20 User G

uide.

The

1S20 is packaged in the ZA12

case that may be flush panel,

surface or rail

mounted.

A plug in terminal block is provided to allow

panel pre-wiring

.

Arc Flash Protection

Arc

fault p

rotection is a relatively new technique employed for

the clearance of arcing faults on low voltage panels, MCC’s, BUS

bars and within metal clad switchgear and associated cable

boxes.

Conventional current based protection techniques are at times

challenged by the nature of arcing faults, and can result in slow

protection clearance times. Slow protection

clearance

times

increase the risk to nearby personnel and increase the degree of

damage to plant and equipment.

By employing an optical detection technique, Arc Fault

Protection results in fast clearance of arcing faults.

Features

>Compact, economic design

>Simple panel mounting for retrofit

applications

>Two or three arc sensor inputs

>Two high speed tripping duty arc sense

output contacts

>Push button reset

>Continuous arc sensor supervision

>Integrated self-supervision

>Fail alarm contact

>24, 32, 48, 110, 125, 220, 240, and 250 V

AC/DC auxiliary

>Made in Australia

www.rmspl.com.au

rms

3

Applications

1S20

Arc Sensors

The 1S20 is designed to monitor remote optical sensors that to

respond to the flash of light emitted during the incidence of an

arcing fault. Onset of the light flash & detection by the sensors

occurs in a few ms.

1S30 Point Sensor

The 1S30 is an electrically wired point sensor suitable for

application in discrete compartments in metal clad switchgear

and cable ducts. When an arc is detected, the resistance

presented by the 1S30 drops to a level where the current flow

increases to approximately 20mA. This increased current flow is

instantaneously detected by the 1S20 & its trip output contacts

closed. Refer to the 1S30 Technical Bulletin for further details.

Figure 2: 1S30 Point Sensors

Low Current Arcing Faults

Arcing faults c

an occur at low current levels and

it is possible for

the over

-

current starter element to be set above this level. To

avoid this problem & obtain very fast clearance (<10ms),

of an arc

fault, the 1S20 arc fault trip contact may be wired directly to the

breaker operate coil. It should be noted that this method may

lead to reduced system security.

Independent Trip Output Contacts

The 1S20 may be set using configuration switch 3 for both trip

output contacts to pick up when an arc is detected by any sensor

input. Alternatively arc sensor 1 can be linked to trip contact 1 &

arc sensor 2 (& 3 if fitted), to trip contact 2. This function may be

applied where an arc fault detected in the cable box is directed to

trip the feeder circuit breaker while an arc fault in the BUS

chamber is

to be directed to trip the BUS.

Arc Fault Tripping Using Current Check

Fast

operation of a tripping scheme usually results in reduced

system security. The arc detection method can however,

combine the 1S20 optical detection technique with a traditional

overcurrent method to maximize system security particularly for

BUS bar protection schemes. Both conditions must coexist for

the trip condition to be met as depicted in figure 3.

Figure 3:

Key components required to implement an Arc Fault Protection

scheme with an overcurrent check stage to enhance system

security.

The applicati

on examples in figures 4 to 8

utilize this concept for

enhanced system security in

that both the 1S20 AND

the OC 50

starter contact must be picked up for a CB trip signal to be

initiated.

As the arc fault trip contact picks up considerably faster

than the overcurrent relay starter element, the CB trip time will

be dictated by the overcurrent relay performance.

Arc Sensor Continuously Picked Up

High ambient light levels may cause a 1S30 to be continuously

picked up. This condition could occur for example if the CB cable

box cover was left open in very high ambient light level

conditions.

To avoid possible mal operation due to this condition, the 1S20

is designed to automatically disable the arc fault tripping function

if any sensor input is picked up for >10s. The 1S20 alarm contact

will be set & the front LED flash alternate orange & red until the

ambient light level problem is corrected. The 1S20 will then

perform an arc sensor test function & automatically reset.

Arc Detection Reset Time

(Effect of multiple

arc trips)

A delay of 2s is required to reset the 1S20 after an initial arc

sensor trip. Subsequent arc detection will cause the trip output

contacts to re

-operate.

Type:1S20K1 [C] Vx: 48V DC

Serial No: 126578

1S20 Arc Fault Monitor

ARC FAULT TRIP INITIATE

CB ARC FAULT

MONITORSENSOR

O

VER-

C

URRENT RELA

Y

3 Pole OC + EF

RESET / TEST

System Functi oning

Arc Fault Trip

System Service

DC Fail

GREEN:

RED:

ORANGE:

DARK:

www.rmspl.com.au

rms

4

Applications

1S20

Switchgear ARC Flash Protection

Risk of arc fault damage exists at the CB cable termination and in

the CB chamber itself. The CB cable termination is particularly at

risk to ingress of moisture and rodent damage.

One, two or three arc sensors may be connected to the 1S20 Arc

Fault Monitors as depicted in the single line application diagrams

at right.

Figures 4 and 5 show the trip signals being used to trip the feeder

circuit breaker in the event of an arc fault occurring at any sensor

provided the overcurrent relay starter contact is picked up. In

these applications the overcurrent check stage is optional as the

consequence of a single feeder outage is less than the loss of an

entire BUS.

Figure 7 shows an application where a single 1S20 is applied for

the protection of the Cable box, CT chamber and CB chamber

using three sensors. In this configuration one arc trip output is

used to trip the feeder circuit breaker in the event of an arc fault

in the cable box / CT chamber. The second trip output is set for

independent operation to trip the BUS breaker (BUS overcurrent

check not shown), in the event of an arc fault in the CB chamber.

Existing Switchgear Applications

The existing overcurrent relay protecting the feeder will normally

provide an independent output contact associated with the start

current setting of the relay. That is an output contact that will

close when a phase or earth fault current is detected above the

threshold which starts the internal relay timers. This starter

element should be set for instantaneous operation so that it will

pick up in the o

rder of 15ms.

An Arc Fault Monitor relay 1S20 is installed on the switchgear

panel adjacent to the protection relay. The 1S20 is specifically

designed for simple retrofit to existing panels or DIN rail mounted

within the instrument chamber.

1S30 optical arc sensors are fitted in the cable termination box

and CT chamber as depicted in figure 5.

The overcurrent relay starter contact may optionally be wired in

series with the arc fault detection trip output contact as depicted

in figure 6. The resulting “AND” function trip output is wired to

trip the breaker in ~15ms in the event that an arc fault is detected

while the overcurrent start element is picked up.

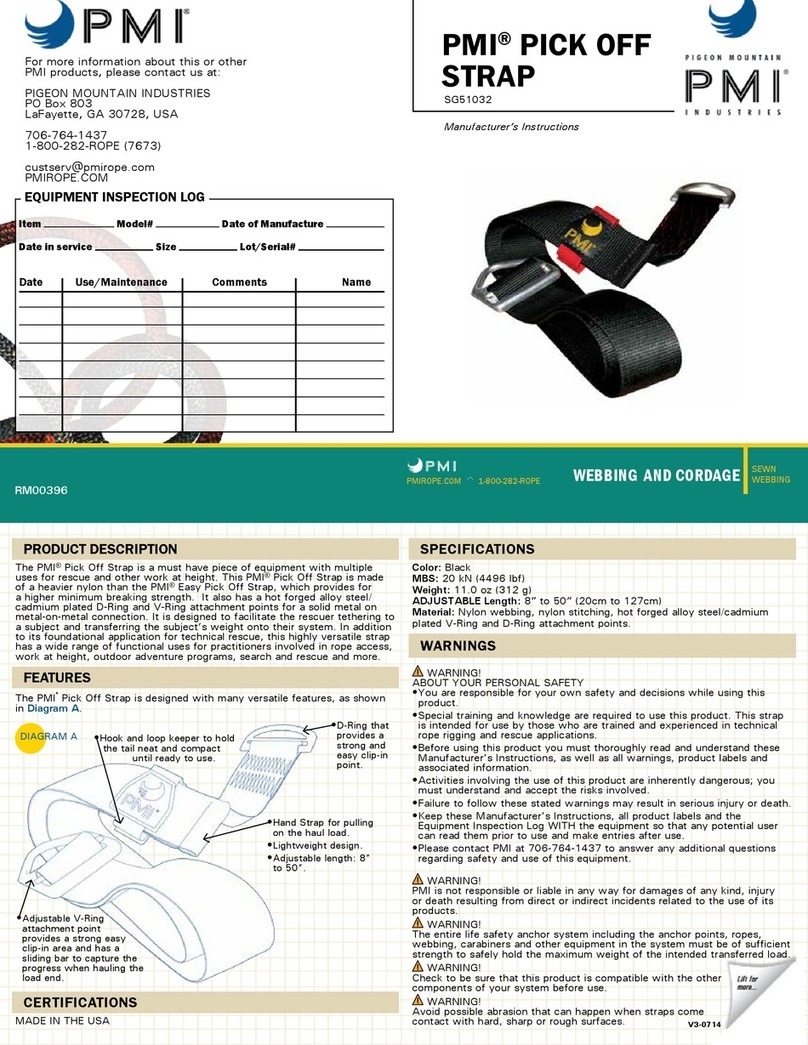

Figure: 4:

Single point sensor -

Cable box

Figure: 5:

Two point sensors - Cable box and

CT chamber

1S30

1S20

50/51

1S30

1S30

1S20

50/51

www.rmspl.com.au

rms

5

Applications

1S20

New Switchgear A

pplications

For new switchgear installations a modern numeric feeder

protection relay is likely to be employed which will have numerous

programming and configuration options.

The basic concept is the same as for the existing switchgear

application described above except that the additional features

and flexibility of modern feeder protection relay allows improved

system integration.

This may be achieved by using the second arc trip output contact

to interface to a programmable status input on the feeder

protection relay. Depending on the model of protection relay

being used this input may be programmed to provide an alarm

message on the HMI, time stamped event record available via its

communications link.

Where this level of system integration is employed the 1S20 does

not need to be mounted on the front panel as the alarm

indications are available on the feeder relay. Remote reset of the

1S20 LED is achieved by momentary interruption of the power

supply using a SCADA controlled series contact. The DIN rail

mounting option is a convenient alternative in this situation.

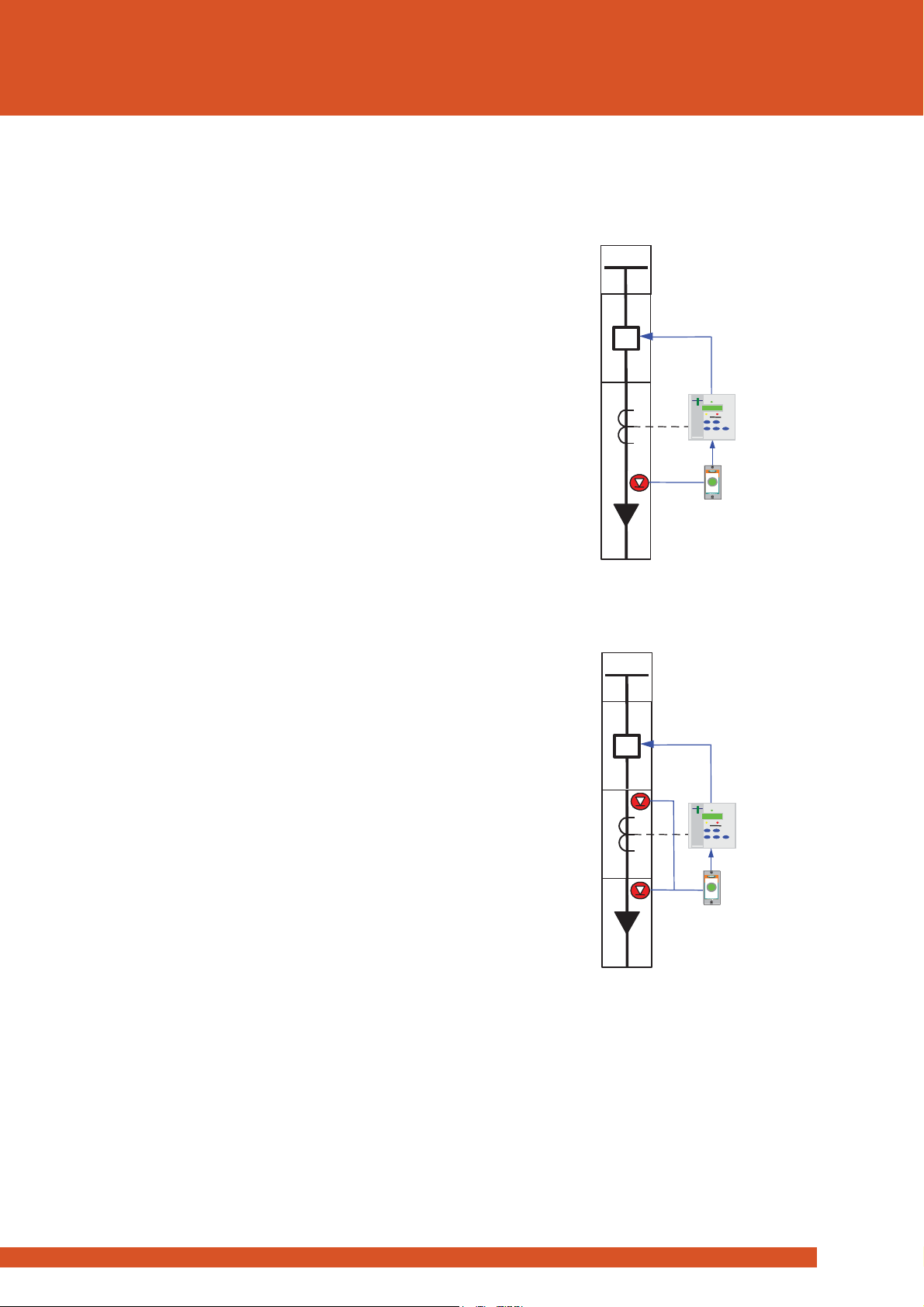

Combined Bus Bar & Switchgear Arc Protection

Figure 7 shows an application where a single 1S20 is applied for

the protection of the Cable box & CT chamber plus the CB chamber

& B

US chamber using three sensors.

In this configuration one arc trip output is used to trip the feeder

circuit breaker in the event of an arc fault in the cable box / CT

chamber. The second trip output is set for independent operation

to trip the BUS breaker

(BUS overcurrent check stage not shown),

in the event of an arc fault in the CB chamber or BUS chamber.

Figure: 7:

One arc sensor - Cable box / CT chamber

Independent trip to CB

Two arc sensors - CB chamber & BUS chamber

Independent trip to BUS breaker

(BUS overcurrent check stage not shown)

Figure: 6:

Two point sensors in zone 1 - Cable box and

CT chamber

One point

sensor in zone 2 for CB chamber

1S20

1S30

1S30

1S30

50/51

Trip BU

S

C

B

(

s

)

1S20

1S30

1S30

1S30

50/51

Trip BU

S

C

B

(

s

)

1S20

1S30

1S30

1S30

50/51

Trip BU

S

C

B

(

s

)

1S20

1S30

1S30

1S30

50/51

Trip BU

S

C

B

(

s

)

www.rmspl.com.au

rms

6

Applications

1S20

Figure: 8: Bus bar arc protection single line schematic

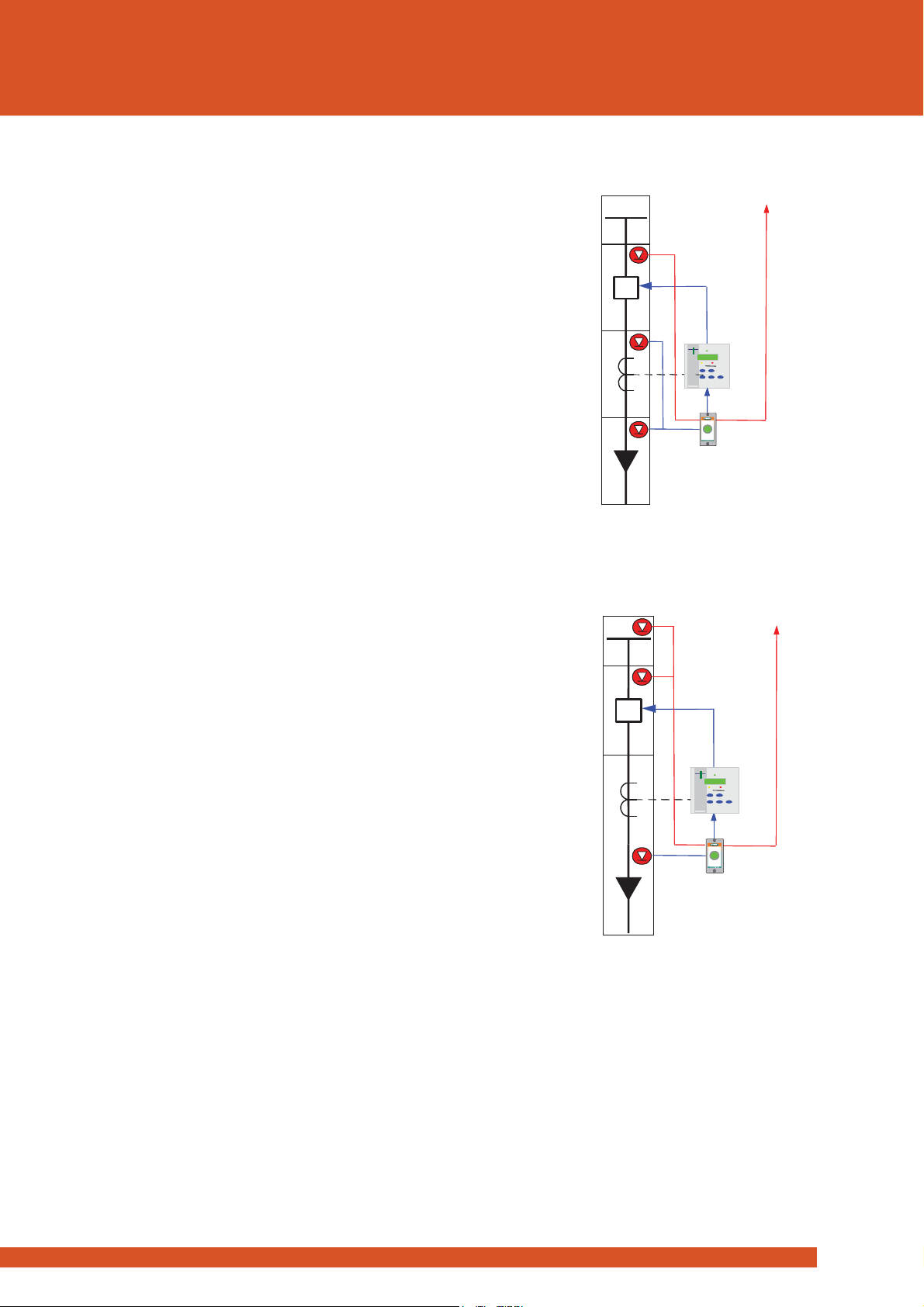

Bus Bar Arc Protection

Figure 8 depicts how the 1S20 may also be applied for the

protection of bus bars. The number of sensors in the bus

chamber is dictated by the switchgear design and the length of

switchboard.

In most indoor metal clad switchgear the bus bar chamber is a

continuous chamber between panels only broken into

segregated sections at a bus section breaker & as such the

strategic placement of one or two arc sensors in each bus bar

chamber run is normally adequate.

Some indoor metal clad switchgear may segregate the bus

chamber of each panel from the next via insulated bus chamber

side barriers per panel, if this is the case then each bus chamber

per panel would need to be monitored by at least one arc

sensor.

In large enclosures the arc sensors should be placed at

approximately 5m intervals.

1S30 Shielded Cables

Shielded cables are recommended when the length of the 1S30

cable con

nections exceed 6m.

1S20

1S30 1S30

50/51

50/51 50/51

www.rmspl.com.au

rms

7

Configuration

1S20

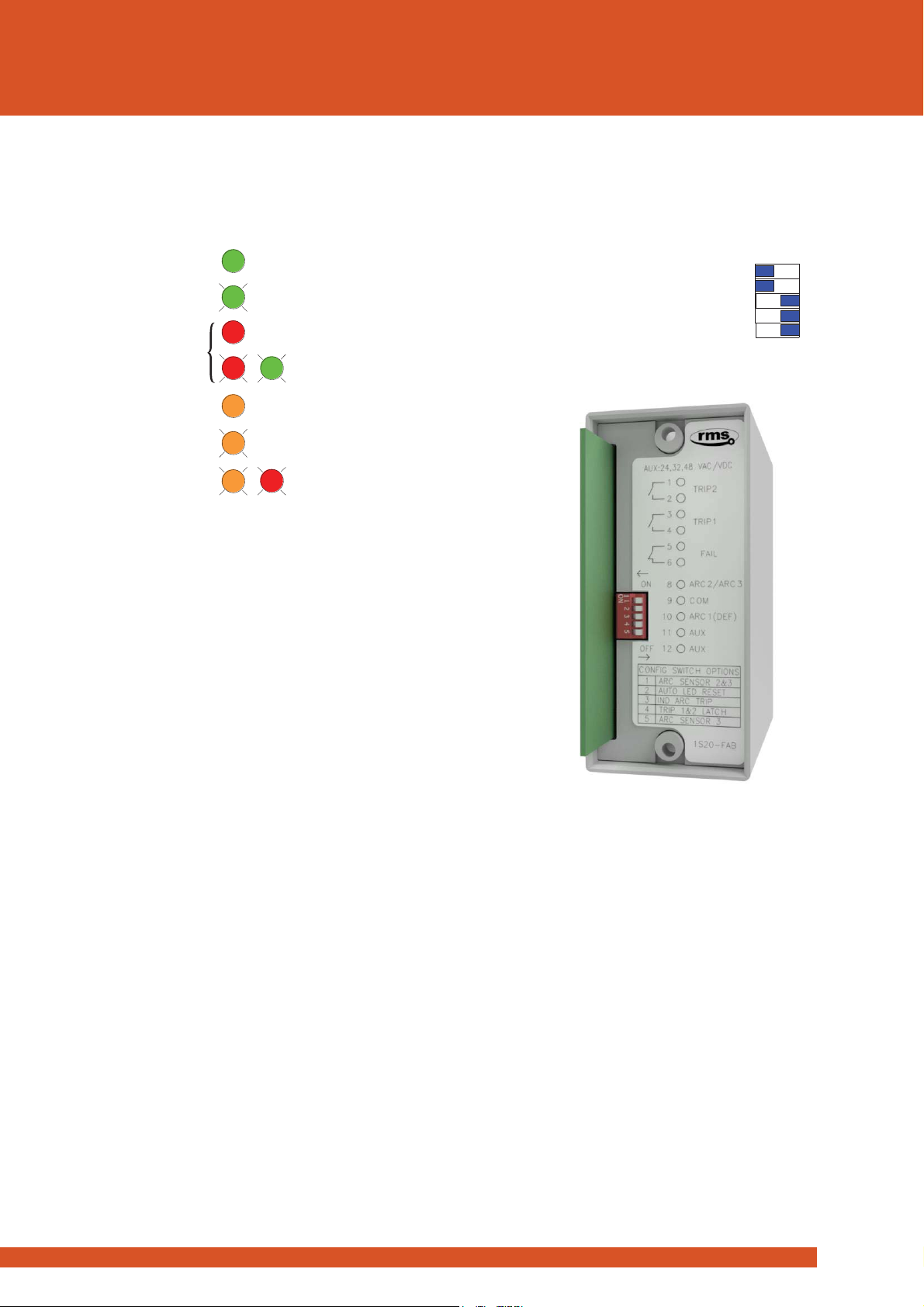

Operation Indicator

A single tri colour LED is integrated into the front panel reset push

button to provide the following status indications:

Figure 9: Front panel LED indication

Configuration Switch Settings

The internal wiring label identifies the position of the following

switch functions:

Switch 1:

Arc sensor 2

ON - Arc Sensor 2 fitted

OFF - Arc Sensor 2 not fitted

Switch 2:

Arc fault trip indication LED reset

ON - Latching until manually reset

OFF - Automatic self-

reset (Extinguish) after 4

hours Will also reset conta

cts set for

latching function

Switch 3:

Independent arc trip output contacts

ON -

Arc Sensor 1 activates trip output contact 1

& Arc sensor 2 or 3 activates trip output

contact 2

OFF -

Arc Sensor 1, 2 or 3 activate both trip

outputs

Switch 4:

Arc fault trip output contact reset

ON - Latching – Reset with trip LED

OFF - Self-reset after 2s

Switch 5:

Arc sensor 3

ON - Arc Sensor 3 fitted

OFF - Arc Sensor 3 not fitted

Function Configuration

The configuration switches are accessible to the user by first

unplugging the electronic module from

the terminal base as

shown in

figures 10 and 11.

Figure 10

: Front panel mode selector switch

Figure 11:

1S20 rear view showing configuration switches

WARNING:

Removal of the 1S20 from the base may

expose live terminals

Arc Sensor

Circuit Supervision

The 1S30 Arc Sensor is the heart of the system & supervision of

circuit continuity is critical for correct operation. To monitor the

integrity of the wiring between the 1S30 arc sensor & 1S20 Arc

Monitor, a continuous 2mA supervision current flows between

the units. The 1S20 alarm contact will drop out after a 1s time

delay if it fails to detect this current.

Where a fault is detected on the Arc Sensor 1 circuit the front

panel LED will give a solid orange indication.

Where a fault is detected on Arc Sensor 2 or 3 circuits the front

panel LED will give a flashing orange indication.

Where a fault is detected on Arc Sensor 1 & 2 or 1& 3 circuits the

front panel LED will give a solid orange indication.

Solid red for 2s followed by:

Alternate red & green until reset.

Green solid

Orange flashing

Orange solid

Alternate orange & red.

System healthy

1S30Arc Sensor 2 or 3 service

1S30Arc Sensor 1 service

1S30Arc Sensor continuous pick up

Flash green 3 times1S30 Power up test OK

Arc fault trip

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

1: ARC SENSOR 2

2: LATCHING TRIP LED

3: INDEPENDENTARC TRIP

4: LATCHING TRIP CONTACTS

5: ARC SENSOR 3

www.rmspl.com.au

rms

8

Technical Data

1S20

Auxiliary Supply

Low Range Version

Order Code F

Nominal dc Voltage Supply

24 / 32 / 48

Standards Compliant Range

(Shown on relay

rating plate

)

19

-85V dc

19

-65V ac

Absolute Range

18-100V dc

15-75V ac

Mid-Range Version

Order Code G

Nominal dc Voltage Supplies

110 / 125

Standards Compliant Range

(Shown on relay

rating plate

)

45

-165V dc

38

-150V ac

Absolute Range

36-200V dc

30-175V ac

High Range Version

Order Code H

Nominal dc Voltage Supplies

220 / 240 / 250

Standards Compliant Range

(Shown on relay

rating plate

)

125

-250V dc

94

-240V ac

Absolute Range

100

-300V dc

75

-275V ac

Allowable breaks/dips in

supply (Collapse to zero)

As per IEC60255

-26 *7.2.11

Burden - Quiescent

8W at 110V dc

Burden - Maximum

15W at 110V dc

Output

Contacts

Operating Voltage

Voltage free

Operating Mode

Self-reset

Trip Contact Operate Time

<10ms (Flash to contact closure)

Reset Time

2s (Self reset setting)

Making Capacity

Carry Continuously

5A ac or dc

Make and Carry

L/R

≤ 40ms and ≤ 300V

20A ac or dc for 0.5s

30A ac or dc for 0.2s

Breaking Capacity

L/R ≤ 40ms and ≤ 300V

AC Resistive

1,250VA

AC Inductive

250VA at p.f. ≤ 0.4

DC Resistive

75W

DC Inductive

30W at L/R ≤ 40ms

50W at L/R ≤ 10ms

Minimum Load

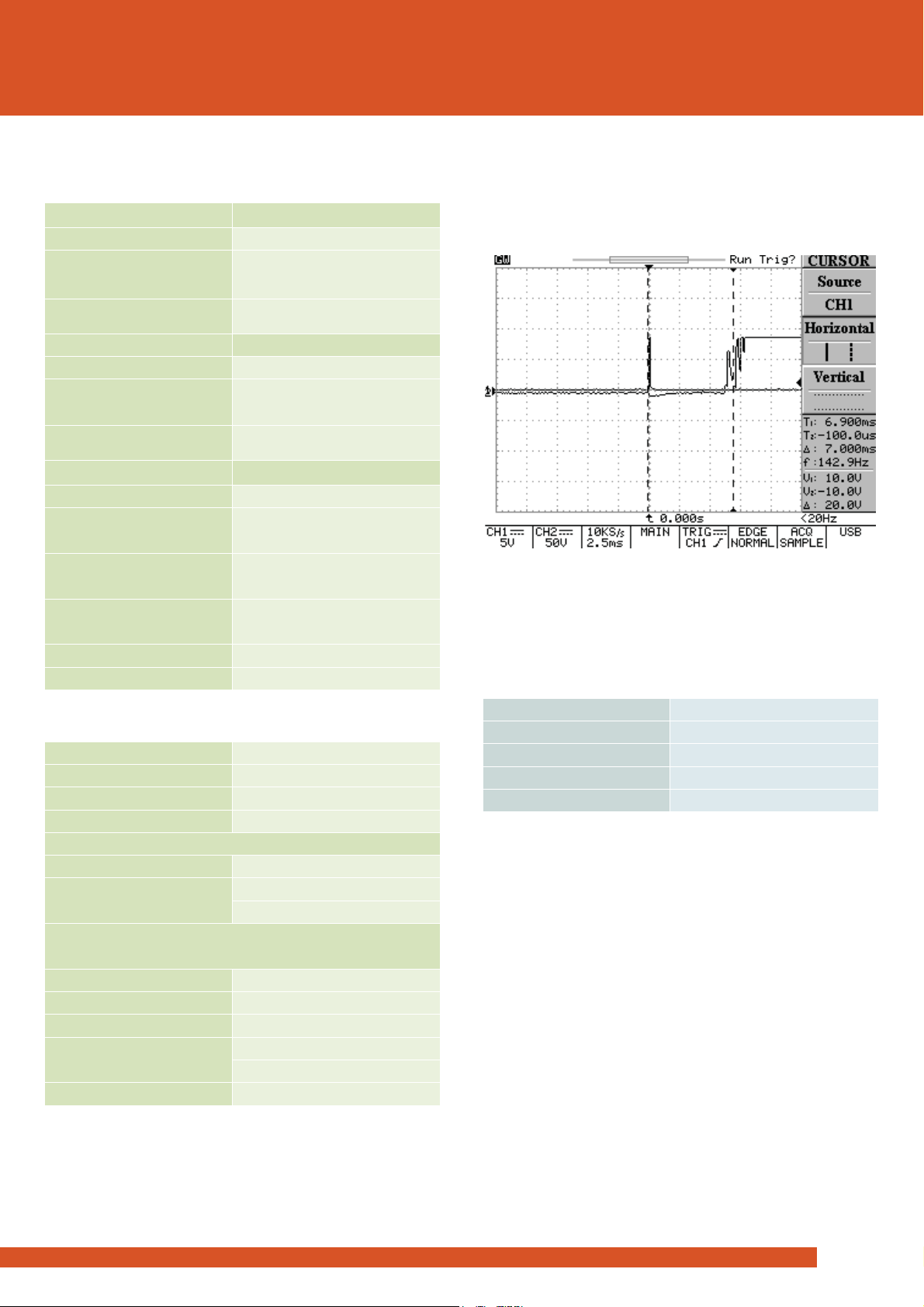

100mA ≥12V

Operating Time

Arc fault trip contacts guaranteed to pick up in less than 10ms

including bounce. Typical operate time is 7ms.

CRO trace showing nominal operation time of the trip contacts at

7ms. First contact touch at 6.25ms and fully closed by 7.25ms.

Operation in <10ms is considered acceptable as current check

relay operate time is ~15ms.

Arc Fault Point Sensor Inputs

Number

2 or 3

Type

1S30 point sensors

Connection

Electrical termination

Zones

1 or 2

Supervision duration

Continuous

Minimum Arc Duration

The minimum arc “flash” duration required to guarantee

operation of the output contacts is

2.2ms.

Trip Contact Reset Time

Once operated the trip output contacts reset as per the

configuration switch 4 setting

.

Manual Reset

Press

front button or interrupt power supply to reset LED’s.

Case

ZA12 flush or DIN rail mount type

12 M4 screw terminals

Plug in module to facilitate easy wiring & fast changeover

www.rmspl.com.au

rms

9

Compliance Data

1S20

ELECTRICAL ENVIRONMENT

AC and DC Voltage Dips

Standard

IEC 60255-26, #7.2.11

Test Level

Test specification

Dip to 0% of residual voltage

Acceptance criterion A

DC: 20 ms

AC: 1 cycle 50/60 Hz

Dip to 40% of residual voltage

Acceptance criterion C

DC: 200 ms

AC: 10/12 cycles 50/60 Hz

Dip to 70% of residual voltage

Acceptance criterion C

DC: 500 ms

AC: 25/30 cycles 50/60 Hz

AC and DC Voltage Interruptions

Standard

IEC 60255-26, #7.2.11

Acceptance criterion C

Test Level

Test specification

Drop to 0% of residual voltage

DC: 5 s

AC: 250/300 cycles 50/60 Hz

AC Component in DC (Ripple)

Standard

IEC 60255-26, #7.2.12

Acceptance criterion A

Test Level

Test specification

15% of rated DC value

100/120 Hz, Sinusoidal

Gradual Shut

-down/Start-

up (DC Power Supply)

Standard

IEC 60255-26, #7.2.13

Acceptance criterion C

Test Identification

Test specification

Shut-down ramp

60 s

Power off

5 min

Start-up ramp

60 s

Clearances and Creepage Distances

Standard

IEC 60255-26, #10.6.3

Test Identification

Test specification

Pollution degree

2

Overvoltage category

III

Rated insulation voltage

300 V rms or dc

Clearances and Creepage

Compliance

CAD drawings assessment

Safety

-related Electrical Tests

Standard

IEC 60255-27, #10.6.4

Test Identification

Test specification

Between Independent Circuits

5 kV 1.2/50 μs 0.5 J

3 pulses of each polarity

2.0 kV ac rms for 1 minute

Any Terminal and Earth

5 kV 1.2/50 μs 0.5 J

3 pulses of each polarity

2.0 kV ac rms for 1 minute

Across Normally Open Contacts

1 kV ac rms for 1 min

Electrical Environment and Flammability

Standard

IEC 60255-27, #10.6.5

Test Identification

Test specification

Single-fault condition

Assessment

Maximum temperature of

accessible

parts at ambient

temperature +40°C

Metal parts: < 70°C

Non

-metallic parts: < 80°C

Flammability of insulating

materials, components and fire enc

Assessment

Reverse Polarity and Slow Ramp Test

Standard

IEC 60255-27, #10.6.6

Test Identification

Test specification

Maximum voltage dc

V start-up + 20%

Minimum voltage dc

V shutdown - 20%

Ramp down/up gradient

1 V/min

www.rmspl.com.au

rms

10

Compliance Data

1S20

ATMOSPHERIC

ENVIRONMENT

Temperature

Standard

IEC 60068-2-1, IEC 60068-2-2

Test Identification

Test specification

Auxiliary power

Supply voltage

Operating Range

-10 to +55°C

Min and Max

Storage Range

-25 to +70°C

Non-energized

Test duration

16 h at top and bottom temperatures

Damp Heat (Humidity)

Standard

IEC 680068-2-78

Test Identification

Test specification

Operating Range

40°C and 93% RH non condensing

Test duration

16 h

IP Rating

Standard

IEC 60529

Test Identification

Test specification

Installed

IP4x

MECHANICAL ENVIRONMENT

Vibration

- Sinusoidal

Standard

IEC 60255-21-1 Class 1

Test Identification

Test specification

Variation

Vibration Response

in each of 3 axes

0.035 mm/0.5 gn peak

1 sweep cycle 10-150 Hz

No Mal

-Op

Vibration Endurance

in each of 3 axes

1.0 gn peak

20 sweep cycles

10-150 Hz

Non

-

energized

Shock and Bump

Standard

IEC 60255-21-2 Class 1

Test Identification

Test specification

Variation

Shock Response

in each of 3 axes

5 gn, 11 ms, 3 pulses

in each direction

No Mal

-Op

Shock Withstand

in each of 3 axes

15 gn, 11 ms, 3 pulses

in each direction

Non-

energized

Bump Test

in each of 3 axes

10 gn, 16 ms, 1,000

bumps in each direction

Non-

energized

Seismic

Standard

IEC 60255-21-3 Class 1

Test Identification

Test specification

Variation

Seismic Response

Horizontal, on each axis

3.5 mm/1.0 gn,

1 sweep cycle 1-35Hz

No Mal

-Op

Seismic Response

Vertical

1.5 mm/0.5 gn,

1 sweep cycle 1-35Hz

No Mal

-Op

www.rmspl.com.au

rms

11

Compliance Data

1S20

ELECTROMAGNETIC COMPATIBILITY (EMC)

IMMUNITY

Electrostatic Discharge (ESD)

Standard

IEC 60255-26, #7.2.3, Acceptance criterion B

Port

Enclosure

Test Identification

Test specification

Variation

Air Discharge

8 kV

No Mal-Op

Radiated Electromagnetic Field

Standard

IEC 60255-26, #7.2.4, Acceptance criterion A

Port

Enclosure

Test Identification

Test specification

Variation

Frequency sweep

10 V rms, 80 to 1000 MHz

1400 to 2700 MHz

No Mal

-Op

Spot frequencies

10 V rms, 80, 160, 380,

450, 900, 1850 & 2150 MHz

No Mal

-Op

Fast Transients (EFT)

Standard

IEC 60255-26, #7.2.5, Acceptance criterion B

Port

Auxiliary power supply, Input and Output,

Functional Earth

Test level

Test specification

Variation

Zone A

4 kV peak, 5/50 ns, 5 kHz

No Mal-Op

Slow Damped Oscillatory Wave (HFD)

Standard

IEC 60255-26, #7.2.6, Acceptance criterion B

Port

Auxiliary power supply, Input and Output

Test Identification

Test specification

Variation

Common Mode

1 MHz 2.5 kV peak

No Mal-Op

Differential Mode

1 MHz 1.0 kV peak

No Mal-Op

Surge

Standard

IEC 60255-26, #7.2.7, Acceptance criterion B

Port

Auxiliary power supply, Input and Output

Test Identification

Test specification

Variation

Line-to-earth

4 kV peak

No Mal-Op

Line-to-line

2 kV peak

No Mal-Op

Conducted Disturbance Induced by RF Fields

Standard

IEC 60255-26, #7.2.8, Acceptance criterion A

Port

Auxiliary power supply, Input and Output,

Functional Earth

Test Identification

Test specification

Variation

Frequency sweep

10 V rms, 0.15 to 80 MHz

No Mal-Op

Spot frequencies

10 V rms, 27 & 68 MHz

No Mal-Op

Power Frequency Magnetic Field

Standard

IEC 60255-26, #7.2.10

Port

Enclosure only

Test Identification

Test specification

Continuous ≥ 60 s

30 A/m - Acceptance criterion A

Short time 1 s to 3 s

300 A/m - Acceptance criterion B

EMISSION

Emission Enclosure

Standard

IEC 60255-26, #5.1

Test Identification

Frequency range

Limits, dB (μV/m)

Radiated emission

<1 GHz

30

- 230 MHz

40, quasi peak at 10 m

50, quasi peak at 3 m

230

-

1000 MHz

47, quasi peak at 10 m

57, quasi peak at 3 m

Radiated emission

>1 GHz

1

– 3 GHz

56, average

76, peak at 3 m

3

– 6 GHz

60, average

80, peak at 3 m

Emission Auxiliary Power Supply Port

Standard

IEC 60255-26, #5.2

Test Identification

Frequency range

Limits, dB (μV/m)

Conducted emission

0.15

–

0.50 MHz

79, quasi peak

66, average

0.5

- 30 MHz

73, quasi peak

60, average

www.rmspl.com.au

rms

12

Wiring

1S20

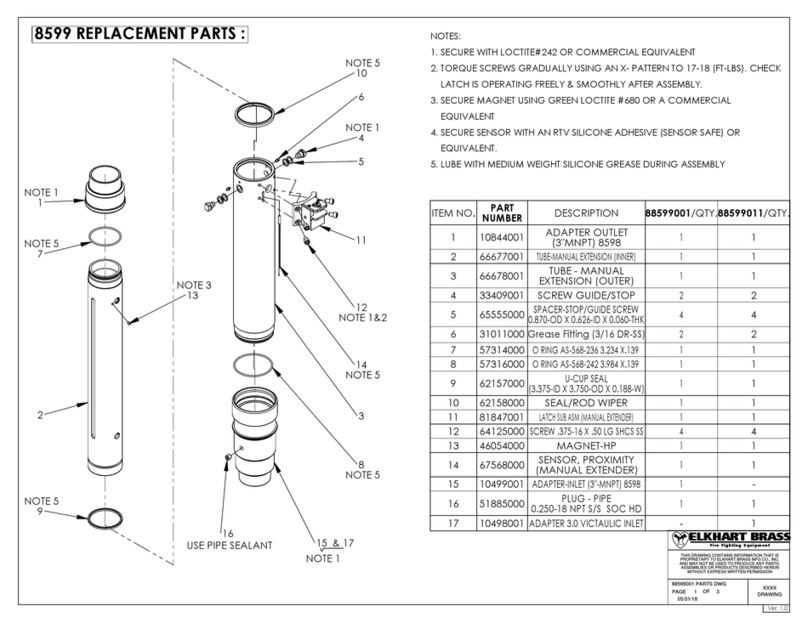

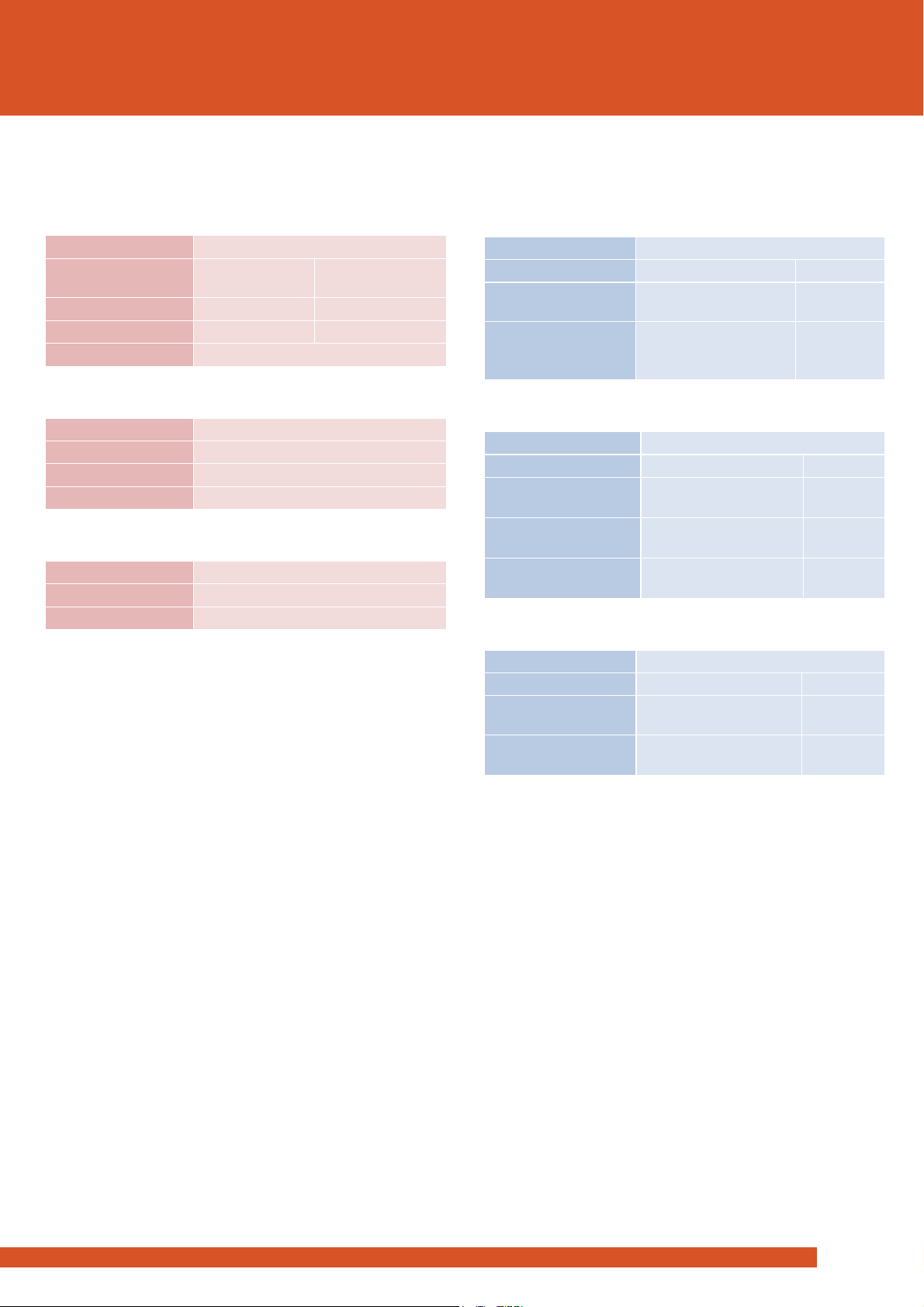

1S20 Wiring Diagrams

Figure 12: 1S20 Socket Terminal Layout viewed from the front when un-

plugged from the main housing.

Note: * Always wire Arc Sensor 1. Arc Sensors 2 & 3 are optional

1S20 application diagram - Circuits shown in de-energised condition

12

8

10

9

9

5

1

3

11

6

2

4

Vx

+

+

-

-

Fail

alarm

Arc 1

(Must b ewire d)

Arc3 Arc2

Arc fault trip alarm signal to

protection relay status input for comms.

I>start

Control

Protection

1S20

50/51

Overcurrent

relay

Arc fault

relay

I>

CBAux Switch Trip Coil

52

T

52 - a

www.rmspl.com.au

rms

13

1S20

Mounting and Dimensions

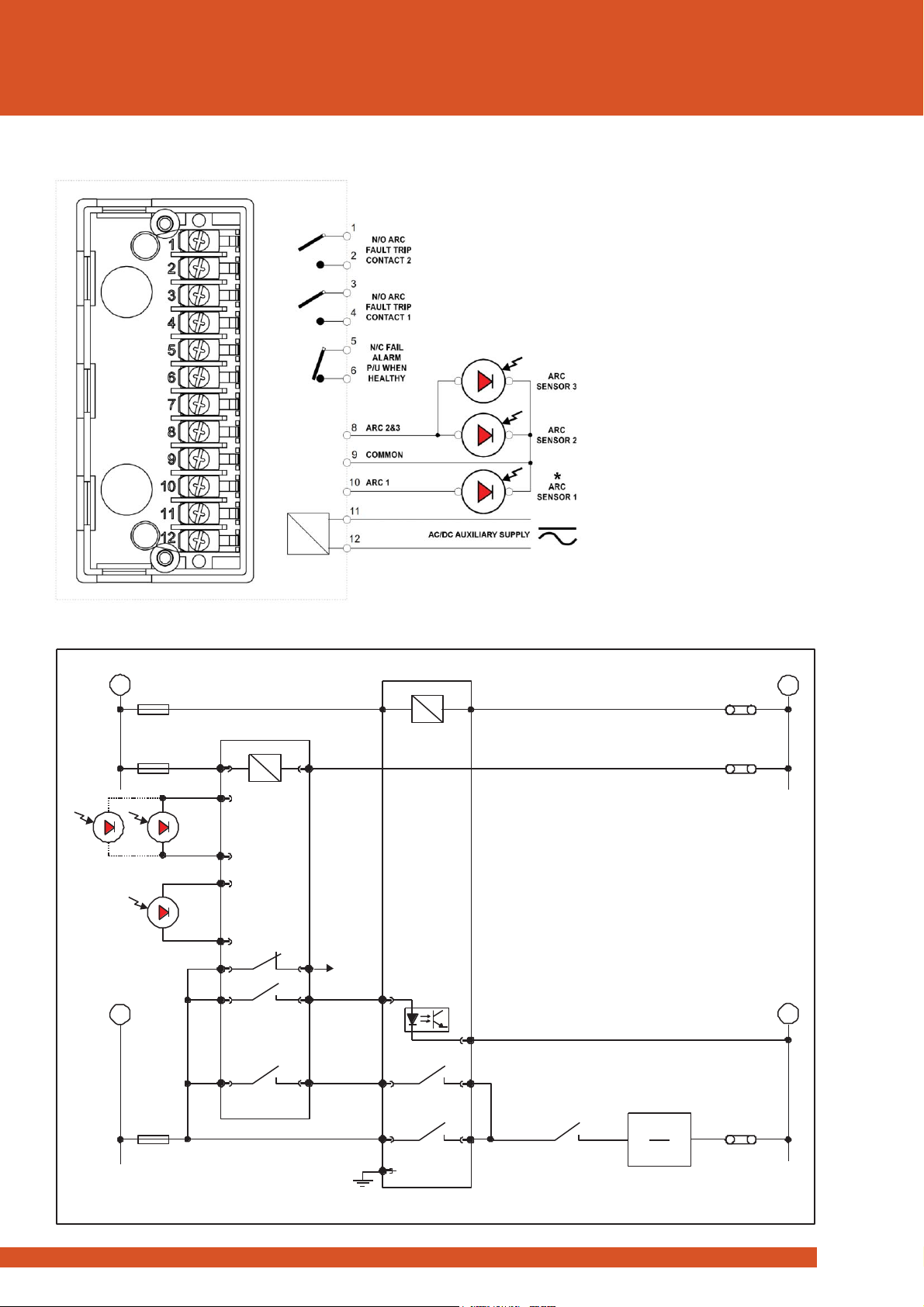

Mounting Options

The 1S20 is available in two versions:

1. A surface mount version which has a separate reset button

& LED indicator on the front panel. The advantage of this

version is the lower cost &

where front panel space in

limited.

2. A panel mount version which has a combined reset button &

LED indication. The advantage of this version is that it can be

either panel or surface mounted.

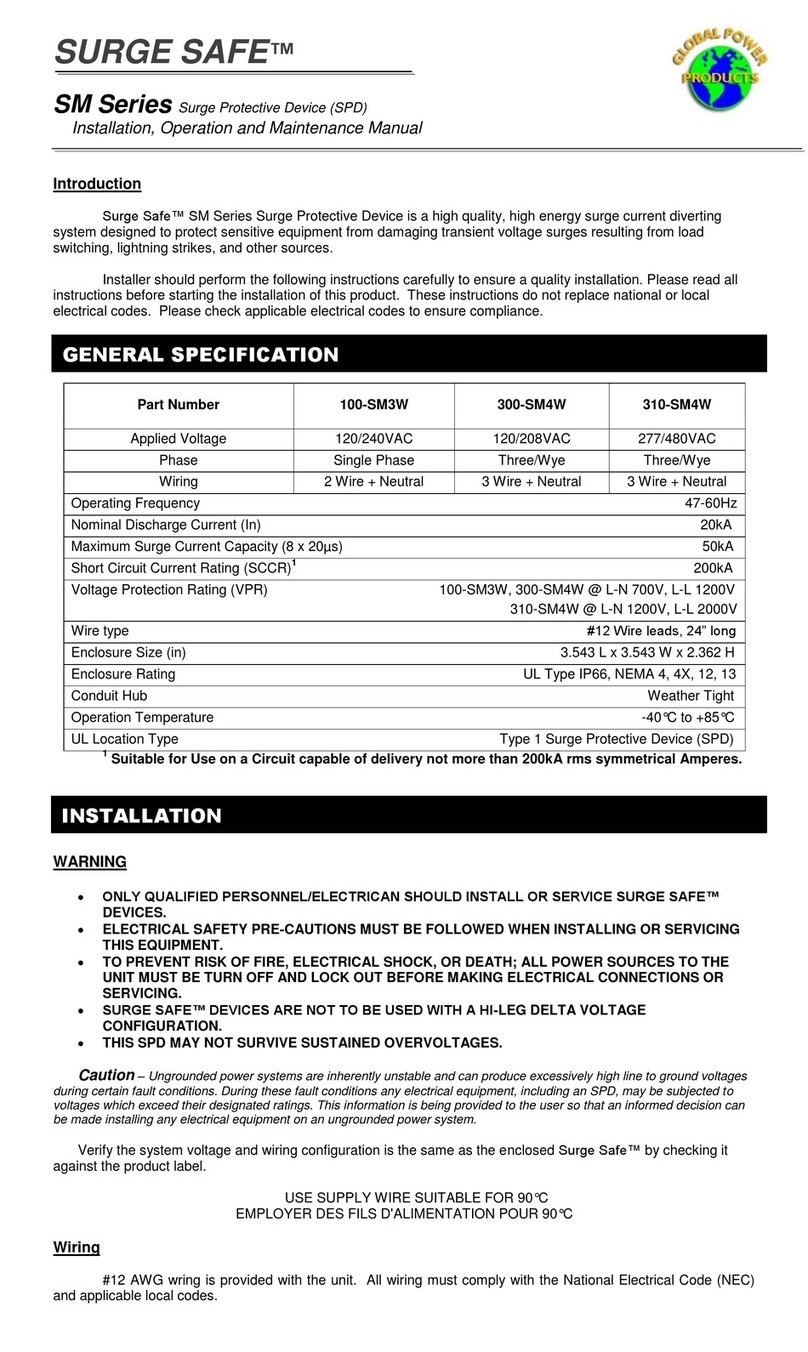

Surface Mount Version

This version is suitable for location in

the rear of a cubicle. It may

be surface mounted as shown in figures 13, 14 and 18. It may

also be DIN rail mounting when the optional 290407157 DIN Rail

Mounting Kit is fitted. Refer figures 21 and 22.

Figure 13: 1S20 surface mount versi

on front panel

Figure 14

: Surface mount version side view

Panel

Mount Version

This version is suitable for mounting on the front panel of a

cubicle or door. This is achieved using a 31mm diameter hole in

the panel adjacent to the protection relay as depicted in figures

15, 16 and 17.

This version may also be surface mounted by reversing the

terminal block retaining screws. It may also be DIN rail mounting

when the optional 290407157 DIN Rail Mounting Kit is fitted.

Refer figures 19 and 22.

Figure 15: 1S20 through hole panel mount version

Figure 16

: Panel mount version side view

SERIAL NO. &

RATING LABEL

ON MODULE SIDE

FOR PANEL

MOUNT VERSION

REMOVE FOR

REAR CABLE

ENTRY OPTION

REMOVE FOR

TWO M4 OR 4BA

MOUNTING SCREWS

TOP & BOTTOM REAR

TERMINAL BLOCK

RETAINING SCREWS

S

LIDE

O

UT

C

ABLE

ENTRY POINTS

3 ON ONE SIDE

1 AT EACH END

1S20K2 (CAB)

AUX:36-150V DC S/N:123456

Use double sided tape supplied

Top & bottom positions

RELAY PANEL

3mm THICK

MAXIMIUM

FRONT PANEL

LABEL

(Supplied with module)

SLIDE OUT CABLE

ENTRY POINTS

3 ON ONE SIDE

1 AT EACH END

TOP & BOTTOM REAR

TERMINAL BLOCK

RETAINING SCREWS

THESE MAY BE

UNSCREWED &

REVERSED TO FIT

FROM THE FRONT OF

THE 1S20 MODULE TO

ALLOW SURFACE

MOUNTING

RETENTION

SHROUD

1S20 Arc Fault Monitor

RESET / TEST

System Functioning

Arc Fault Trip

Sensor 1 Service

Sensor 2 or 3 Service

Continuous Sensor P/U

DC Supply Fail

GREEN:

RED:

ORANGE SOLID:

ORANGE FLASH:

ORANGE / RED:

NONE:

www.rmspl.com.au

rms

14

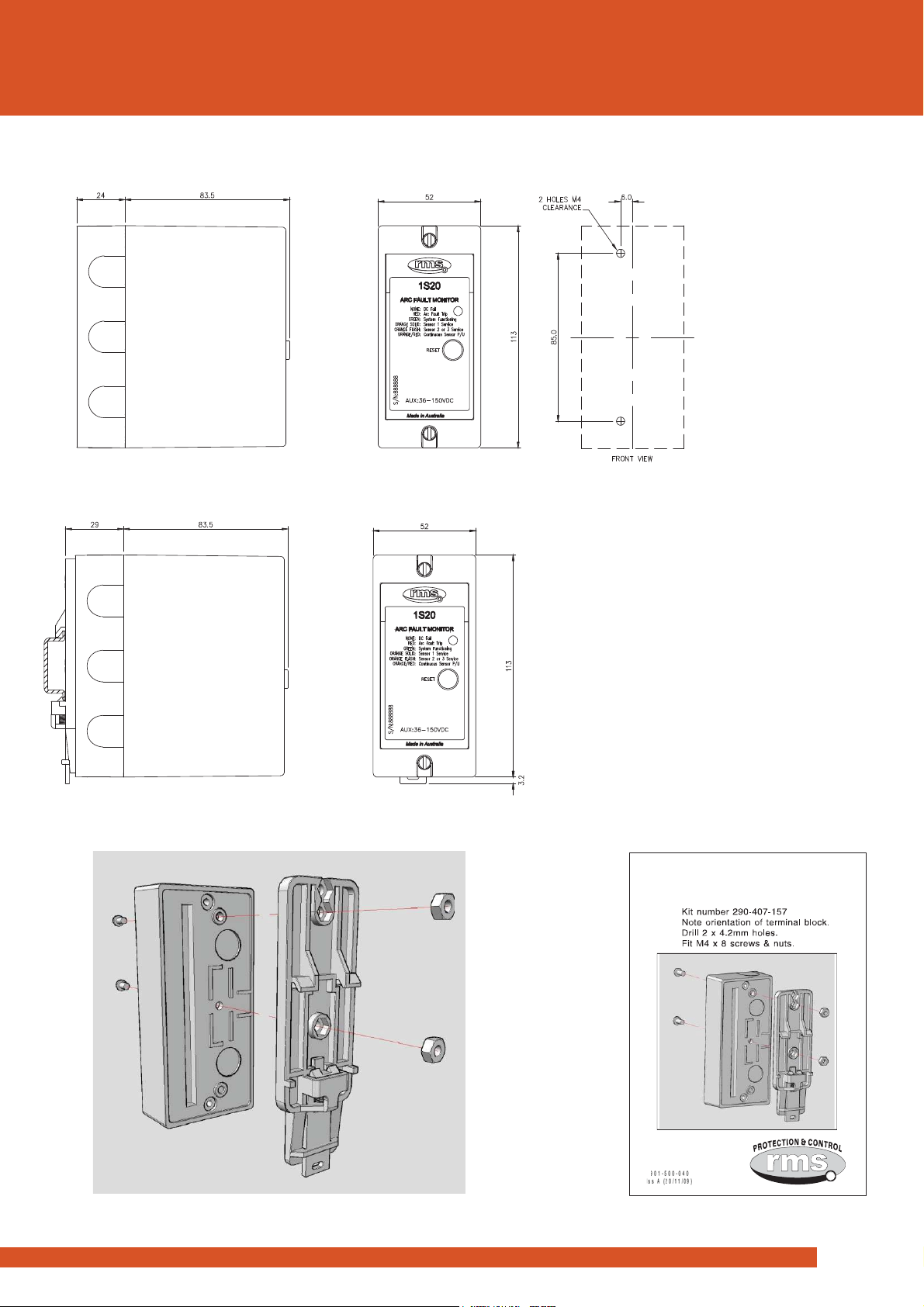

1S20

Mounting and Dimensions

Panel Mount Version

Figure 17: Panel mounting cut out detail

Figure 18: Surface mounting

detail

Figure 19: DIN rail mounting detail

1S20

15

Mounting and Dimensions

rms

Surface Mount Version

Figure 20: Surface mounting detail

Figure 21: DIN rail mounting detail

Figure 22: DIN rail clip fitting detail –

Specify DIN Rail Mounting Kit P/N 290407157

DIN RAIL

MOUNTING KIT

16

rms

Order Codes

1S20

1S20 -

Auxiliary Supply

F

19-85 V DC or 19-65V AC

G

45-165 V DC or 38-150V AC

H

125-250V DC or 95-240 V AC

Mounting

A

Panel mount or surface mount

B

Surface mount only

C

As per A with DIN rail kit supplied

D

As per B with DIN rail kit supplied

Sensors

A

Two arc sensor inputs (Default)

B

Three arc sensor inputs

1S20 Relay

Order Codes

Auxiliary Supply Order Code Change Guide

Old

Applied Auxiliary Voltage

New

1S20-Axx

1S20-

Axx *

1S20-

Axx *

24/32/48V DC

110V AC

230/240/250V AC

1S20-Fxx

1S20-Gxx #

1S20-Hxx

#

1S20-Cxx

110/125V DC

1S20-Gxx

1S20-Dxx

220/240/250V DC

1S20-Hxx

1S20-Exx *

110V AC

1S20-Gxx #

* When used with AC/DC power supply adaptor

# Direct connection to AC auxiliary supply

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S30/Issue I/03/05/16 - 1/5

Features

Compact rugged design

One or two optical detectors

High speed arc detection

Heavy duty 6m termination

cable

Optional 20m & screened

cables

Simple flush panel mounting

outside or inside switchgear

compartment

Integrated sensor circuit

supervision

Very low sensitivity to ambient

light levels to avoid nuisance

tripping even in direct sunlight

Sealed module for harsh

environments

Optional metal reinforced

mounting shield

Application

Arc fault protection is a relatively new

technique employed for the fast clearance

of arcing faults on BUS bars & within

metal clad switchgear & associated cable

boxes. The arc is detected using an

optical sensor & the signal input to a

protection device which also monitors the

load current on the system. A trip signal

can be achieved in less than 10ms using

arc detection.

RMS manufactures a protection class arc

fault optical sensor & monitoring system

suitable for both low & medium voltage

switchgear and BUS bar applications.

1S20 3 sensor, 2 zone Arc Fault Monitor

1S25 8 sensor, 4 zone Arc Fault Monitor

1S26 1S25 with integrated current check

1S30 Optical Arc Fault Sensor

While the high intensity flash caused by

an electrical arc will be reflected within the

metal clad switchgear, it is recommended

that one or more sensors be mounted in

each enclosed switchgear compartment.

For BUS bar protection applications

multiple sensors are required to achieve

adequate coverage along the length of the

BUS. A sensor version with two optical

detectors “looking” in opposite directions

is available for this purpose (Refer figure 3

for generic layout).

Technical Bulletin 1S3

0

Optical Arc Fault Sensor

1S30 Arc Fault Sensors

Through panel mounting detector Front panel view of dual detector

View depicted at left version depicted at right

Description Made in Australia

The 1S30 is an optical sensor that responds to the flash of light emitted during the

incidence of an arcing fault. Onset of the light flash & detection by the 1S30 occurs in a

few ms.

Each arc fault sensor consists of one or two silicon PIN photo diode light detectors

mounted on a circuit board together with the associated detection circuit (Figures 1 & 2).

The detector monitors a wide space angle. A broad spectral response in the visible region

is provided as depicted in figure 5.

Sensitivity of the arc sensor has been set to a low level to reduce the possibility of mal

operation under high ambient lighting conditions. This is made possible due the high

intensity of light emitted under arc fault conditions. Additional security can be incorporated

by way of a current check stage as described in the 1S20 Arc Fault Monitor Technical

Bulletin.

In stand by mode the 1S30 sensor presents a high resistance to the 12V DC control signal

provided by the 1S20, 1S25 or 1S26 Arc Fault Monitors. This allows a small circulating

current to flow for continuous supervision of the 1S30 connection circuit. When an arc is

detected, the resistance presented by the 1S30 drops to a level where the current flow

increases to approximately 20mA. This increased current flow is instantaneously detected

by the Arc Fault Monitor & its trip output contacts closed. Refer to the 1S20 Arc Fault

Monitor Technical Bulletin for further details.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S30/Issue I/03/05/16 - 2/5

SINGLE DETECTOR PACKAGE

Figure 1 depicts the 1S30 with a single optical detector. Note the

window where the active part of the detector is positioned to. This

permits convenient mounting on the outside of the panel with the

detector window protruding a hole in the panel.

Figure 1:

DUAL DETECTOR PACKAGE

Figure 2 depicts the 1S30 with dual optical detectors. The two

optical detectors face in opposite directions to provide arc

detection coverage in both directions. This version is particularly

useful when mounted in a BUS chamber or barrier between

adjacent switchgear chambers. The main benefits are reduced

cost compared to two separate sensors & use of only one input

channel on the 1S20 Arc Fault Monitor.

Figure 2:

DETECTOR RANGE

A detection range along the 100% relative sensitivity curve

shown in figure 3 is approximately 3m. Single detector versions

therefore need to be placed at a maximum spacing of 5-6m. The

dual detector versions may be placed at a maximum spacing of

5-6m to provide adequate detection overlap. In switchgear the

light caused by the arc is reflected from the walls & therefore, the

mounting of the sensor is not critical.

While the high intensity flash caused by an electrical arc will be

reflected within the metal clad switchgear, it is recommended that

one or more sensors be mounted in each enclosed switchgear

compartment.

Figure 3:

Detector Characteristics

OPTICAL SENSITIVITY

~10,000 Lux* for white light at normal incidence to the detector

window(s) as depicted in figure 4:

Rear

Detector

1S30 [B]

models only

Light

Source

Front

Detector

1S30 [A] & [B]

models

Light

Source

Figure 4:

For the 1S30-A single detector version the front detector only is

fitted. In this configuration the 1S30-A will be insensitive to white

light incident on the rear surface of the case up to a level of

200,000 Lux.

As the illuminace of diffuse ambient sunlight falls in the range

5,000 to 10,000 Lux, this will not normally be sufficient to trigger

the 1S30 sensor. The luminous intensity from the sun at noon at

the equator however is ~100,000 Lux which will be sufficient to

trigger the 1S30 sensor so measures should be made to avoid

this situation.

Direct sunlight incident on the rear of the 1S30-A model sensor

will not cause it to pick up. This attribute provides a significant

safety margin to avoid nuisance tripping when the option of

mounting the sensor externally on switchgear as depicted in

figure 6 is employed.

DETECTOR DIRECTIONAL CHARACTERISTICS

Detector sensitivity falls to ~40% of the nominal level at

inclination angles up to 70 degrees from the normal for white

light.

DETECTOR SPECTRAL RESPONSE

50%

60%

70%

80%

90%

100%

600 700 800 900 1,000 1,100 1,200

Wavlength (nm)

Relative Sensitivity

Figure 5:

Arc detector spectral response

* Due to the relatively high sensitivity of the detector to IR

wavelengths the type of light source employed for sensitivity

testing will have a major effect on the results obtained.

Sensitivity testing should therefore be conducted using a 50-75W

halogen lamp with an integrated aluminum reflector.

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S30/Issue I/03/05/16 - 3/5

FLUSH PANEL MOUNTING

The 1S30 is suitable for flush panel mounting in a number of

configurations.

Figure 6:

1S30 shown mounted on the outside of a switchgear panel

Detector oriented to ‘look’ through a hole into the switchgear

Figure 7:

1S30 shown mounted on the inside of a switchgear panel

Detector oriented to ‘look’ out into the switchgear compartment

FLUSH MOUNT REINFORCING PLATE

When mounting the 1S30 on the outside of a switchgear cubicle

as depicted in figure 6, the hole required in the panel may

degrade the short circuit rating. If this is considered to be an

issue then a reinforcing plate may be fitted over the 1S30 as

depicted below.

Figure 8:

Flush mount reinforcing plate

1.2mm zinc plated mild steel

Mounting

Options

DUAL DETECTOR VERSION

The dual detector version can be panel mounted to monitor two

adjacent switchgear compartments simultaneously. This feature

can be used to reduce the total cost for sensors or to increase

the monitoring coverage for each 1S20 Arc Fault Monitor unit.

Figure 9:

1S30 shown mounted on the inside of a switchgear panel

This configuration combines the functions described in

Figures 6 & 7 with the application of a single

dual detector arc fault sensor

PANEL MOUNT CUT OUT DETAIL

Figure 10:

Flush mounting detail

RIGHT ANGLE MOUNTING OFF A SURFACE

A right angle mounting bracket may be fabricated using the panel

cut out detail in figure 10. Single & dual detector models may be

mounted in this manner as depicted below.

Figure 11:

Right angle mounting off a surface

Mount off floor or walls within switchgear / BUS bar chamber

Switchgear

panel

2 x M4

self threading

mounting screws

(Supplied)

Sealed cable

stress relief

Optical detector

protruding through

hole in panel

2 x M4

self threading

mounting screws

(Supplied)

Optical detector

facing away

from panel

2 x M4

self threading

mounting screws

(Supplied)

Flush mount

reinforcing

plate

Internal partition

between switchgear

compartments

Optical detector

protruding through

compartment divider

into adjacent

switchgear chamber

Optical detector

window facing away

from compartment

divider

Hole in panel

to allow detector

to ‘look’ into

switchgear

chamber

Right angle

mounting

bracket

Optical detector

window facing away

from right angle

mounting bracket

Single

optical detector Dual

optical detector

Due to RMS continuous product improvement policy this information is subject to change without notice. 1S30/Issue I/03/05/16 - 4/5

ARC FAULT PROTECTION SCHEME

Refer to the 1S20 Technical Bulletin for further details.

Type:1S20K1 [C] Vx: 48V DC

Serial No: 126578

1S20 Arc Fault Mo nitor

ARC FAULT TRIP INITIATE

CB ARC FAULT

MONITORSENSOR

OVER-CURRENT RELAY

3 Pole OC + EF

RESET / TEST

System Functioning

Arc Fault Trip

System Service

DC Fail

GREEN:

RED:

ORANGE:

DARK:

Figure 12:

Key components required to implement an Arc Fault Protection

scheme with an overcurrent check stage

to enhance system security

ARC PROTECTION SCHEME OPERATE TIME

The total time required for detection of the arc flash to closure of

the 1S20 Arc Fault Monitor trip contacts is less than 10ms

including bounce. Typical operate time is 7 to 8ms.

Figure 13:

CRO trace showing nominal operation time of the trip contacts at

7ms. First contact touch at 6.25ms and fully closed by 7.25ms.

Operation in <10ms is considered acceptable as current check

relay operate time is ~15ms.

MINIMUM ARC DURATION

The minimum arc “flash” duration required to guarantee operation

of the Arc Fault Monitors output contacts is 1.25ms.

AUXILIARY SUPPLY

Voltage from 1S20 Arc Fault Monitor: 12V DC

Power consumption: <2.5mA

CASING

Rugged moulded construction to IP51.

TEMPERATURE RANGE

Operating: -5 to +55oC

Storage: -25 to +75oC

Technical Data

SENSOR CONNECTIONS

The 1S30 is supplied with a 6m two core connection cable as

standard. Two core multi strand wire (2x16/0.2mm), is supplied

stripped & pre tinned at the 1S20 connection end. The standard

6m cable may be cut down to the desired length & crimp ring lugs

fitted for termination to the 1S20, 1S25 or 1S26 Arc Fault

Monitors.

The 1S30 connections are not polarity sensitive. Reversal of the

wires on the arc monitor terminals has no effect on the

performance of the 1S30 or arc detection system.

The cable is factory fitted to the 1S30 Arc Fault Sensor using a

stress relief molding to provide a sealed & durable connection

interface. The cable employs thick inner & outer insulation layers

to avoid damage during installation.

For connection over longer distances shielded cable is

recommended. For distances over 20m, 24/0.2 mm cable should

be employed.

ADDITIONAL 1S30 CABLE LENGTH

Screened arc sensor cables may be increased by wiring

additional series twisted pair SCREENED cable provided it does

not exceed 5 ohms and 30nF loop impedance.

ARC SENSOR SHIELD WIRE EARTH CONNECTION

The arc sensor shield wire(s) should be connected to ground as

detailed in figures 14 to 16.

Figure 14: 1S20 DIN rail mount earth connection detail

Figure 15: 1S20 panel mount earth connection detail

Figure 16: M Series case type earth connection detail

DIRECT MOUNTED EARTH (EK10/35)

TERMINAL

Table of contents

Other RMS Protection Device manuals

Popular Protection Device manuals by other brands

Europapa

Europapa 511220005 instructions

Watershed Innovations

Watershed Innovations HydraBarrier Titan instructions

Global Power Products

Global Power Products SURGE SAFE SM Series Installation, operation and maintenance manual

ABB

ABB Relion REG670 Commissioning manual

Dräger

Dräger CPS 6900 Instructions for use

Honeywell

Honeywell SYNC WIRELESS EARMUFF User instructions