Robertson CRC701 User manual

Robertson Harness

Fort Collins, Colorado

www.robertsonharness.com CRC 700 Series

(970) 682-4470

These instructions are provided to the user by the manufacturer and

should be saved for future reference.

Requirements

▪These items are designed to connect the user to a suitable fall protection

anchor to avoid or limit a fall, and may also allow for safe attachment

to appropriate pulley's used in zip line and canopy tours.

▪Anchorages selected for personal fall arrest systems must be capable ▪

of sustaining a 5,000 lb. (22.2 kN) static load or twice the maximum arrest

force permitted on the system. ▪

▪These items are designed for a single user unless otherwise specified. ▪

▪Lanyard connections to the harness must be approved connectors to the

appropriate fall arrest attachments on the harness. ▪

▪A cursory inspection by a "Qualified Person" is essential before each use of

all equipement. ▪

▪Robertson Harness recommends an annual examination of general

condition and function be carried out and recorded by a Third Party

"Qualified Person" to ensure servicability and proper use.

▪Product should not exceeding 10 years from the date of first use.

See Service Life & Retirement Document for more details.

Call (970) 682-4470 or email Sales@RobertsonHarness.com

Qualifications

This product has been pull tested to 5000 lb. (22.24 kN)

Complies to PRCA/ANSI 1.0-1.3 5000 lb. (MBS) minimum breaking strength

Complies to ANSI z359.1 required 5000lb. Breaking strength.

Tested to ASTM F-1772 12.1.2 / 12.2.2 Standard specification

for harnesses used in Rescue, Safety and Sport Activities. Date Inspected Pass/Fail Comments Signature

For full body harnesses, sit harnesses, and chest harnesses.

Meets and exceeds CE qualifications and standards.

WARNING

▪Serious injury death may result from misusing or improper use of this ▪

equipment.

▪This equipment has been designed and manufactured for use by

experienced professionals only. ▪

▪Do not attempt to use this equipment without proper training.

▪Do not alter this equipment in any way. ▪

▪Do not use equipment on abrasive surfaces or around sharp objects.

▪Do not store or use this nylon webbing near chemicals.

▪Do not use this equipment for anything designed to purposely create a ▪

reoccurring free fall. ▪

▪Only connect to the manufactures designed main belay in the front

of the harness or structural weight bearing Cypress Loop on rear of the

harness.

▪Shoulder and waist V-rings are also designed to be clipped into.

▪Contact Manufacturer if to be used in swing applications defined as a

pendulum in motion from a fixed pivot point.

tearing or ripping on the abrasions.

Look for fraying on the edges, burns or other possible damage.

Carefully inspect the wear and any possible broken stitches in the

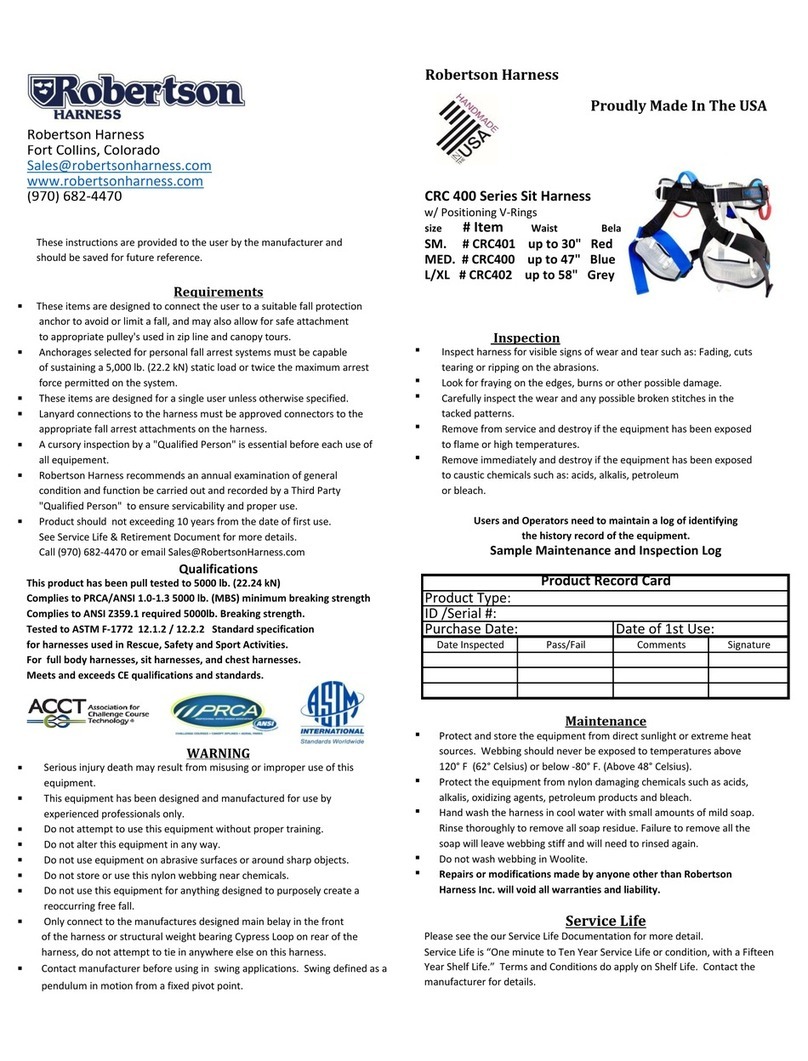

size # Item Waist Belay

MED. # CRC700 up to 47" Blue

L/XL # CRC702 up to 58" Grey

Inspect harness for visible signs of wear and tear such as: Fading, cuts

Inspection

Robertson Harness

Proudly Made In The USA

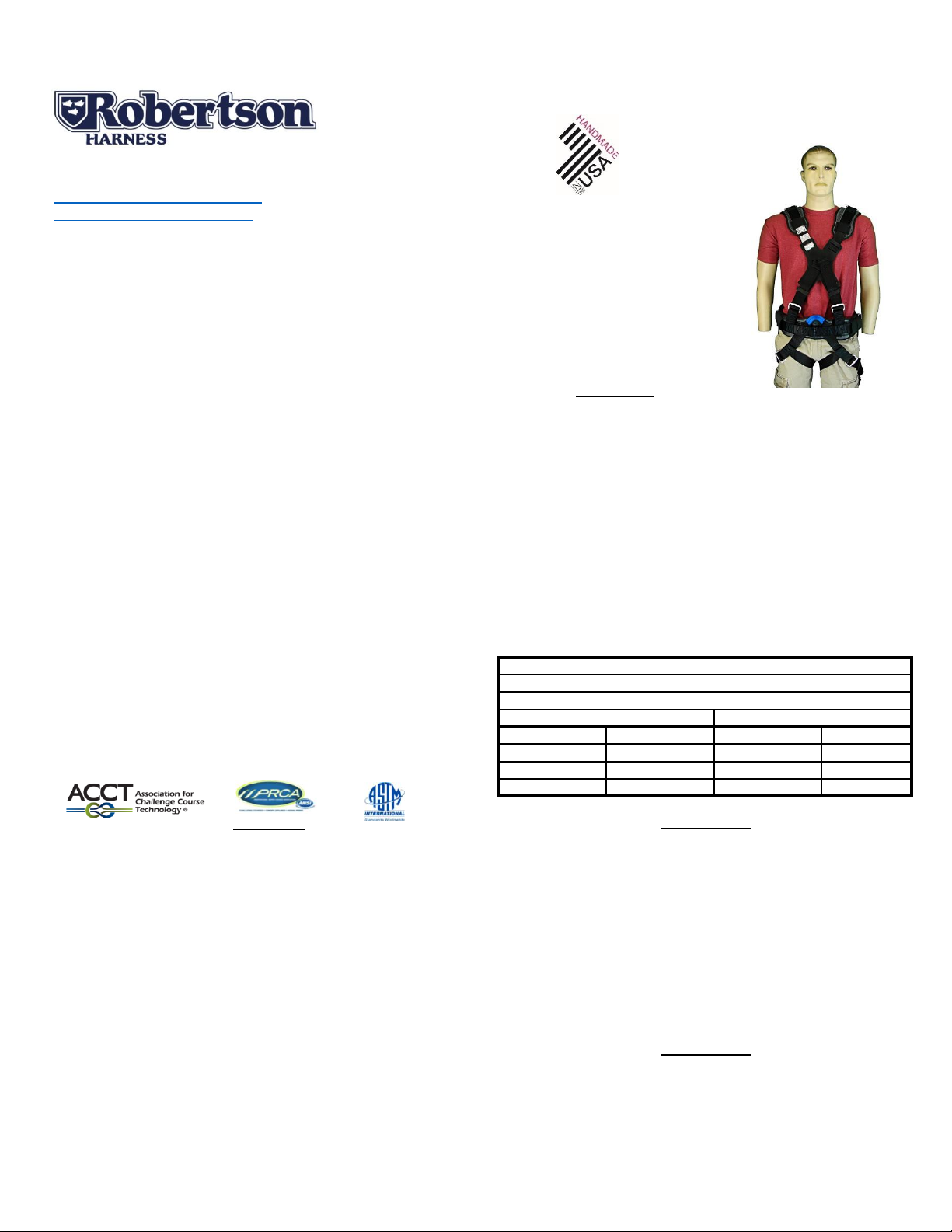

Paratrooper/Superman Harness

SM. # CRC701 up to 30" Red

the history record of the equipment.

alkalis, oxidizing agents, petroleum products and bleach.

Product Record Card

Product Type:

ID /Serial #:

Purchase Date:

Date of 1st Use:

Maintenance

Protect and store the equipment from direct sunlight or extreme heat

sources. Webbing should never be exposed to temperatures above

120° F (62° Celsius) or below -80° F. (Above 48° Celsius).

Protect the equipment from nylon damaging chemicals such as acids,

to flame or high temperatures.

Remove immediately and destroy if the equipment has been exposed

Service Life

Please see the our Service Life Documentation for more detail.

Service Life is “One minute to Ten Year Service Life or condition, with a Fifteen

Year Shelf Life.” Terms and Conditions do apply on Shelf Life. Contact the

manufacturer for details.

tacked patterns.

Remove from service and destroy if the equipment has been exposed

to caustic chemicals such as: acids, alkalis, petroleum

or bleach.

Users and Operators need to maintain a log of identifying

Sample Maintenance and Inspection Log

Hand wash the harness in cool water with small amounts of mild soap.

Rinse thoroughly to remove all soap residue. Failure to remove all the

soap will leave webbing stiff and will need to rinsed again.

Do not wash webbing in Woolite.

Repairs or modifications made by anyone other than Robertson

Harness Inc. will void all warranties and liability.

For your own safety, please read and understand all information included with this product.

Retain the instructions for future use and reference as needed. Provide this sheet to anyone using or

supervising the use of this harness

The Paratrooper offers the ability to clip into the main belay simulating a seat harness while also

having the versatility to position the user in a prone position. Figure.

Installation Instructions

Loosen all buckles and expand the webbing. You will not need to totally

unfasten the ends.

Step down through the waist belt and leg loops. Pull the harness up and

slip on the shoulder straps.

Tighten waist belt until snug. Tighten leg straps until they are ½” larger

than your thigh when tensed. (You should be able to slide your fingers

between the leg strap and your thigh.)

The quick-adjust buckle is laced running web through the back of the

buckle, around the slider, exiting under the buckle again. Figure2

At least 4 inches of web tailing must extend from the buckle once secured

on waist, legs and chest adjust pieces.

Adjust the chest strap height and snugness so that the shoulder straps

will stay on the shoulders in a dynamic fall.

The shoulder straps can then be tightened to a snug fit.

To tie-in, simply clip into the colored belay loop provided in the front of

the harness. See figure 3.

The rear colored loop is a structural loop for tying off at a work station or

platform.

Prone Position

There are four key clip in points, two V-rings above the shoulder blades

and two self-positioning V-rings around the rear waist belt.

*Do not attempt to tie-in anywhere other than the intended

Colored belay loop, rear tie off loop or designated V-Rings

This product has been designed, tested, and manufactured in accordance with

ASTM-F 1772 testing which meets PRCA/ANSI 1.0-1.3 and ANSI/ACCT 03-2016

standards in effect on the date of manufacture.

WARNING! This harness is not designed nor rated for swing applications due to

The exponential force placed on the harness when rising from the well position.

Swing, defined as a body suspended from a fixed support so that it swings freely

back and forth under the influence of gravity. Never adjust the web tailing in the

buckle to its absolute extended length, keep a 4 inch minimum requirement.

Rock climbing, ice climbing, mountaineering and other related activities are extremely

dangerous by their very nature. A mistake or accident may result in injury or death. It is the

sole responsibility of the buyer and the

user of all climbing equipment to get the proper instruction and to practice caution when

climbing or otherwise using this equipment. Frequently inspect every piece

of climbing equipment for possible damage or signs of wear. Climbing equipment cannot be

expected to last forever, and it is up to the individual user to determine when to retire a piece

of equipment.

CLIMB SMART! Seek qualified instruction, and take responsibility for yourself. Inspect this

product regularly and retire it immediately if it shows signs of wear

or damage. Do not attempt to use this product if you are not fully competent in

its use and care. Treat this product as though your life depends on it. Improper

use or care of this product can result in serious injury or death.

Robertson Harness Products

www.robertsonharness.com

Revised 09/19

Figure 1

Figure 2

Figure 3

Figure 4

CRC 700 Series Paratrooper/Superman Harness

CRC 701 Small - Red CRC 700 Med. - Blue CRC 702 L/XL - Grey

Clip

into

the

Red,

Blue,

Gray

loops

or v-

rings.

This manual suits for next models

2

Other Robertson Protection Device manuals

Popular Protection Device manuals by other brands

ITR

ITR Energetyka Map 6 User manual and technical documentation

Arcteq

Arcteq AQ-T215 instruction manual

ABB

ABB Relion REQ650 Applications manual

Selcom Security

Selcom Security SEL-310 Komar manual

Trylon

Trylon COUGAR INSTALLATION DRAWINGS & INSTRUCTIONS

Franklin Electric

Franklin Electric submonitor owner's manual

SymCom

SymCom PumpSaver Plus 231-P-INSIDER installation instructions

MDR Electronics

MDR Electronics MX-2503 manual

ICM Controls

ICM Controls ICM441 Installation, operation & application guide

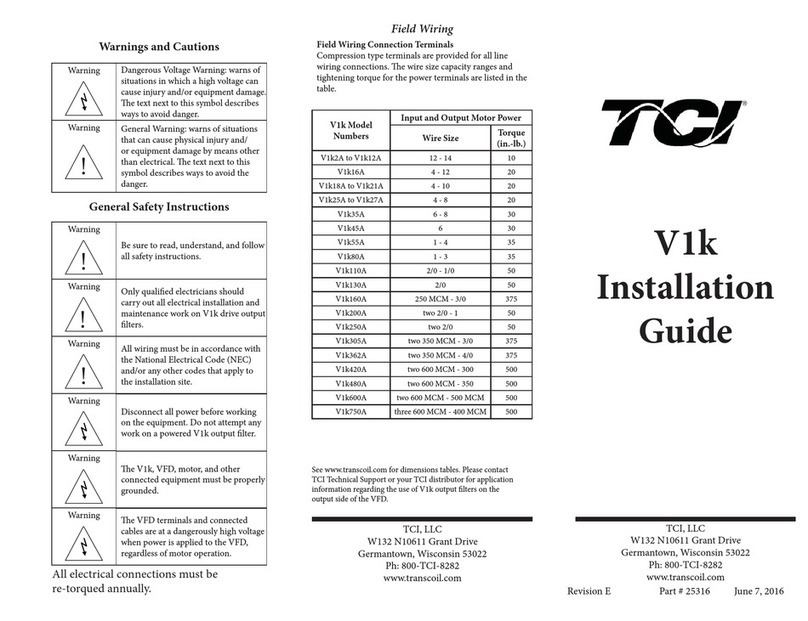

TCi

TCi V1k installation guide

Eaton

Eaton Crouse-Hinds ZoneBarrier 4PPOE Series instruction sheet

TAZ

TAZ LOV3 manual