Robin RGD2500 User manual

SERVICE

MAIUUAL -

--

Model

RGD2500,RGD3300

Generator

PUB-GS1186

Rev. 8198

CONTENTS

.

Section

Tile

Page

1

.

SPEClFlCATlONS

.......................................................................................................

1

2

.

PERFOMANCE CURVES

...........................................................................................

2

2-1 MODELRGD2500

.................................................................................................

2

2-2

MODELRGD3300

.................................................................................................

2

2-3

DC OUTPUT

.........................................................................................................

2

3

.

FEATURES

..................................................................................................................

3

4

.

GENERAL DESCRIPTION

..........................................................................................

4

4-1 EXTERNALVIEW

.................................................................................................

4

4-2

CONTROLPANEL

................................................................................................

5

4-3 LOCATION

of

SERIALNUMBER

and

SPECIFICATION NUMBER

......................

6

5

.

CONSTRUCTION AND FUNCTION

...........................................................................

7

5-1

CONSTRUCTION

.................................................................................................

7

5-2 FUNCTION

............................................................................................................

7

5-3

GENERATOR OPERATION

................................................................................

11

6

.

SAFETY PRECAUTIONS

.........................................................................................

14

7

.

RANGE

OF

APPLICATIONS

....................................................................................

15

8

.

MEASURING PROCEDURES

..................................................................................

18

8-1 MEASURINGINSTRUMENTS

...........................................................................

18

8-2AC OUTPUTMEASURING

.................................................................................

21

8-3

DC OUTPUT MEASURING

.................................................................................

21

8-4 MEASURING INSULATIONRESISTANCE

........................................................

22

9

.

CHECKING FUNCTIONAL MEMBERS

....................................................................

24

9-1VOLTMETER

.......................................................................................................

24

9-2AC RECEPTACLES

............................................................................................

24

9-3 NO-FUSEBREAKER

...........................................................................................

24

9-4STATOR

..............................................................................................................

25

9-5 ROTOR ASSEMBLY

...........................................................................................

26

9-6 CONDENSER

.....................................................................................................

26

9-7 DIODE RECTIFIER

.............................................................................................

27

10

.

DISASSEMBLY AND ASSEMBLY

..........................................................................

29

10-1

PREPARATION

and

PRECAUTIONS

...............................................................

29

Section

Title

Page

10-2

SPECIAL TOOLS

for

DISASSEMBLY

and

ASSEMBLY

....................................

29

10-3

DISASSEMBLYPROCEDURES

.......................................................................

30

10-4

ASSEMBLY PROCEDURES

.............................................................................

38

10-5

CHECKING. DISASSEMBLY

and

REASSEMBLY

of

the

CONTROL

BOX

.......

51

t

1

.

TROUBLESHOOTING

............................................................................................

53

11-1

NO ACOUTPUT

................................................................................................

53

11-2

AC VOLTAGE

IS

TOO THIGH

OR

TOO

LOW

...................................................

54

11-3

AC

VOLTAGE

IS

NORMAL AT NO.LOAD. BUTTHE LOAD CANNOT

BE

APPLIED

.....

55

11

-4

NO

DC OUTPUT

...............................................................................................

56

11

-5

OILSENSOR TROUBLESHOOTING

.......................

.......................................

57

12

.

WIRING DIAGRAM

.................................................................................................

58

r

I

U

0

z

W

s

a

5

a

I

-

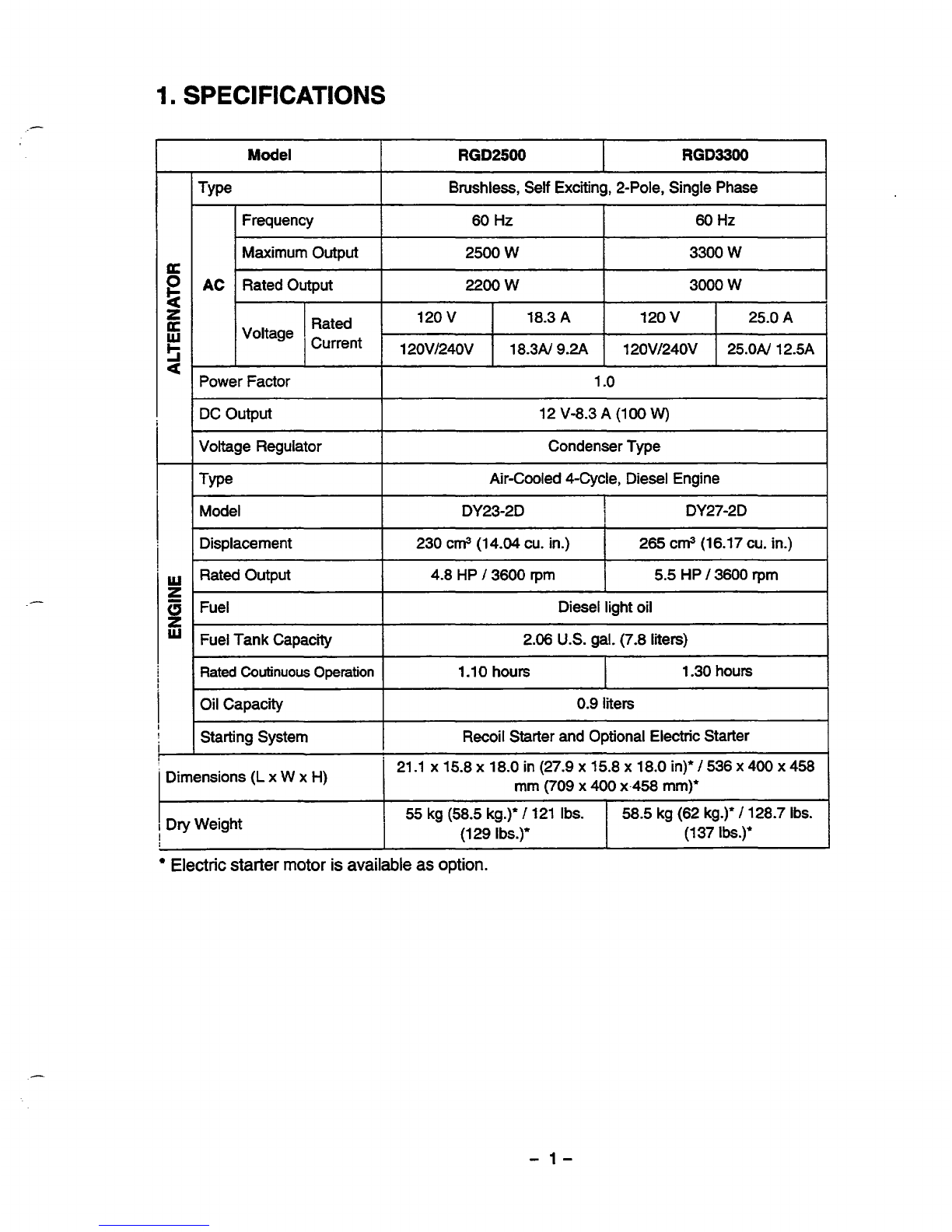

Model

RGD2500

RGD3300

I

Brushless, Self Exciting, 2-Pole, Single Phase

I

I

Frequency 60

Hz

60

Hz

I

Maximum Output

Rated Output

AC

3300

W

2500 W

3000

W

2200

W

Rated

Current

25.0N 12.5A 120Vl240V 18.3N

9.2A

120V/240V

120

v

25.0

A

120

v

18.3

A

Voltage

Power Factor

1

.o

DC Output

Voltage Regulator

12V-8.3

A

(1

00

W)

Condenser Type

Type Air-Cooled CCycle, Diesel Engine

Model DY23-2D

I

i

i

DY27-2D

~

Displacement

I

230 cm3(14.04cu.in.)

I

265

cm3(16.17cu.in.)

I

Rated

Output

4.8

HP

/

3600 rpm

2.06

U.S.

gal. (7.8 liters)

Fuel Tank Capacity

Diesel light oil Fuel

5.5

HP

/

3600

rpm

I

~ ~~ ~~~ ~

Rated

Coutinuous

Operation

I

1.10

hours

I

1.30hours

Oil Capacity

Recoil Starter and Optional Electric Starter

Starting System

0.9

liters

I

Dimensions

(L

x

W

x

H) 21.1

~15.8~18.0in(27.9~15.8~18.0in)’/536~400~458

mm (709

x

400

x.458 mm)*

I

Dry Weight

!

I

55

kg(58.5kg.)’

/

121

Ibs.

58.5 kg (62 kg.)’

/

128.7

Ibs.

I

(129

Ibs.)’

(1

37

I&.)*

Electric

starter motor

is

available as

option.

-

1-

2.

PERFOMANCE

CURVES

2-1

MODEL RGD2500

-

2k

t

A

s

a

n

I-

O

3

-

lk

-0

CURRENT(A)

-

2-2

MODEL

RGD3300

CURRENT

(A)

+

2-3

DC

OUTPUT

16

14

v

5

12

g

10

0246810

CURRENT(A)

"+

3k

2k

t

3

CI

Y

Output

Max.

.................

2500

W

Output Rated

...............

2300

W

Frequency

....................

60

Hz

Voltage

.........................

120

V

Output

Max.

..............

3300

W

Output Rated

............

3000

W

Frequency

.................

60 Hz

Voltage

120

V/240V

e

......................

0

DC

Voltage

..................

12

V

DC

Ampere

.................

8.3

A

DC

output

....................

100

W

The voltage curve shown in the left indicates the char-

acteristic

of

DC

output when charging

a

battery.The

voltage may be decreased

by

20%

when the resis-

tance load

is

applied.

NOTE

:

It

is possible

to

use both

DC

and

AC

outputs

simultaneously up

to

the rated output

in

total.

-

2-

3-1

BRUSHLESSALTERNATOR

Newly developed brushless alternator eliminates troublesome brush maintenance.

3-2

EASYSTARTING

Light pull recoil starter accompanied with automatic decompression system makes the new

RGD

series

generators even easierin starting than gasoline engine generators.

3-3

QUIET

OPERATION

The new

KGD

series generator provides quiet operation by means

of:

The

superb

design

of

intake-exhausr system.

Direct injection combustion system.

A

large super silent muffler.

An efficient

low

noise air cleaner.

3-4

ECONOMICALPERFORMANCE

On

top

of

well

known diesel economy. the air-coolea Robin diesel engine features direct fuel injection

and special designrefinemem for extra fuel efficiency.

3-5

OIL

SENSOR

The

OIL

SENSOR

automatically shuts the engine off whenever the oillevel

falls

down below a safelevel

preventing engine seizure.

3-6

COMPACT, LIGHT WEIGHT

Thecombinationof newiydevelopedbrushless alternatorandair-cooledsinglecylinderRobindiesel

engine enables the new

RGD

series generatorsto be very compact in size and lightin weight.

3-7

RELIABLEPERFORMANCEWITH MINIMAL MAINTENANCE

A

brushless alternator eliminates troublesome brush maintenance.

A

drip-proof alternator design.

A

trouble free condenser voltage regulator.

A

fuselesscircuitbreaker.

A

dust-proof dual element air cleaner.

The

OIL

SESSOR

automatically shuts the engine off whenever the

oil

level falls down below a safe

level preventing engine seizure.

3-8

LONG-LIFEDURABILITY

C'onlpact

and

smooth

running

air-cooledRobindieselenginelastsmuchlongerthanthegasoline

engine

of

the same size.

Trouble-freebrushlessalternatorwithcondensertypevoltageregulatorworksalltheyearround

without any maintenace work.

-

3-

4.GENERAL

DESCRIPTION

4-1

EXTERNAL

VIEW

No-fuse

bmakei

Speed

controlleverRockercover

Fullmwerswitch

I-

/

/

Air cleaner

(DU~

voltage

type

o

Key

switch

(Only

for RGD3300)

\

/

Fuel injection pump

\

DC

output

terminal

Stop

lever

.

Earth

terminal Fuelfi&rOil

filter

Fuelcock

/

Muffler

Electric starter

(only for

RGDSOO)

/

\

Oil

gauge

-

4-

4-2

CONTROL

PANEL

_-

RGD2500, RGD3300

:

60HZ-l20V, 60H~-120V/240V

TYPE

Full

power

switch

Key switch

(Only

for

RGD3300)

Vottmeter

i,

I((

DC

output

terminal

7

DC

fuse

@

1111

/

No-fuse

breaker

/Ac

receptacle

/

Earth

terminal

-

5-

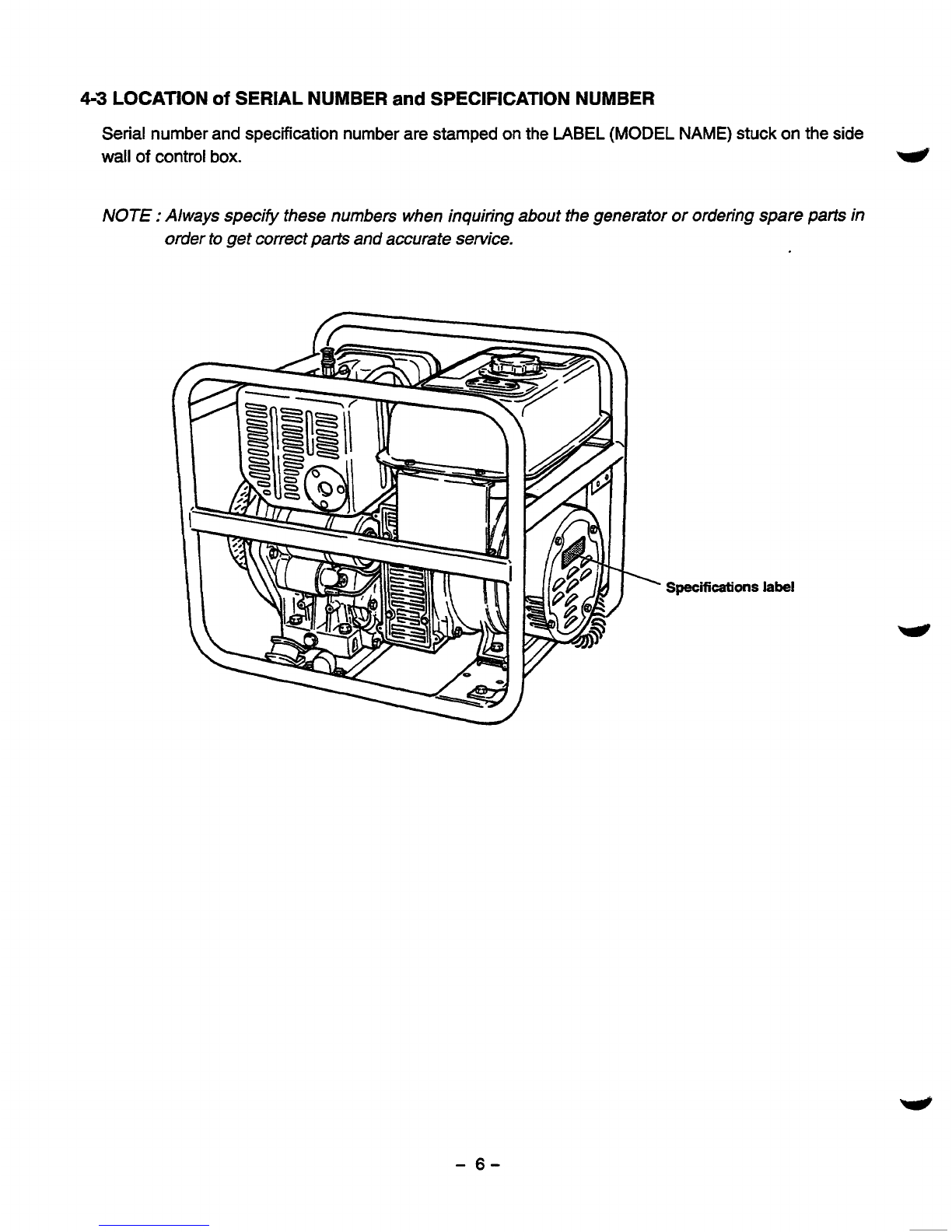

4-3

LOCATION

of

SERIAL NUMBER

and

SPECIFICATION NUMBER

Serial number and specification number are stamped

on

the

LABEL

(MODEL

NAME)

stuck on the side

wall

of

control

box.

w

NOTE

:

Always specify these numbers when inquiring about the generator or orderingspare

parfs

in

order to get correct

parts

and accurate service.

Specifications

label

-

6-

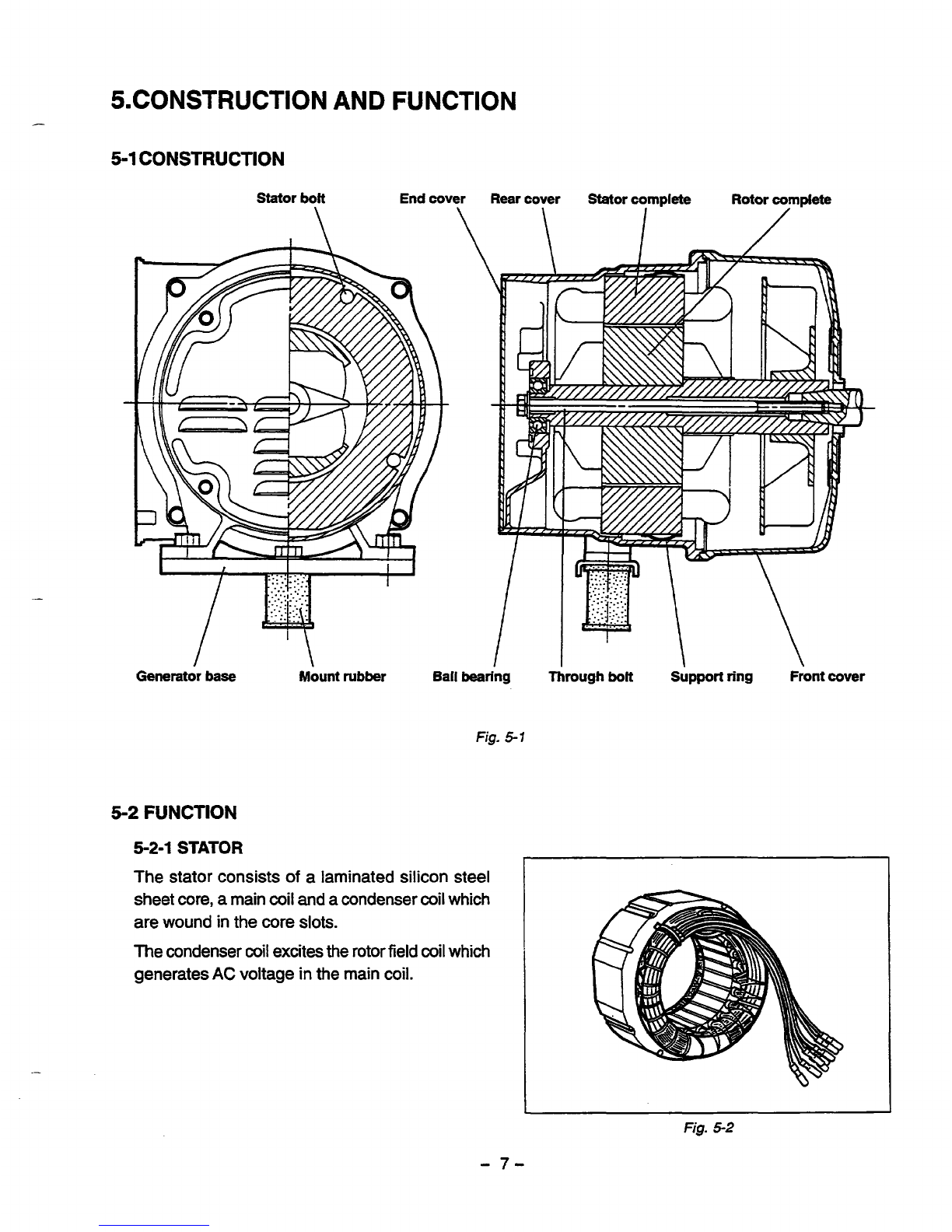

5.CONSTRUCTION

AND

FUNCTION

GeneratorbaseMountrubber BallbearingThrough

bolt

Support

ring

Frontcover

Fig-

5-7

5-2

FUNCTION

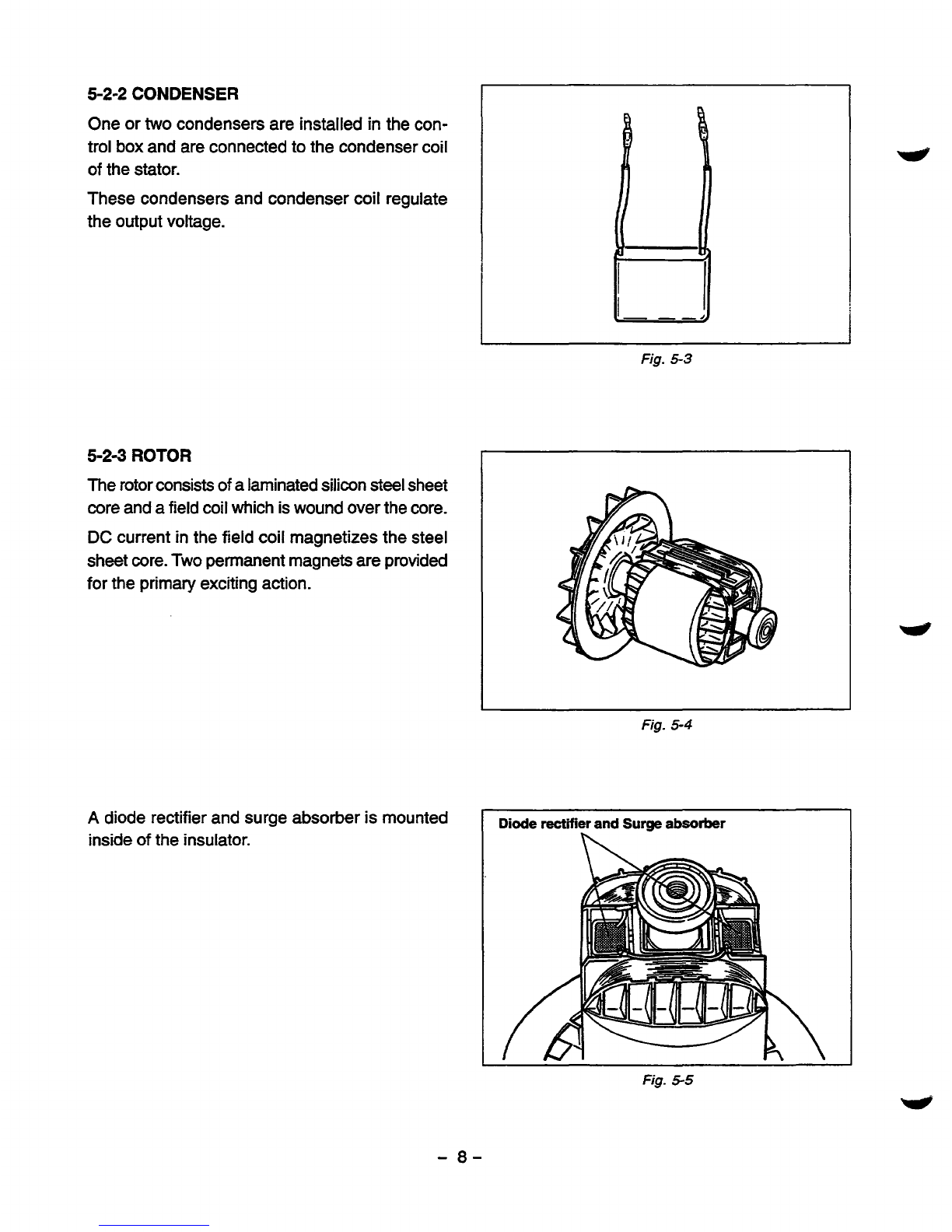

5-2-1

STATOR

The stator consists

of

a

laminated silicon steel

sheet

core,

a

main

coil

and

acondenser coil which

are woundinthe core

slots.

The condenser coil excites the rotor field

coil

which

generates

AC

voltage inthe main

coil.

Fig.

5-2

-

7-

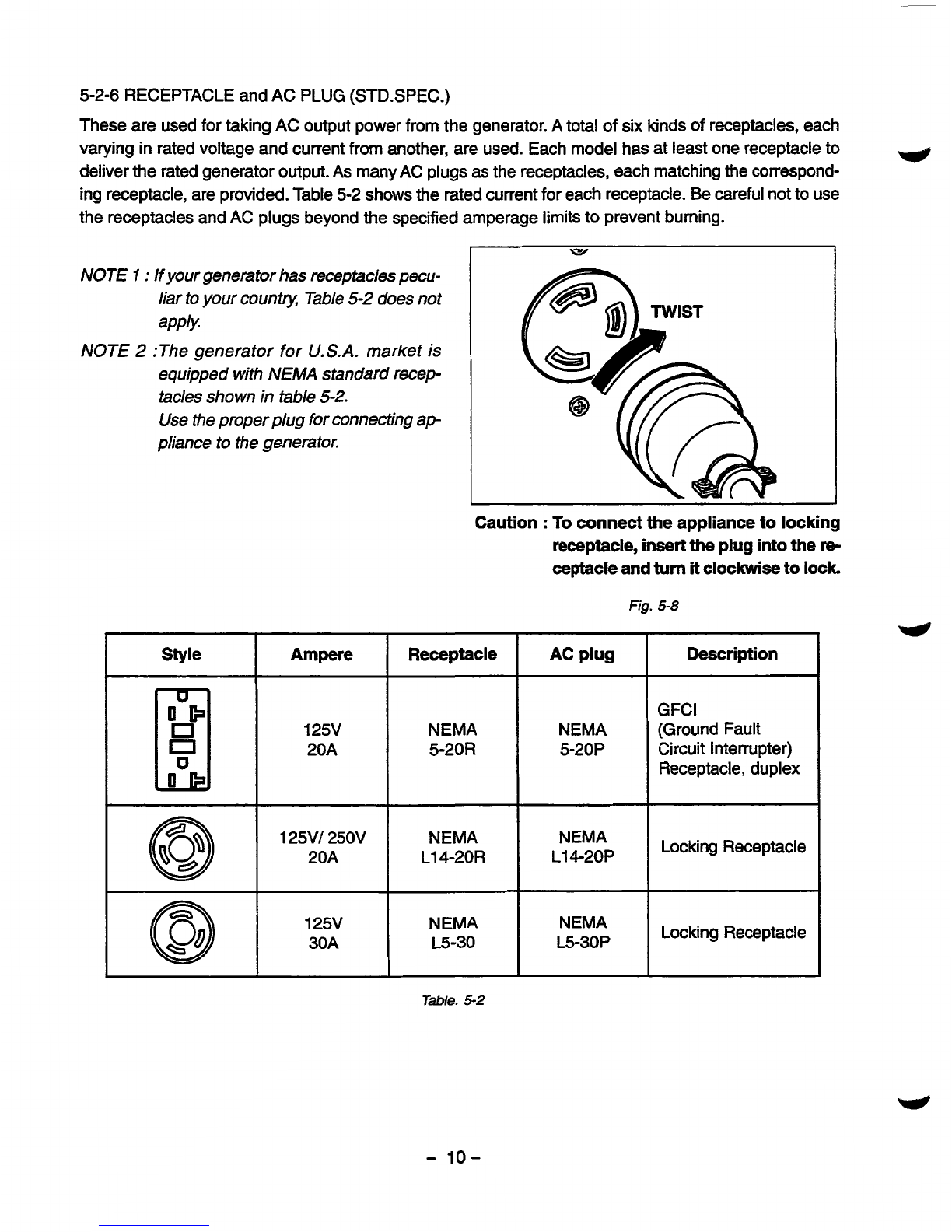

5-2-2

CONDENSER

One or

two

condensers are

installed

in

the

con-

trol

box

and are connected

to

the condenser coil

of

the stator.

These condensers and condenser coil regulate

the

output

voltage.

5-24

ROTOR

The rotor consists

of

a laminated silicon steel sheet

core andafield coil which

is

wound over the core.

DC

current

in

the field coil magnetizes

the

steel

sheet

core.Two permanent magnetsare

provided

for

the primary exciting action.

A

diode rectifier and surge absorber

is

mounted

inside

of

the

insulator.

I

Fig.

53

Fig.

5-4

Diode

rectifier and

Surge

absorber

Fig.

5-5

-

a-

5-2-4

DC

FUSE

(1)

The

10

ampere DC fuse mountedon the con-

trol panel protects whole DC circuit from get-

ting damage by overload or short circuit.

(2)

The

15

ampere DC fuse

in

the control box pro-

tects the diode rectifier from getting damage

by reverse connectionto thebattery.

(Electric

start

model)

I

Fig.

5-6

5-2-5

NO-FUSE

BREAKER

The no-fuse breaker protects the generator from getting damage by overloading or short circuit

in

the

appliance.Table

5-1

shows

thecapacrty of no-fuse breaker by each spec.

and

their object of protection.

MODEL OBJECT

or

PROTECTION

NO-FUSE

BREAKER

SPECIFICATION

60

HZ-120

V

RGD2500 20

A

10Ax2

60

HZ-1

20

V,

240V

Total output amperage

Total

output

amperage

RGD3300 60 HZ-120

V

Total output amperage

14Ax2

60

HZ-1 20 V, 240V

Total output amperage

27

A

Table.

5-1

1

Fig.

5-7

-

9-

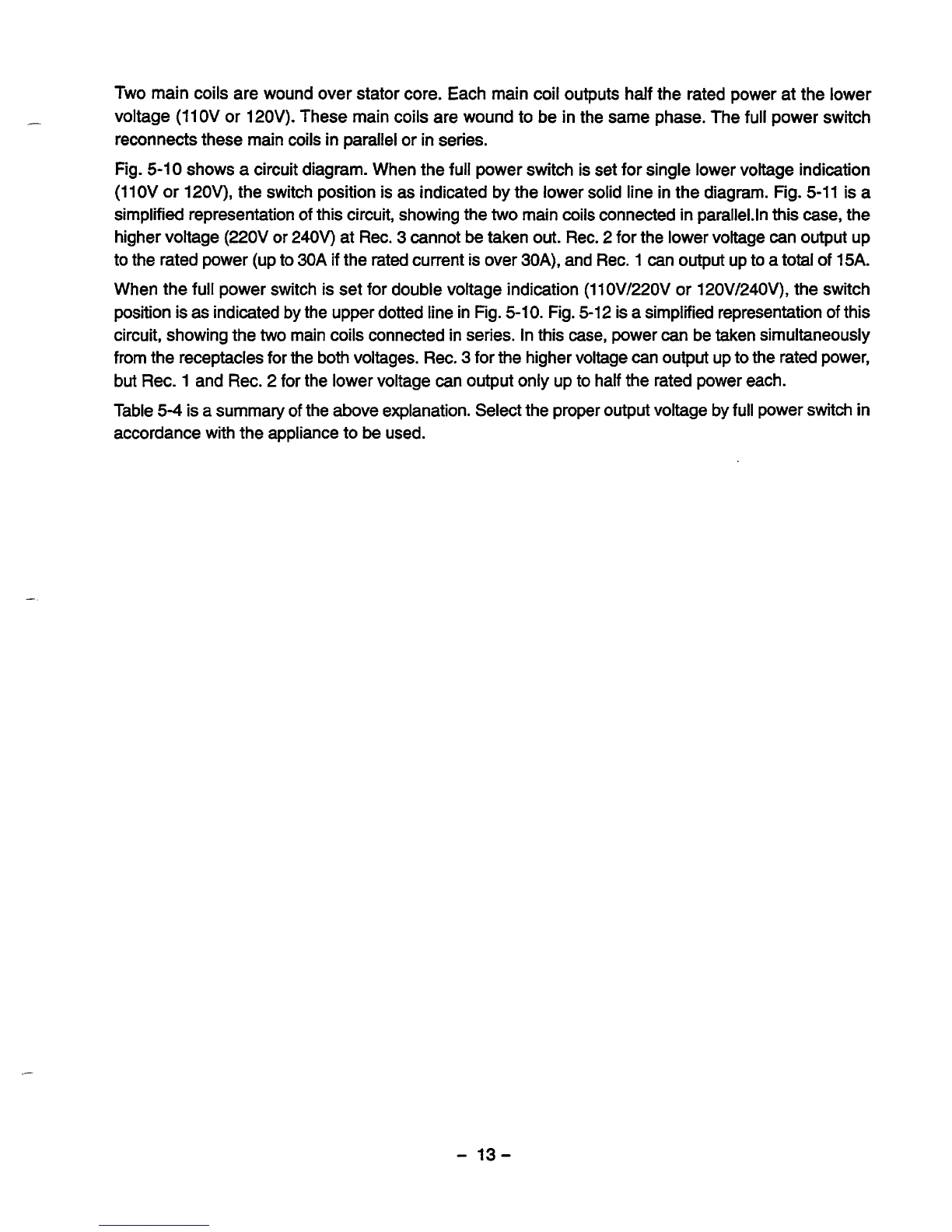

5-2-6 RECEPTACLE

and

AC PLUG

(STD.SPEC.)

These are used for taking AC output power from the generator.

A

total

of

six kinds

of

receptacles, each

varying inrated voltage and current from another, are used. Each model has at least one receptacle to

deliver the rated generator output.

As

many AC plugs

as

the receptacles, each matching the correspond-

ing receptacle, are provided. Table

5-2

shows the rated current for each receptacle. Be careful not to use

the receptacles and AC plugs beyond the specified amperage limitsto prevent burning.

w

NOTE

7

:

If

your generator has receptacles pecu-

liar

to

your

county,

Table

5-2

does not

apply.

NOTE

2

:The generator for

U.S.A.

market is

equipped withNEMA standard recep-

tacles shown

in

table

5-2.

Use the proper plug for connecting ap-

pliance to the generator.

Caution

:

To

connect the appliance

to

locking

receptacle, insert

the

plug intothe

re-

ceptacle and

turn

it

clockwise to

lock.

Fig.

5-8

Style

Description

AC plug

Receptacle

Ampere

~1

20A

GFCl

125V

(Ground Fault

NEMA NEMA

5-20R

Circuit interrupter)

5-20P

Receptacle, duplex

@

125VI250V NEMA NEMA

20A

L14-2OP L14-20R

Locking Receptacle

1

25V

L5-30P

L5-30

30A NEMA

NEMA

Locking Receptacle

Table.

5-2

-

10-

5-3

GENERATOR OPERATION

PERMANENT MAGNET

FOR

INITIAL EXCITATION

FIELD

COIL

\

STATOR

r---

1

MAIN

COIL

I

"""1

I

"""""I

Fig.

5-9

5-3-1

GENERATION

Of

NO-LOAD VOLTAGE

(1)

When the generator starts running,

the

permanent magnet built-intothe rotor generates

3

to

6V

of AC

voltage inthe main coil and condenser coil wound on the stator.

(2)

As

one or

two

condensers are connected to the condensercoil, the small voltage at the condenser

coilgenerates a minute current

8)

which flows through the condenser coil.

At

this time,

a

small fluxis

produced with which the magnetic force at the rotor's magnetic pole is intensified.When this mag-

netic forceis intensified, the respective voltages in the main coil and condenser coil rise up.

As

the

current

3

increases, the magnetic flux at the rotor's magnetic pole increases further. Thus the volt-

ages at the main coil and condenser coil keep rising

by

repeating this process.

(3)

As

AC

current flows through the condenser coil, the density of magnetic fluxinthe rotor changes. This

change of magnetic flux induces

AC

voltage in the field coil, and the diode rectifierinthe field coil

circuit rectifies this

AC

voltage into DC. Thus a DC current

13

flows through the field coil and magne-

tizes the rotor core to generate an output voltage in the main coil.

(4)

When generator speed reaches

3000

to

3300

rpm, the currentinthe condenser coil and field coil

increases rapidly. This acts to stabilize the output voltage

of

each coils.

If

generator speed further

increasestothe rated value, the generator output voltage

will

reach to the rated value.

5-3-2

VOLTAGE FLUCTUATIONS UNDER LOAD

When the

output

current

@

flows through the main coil to the appliance, a magnetic fluxisproduced and

serves to increase current

@

in the condenser coil. When current

@

increases, the density

of

magnetic

flux across

the

rotor core rises.

As

a result, the current flowing in the field coil increases and the genera-

tor output voltage is prevented from decreasing.

-

11

-

5-3-3 FULL

POWER

SWITCH

(Dual

Voltage

Type)

The full power switch

is

provided forthe dual voltage typetotake

out

the full rated power from one

receptacle ineach voltage.

1"

REc21&

$""

/

-

-

I

,

IREC1

Fig. 5-

11

-1

1

OV)

1 1

RECEPTACLE

I

RECEPTACLE

LOWER

VOLTAGE

HIGHER

VOLTAGE

110

v

I

,orv

I

Rated

output

I

No

output

can

be

taken.

I

110/220

v

120/240

V

or

Tale.

5-4

Rated output

Half

of

rated

output

Fig. 5-12

-

12-

Two main coils are wound over stator core. Each main coil outputs

half

the rated power at the lower

voltage

(11OV

or

12OV).

These main coils are wound to beinthe same phase. Thefull power switch

reconnects these main coils

in

parallel or

in

series.

Fig.

5-1

0

shows

a

circuit diagram. Whenthe fullpower switchisset for single lower voltage indication

(11OV

or

12OV),

the switch positionisas indicated by the lower solid line in the diagram.Fig.

5-11

is

a

simplified representation of this circuit, showing the

two

main coils connected

in

parallel.ln this case, the

higher voltage

(22OV

or

240v)

at Rec.

3

cannot be taken out. Rec.

2

for the lower voltage can output up

to the rated power (up to

30A

if

the rated current

is

over

30A),

and Rec.

1

can

output

up to

a

totalof

15A.

When the fullpower switchisset for double voltage indication

(11OV/22OV

or

120V/240V),

the switch

positionisas indicated by the upper dotted line in Fig.

5-10.

Fig.

5-12

is a simplified representation

of

this

circuit, showing the

two

main coils connectedinseries. In thiscase, power

can

be taken simultaneously

fromthereceptacles for the both voltages. Rec.

3

for the higher voltage can output uptothe rated power,

but Rec.

1

and Rec.

2

for the lower voltage can output only up to half the rated power each.

Table

5-4

is

a

summary

of

the above explanation. Select the proper output voltage by full power switch

in

accordance withtheappliance to beused.

"

-

13-

6.:

SAFETY

PRECAUTIONS

1.

Useextreme caution near fuel. A constantdanger

of

explosion or fireexists.

Do

not fill the fuel tank whilethe engineis running.

Do

not smoke or use opem flame nearthe fuel

tank. Be careful not to spill fuel when refueling.

If

spilt, wipeitand let dry before starting the engine.

2. Do

not place inflammablematerialsnear the generator.

Be careful notto put fuel, matches, gunpowder, oily cloth, straw, and any other inflammables near the

generator.

3.

Do

notoperatethe generator inaroom,cave ortunnel. Always operatein

a

well-ventilatedarea.

Otherwise the engine may overheat and also, the poisonous carbon monoxide contained in the ex-

haust gases will endanger human lives. Keep the generator at least

1

m

(4

feet) away from structures

or facilities duringuse.

4.Operate the generator ona levelsurface.

5.

6.

If

the generator

is

tilted or moved during use, thereisa danger

of

fuel spillage and a chance that the

generator may tip over.

Do

notoperatewith wet handsor

in

the rain.

Severe electric shock may occur.

If

the generatoriswet by rain or snow, wipe

it

and thoroughly

dry

it

before starting.

Don't

pour water overthegenerator directly nor washitwith water. If the generatoris

wet with water, the insulations

will

be adversely affected and may cause current leakage and electric

shock.

Do

notconnectthe generatortothecommercial power

lines.

w

This may cause a short-circuit or damagetothe generator. Use a transfer switch (Optional parts) for

connecting with indoor wiring.

NOTE

:

Theparts numbers

of

the transfer swifches and

of

the

plastic box to store themareas

shown

in

Table

6-

1.

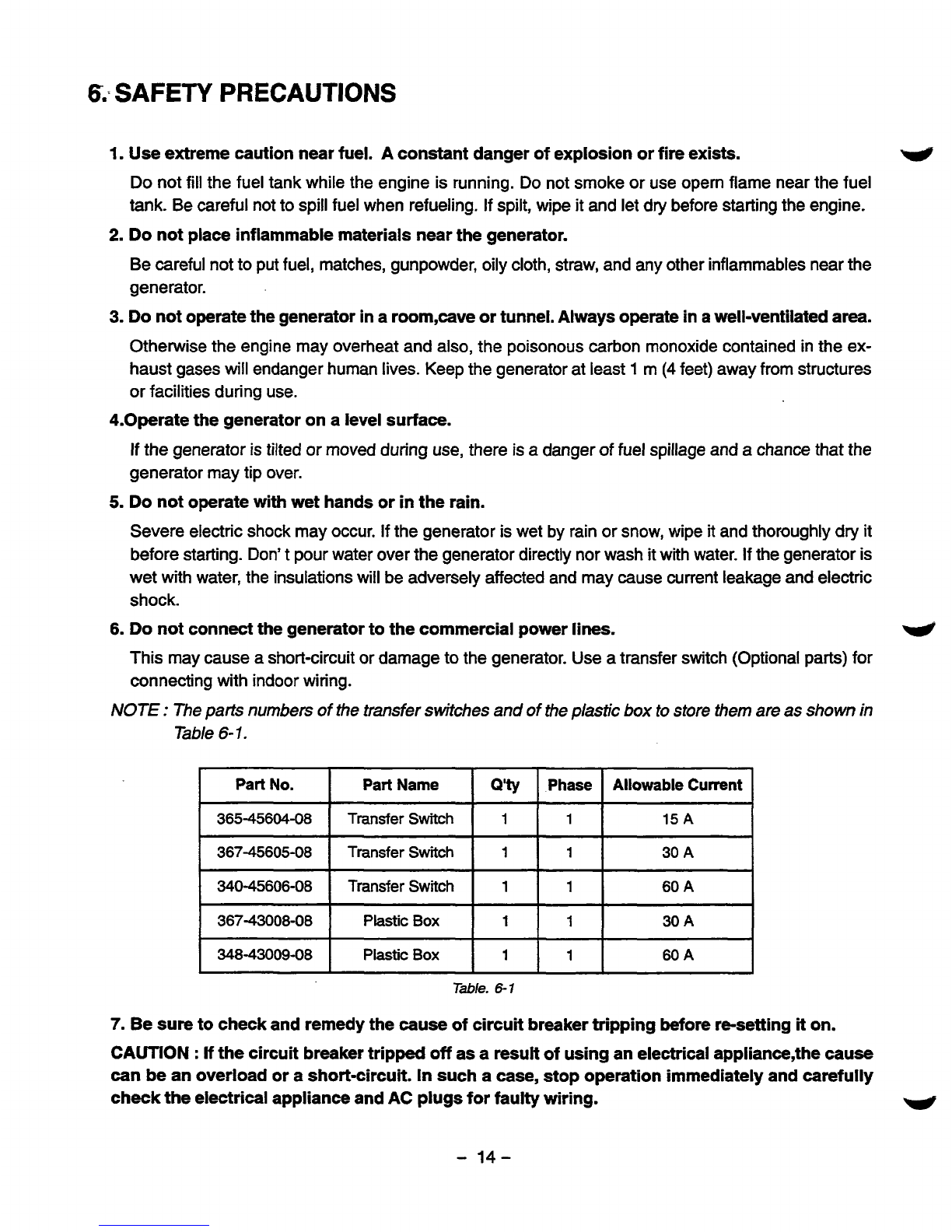

Part

No.

PartName

Q'ty

Phase

Allowable

Current

Table.

6-1

365-45604-08 Transfer

Switch

11 15

A

367-45605-08 Transfer

Switch

11 30

A

340-45606-08

Transfer Switch

1

1

60

A

367-43008-08

Plastic

Box

11

30

A

348-43009-08

Plastic

Box

1160

A

Table.

6-1

7.

Be sureto check andremedy thecauseof circuitbreaker tripping

before

resetting

it

on.

CAUTION

:

If

the circuitbreakertripped

off

asa resultof using anelectricalappliance,the cause

can

be

an overload or a short-circuit.

In

sucha case, stop operationimmediatelyand carefully

check theelectricalapplianceandAC

plugs

for faulty wiring.

-

14-

Generally, the power rating of an electrical appliance indicates the amount of work that can be done by

it.

The electric power required for operating an electrical applianceis not always equal to the output watt-

age of the appliance. The electrical appliances generally have a label showing their rated voltage, fre-

quency, and power consumption (input wattage). The power consumption

of

an electrical appliance is

the power necessary for using it. When using a generatorfor operating an electrical appliance,the power

factor and starting wattage must be taken into consideration.

Inorder to determine the right size generator,itis necessary to add the

total

wattage of all appliancesto

be connectedtothe unit.

Refer

to the followings to calculate the power consumption of each appliance or equipment by its type.

(1)

Incandescent lamp, heater, etc. witha power factor of

1

.O

Total power consumption must be equal to or less than the rated output of the generator.

Example

:

A

rated 3000W generator can turn thirty

lOOW

incandescent lamps on.

(2)

Fluorescent lamps, motor driven tools, light electrical appliances, etc. witha smaller power

factor

Select a generator with a rated output equivalent to

1.2

to

2

times of the power consumption of the

load. Generally the starting wattage of motor driven tools and light electrical appliances are

1.2

to 3

times lager than their running wattage.

Example

:

A

rated

250

W electric drill requires a

400

W

generator to start

it.

NOTE

7

:

If a power factor correction capacitor is not applied to the fluorescent lamp, the more power

shall be required to drive the lamps.

NOTE2

:

Nominal wattage of the fluorscent lamp generally indicates the output wattageof the lamp.

Therefore,

if

the fluorescent lamp has no special indication as to the power consumption,efi-

ciency should be taken into account as explainedinitem

(5)

on the following page.

(3)

Mercury lamps witha smaller power factor

Loads for mercury lamps require

2

to 3 times the indicated wattage during start-up.

Example

:

A

400

W mercury lamp requires

800

W to

1200

W power source to be turned on.

A

rated

3000

W

generator can power

two

or three

400

W

mercury

lamps.

(4)

Initially loaded motor driven appliances suchas water pumps,compressors,etc.

These appliances require large starting wattage whichis3 to

5

times

of

running wattage.

Example

:

A

rated

900

W compressor requires a

4500

W

generator to drive it.

NOTE

7

:

Motor-driven appliances require the aforementioned generator output onlyattheshdng. Once

their motors are started, the appliances consume about

7.2

to

2

times their rated power con-

sumption

so

that the excess power generated by the generator can

be

used forother electrical

appliances.

NOTE2

:

Motor-driven appliances mentioned in Items(3) and

(4)

vary

in their required motorsbrting

power depending on the kind of motor and start-up load.

if

it

is

dficulttodetermine the

optimum

generator capacw, select a generator with a larger capaciw.

-

15-

(5)Appliances without

any

indication as to power consumption

Some appliances have no indication asto power consumption; but instead the work load (output)is

indicated. In such a case, power consumptionisto beworked out accordingto the numerical formula

mentioned below. (Output

of

electrical appliance)

(Efficiency)

=

(Power consumpition)

Efficiencies of some electrical appliances are as follows

:

Single-phase motor

................................

Fluorescentlamp

...................................

0.7

to

0.8

lowertheefficiency.

Oe6

to

0-753(

The smaller the motor, the

Example

1:

A

40W

fluorescent lamp means that its luminous output

is

40W.

Its efficiencyis0.7 and

accordingly, power consumptionwill be

40

t

0.7=

57W.

As

explained in Item (2), multiply

this power consumption value of57

W

by

1.2

to

2

and you

will

get the figure of the neces-

sary

capacity

of

a generator.

In

other words, a generator with a rated output

of

1OOOWcapacity

can

light nine to fourteen

40

W fluorescent lamps.

Example

2

:

Generally speaking, a

400

W

motor means that its work loadis

400

W.

Efficiency

of

this

motor is

0.7

and power consumption will be

400+0.7=

570

W.

When this motoris used for

a motor-driven tool, the capacity of the generator should

be

multiple of 570

W

by 1.2to

3

as

explained in the Item

(3).

570

(W)

x

1.2

to

3

=

684

(W)

to 1710

(W)

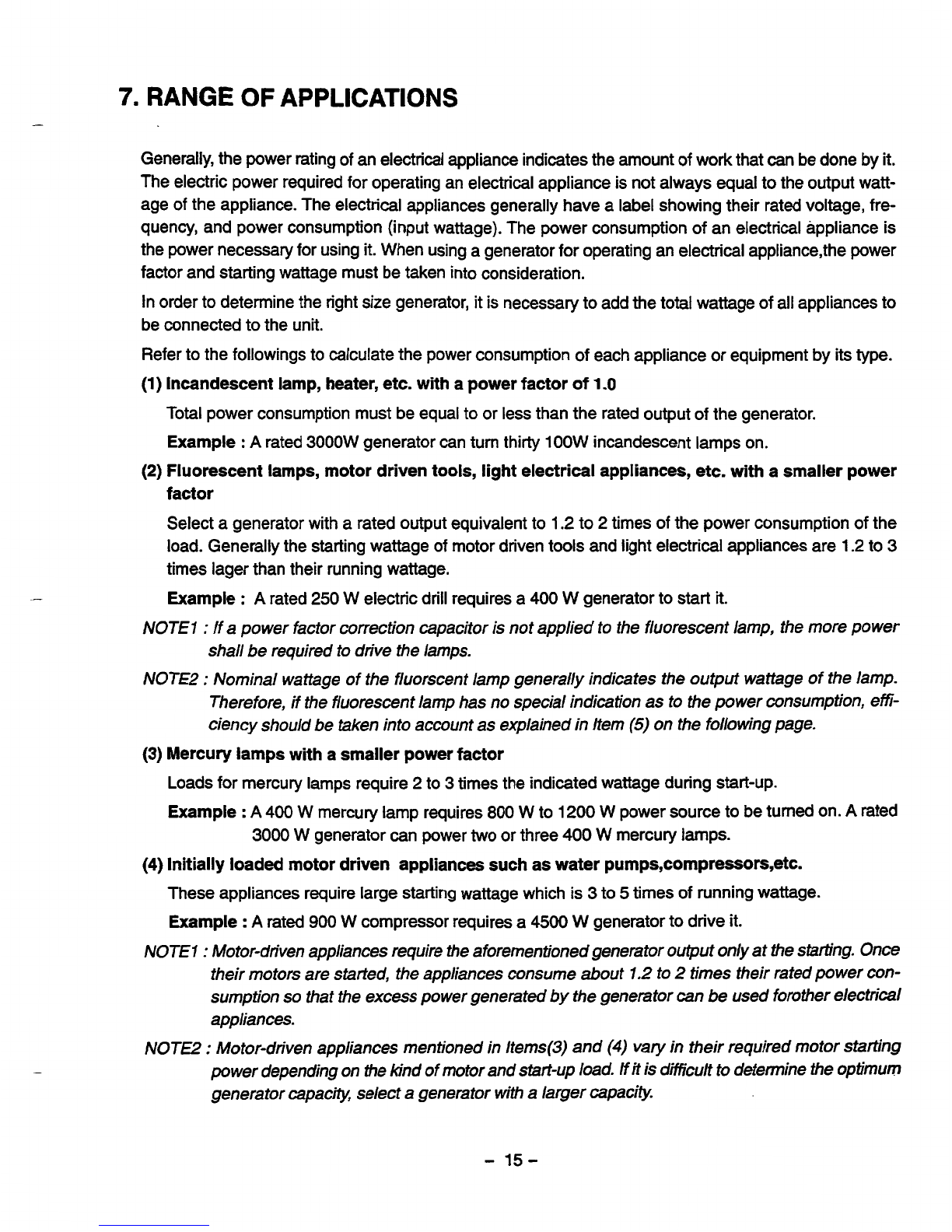

MODEL RGD3300 RGD2500

Frequency

I I I

60

Hz

60

Hz

lncandesent

lamp,

heater, etc.

I

22OOw

I

30OOW

Fluorescent lamp, Motor-

2100

w

15OOW

driven

tool,

general-porpose approx.

approx.

~~~~~

Mercury

lamp,

etc.

approx. approx.

1

13OOW

I

18WW

Pump, compressor, etc. approx.

approx.

1

650

W

Table.

7-1

-

16-

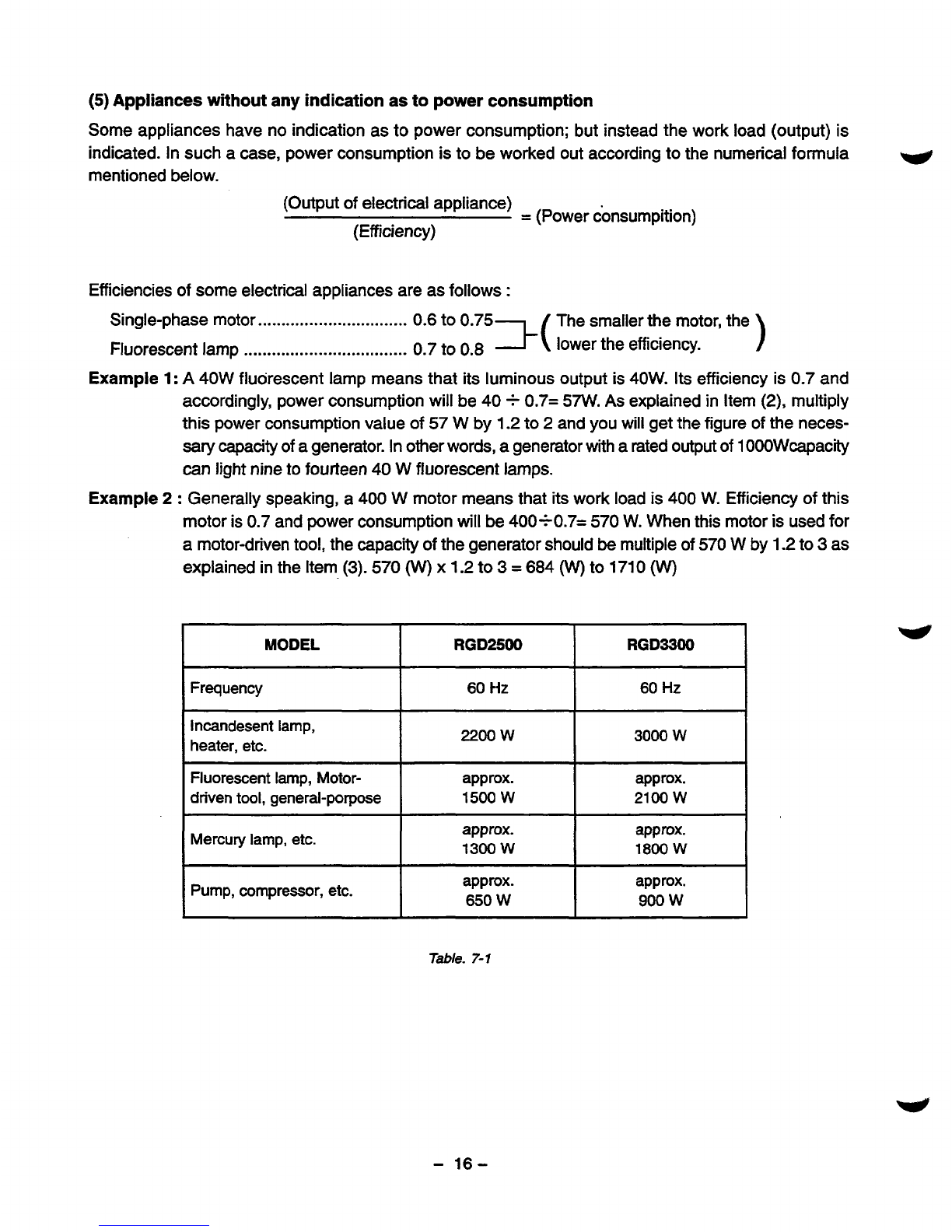

NOTES

:

Wringbetween generator and electrical appliances

I.

Allowable current ofcable.

Use a cable with an allowable current that is higher than the rated input current of the load (electrical

appliance). If the input current is higher than the allowable current

of

the cable used, the cable will

become excessively heated and deteriorate the insulation, possibly burning it out. Table

7-2

shows

cables and their allowable currents for your reference.

2.

Cable length

If a long cable is used, a voltage drop

occurs

due to the increased resistance in the conductors de-

creasing the input voltage to the load (electrical product). As a result, the load

can

be damaged.Tabe

7-2

shows voltage drops per

I00

meters

of

cable.

"

"

Sectional

area

/

mm3

0.75

1.25

2.0

3.5

5.5

Gauge

No'

wire

dement

Resistance

Voltage

A"owab'e

current

/

A

mm

Ohm/100m

1~

3~

5~

7

I

3010.18

I

2.477

I

2.5

V

I

8

V

112.5

V

12

50

10.18

1.486

1.5V 5V 7.5V

17

3710.26

0.952

1.0

V

3V 5.0

V

23

I

45/0.32

I

0.517

I

I

1.5V

I

2.5

V

Table.

7-2

Voltage drop indicatesas

V=

-

x

R

x

I

x

L

1

100

drop

per

100

m

4V

I

5V

16.5V

2.5v

I

35-v

I

4

v

7.5

v

I

5v

I

R

meansresistance

(

hz

/

100

m)on the abovetable.

I

meanselectriccurrentthroughthewire

(A).

L

meansthelength

of

thewire

(m).

The length

of

wire indicaters round length, it means twice the length from generator to electrical tools.

-

17-

This manual suits for next models

1

Table of contents

Other Robin Inverter manuals

Popular Inverter manuals by other brands

EG4

EG4 3000 EHV-48 user manual

Midian Electronics

Midian Electronics MOT-TVS-2-PRO instructions

Gondzik

Gondzik NL-BKDX30-95II/R user manual

SEW-Eurodrive

SEW-Eurodrive MOVIDRIVE modular Compact operating instructions

SolarEdge

SolarEdge BI-EU1P Quick installation guide

Generac Power Systems

Generac Power Systems 2.4L owner's manual