Copyright@2020 - Ro an Model Limited – all rights reserved

IMPORTANT NOTES

*This radio controlled helicopter is not a toy.

*This radio controlled helicopter can e very dangerous.

*This radio controlled helicopter is a technically complex device which has to e uilt and handled very carefully.

*This radio controlled helicopter must e uilt following these instructions. This manual provides the necessary information

to correctly assem le the model. It is necessary to carefully follow all the instructions.

*Inexperienced pilots must e monitored y expert pilots.

*All operators must wear safety glasses and take appropriate safety precautions.

*A radio controlled helicopter must only e used in open spaces without o stacles, and far enough from people to minimize

the possi ility of accidents or of injury to property or persons.

*A radio controlled helicopter can ehave in an unexpected manner, causing loss of control of the model, and make it a very

dangerous flying o ject.

*Lack of care with assem ly or maintenance can result in an unrelia le and dangerous model.

*Neither Ro an Limited nor its agents have any control over the assem ly, maintenance and use of this product. Therefore, no

responsi ility can e traced ack to the manufacturer. You here y agree to release Ro an Limited from any responsi ility or

lia ility arising from the use of this product.

SA ETY GUIDELINES

*Fly only in areas dedicated to the use of model helicopters.

*Follow all control procedures for the radio frequency system.

*It is necessary that you know your radio system well. Check all functions of the transmitter efore every flight.

*The lades of the model rotate at a very high speed; e aware of the danger they pose and the damage they may cause.

*Never fly in the vicinity of other people.

NOTES OR ASSEMBLY

Please refer to this manual for assem ly instructions for this model.

Follow the order of assem ly indicated. The instructions are divided into chapters, which are structured in a way that

each step is ased on the work done in the previous step. Changing the order of assem ly may result in additional or

unnecessary steps.

Use thread lockers and retaining compounds as indicated. In general, each olt or screw that engages with a metal part

requires thread lock.

Factory pre-assem led components have een assem led with all the required thread lock and lu ricants,

and have passed quality control. It is not necessary to disassem le and re-assem le them.

We do not recommend the use of thin cyanoacrylate glue for surface mount of painted parts. The fumes of the curing glue leave

white stains on the clear coat, which are hard to remove.

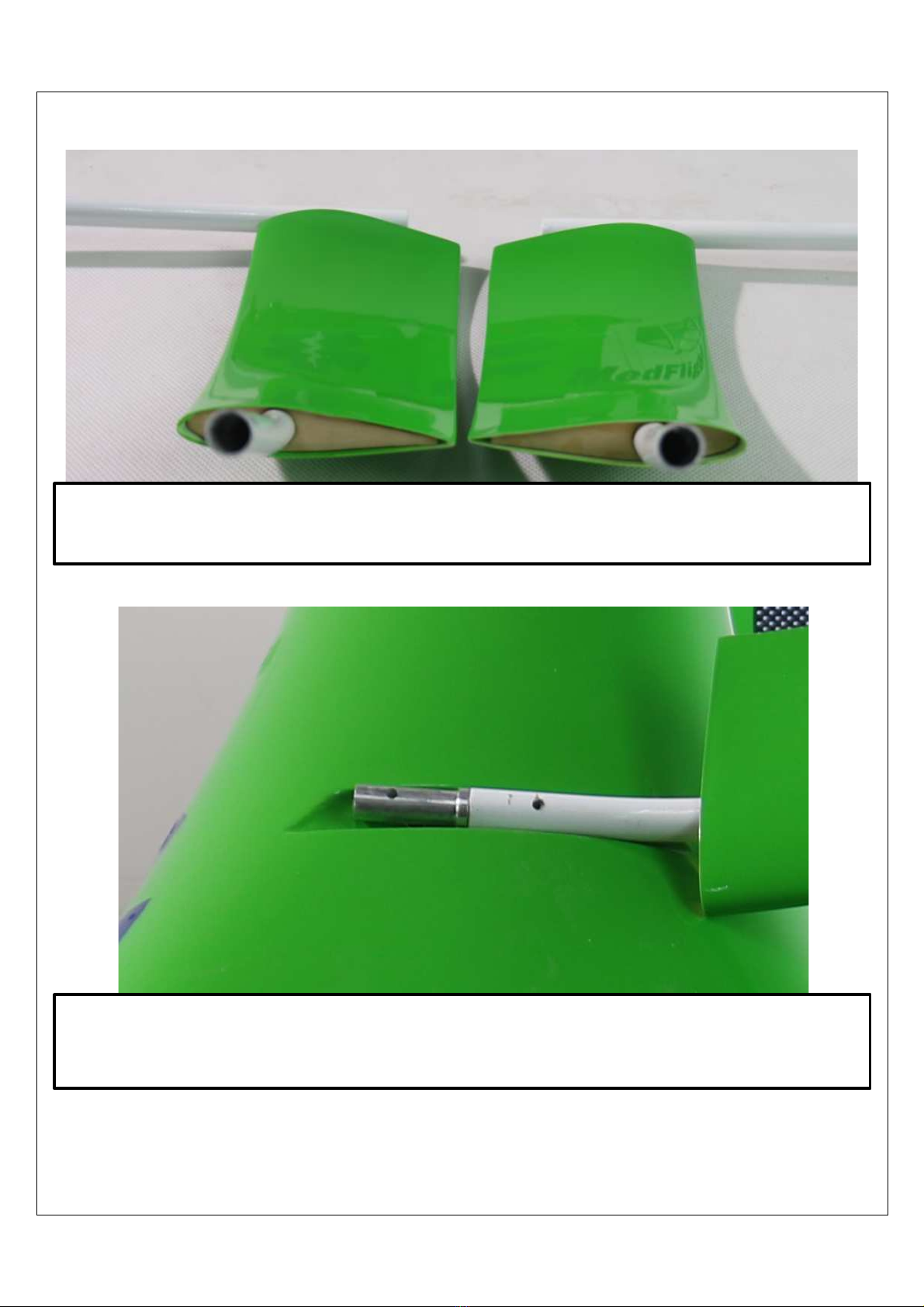

ENESTRON OPERATION

The Ro an fenestron unit provides sufficient thrust to cope with any flight situation a ove a main rotor rpm of 1000 r/min. We have

implemented our clients desire to e a le to fly realistically at a low head speed. However, and due to the physical layout of the

fenestron much higher required controlling forces are required compared to a typical RC helicopter tail rotor. To guarantee safe

operation and due to the fact that the control forces that a tail servo has to exert rise with the rotational speed of the tail, a main

rotor head speed of 1200 r/min are not to e exceeded. Please chose a high-power servo with at least 15kgcm of torque. The speed

of the servo isn’t key to good performance, a scale helicopters tail is inherently slow, a fast servo can even result in over tuning and

having your flight controller overwork the servo, as the heavy tail won’t respond to fast inputs. A regular cyclic servo is more than

sufficient. Please also ear in mind that such a heavy loaded servo WILL consume as much power in hover than your three cyclic

servos consume TOGETHER! Please have ear that in mind when choosing your BEC power rail components.