SlimZone Premier i

TABLE OF CONTENTS

1. INTRODUCTION.............................................................................................................................1

1.1 IMPORTANT NOTE....................................................................................................................................1

1.2 FEATURES.................................................................................................................................................1

1.3 SAFETY INSTRUCTIONS..........................................................................................................................2

2. APPLICATION AND DESIGN CONSIDERATIONS........................................................................2

3. COMPONENT REQUIREMENTS...................................................................................................3

3.1 BASIC SYSTEM ........................................................................................................................3

3.2 EXPANDER MODULE...............................................................................................................3

3.3 ENVIRONMENTAL MODULE....................................................................................................4

3.4 SIZING TRANSFORMERS........................................................................................................4

3.5 SIZING DAMPERS ....................................................................................................................4

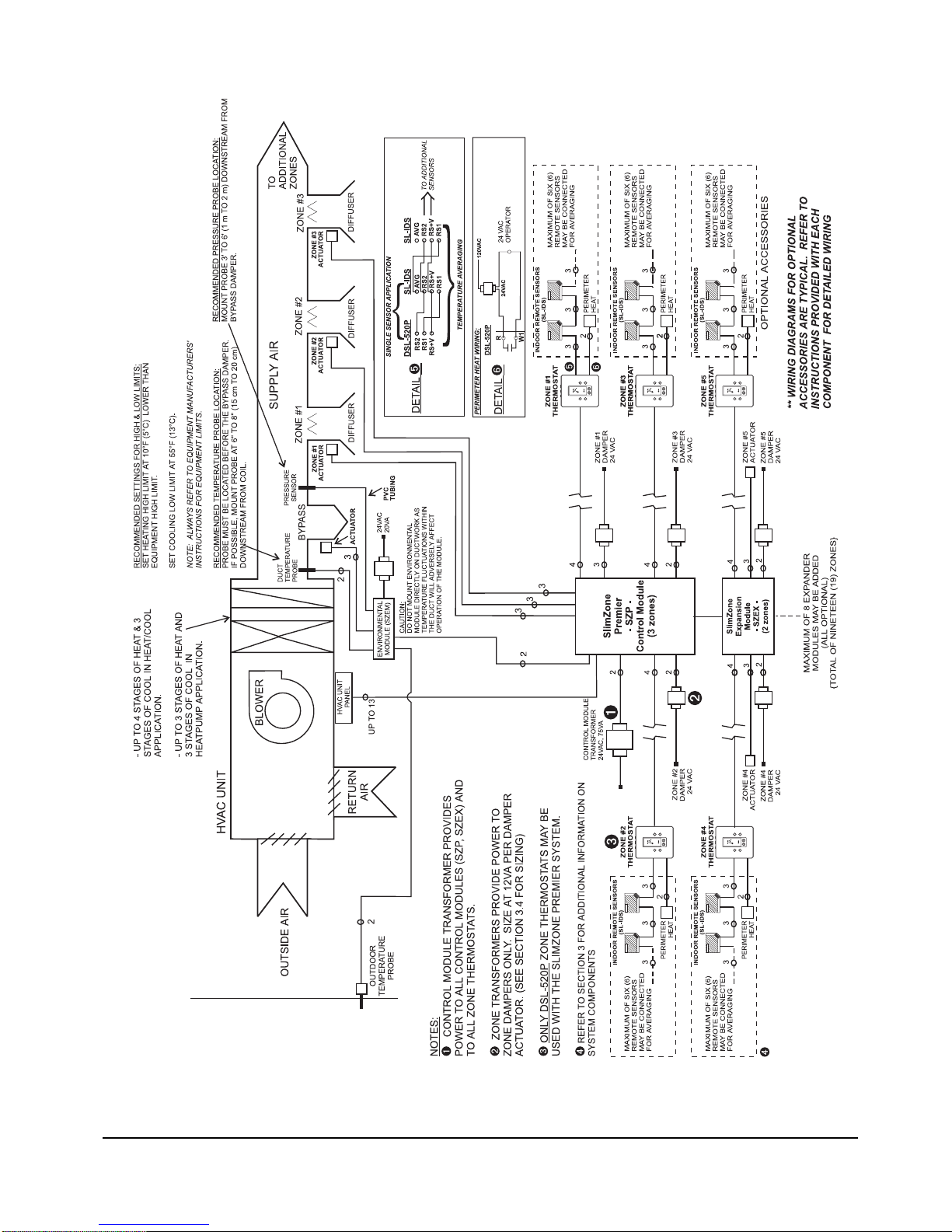

3.6 TYPICAL SYSTEM DIAGRAM...................................................................................................4

4. SYSTEM INSTALLATION................................................................................................................6

4.1 SLIMZONE PREMIER CONTROL MODULE (SZP)..................................................................................6

4.1.1 REMOVAL AND INSTALLATION OF THE DOOR .........................................................................6

4.1.2 INSTALLATION OF THE BACKPLATE..........................................................................................6

4.2 THERMOSTAT INSTALLATION: DSL-520P...............................................................................................7

4.3 DAMPERS..................................................................................................................................................7

4.4 WIRING INFORMATION..........................................................................................................................10

4.5 CURRENT LIMITED OUTPUT TERMINALS...........................................................................................10

4.6 SLIMZONE ENVIRONMENTAL MODULE (SZEM)..................................................................................11

5. SYSTEM OPTIONS AND OPERATION........................................................................................12

5.1 INTERACTION BETWEEN MODULES ...................................................................................................12

5.1.1 SZP CONTROL MODULE............................................................................................................12

5.1.2 DSL-520P ZONE THERMOSTAT.................................................................................................13

5.1.3 SZEM ENVIRONMENTAL MODULE ...........................................................................................14

5.2 SYSTEM PROGRAMMING......................................................................................................................14

5.2.1 PROGRAMMING FEATURES .....................................................................................................14

5.2.2 SCHEDULES................................................................................................................................14

5.2.3 FACTORY DEFAULTS .................................................................................................................15

5.3 USER OPTIONS......................................................................................................................................15

5.4 HVAC OPTIONS.......................................................................................................................................15

5.5 CONTROL METHODS.............................................................................................................................16

5.5.1 TIMESHARE.................................................................................................................................16

5.5.2 DIFFERENTIAL............................................................................................................................16

5.6 SEQUENCE OF OPERATION.................................................................................................................17

5.6.1 TIMESHARE MODE.....................................................................................................................17

5.6.2 DIFFERENTIAL MODE................................................................................................................18

5.7 USER INTERFACE ..................................................................................................................................18

5.7.1 LCD SYMBOL DESCRIPTION.....................................................................................................18

5.8 FLOW DIAGRAM .....................................................................................................................................19