Trylon COUGAR Guide

IS0

9001

:2000

Registered

INSTALLATIONDRAWINGS

&

INSTRUCTIONS

*

[CDN

VERSION]

Revision date:

May,

2006

/

*

include

with

complete

Kits

I

Fall Protection System

For Ladder Installations

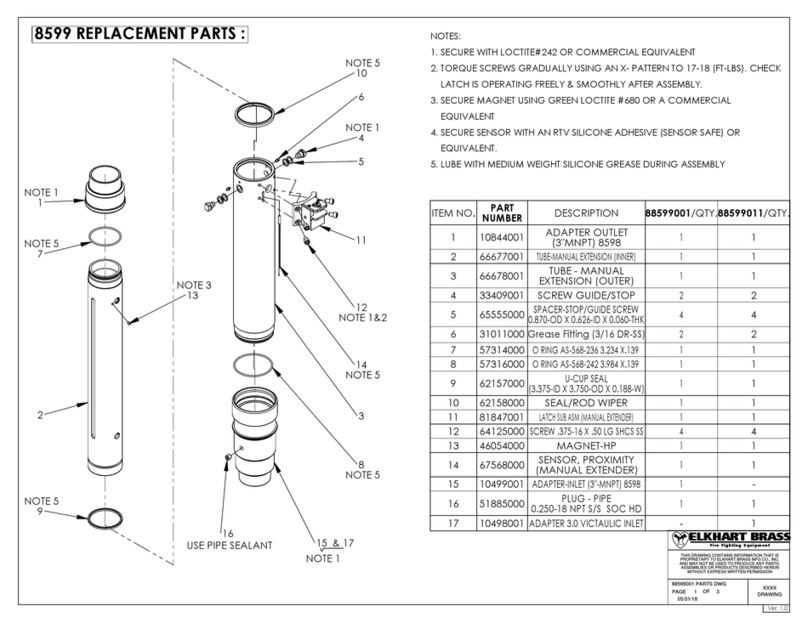

COUGAR INSTALLATION DETAILS FOR CUSTOM TOWERS

[CAN]

START

BOTTOM

RAIL

APPROX~MATELY

3

FEET

FROM

BOTTOM OF LADDER OR BASE STARTING POSITION. LOCATE

RAlL AT CENTER OF LADDER OR CLIMBWAY TO ALLOW

BALANCED FOOT PLACEMENT.

ATTACH THE FIRST CLAMP ONE FOOT FROM ME LOWER

END OF THE BOTTOM RAIL. CLAMP EVERY

4'

TO

5'

AS RUNGS

PERMIT. TOP CLAMP SHOULD BE ON TOP RUNG OF LADDER.

RAlL CAN SAFELY EXTEND MAX.

1.5

FEET ABOVE LADDER

TOP

TO

PERMIT SAFE ARRIVAL AT LADDER TOP. FOR BEST

RESULTS, PLACE CLAMP BOLTS IN CONTINUOUS T-SLOTS

AND FINGER TIGHTEN AT APPROXIMATE LOCATIONS BEFORE

RAISING RAlL SECTIONS INTO PLACE. PUT SPLICE SECTIONS

RAlL TOPS AND TIGHTEN TO ALLOW POSITIVE JOINING OF

RAILS. RAISE AND SECURE THE FIRST RAlL BEFORE

CONTINUING WlTH INTERMEDIATE RAILS. LEAVE 1/16" OPEN

AT EACH JOINT FOR EXPANSION AND CONTRACTION. INSTALL

SPACING TYPICAL TOP RAIL WITH BOLT STOP (3/8' X

2-1/2")

THROUGH

TOP HOLE. THE

318"

BOLTS SUPPLIED ARE SUITABLE FOR

MOST APPLICATIONS.

IMPORTANT NOTE: LADDER TYPE, RUNG SIZE, RUNG

SPACING AND ALL INFORMATION PERTINENT TO THE

INSTALLATION SHOUU) BE GIVEN WHEN ORDERING EACH

KIT. INSTALLATION RECOMMENDATIONS AND SPECIAL

BRACKETS FOR NON-TYPICAL INSTALLATIONS AVAILABLE

REGULAR RAIL BY CONTACTING TRYLON TSF.

TO CLIMB: SLIDE TROLLEY ONTO RAIL. ATTACH SAFETY

HARNESS SNUGLY AROUND WAIST WITH

'0'

RING AT FRONT.

REFER TO MANUFACTURERS INSTRUCTIONS FOR PROPER

BODY FIT ON THE HARNESS. ATTACH TROLLEY SNAP

TO 'D' RING ON HARNESS. LEAN SLIGHTLY AWAY FROM RAlL

TO DISENGAGE PAWL AN0 CLIMB OR DESCEND IN LIKE

MANNER. RELEASING TENSION AUTOMATICALLY ENGAGES

LOCK.

12"f

TO

TYP.

ATTACHMENT NOTES AND DETAILS

ATTACHMENT 3/8"

x

2-1/2"

I

f

BOLT STOP

STAR;

RAIL

Sm

APPROX. 3'-0" FROM FACE VIEW

1.5'

MAX ABOVE TOP RAIL

I

THROUGH LADDER PLATFORM R GRADE OF LADDER TOP CLAMP

I

(LENGTH

TO

SUIT)

TYP,

INSTALLATION DETAIL

FOR

LADDERS

*

BACKING 3/8"0 BOLT

(FULL THREAD)

RAlL

STANDARD RAlL ATTACHMENT

NOTES:

1)

CONFORMS TO STANDARDS:

CSA 2259.2.1

-98

(NOV 16/02 AMENDMENT)

PLEASE NOTE: C.S.A. CERTIFICATION IS VALID ONLY IF THE

SYSTEM IS INSTALLED USING MANUFACTURERS

COMPONENTS AND IN ACCORDANCE NTH

THE MANUFACTURERS INSTRUCTIONS

1/16"

EXPANSION

GAP

\INTERNAL

SPLICE

BAR

AT ALL SPLICES

-k

EplN

REGULAR RAlL

(20' Lg.)

3/8"0 BOLT

(FULL

THREAD)

COUGAR TROLLE

TROLLEY LEVER

KARABINER

t

13'

APPROX.

(TO GROUND OR PLATFORM)

BODY

fi

TRYLON

TIF

21

?O;THFIELO

DRIVE,

PO

BOX 186, ELMIRA, ONTARIO. N3B 226

TFI

.1.519\ 669-5431

FAX.(!i19)

669-8917

0

TRY

LON

TIF

21

Southfield Drive, PO Box

186,

Elmira, Ontario,

N3B

226

-

Tel:

(519) 669-5421

-

Fax:

(519)669-8912

SAFETY RAIL SYSTEM INSTRUCTIONS

Important

-

Read and UnderstandThis Document Before Installationor Useof Svstem!

Warning

Manufacturer's instructions must be followed regarding proper system use, maintenanceand installation.

Alternations or misuse of product or failureto follow instructionsmay result in serious injury ordeath.

All safetv rail systems and components are to be used under the safetv standards in place in the iurisdiction in which

you are working. These instructions are not meant to supersede anv local or federal safetv standards.

Any Safety Trolley, which has seen fall arresting service, should not beused after such service and returned

tothe manufacture for immediate inspection. Aswell the whole svstem: trolley, rail and all accessories will

need to be inspected and replaced at once. Until a full replacement ofthe system

is

implemented you should

not ascend ordescend

on

a

system that has incurred usage of

a

fall.

Use

-

Trylon's Safety Trolley

&

Rail system is intended to arrest personnel (not material) should they (the individual) slip or

fall while climbing.

Ensure the anchorage system can support a minimum load of

2500

pounds. Certification is applicable to the device

only. Neither the manufacturer nor CSA has investigated the anchorage system. The Safety Rail Trolley is designed to

work onTrylon's Safety Rail Systems only.

Climbers should always tie off to a structure by means of a lanyard while working or resting. When detaching from the

trolley to work elsewhere on the structure, as a best practice, climbers should also tie off their trolley to avoid the

unlikely event ofthe trolley 'slipping' down the rail during extreme vibrations.

Trylon Fall Protection systemsare not intended to be used asa life line or work position device while working.

Body harnesses supplied with the Fall Protection system may require the use of D-Rings or carabiners to provide a safe

and comfortable fit for the attachment on climber's harness. Length of attachment and clothing should not impede the

locking mechanism on the slider.

Do not exceed

6

inches of distance between slider and attachment point.

Training

Climbers should fully familiarize themselves with the operation of the system before ascendingthe structure or tower.

As well they should insure that the body harness is properly equipped sb

it

does not interfere with arresting features of

the fall protection system. Make certain all applicable hazards are addressed properly to provide climber safety.

Hazardous power lines, antenna radiation, physical obstructions, icing, frost, in addition to climber's knowledge,

ability and health. The Safety Trolley and Rail System is designed for use by one climber at a time.

Inspection

The Safety Rail Trolley system is designed to function as an integrated system and the use of non-compatible materials

is not recommended and may impair performance.

(cont'd)

SAFETYRAIL SYSTEM INSTRUCTIONS

--

-

A visual inspection of the Trolley is required before each use. Some of the main inspection points include ensuringthat

the compression spring is in place and not missing, ensure that all four rollers (wheels) are in place and secure, turning

the unit over to ensurethat the SafetyLockTMorientation lock-out device moves freely. Always check Trolley before

ascending to ensure it runs free and locksproperly onto the rail.

Detailed inspections should be conducted on a regularly scheduled basis as determined by user; a minimum

(2)

detailed inspections per year. All worn Trolley parts should be returned to the manufacturer for repair or replacement.

If

a

unit is unsatisfactory due not attempt to climb with

it

and remove it from service immediately and notify

supervisor.

Care and Maintenance

All trolleys should be stored in a clean, dry areawith limited exposure tothe following:

1)

sunlight

2)

excessive heat

3)

harmful fumes

4)

corrosive chemicals or conditions

The trolley can be cleaned by dipping it in a mild soap and water solution. Donot use harsh detergents or chemicals or

pressure washers. After cleaning, the unit should be rinsed in clear water and allowed to air dry naturally. After

washing, hardware should be inspected. No lubrication is necessary.

CAN

Cougar rail install manual.pdf\

Last revised:

May!Ob

TRYlON

TIC

21

SouthfieldDrive,

PO

Box

186,

Elmira,

Ontario,

N3B

226

-

Tel:(519) 669-5421

-

Fax:

(519) 669-8912

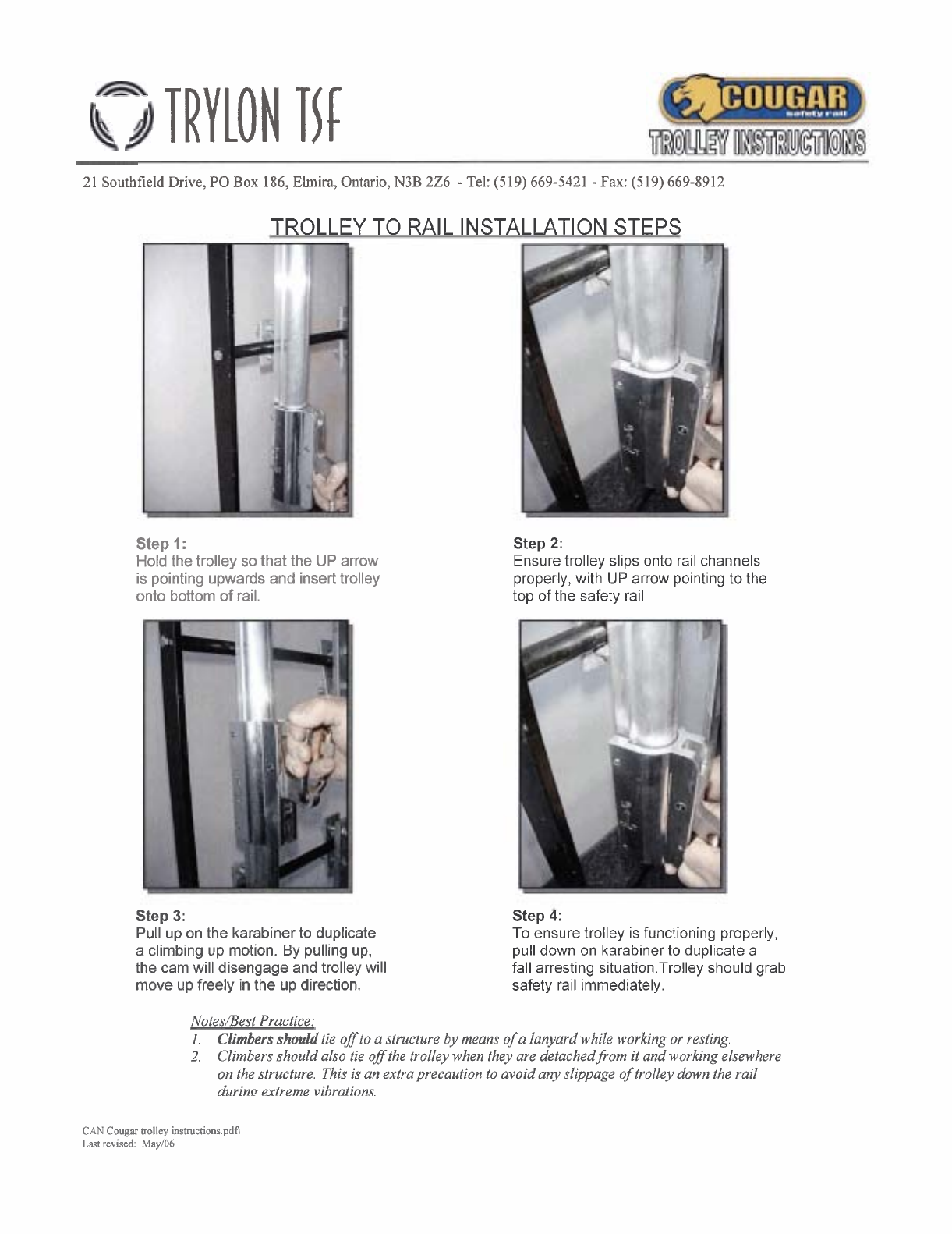

TROLLEY TO RAIL INSTALLATION STEPS

Step

1

:

Holdthe trolley sothat the UP arrow

is pointing upwards and inserttrolley

onto bottom of rail.

Step

2:

Ensuretrolley slips onto rail channels

properly,with

UP

arrow pointing to the

top of the safety rail

Step

3:

Pull up on the karabiner to duplicate

a climbing up motion.

By

pulling up,

the cam will disengage and trolley will

move upfreely in the up direction.

Step

4:

To ensure trolley is functioning properly,

pull down on karabiner to duplicate a

fall arresting situation.Trolley should grab

safety rail immediately.

Notes/Best Practice:

I.

Climbersshould tie off toa structure

by

means of a lanyardwhile working or resting.

2.

Climbersshould also tie off the trolleywhen they are detachedfiom it and working elsewhere

on thestructure. Thisisan extraprecaution toavoid anyslippage of trolleydown the rail

durin~extreme vibrations.

CAN

Cougar

trolley

instructions.pdA

Last

revised:

May106