Record- Playback Head A lignment

l. Thread a standard alignment tape on the trans-

port as described under "Threading the Tape".

2. Connect an AC voltmeter to a standard phono

plug and insert the plug into the Output jack.

3. Remove the head cover.

4. Insert ascrewdriverthrough the holein thehead

into the alignment screw.

5. Playthe tape back at full volume, and rotate the

alignment screw in either direction until the

10,000 cycle note gives the highest meter read-

ing.

Brake Shoes

When brake shoes (34) and (80) become worn,

loosen the mounting screws and rotate the shoes a few

degrees until a new braking surface j,s exposed.

ADJUSTMENTS

LUBRICATION

CLEAN I NG

TROUBLE CHART

Lubricate the following parts every three months

in heavy service, every six months in moderate ger-

vice, or once a year in light service.

l. Supply and take-up reel spindle shafts, with two

drops of light oil.

2. Rewind idler bearing and take-up idler bearing

with one dropof light machine oil on each bear-

ing.

3. Apply a liberal amount of light machine grease

to the pressure roller bearing shaft. Replace

the pressure roller and wipe a\pay any excess

grease.

4. Remove the thumbscrew (120) and? L/ 2 ips bush:

ing (l2l) from the capstan. place a few diops of

oil in the oil hole in the capstan retaining ring.

Allow the motor to run for a few minutes. Wipe

away any excess oil and replace the bushing.

5. Place a small amount of grease on the index

counter rilorm gear.

6. Applya liberalamountof machinegrease to each

roller on all levers and cams.

7. Disassemble the motor and saturate the upper

and lower oil pads. Clean away all excess oil.

Most defects, other than wear or breakage, can

be traced to dirty surfaces with which the tape makes

contaet. The Record-Playbaek head, capstan and

pressure roller may accumul,ate a coating of residue

which is worn off the tape as it passes these parts.

Usinga soft cottoncloth and aleohol, clean theseparts

periodically.

=On

E9

'E

t7l

sd

.ll

{

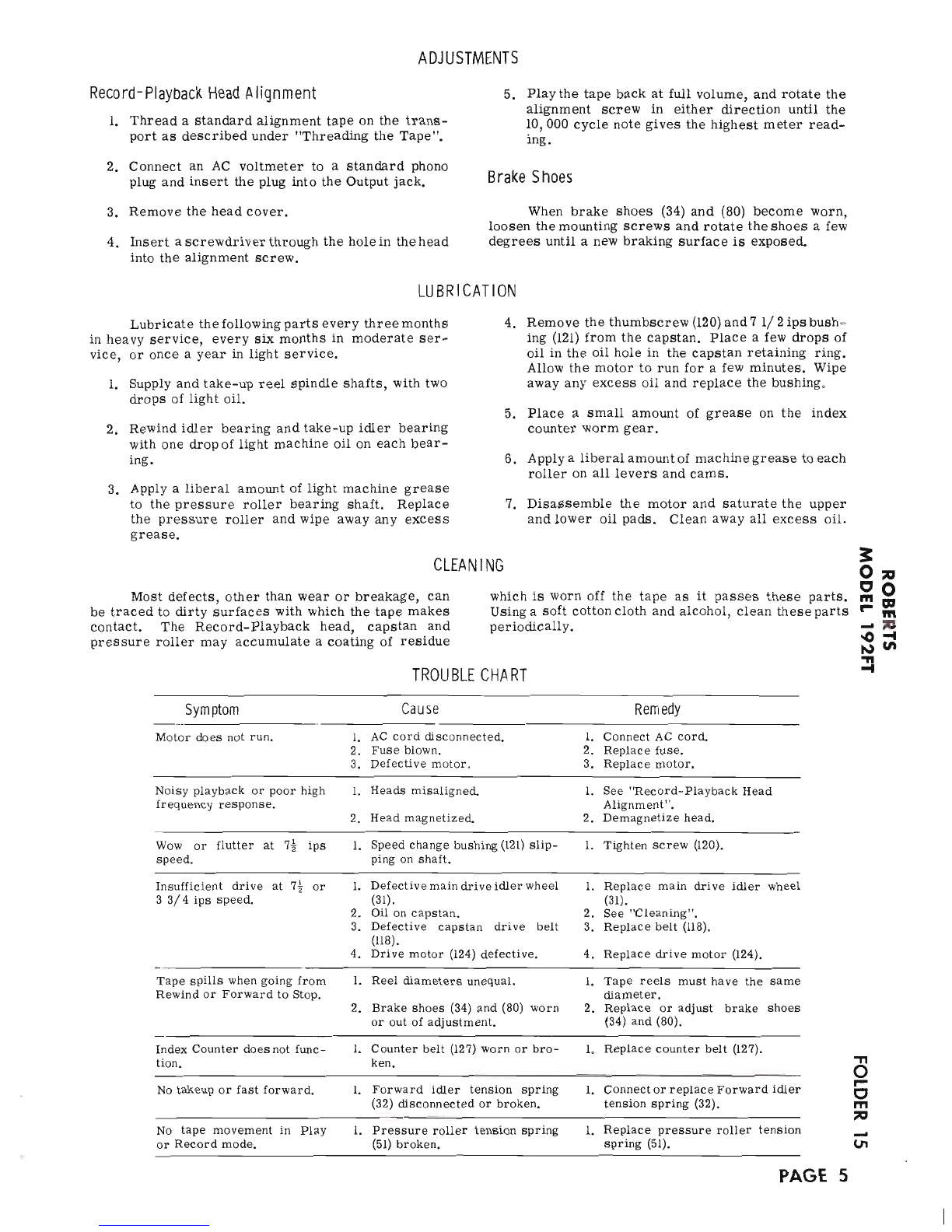

Sym ptom Cause Remedy

Motor does not run. AC cord disconnected.

Fuse blown.

Defective motor.

Connect AC cord-

Replace fuse.

Replace motor.

I.

2,

3.

t.

2.

3.

Noisy playback or poor high

frequency response. Heads misaligned.

Head magnetized-

See "Record-PIayback Head

Alignment".

Demagnetize head.

i.

2.

l.

2.

Wow or flutter

speed. at 7j ips 1. Speed change bushing (f2l) slip-

ping on shaft. l. Tighten screw (120).

Insufficient drive

3 3/4 ips speed. at 7! or l.

2.

3.

4.

Defective main drive idler wheel

(31).

Oil on capstan.

Defective capstan drive belt

(u8).

Drive motor (I24) defective.

l. Replace main drive idler wheel

(3t).

See 'Cleaning".

Replace belt (ll8).

Replace drive motor (124).

2.

3.

4.

Tape spills when going from

Rewind or Forward to Stop. Reel diameters unequal.

Brake shoes (34) and (80) worn

or out of adjustment.

Tape reels must have the same

diameter.

Replace or adjust brake shoes

(3a) and (80).

l.

2.

l.

2.

Index Counter doesnot func-

tion. l. Counter belt (12?) worn or bro-

ken. I" Replace counter belt (127).

No takeup or fast forpard. l. Forward idler tension spring

(32) disconnected or broken. l. Connect or replace Forward idler

tension spring (32).

TI

o

0

m

F

(.'t

No tape movement in Play

or Record mode. l. Pressure roller tension spring

(51) broken. I. Replace pressure roller tension

spring (51).

PAGE 5