RMS 2V164-S User manual

2V164-S User Guide

Voltage Regulating & Control Relay

relay monitoring systems pty ltd

Advanced Protection Devices

User Guide

Test Manual

Relay Software

µ

MATRIXwin

2V164-S

User Guide

About This Manual

This User Guide covers all 2V164-S relays manufactured from April 2009. Earlier relays do not

necessarily incorporate all the features described. Our policy of continuous may means that extra

features & functionality may have been added.

The 2V164-S User Guide is designed as a generic document to describe the common operating

parameters for all relays built on this platform. Some relay applications are described but for specific

model information the individual “K” number Product / Test manuals should be consulted.

The copyright and other intellectual property rights in this document, and in any model or article produced

from it (and including any Registered or unregistered design rights) are the property of Relay Monitoring

Systems Pty Ltd. No part of this document shall be reproduced or modified or stored in another form, in any

data retrieval system, without the permission of Relay Monitoring Systems Pty Ltd, nor shall any model or

article be reproduced from this document without consent from Relay Monitoring Systems Pty Ltd.

While the information and guidance given in this document is believed to be correct, no liability shall be

accepted for any loss or damage caused by any error or omission, whether such error or omission is the

result of negligence or any other cause. Any and all such liability is disclaimed.

Contact Us

©Relay Monitoring Systems Pty Ltd 2001-2009

6 Anzed Court • Mulgrave 3170 • AUSTRALIA

Phone 61 3 9561 0266 • Fax 61 3 9561 0277

Email [email protected] • Web www.rmspl.com.au

To download a PDF version of this guide:

http://www.rmspl.com.au/userguide/2v164-s_user_guide.pdf

To download the model specific Test Manual:

http://www.rmspl.com.au/search.asp

How this guide is organised

This guide is divided into five parts:

Part 1 Overview

About this Manual

Contents

Test Manual

Mechanical Configuration

Description of Operation

L

ine Drop Compensation

Part 2 Technical Bulletin

Part 3 Software Function

Compatible Software

Factory Default Software

Determining Software UMX

Determining UMX Functionality

User Interface

Field Calibration

Part 4 Installation

Handling of Electronic Equipment

Safety

Unpacking

Accessories

Storage & Handling

Recommended Mounting Position

Relay Dimensions & Other Mounting Accessories

Equipment Connections

Part 5 Maintenance

Mechanical Inspection

Test Intervals

Defect Report Form

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Part

1

Test Manual

This User Guide covers all 2V164-S relay versions & describes the generic features & attributes

common across all versions.

Different relay versions are required to cater for varying customer requirements such as auxiliary

voltage range, I/O configuration, case style, relay functionality etc.

The product ordering code described in the Technical Bulletin is used to generate a unique

version of the relay specification & is called a type number. The type number takes the form

2V164-SKxx where the Kxx is the “K” or version number.

Refer to: www.rmspl.com.au/handbook/parta3.pdf

for a complete description of the RMS “K” number system.

Each 2V164-S version has a specific Test Manual which provides details on the unique attributes

of the relay. Each Test Manual includes the following information:

•Test Certificate

•Specific technical variations from the standard model if applicable

•Test & calibration record

A Test Manual is provided with each relay shipped.

A CD & serial comms. cable is supplied with each relay order.

If you require a copy of the Test Manual for an RMS product the following options are available:

•Check the RMS web site at: www.rmspl.com.au/search.asp

•RMS CD catalogue select: List all Product/Test Manuals under Technical Library

•Contact RMS or a representative & request a hard copy or PDF by email.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

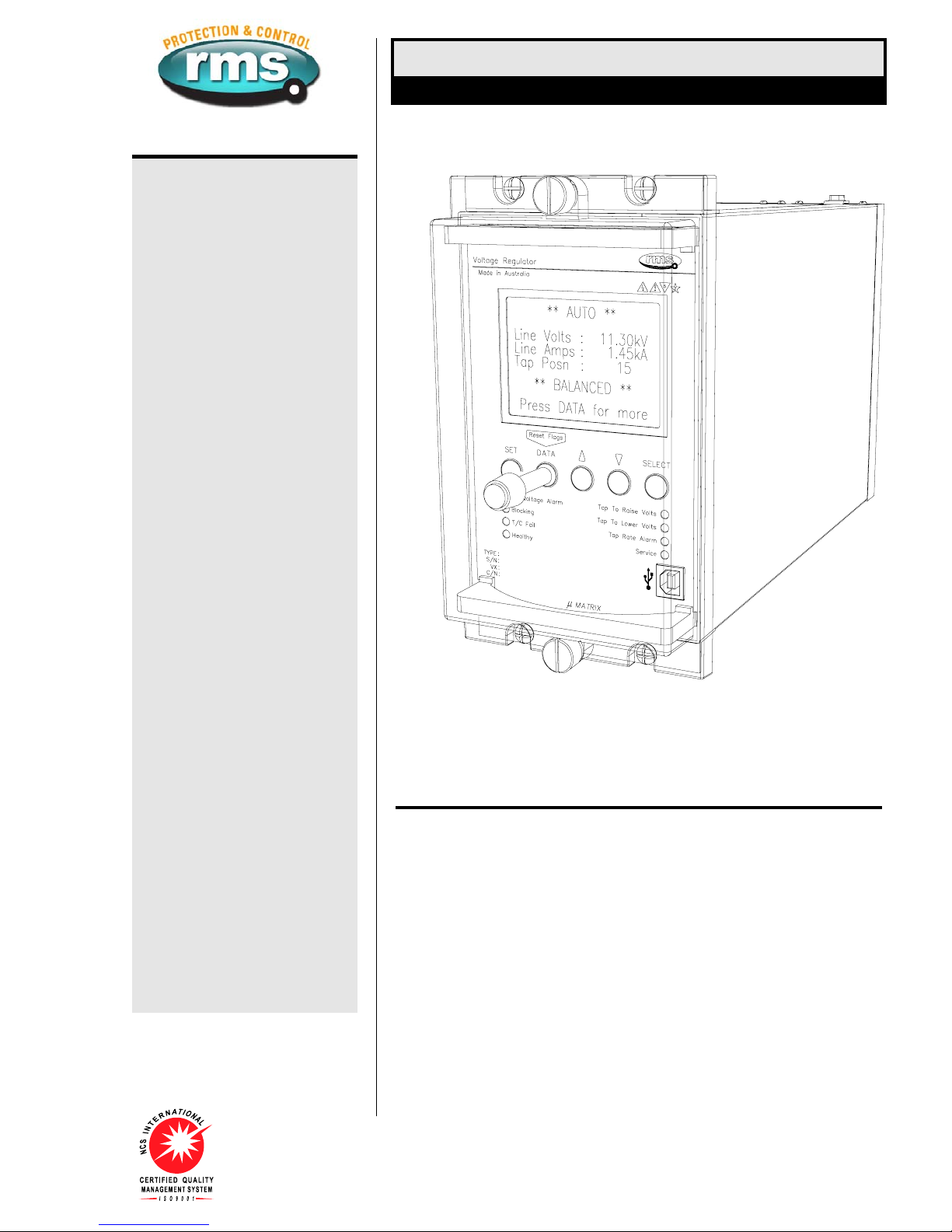

Mechanical Configuration

Great care has been taken to design a rugged, cost effective & flexible mechanical solution for

the MATRIX range of RMS protection relays. The MATRIX range provides a compact draw out

case solution with M4 screw terminals:

•2M28 Size 2 with 28 terminals

•4M28 Size 4 with 28 terminals

•4M56 Size 4 with 56 terminals

Complete details & attributes for the M (MATRIX) cases & accessories may be found at:

http://www.rmspl.com.au/mseries.htm

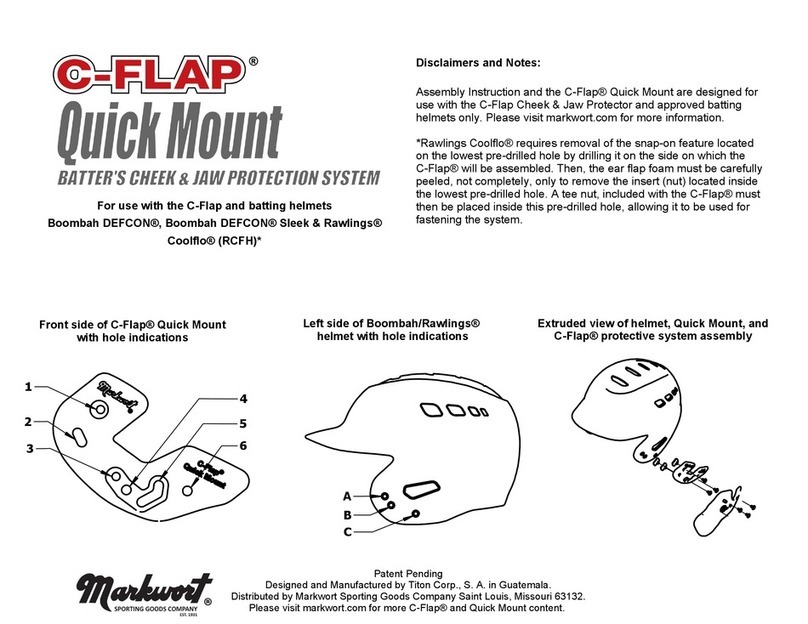

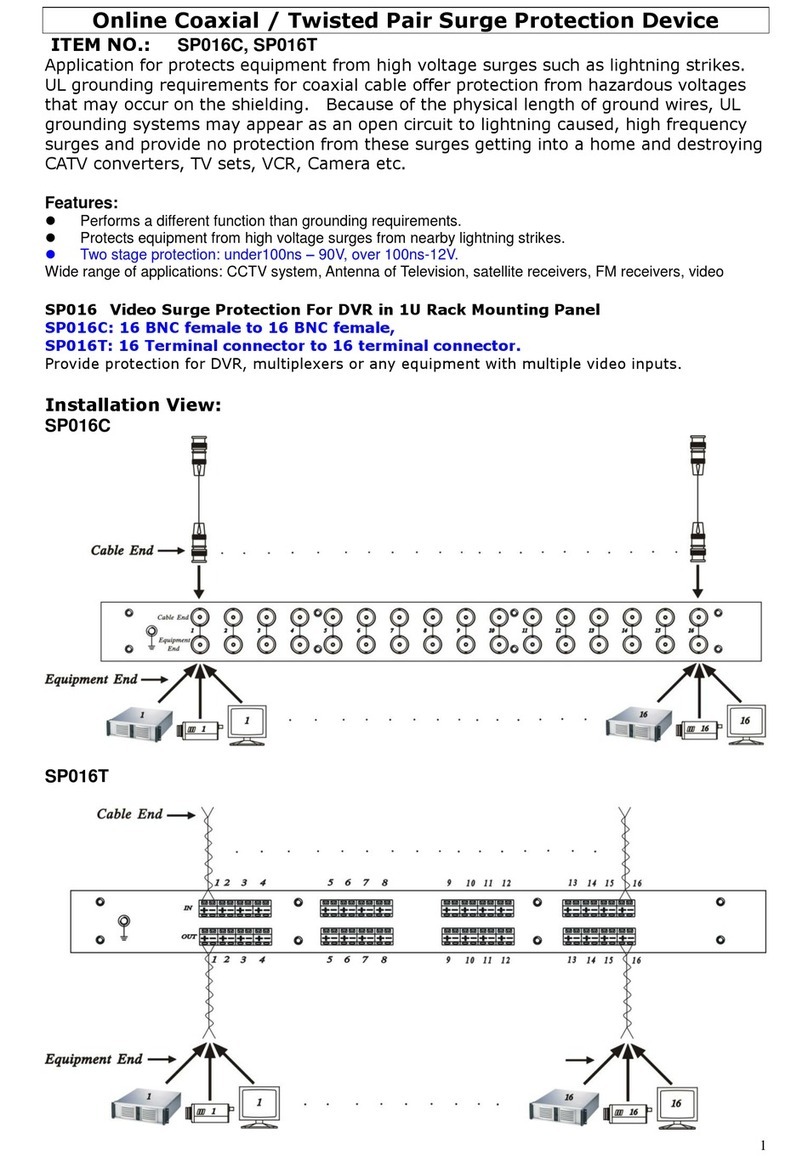

The 2V164-S is configured in a 4M56-S case & the following photographs depict the general

mechanical configuration. It should be noted that re-usable JIS plastic threading (PT type) screws

are used to bind the draw out relay module.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Image of generic inner relay module after removal from the outer case.

Primary circuit board showing the wide range power supply at the top.

Front panel circuit board showing graphic LCD panel and push buttons.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Secondary circuit board showing analogue voltage and current channels.

Optional network communications circuit board with additional I/O.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Description of Operation

The 2V16x Series relays are designed for the control of motor driven on-load power transformer

tap changers.

The 2V164-S Voltage Regulator Relay continuously monitors the transformer output voltage &

current & provides "RAISE" & "LOWER" control commands to the on-load tap changer such that

the load centre is automatically maintained within acceptable limits. Small variations in supply

frequency will not affect the system performance.

When designing the 2V164-S, considerable emphasis was placed on producing a relay, which

would be very simple to install, set up & operate in the field. The result is a simple yet effective &

very dependable voltage regulator relay available at a competitive price. The standard Micro

MATRIX human machine interface (HMI) is combined with fully solid state voltage sensing &

measuring circuitry to provide high accuracy, simple set up & flexible operation.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Line Drop Compensation

The line drop compensation, i.e. the inclusion of the voltage drop of a line connected to the

transformer in the regulating process, can be accomplished in two different ways. Two modes are

available:

Z-Compensation

Z-compensation is easier to set than the vectorial compensation method and is suitable where

only small shifts in the phase angle cosΦare experienced.

Vectorial compensation (Four setting modes: +PHASE and +QUAD)

Vectorial compensation is more difficult to set as exact line data must be known but is more

accurate when set correctly.

Setting the LDC Mode of Operation

Six settings are selected in the 2V164-S from the LDC menu as follows:

LDC mode: OFF LDC inactive

+ PHASE Use when relay wired in phase configuration

- PHASE Use when relay wired in phase configuration

+ QUAD Use when relay wired in quadrature configuration

- QUAD Use when relay wired in quadrature configuration

Z-COMP Use when relay wired in phase configuration

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Z Mode LCD Compensation Setting

Z-Compensation may be employed with the relay wired in phase or in quadrature configuration

where only small shifts in the phase angle cosΦare experienced.

The calculated percentage of the voltage rise, referred to the voltage level, set at the 2V164-S

LDC menu Z-Comp value in % as per the following formula:

Voltage rise % = 100 . UTr - ULoad . IN. RCT

______________ __________

U

Load

I

Where:

Voltage rise = setting of Z-compensation in %

UTr = transformer voltage at current I

ULoad = line end voltage at current I and with the same service position of the tap

changer

I= load current in amps

IN= rated current in amps of the selected current transformer connection to the

voltage regulator, i.e. 1A or 5A

RCT = current transformer ratio e.g. 200A/5A

Check the Z-compensation operation using the following steps:

1. Set Z-compensation voltage rise to 0%;

2. Apply a voltage to achieve balanced state;

3. Set Z-compensation voltage rise to 15%;

4. A voltage raise LED must light up when a load current of 10% of the rated current input is

applied;

5. Now carry out the required setting of the Z-compensation as per the above formula.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Vectorial Compensation (Phase and quadrature mode) LDC setting

Refer to the wiring diagram to choose the appropriate mode setting. The negative modes simply

reverse the sense of the compensation voltage which is more convenient than changing the

wiring polarity.

For the correct setting in these modes it is necessary to calculate the resistive and inductive line

voltage drop, referred to the secondary side of the voltage transformer in V and the correct

setting of the existing measuring transformer configuration according to the following formula:

RCT

Ur= IN. . r . L Volts

____

R

VT

RCT

Ux= IN. . x . L Volts

____

R

VT

Where:

Ur= LDC setting for resistive line voltage drop in Volts

Ux= LDC setting for inductive line voltage drop in Volts

IN= rated current in A of the selected current transformer connection to the voltage

regulator, i.e. 1A or 5A

RCT = current transformer ratio, e.g. 200A/5 Amps

R33,000V / √3

VT = voltage transformer ratio: e.g. IN PHASE connection wiring

________________

110V

33,000V

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

e.g. IN QUAD connection wiring

___________

110V

r= ohmic resistance of the line in ohm/km per phase

x= inductive reactance of the line in ohm/km per phase

L= length of the line in km

The resistive and reactive line drop compensation settings are entered into the 2V164-S at the

LDC page in volts.

Check the vectorial compensation operation using the following steps:

1. Set the Resistive and Reactive voltage settings to 0V;

2. Set the LDC mode to +PHASE or +QUAD based on the wiring configuration used;

3. Apply a voltage to achieve balanced state;

4. Set the Reactive voltage (Ux) setting to 15V;

5. A voltage raise LED must light up when the rated current input is applied at 90 degree lag

relative to the line voltage;

6. Set the LDC mode to -PHASE or -QUAD based on the wiring configuration used;

7. A voltage lower LED must light up when the rated current input is applied at 90 degree lag

relative to the line voltage;

8. Now carry out the required setting of the LDC Resistive (Ur) and Reactance (Ux)

compensation as per the above formula.

Provided the resistive and inductive line voltage drops Urand Uxare correctly set the voltage at

the load end will remain constant, independent of the load current.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Part

2

Technical Bulletin

The detailed technical attributes, functional description & performance specifications for the

V164-S are described in the attached Technical Bulletin. For the most up to date version go to:2

www.rmspl.com.au/handbook/2v164-s.htm

For any specific attributes of a particular version refer to the Test Manual for that type (K)

number.

The order of precedence for technical information is as follows:

•Test Manual

•Technical Bulletin

•User Guide

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S_Guide/Iss A - 01/04/09

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S/Issue F/08/04/11 - 1/9

Features

SYSTEM FEATURES

Large back lit display panel

System status LED indicators

Simple menu setting procedure

Wide auxiliary supply range

with fail alarm contact

Self diagnosis and fail alarm

Size 4M56-S draw out case

Made in Australia

VOLTAGE CONTROL

Line drop compensation with

1A and 5A CT inputs

Z Compensation

63.5 and 110V AC VT inputs

Definite time and inverse time

delays

Independent fine and coarse

voltage bandwidth windows

Over and under voltage alarms

Under voltage blocking function

Tap change fail alarm

Two digital input load step

stages

Overcurrent blocking

METERING AND EVENT RECORDING

Line voltage display

Line current display

Tap position indicator

Tap rate of change alarm

Tap change event counter

Tap position mA output

Line voltage mA output

COMMUNICATION

USB front programming port

Non platform specific PC

programming software:

µ

MATRIXwin

Optically isolated RS485

network communication port

MODBUS RTU compatible

network protocol

Technical Bulletin 2V164-S

Voltage Regulating & Tap Change Control Relay

2V164-S depicted in a size 4M56-S draw out case

Application Made in Australia

The 2V164 Series relays are designed for the control of motor driven on-load power

ransformer tap changers.t

The 2V164 Voltage Regulator Relay continuously monitors the transformer output voltage

and current and provides "RAISE" and "LOWER" control commands to the on-load tap

changer such that the load centre is automatically maintained within acceptable limits. Small

ariations in supply frequency will not affect the system performance.v

When designing the 2V164, considerable emphasis was placed on producing a relay, which

would be very simple to install, set up and operate in the field. The result is a simple yet

effective and very dependable voltage regulator relay available at a competitive price. The

standard Micro MATRIX human machine interface (HMI) is combined with fully solid state

voltage sensing and measuring circuitry to provide high accuracy, simple set up and flexible

peration.o

PARALLEL CONTROL SCHEMES

Parallel control schemes are available to meet a range of transformer control configurations

based on the master / follower principal. These systems are supplied fully wired in 19” sub

rack frames ready for integration into customer panels. Up to 4 transformers operating in

arallel on one or two groups are possible.p

For further details refer to the RMS 1M122A, 1M122D and 2V165 technical bulletins which

rovide details on our range of transformer parallel control systems.p

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S/Issue F/08/04/11 - 2/9

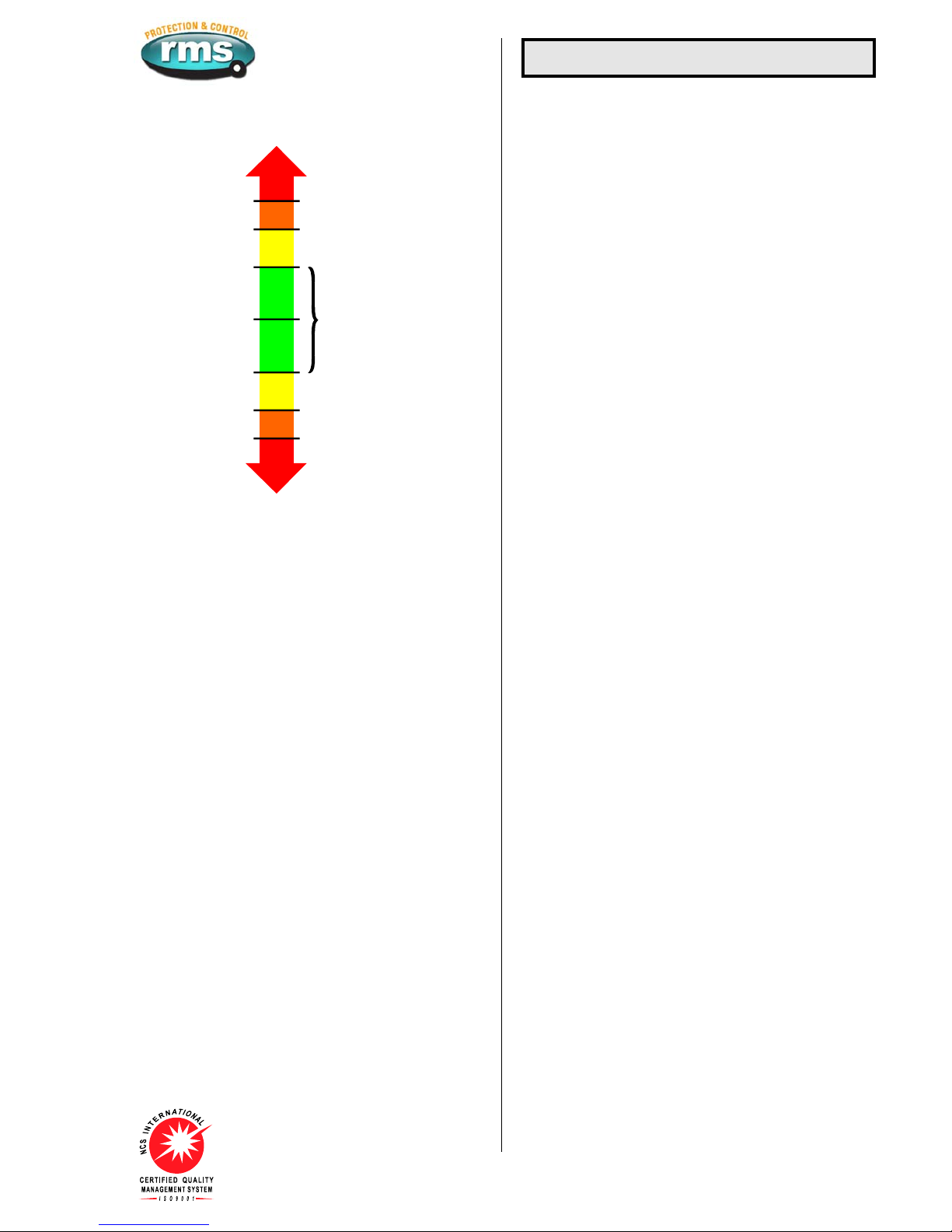

+ Fine bandwidth

+ Coarse bandwidth

- Coarse bandwidth

- Fine bandwidth

Initial / interval tap raise

Initial / interval tap lower

Fast tap down

Fast tap raise

Tap raise blocked & U/V alarm

Fast tap down & O/V alarm

Setpoint voltage

VOLTS HIGH

VOLTS LOW

Balanced voltage

O/V Alarm

U/V Blocking

Figure 1: User defined voltage set points

SETPOINT VOLTAGE RANGE

90V to 130V in 0.1V steps.

110V and 63.5V nominal inputs.

“FINE” VOLTAGE BANDWIDTH SETTING (SENSITIVITY)

0.3 V to 5.0V in 0.1V steps.

The bandwidth setting should be made in accordance with the

relative step voltage of the tap changer. A narrow bandwidth may

result in the tap changer hunting between adjacent taps.

INITIAL RAISE / LOWER TIMER

10s to 300s in 10s steps.

The initial time delay between the detection of an error in the

monitored voltage and the resultant tap change output, is switch

selectable as either a definite time or true inverse time response.

The initial time delay starts when the voltage deviation exceeds

the upper or lower limit. The respective instantaneous HIGH /

LOWER LED illuminates.

If the deviation falls back to within bandwidth limits before the pre

set time delay is completed, the timer is reset.

At the completion of the pre set time delay the respective RAISE /

LOWER tap output contact will close.

INTERVAL TIME DELAY

1s to 100s in 1s steps.

The interval time delay only becomes active when the initial delay

has caused a tap change but without affecting a balanced

condition, ie. if more that one tap change operation is necessary

to bring the voltage within set limits.

INVERSE TIME DELAY CHARACTERISTIC

In the inverse time mode, the initial time delay is inversely

proportional to the ratio of deviation to bandwidth down to a

minimum of a one-second delay. For example:

♦When the detected error is equal to the selected bandwidth the

time delay is equal to the delay setting.

♦For a detected error of N times the selected bandwidth, the

time delay is 1/N times the delay setting.

Voltage Control Functions

“COARSE” VOLTAGE BANDWIDTH SETTING

1V to 20V in 1V steps.

1s to 60s in 1s steps.

A second independent voltage control window can be set with a

definite time delay. This can be used for a fast tap change

function for large voltage deviations, which are outside the fine

bandwidth window.

UNDER VOLTAGE BLOCKING FUNCTION

60V to 90V in 1V steps.

0s to 60s in 1s steps.

An undervoltage blocking function is combined with a definite

time delay output.

Undervoltage blocking suppresses tap change operations during

a system breakdown to avoid the tap changer mechanism from

being driven to the top tap. The self reset Blocking alarm relay is

activated when this element has timed out and a message

reported on the HMI.

OVER VOLTAGE ALARM

110V to 140V in 1V steps.

0s to 60s in 1s steps.

An overvoltage alarm is combined with a definite time delay

output. The self reset overvoltage alarm relay contact is activated

when this element has timed out and a message reported on the

HMI.

OVER CURRENT BLOCKING

50 to 150% in 5% steps – Can also be set to OFF

0s to 60s in 1s steps

Reset: >0.97Iset

When timed out all tap commands are inhibited / cancelled.

The self reset Blocking alarm relay is activated when this element

has timed out and a message reported on the HMI.

LINE DROP COMPENSATION

Resistance and reactance compensation: 0V to 20V in

0.1V steps

Settings are provided to cater for in phase and in quad

connections, with either positive or negative reactance

compensation.

Correct setting of the LDC requires the calculation of the resistive

and reactive line-drops as a voltage with reference to the

secondary side of the VT and the setting of the instrument

transformer for IN PHASE or IN QUAD connection. Z

compensation is also available: 0 to +15% setting range.

The LDC function does not effect the under or over voltage alarm

set points. These operate from the direct voltage measurements.

VOLTAGE LOAD STEP INPUTS

-10% to +10% of the set point voltage in 0.5% steps

Two independent load step stages are provided. The voltage

reduction or boost level for each stage can be independently set

while a separate digital input is provided to initiate each stage. If

both stages are initiated then the stage 2 level is operative.

OPERATIONAL INDICATORS

Red LED’s on the front panel indicate the following conditions:

Over voltage Bus voltage above alarm setting

Blocking BUS voltage / current outside block settings

Tap change fail Tap change time out alarm

Raise volts Flash when timing / On for Raise tap initiate

Lower volts Flash when timing / On for Lower tap initiate

Tap rate Tap rate alarm level exceeded

TAP CHANGE FAIL ALARM

10s to 300s in 10s steps.

The tap change fail alarm timer is initiated when an out of

bandwidth voltage error is detected. Time out will result in the

alarm contact closing. The alarm timer and contact is reset when

he sensed voltage has moved back to a balanced condition.t

AUTO / MANUAL MODE CONTROL INPUT

A digital input is provided to change the relay from AUTO to

ANUAL mode.M

In AUTO mode the 2V164 will monitor the voltage and current

inputs and output tap raise / lower commands to maintain the load

enter in accordance with the relay settings.c

In MANUAL mode tap raise and lower commands are inhibited.

The Blocking and Overvoltage alarm outputs remain active.

The relay fail alarm remains active.

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S/Issue F/08/04/11 - 3/9

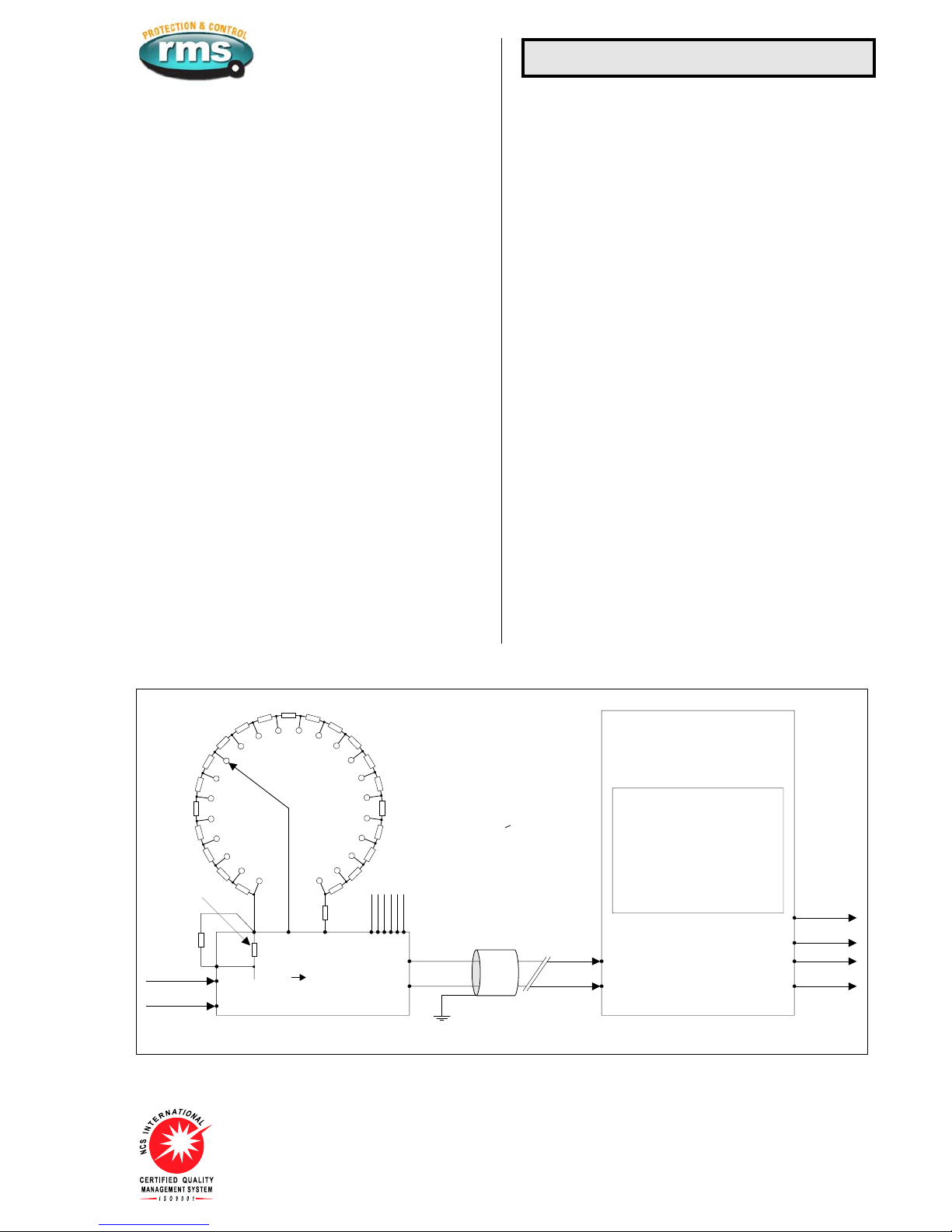

TAP POSITION INDICATOR

A tap position indicator input is provided to enable the transformer

tap to be displayed on the HMI. The output from the RMS type

2V200 Tap Position Transducer is required for this function to

operate. Refer to the 2V200 Technical Bulletin for details.

TAP POSITION INDICATOR INPUT

For this function to operate an RMS type 2V200 transducer /

sender unit is required at the tap changer. Refer to the 2V200

Technical Bulletin for application details.

The 2V200 is designed to interface to tap changes and convert

one of the following parameters:

an analogue voltage signal proportional to the tap position

a binary coded decimal signal

a BCD signal

The 2V200 converts any of these inputs to a frequency signal

proportional to the tap position.

The 2V164 VRR is then simply programmed with the number of

tap positions within the range 10 to 30. Scaling is carried out

automatically so that the correct tap position is indicated on the

2V164 display.

A 4-20mA analogue output proportional to tap position is also

provided by the 2V164 for local panel indication or interface to

SCADA.

VOLTAGE DISPLAY

The HMI displays the line voltage. The VT ratio may be entered so

that the HMI display reads in primary voltage. A 4-20mA analogue

output is also provided.

Display range (Secondary): 10-145V

VT setting range: 0.11KV to 132.00KV

CURRENT DISPLAY

The HMI displays the line current from the LDC input. The CT

ratio may be entered so that the HMI display reads in primary

current.

Display range (Secondary): 0.1-1.35Is

CT setting range: 1A to 6.00KA

Metering & Event Logging

TAP CHANGE EVENT COUNTER

A record is maintained and displayed of the number of tap

operations since this function was last reset. The tap rate

indicator takes account of all tap changes initiated by the 2V164

tap raise / lower contacts. Manual taps initiated by external

control contacts are not included.

RANGE OF TAP OPERATION

A record is maintained and displayed of the minimum and

maximum tap position reached since this function was last reset.

TIME ELAPSED SINCE TAP COUNT RESET

A record is maintained and displayed of the time in hours since

the tap count was last reset.

TAP RATE ALARM

The 2V164 records and displays the rate at which tap raise/lower

commands have been output over the preceding 15-minute

period. If the set point rate is exceeded (taps per hour), an alarm

contact is picked up. This alarm contact is automatically reset

when a tap rate lower than the alarm set point is updated to the

display or when the tap count is manually reset. The tap rate

indicator takes account of all tap changes initiated by the 2V164

tap raise / lower contacts. Manual taps initiated by external

control contacts are not included.

TAP POSITION INDICATOR ANALOGUE OUTPUT

A single tap position indicator analogue output signal is provided

for interface to an RTU. The analogue output is linked to the tap

position as follows:

Output: 4 to 20mA

Compliance voltage: 5V

Maximum burden: 250 Ohms

Accuracy: +/-3%

Analogue output:

Tap 1 4mA

Tap N 20mA

Where N = maximum selected tap setting

Ta p 1

Use 400 Ohm 1% 0.5W resistors for Rs

Other resistor values possible:

refer 2V200 Technical Bulletin

for tap 1 reference

padding resistor (Rp) values

Rs 1 Rs 21

Ra*

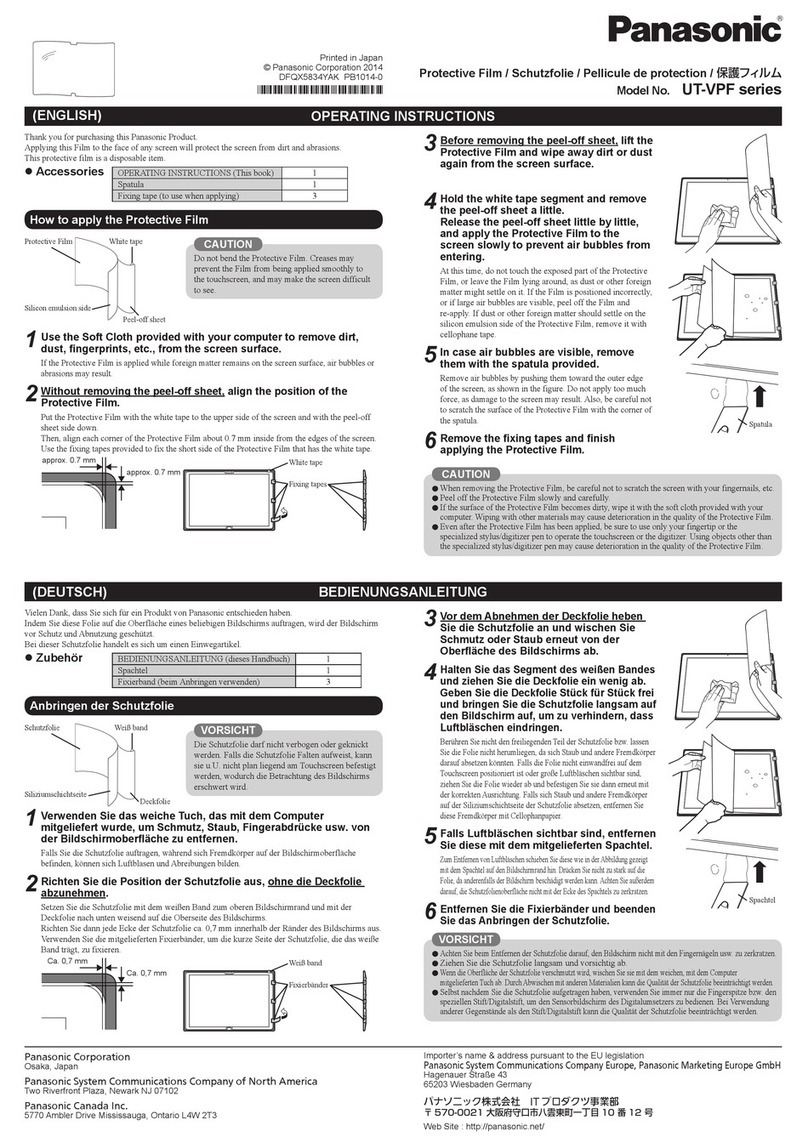

Tap position indicator (TPI) hardware requirements and wiring configuration.

Transformer TPI selector switch

Frequency

output

Shielded cable recomended

for long runs & parallel control

(2V165), applications

5KHz Max.

Integrated TPI display

** T/C EVENTS PAGE **

DATA to return

V F TPI

Transducer & sender unit

Ta p R a t e :

Max Tap:

Min Tap:

Tap Count:

Time Elapsed:

4

18

4

620

160

2V164 VRR

2V200

11 15

16

1

2

13 1012 4 5

The RMS type 4O200 Resistor Box

provides a packaged TPI Rs solution

TPI output

Volts output

Alternative

Binary or BCD coded interface

Ta p 1

internal

reference

resistor

(400 ohms)

** Tap 1

external

padding

resistor

Rp

Vx

110V AC

or 240V AC

* If Rs x number taps > 600 ohms

then resistor Ra is not required.

** If Rs = 400ohm

then resistor Rp is not required.

Figure 2

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S/Issue F/08/04/11 - 4/9

RELAY CONFIGURATION USING

µ

MATRIXwin

The purpose of the

µ

MATRIXwin application is to provide display,

configuration and diagnostic facilities required to support the

entire family of

µ

MATRIX digital relays. The prime functions of the

application are:

Create a setting file off line

To create and view relay setting files at your PC without the need

for a relay;

Relay setting

To down load a setting file (UMP) into a relay connected to a PC;

To display and change settings in a connected relay;

Relay status

To display the Status of nominated inputs and outputs of a

connected relay;

Relay Control

Manual raise / lower commands and resetting functions can be

performed;

Commissioning

To export reports of setting parameters and status screen to

confirm correct functionality during commissioning;

Upgrade relay software

To configure a

µ

MATRIX relay for a specific customer application;

To upgrade the operational software (UMX) of a

µ

MATRIX relay;

All current UMX software applications may be downloaded from:

www.rmspl.com.au/umatrix

Maintenance

To provide utility and diagnostic facilities at a technical level.

Communications

COMMUNICATION PORTS

Two (2) communications ports are available. The front USB

programming port is provided as standard while the rear RS485

network port is available as an option.

Programming port

The programming port is accessible from the front panel of the

relay via a USB physical link and PC configuration program

supplied with the relay. The

µ

MATRIXwin configuration program

is designed to operate with all relays from the

µ

MATRIX range

and with all installed firmware version.

Network port

The network port is intended for applications where permanent

connection to a master control system is required. An optically

isolated RS485 physical layer is provided for this function.

The RS485 connection is intended for applications where multiple

µ

MATRIX relays are to be connected on a common

communications bus.

Network Port Terminating Resistor

Where multiple relays are connected in a multi-drop configuration

the RS485 comms. bus must have a 120 ohm terminating resistor

fitted at each end. If the

µ

MATRX-S relay is at one end of the

transmission line a terminating resistor can be added by placing

SW100-3 and SW100-4 in the ON position as depicted in the

wiring diagram.

Network Port BIAS Resistors

Where a single relay is connected to the network, or where the

relay is a long distance from other devices on the comms. bus,

BIAS resistors may need to be fitted to ensure reliable operation.

To simplify this configuration, BIAS resistors are fitted to each

µ

MATRIX-S relay and may be selected IN by setting switches

SW100-1 and SW100-2 to the ON position as depicted in the

wiring diagram. This bank of four switches can be accessed by

withdrawing the relay module from it’s case, turning upside down

and looking at the centre PCB near the rear terminal blocks.

PC TO

µ

MATRIX USB CONNECTION

2V164-S front panel USB programming port

USB DRIVERS

The uMATRIX-S USB port is configured as a Virtual

Communications Port (VCP) and is operated through a PC COM

port. USB drivers must be installed on the PC to enable correct

communication. A ZIP file containing the driver files needed for

this process may be downloaded from:

www.rmspl.com.au/umatrix

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S/Issue F/08/04/11 - 5/9

VOLTAGE SENSING CIRCUITRY

Nominal monitoring voltage

IN QUAD connection: 110V 50HZ

I

N PHASE connection: 63.5V 50Hz

Sensing supply burden: Less than 0.2VA

T

hermal rating: 300V continuous

N

ominal sensing frequency: 40 to 60Hz

Voltage measurement secondary accuracy (110V tap):

Precision of voltage setting: 0.1V steps

Voltage pick up repeatability: +/-0.1V from 90 to 120V

Voltage measurement resolution: 45mV

Resolution of voltage display: 0.1V

A

ccuracy of displayed voltage: +/-0.1V from 90 to 120V

ACCURACY OF TIMERS

All timers +/-0.1s

LINE DROP COMPENSATION (LDC) INPUT

Nominal sensing current: CT taps for 1A and 5A inputs

LDC input burden: <0.5VA

Thermal rating: 3x nominal continuous

3.5x nominal for 10 minutes

6x nominal for 2 minutes

100A for 1s on 1A input

350A for 1s on 5A input

700A for 1 cycle on 1A input

2,500A for 1 cycle on 5A input

Note: M Series case terminals and CT shorting

switches are limited to 400A for 1s.

LDC accuracy: +/- 0.3V error at nominal 110V setting and 10 to

120% CT input

SET POINT HYSTERESIS

All voltage set points have a hysteresis equal to 50% of the

bandwidth voltage setting. Other values available on application.

Technical Data

TAP CHANGE FEEDBACK FUNCTION

When a tap change command is output to the OLTC, the tap

change fail timer is started. If a single tap change restores the

sensed voltage to a balanced condition the relay is reset. If the

sensed voltage remains in error the interval time delay will start

based on one of the three methods described below: The

required operating mode is selected using the UMX order code.

VOLTAGE MONITORING (Automatic mode) UMX2V164A

In this mode the 2V164 provides a 1s output pulse to initiate a tap

change. This output pulse is then repeated at a rate set by the

Interval Timer setting until the sensed voltage has moved back to

a balanced condition. This is the simplest connection method as it

does not require a hard-wired contact between the OLTC and the

VRR.

The output pulse may be selected as continuous for application

with linear voltage regulators. The continuous output contact and

interval timer delay is reset once the sensed voltage moves back

to the balanced condition.

OLTC AUXILIARY CONTACT METHOD UMX2V164B

In this mode an auxiliary contact on the OLTC is employed to

signal completion of a tap change sequence. This signal is used

by the 2V164 to pause the interval time delay until the previous

tap change sequence has been completed.

The default 2V164 T/C feedback status input is set for a control

voltage to be removed when the tap change starts (OLTC

auxiliary contact opens) and re-applied when the tap change

sequence is completed (OLTC auxiliary contact closes). The

interval time delay is paused until the completion of the tap

change sequence has been signaled.

The output pulse may be selected as continuous or to provide a

1s pulse output.

The continuous output contact and interval time delay is reset

once the sensed voltage moves back to a balanced condition.

TPI FEEDBACK METHOD UMX2V164C

In this mode the 2V200 TPI transducer must be connected as per

figure 2. The control sequence is as follows:

1. A voltage deviation starts the initial time delay.

2. The time delay expires and a tap change command is output.

3. The tap change contact will remain closed until a signal is

received from the TPI transducer confirming that a tap

change event has occurred.

4. The interval time delay is initiated.

5. Sequence 2 to 4 will repeat at the rate determined by the

Interval timer setting until the sensed voltage has moved back

to a balanced condition.

TAP POSITION TRANSDUCER FAIL (UMX2V164C only)

In the event that a 2V200 TPI transducer loses connection to the

2V164 or fails, any pending tap commands are blocked.

For TPI transducer (2V200) failure conditions, a ‘TPI Fail’

message is displayed on the MMI and the tap position displays as

‘TPI Offline’. The TPI fail output contact is also set.

Normal tap change feedback and voltage regulation control

function is automatically restored once the TPI transducer signal

is recovered.

It should be noted that the ‘TPI fail alarm’ and the ‘Tap change fail

alarm’ share a common output contact.

LINE VOLTAGE ANALOGUE OUTPUT

Output: 4 to 20mA

Compliance voltage: 5V

Maximum burden: 250 Ohms

Accuracy: +/-3%

Analogue output: Lower (4mA) set point range: 0V - 146V

Upper (20mA) set point range: 50V - 146V

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S/Issue F/08/04/11 - 6/9

STATUS INPUT MINIMUM OPERATING CURRENT

1

0 mA P/U for 1 ms then reducing to1.5 mA after 4 ms.

S

TATUS INPUT OPERATING TIME

Initiate input Parameter Delay

P/U <4 ms

DC D/O <16 ms

P/U <23 ms

AC D/O <33 ms

Technical Data

AUXILIARY SUPPLY

20-70V DC switchmode supply or

40-275V AC / 40-300V DC switchmode supply

Burden: Less than 10 watts with all output relays energized

using 110V DC nominal supply.

Inputs:

A high efficiency switchmode power supply is incorporated which

provides a low burden to the auxiliary supply.

Input Transients:

Withstands multiple high-energy transients and ring waves in

accordance with IEEE28 - ANSI C26.1 Cat. II, accordingly:

0.5uS 100kHz 6kV O/C, 500A S/C, 4J

1.2/50uS 6kV O/C

8/20uS 3kA S/C, 80J clamped at 1,000V

Mains conducted EMI within limits specified by AS 3548 Class B.

Isolation:

The inputs are isolated from the outputs in accordance with

AS3260 Class II Limited Current Circuitry, accordingly:

Withstand voltage of 2.5kV RMS 50Hz for one minute

Creepage and clearance distance greater than 4mm

Output leakage current less than 0.25A to earth

Output Protection:

Outputs will withstand continuous short circuit. Output regulators

and switching control regulator are thermally protected.

RELAY FAIL ALARM

A C/O alarm contact is maintained in the energized state when all

of the following conditions are met:

The auxiliary supply is applied

The internal 24V DC rail is within acceptable limits

The CPU hardware watchdog maintains a pulsing output

A CPU software watchdog records “suspect” events to an assert

register and if necessary performs a soft restart.

A front panel green LED is illuminated when the relay is healthy.

A separate flashing red LED indicates a software problem has

been encountered which caused causing the CPU to perform a

arm boot.w

CASE

Size 4 draw out with 56 M4 screw terminals

Flush panel mount or 4U high 1/4 width 19 inch rack mount

I

P51 rating

SHIPPING DETAILS

Each relay is supplied individually packed in pre formed

cardboard cartons with internal moulded polystyrene former.

Weight: 3.5Kg

S

ize: 370(L) x 240(W) x 145(D)mm - Size 4 case

For large shipment individual cartons are packed in sturdy

cardboard pallet boxes and surrounded by loose fill to absorb

ibration and shock during transit.v

ACCESSORIES SUPPLIED

1 x M4 self threading mounting screw kit P/N 290-406-151

2 x M4 terminal screw kit (28 per kit) P/N 290-407-153

1 x

µ

MATRIX User Guide per order

1 x USB cable per order

1 x CD -

µ

MATRIXwin software, setting files and applications per

order

Visit www.rmspl.com.au for the latest product information.

Due to RMS continuous product improvement policy this information is subject to change without notice. 2V164-S/Issue F/08/04/11 - 7/9

Technical Data

OUTPUT CONTACT RATINGS IEC60255-0-2

Carry continuously 5A AC or DC

0.5 s 20 A AC or DCMake and carry

L/R ≤40ms & V ≤300V 0.2 s 30 A AC or DC

AC resistive

AC inductive

1,250 VA

250 VA @ PF ≤0.4

DC resistive 75 W

Break capacity

I ≤5A and V ≤300V

30 W @ L/R ≤40 ms

DC inductive 50 W @ L/R ≤10 ms

Minimum number of operations 106at maximum load

Minimum recommended load 0.5W limit 10mA / 5 V

TRANSIENT OVERVOLTAGE IEC60255-5 CLASS III

Between all terminals and earth 5 kV 1.2/50 us 0.5 J

Between independent circuits without

damage or flashover 5 kV 1.2/50 us 0.5 J

INSULATION COORDINATION IEC60255-5 CLASS III

Between all terminals and earth 2.0 kV rms for 1 min.

Between independent circuits 2.0 kV rms for 1 min.

Across normally open contacts 1.0 kV rms for 1 min.

AUXILIARY SUPPLY IEC60255-11

Allowable breaks / dips in supply

Collapse to zero from nominal voltage ≤20 ms

HIGH FREQUENCY DISTURBANCE IEC60255-22-1 CLASS III

2.5 kV 1MHz common mode

1.0 kV 1MHz differential mode ≤3% variation

ELECTROSTATIC DISCHARGE IEC60255-22-2 CLASS III

6 kV contact discharge ≤5% variation

FAST TRANSIENT IEC60255-22-4

4 kV, 5/50 ns, 100 KHz repetitive ≤3% variation

TEMPERATURE RANGE IEC68-2-1/2

Operating: -5 to +55oC

Storage: -25 to +75oC

HUMIDITY IEC68-2-78

40 oC and 95% RH non condensing

Front view 4 holesof 3.7

Indicative

position

Sideview

Size 4M56-S

drawout case

Drawingunits:mm

Terminallayout Panelcutout

Suits flush panelmounting &

4U high 19 inch rack frame

15

129230

27 5528 56

Table of contents

Other RMS Protection Device manuals