Page 6

Limited 3 Year Warranty

Otterbine® Product

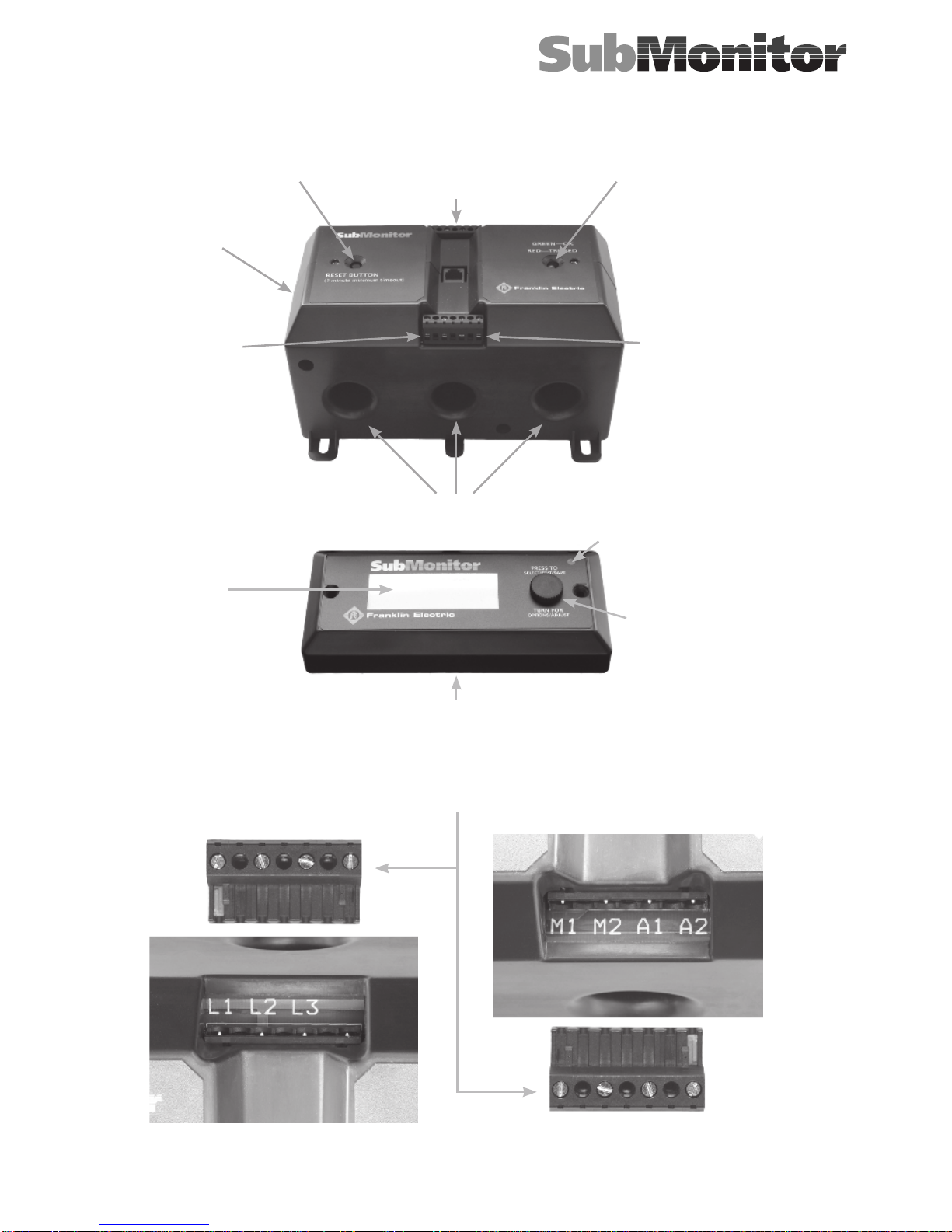

Giant Fountain with SubMonitor System

WARRANTY: Barebo, Inc 3840 Main Road East, Emmaus Pennsylvania 18049,U.S.A. hereby

warrants, subject to the conditions hereinbelow set forth, that should the OTTERBINE product

prove defective by reason of improper workmanship or materials at any time during the warranty

period the Purchaser at retail will be guarantee that BAREBO will repair or replace the said

OTTERBINE product as may be necessary to restore it to satisfactory operating condition, with-

out any charge for materials or labor necessarily incident to such repair or replacement, provided

that:

a) The enclosed Warranty Registration Card should be mailed to BAREBO within

fifteen (15) days of the original receipt by the Purchaser at retail in order to avoid delays:

b) The OTTERBINE product must be delivered or shipped, prepaid, in its original

container or a container offering an equal degree of protection, to BAREBO or a

facility authorized by BAREBO to render the said repair or replacement services

or, if purchased from an authorized OTTERBINE dealer, to such dealer;

c) The OTTERBINE product must not have been altered, repaired or serviced by

anyone other than BAREBO, a service facility authorized by BAREBO to render

such service, or by an authorized BAREBO dealer, and the serial number of the

OTTERBINE product must not have been removed or altered: and

d) The OTTERBINE product must not have been subjected to lightning strikes and

other Acts of God, vandalism, freezing-in, accident, misuse or abuse, and must have

been installed in conformance with applicable electrical codes (including proper

electrical protection), and also installed, operated and maintained in accordance with

guidelines in the Owner's Manual shipped with the Otterbine product.

No implied warranties of any kind are made by BAREBO in connection with this OTTERBINE

product, and no other warranties, whether expressed or implied, including implied warranties of

merchantability and fitness for a particular purpose, shall apply to this OTTERBINE product.

Should this OTTERBINE product prove defective in workmanship or material, the retail

Purchaser's sole remedy shall be repair or replacement as is hereinabove expressly provided and,

under no circumstances, shall BAREBO be liable for any loss, damage or injury, direct or conse-

quential, arising out of the use of, or inability to use, the OTTERBINE product, including but not

limited to retail Purchaser's cost, loss of profits, goodwill, damages due to loss of product or

interruption of service, or personal injuries to Purchaser or any person.