EG4 3000 EHV-48 User manual

April 2022 | Rev A | Information subject to change without notice.

Legal Notice: Not to be duplicated or

modified without EG4 Electronics approval.

EG4 Electronics

www.eg4electronics.com

EG4 Inveer Set Up Guide:

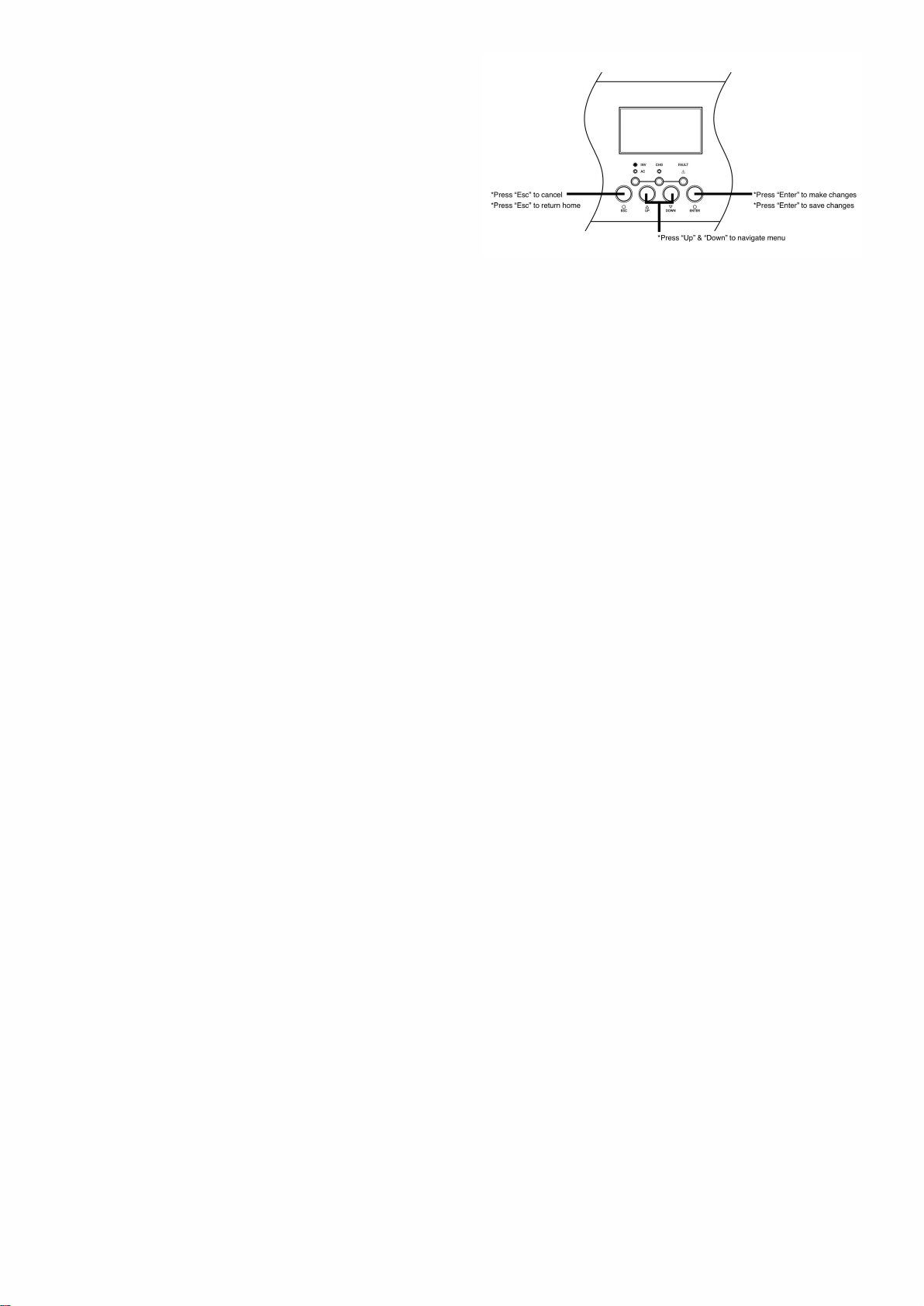

To enter Menu - Press and ENTER for 3 seconds

•Program Seing 1

•Program Seing 2

r = BOA

•Program Seing 3

•Program Seing 4

•Program Seing 5

r = U-

4

•Program Seing 6

•Program Seing 7

•Program Seing 8

•Program Seing 9

•Program Seing 10

•Program Seing 11

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

•Program Seing 30

•Program Seing 32

•Program Seing 34-39

=

EG4 Electronics

www.eg4electronics.com

Quick Installation Guide

Wi-Fi Plug Pro

1

3

Tap the WiFi symbol in the upper right-

hand corner of the screen to search for

the WiFi network.

Once your network is located select it

and click confirm

Enter the password for your home

internet. Once you've entered the

password - click DONE in the bottom

right-hand corner

You should see a message reading

"The setting is successful, please wait

for the collector to restart before

connecting to it and operating again."

Once the message goes away, click the

"Connect to WIFI-Data Logger" button

on the screen

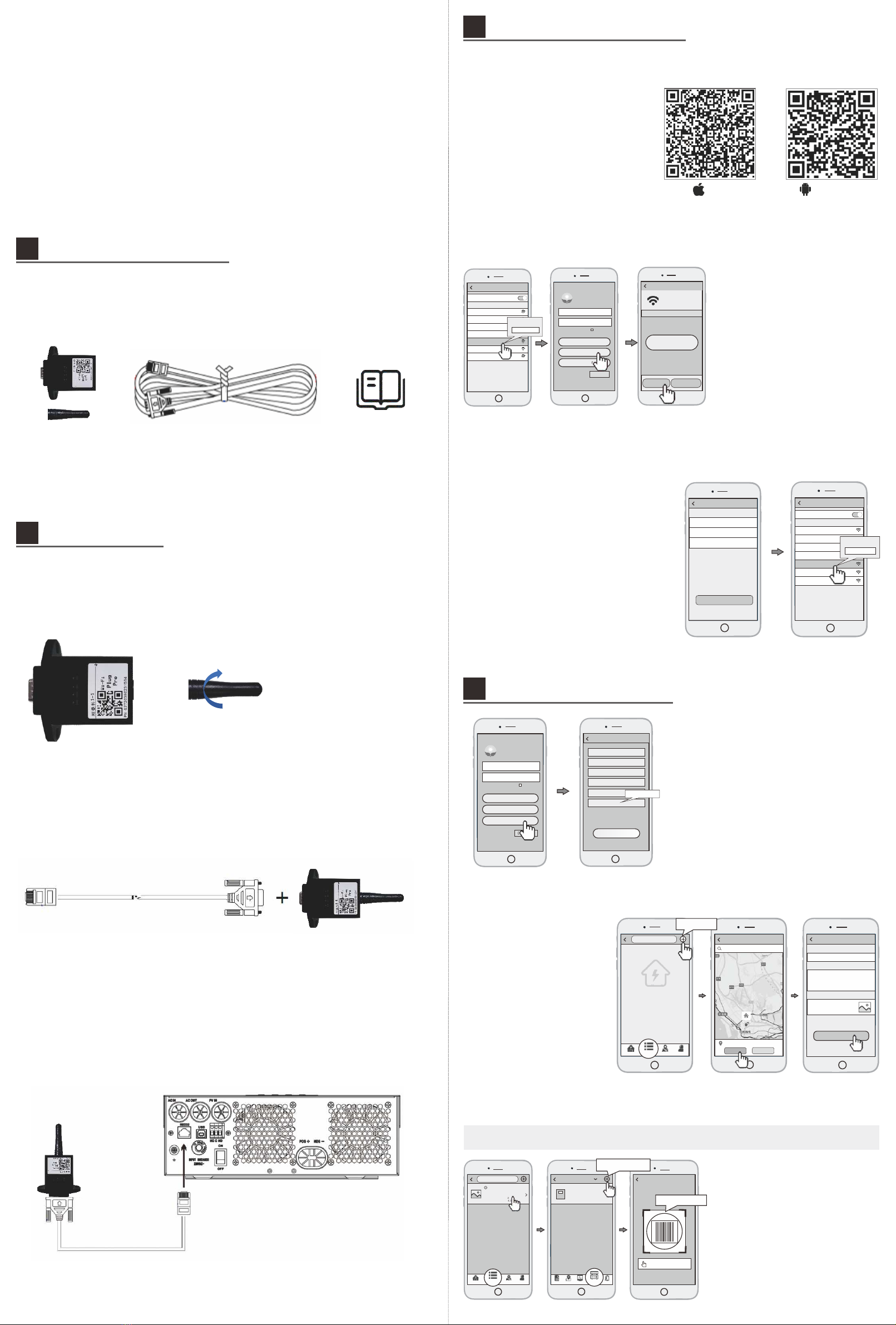

3.1 Download APP

1 Scan the QR Code on the right

side and download the APP.

Register

User Name

Passwor d

Confirm P asswo rd

E-mail

Phone Num ber

PN

Register

Datalogger PN

1

2

Go back to your phone's WiFi

Settings and reconnect to your home

internet.

Open the APP, tap the Register button

to enter this page.

According to the prompts, type in the

information to create an account.

4.3

Add Multiple Dataloggers

①Tap the new plant you just created,

and enter its home page.

②Click the Device button on the

bottom of the home page.

1Tap the new plant you just created,

and enter its home page.

Click the DEVICE button on the

bottom of the home page.

Note: One account can create multiple plants and one plant can add multiple dataloggers. If you only have one

datalogger, you could ignore this step.

新建电站

SmartClient

Kee p passw ord

Please en ter use r name

Please en ter pas sword

Login

Wi-Fi Config

Register

Demo>

Create Plants

Pleas e ent er plant’s name

Plant Nam e*

Finish

Plant description

Plant picture

Pleas e inp ut the descript ion t he plant

Plant pic ture

4.2

Create Plant

4.1

Create Account

Plant Name

Cur ren t powe r: 55 .6kW

Daily gene ratio n: 141. 6kWh

Dai ly inco me: ¥15 8.2

Total g enera tion: 3 64.3k Wh

OVE RVIEW LIST MAP ME

Input the Data logge r PN

Datalogger PN

Add Datalogger

Add Datalogger

Device

Device 1

Cur rent po wer: 125kW

Dai ly gene ratio n: 125 kWh

PN:123 456 789

Inf o Map Da ta Ala rm

Devices

3.3

Network Setting

3.2

Connect Wi-Fi Datalogger

Android

iOS

Wireless Router Connection

3.

Create Account And Plant

4.

Location of the plant

Locat ion:B aoan, Shenzhen

Pleas e enter the locatio n of the plant

Confi rm Canc el

新建电站

Create Plant

You don't have

a plant yet.

OVE RVIE W LIST M AP ME

WLAN

CHOOS E A NET WOR K...

W2015

2018LA

WLAN

Eybond 2. 4g

Eybond2 015

W001625 00206 17

Wifi111

Wifi-te st

PASSWORD

12345678

Network Sett ings

Router Name:

Password:

Pleas e con nec t to th e wireless rout er

Setting

Confirm passwo rd:

1

2

3

In the WiFi connection settings of

your phone, select the PN of the

Datalogger you are attempting to

configute (Initial Password:12345678)

Open the APP, Tap the Wi-Fi Config

button.

Then tap the Network Setting

button.

SmartClient

Kee p passw ord

Pleas e enter u ser nam e

Pleas e enter p asswo rd

Login

Wi-Fi Con fig

Regist er

DEMO>

W0016250020617

Please c hoo se a Wi -Fi a nd connec t.

Connected

Netwo rk Di agnose

Netwo rk Se tting

Connect

Wi-Fi Da talogger

WLAN

CHOOSE A N ETW ORK ...

W2015

2018L A

WLAN

Eybon d 2.4 g

Eybon d20 15

W0016 250 020617

Wifi111

Wifi- tes t

PASSWORD

1234567 8

1-1 WIFI Module;1-2 Communication cable;1-3 Instruction book;

Packing Accessories Detail

1.

1-1 1-2 1-3

2.1 Plug antenna into WIFI box

Installation Steps

2.

2.2

Plug communication cable into WIFI Module

2.3 Plug the communication cable (RJ45 head) into the inverter RS232 port (RJ45

Port Type)

+

4

5

2

1 Login to the account and click

the List button on the bottom

of the homepage

2 Tap the + button on the top

right corner of the list page

3 According to the prompts,

type in the information to finish

creating the plant

2

4

Tap the “+” button at the top-right

corner to add the datalogger.

Scan the datalogger PN on the

Wi-Fi Plug Pro, or input it manually.

3

EG4 Electronics

www.eg4electronics.com

Table Of Contents

ABOUT THIS MANUAL....................................................................................................................................................1

Purpose............................................................................................................................................................................. 1

Scope.................................................................................................................................................................................1

SAFETY INSTRUCTIONS............................................................................................................................................... 1

INTRODUCTION...............................................................................................................................................................2

Features............................................................................................................................................................................ 2

Basic System Architecture..............................................................................................................................................2

Product Overview............................................................................................................................................................ 3

INSTALLATION.................................................................................................................................................................4

Unpacking and Inspection..............................................................................................................................................4

Preparation....................................................................................................................................................................... 4

Mounting the Unit............................................................................................................................................................4

Battery Connection..........................................................................................................................................................5

AC Input/Output Connection......................................................................................................................................... 6

PV Connection.................................................................................................................................................................. 8

Final Assembly................................................................................................................................................................. 9

Dry Contact Signal........................................................................................................................................................ 10

OPERATION.................................................................................................................................................................... 11

Power ON/OFF............................................................................................................................................................... 11

Operation and Display Panel....................................................................................................................................... 11

LCD Display Icons......................................................................................................................................................... 12

LCD Setting.................................................................................................................................................................... 14

Display Setting............................................................................................................................................................... 23

Operating Mode Description........................................................................................................................................ 27

Fault Reference Code................................................................................................................................................... 29

Warning Indicator......................................................................................................................................................... 30

BATTERY EQUALIZATION.......................................................................................................................................... 31

LITHIUM BATTERY SETTINGS................................................................................................................................. 33

SPECIFICATIONS..........................................................................................................................................................38

Table 1 Line Mode Specifications................................................................................................................................38

Table 2 Inverter Mode Specifications.........................................................................................................................39

Table 3 Charge Mode Specifications.......................................................................................................................... 39

Table 4 General Specifications.................................................................................................................................... 40

TROUBLE SHOOTING.................................................................................................................................................. 42

Parallel Installation Guide........................................................................................................................................ 47

1. Instruction................................................................................................................................................................. 47

2. Package Contents..................................................................................................................................................... 47

3. Mounting the Unit.....................................................................................................................................................47

4. Wiring Connection.................................................................................................................................................... 48

5. Parallel Operation in Single phase......................................................................................................................... 50

6. Support 3-phase equipment................................................................................................................................... 53

7. Support split phase...................................................................................................................................................55

8. PV Connection........................................................................................................................................................... 56

9. Split-Phase and 3 Phase LCD Setting and Display.............................................................................................. 57

10. Commissioning........................................................................................................................................................ 59

11. Parallel Trouble shooting.......................................................................................................................................60

Typical Application........................................................................................................................................................ 22

Table 5 Parallel Specifications..................................................................................................................................... 41

EG4 Electronics

www.eg4electronics.com

1

ABOUT THIS MANUAL

Purpose

This manual describes the assembly, installation, operation and troubleshooting of this unit. Please read

this manual carefully before installation and operation.

Scope

This manual provides safety and installation guidelines as well as information on tools and wiring.

SAFETY INSTRUCTIONS

WARNING: This chapter contains important safety and operating instructions. Read and

keep this manual for future reference.

1.Before using the unit, read all instructions and cautionary markings on the unit, the batteries and all

appropriate sections of this manual.

2.CAUTION -

To

reduce

risk

of

injury,

charge

only

deep-cycle,

lead

acid, or

Li-Ion type rechargeable

batteries.

Other

types

of

batteries

may

burst,

causing

personal

injury

and

damage.

3.Do not disassemble the unit. When service or repair is required, take it to a qualified service center.

Incorrect re-assembly may result in a risk of electric shock or fire.

4.To reduce risk of electric shock, disconnect all wirings before attempting any maintenance or cleaning.

Turning off the unit will not reduce this risk.

5.CAUTION –

Only

qualified

personnel

should

install

this

device

with a

battery.

6.NEVER charge a frozen battery.

7.For optimum operation of this inverter/charger, please follow required spec to select appropriate

cable size.

8.Be very cautious when working with metal tools on or around batteries. A potential risk exists for a

dropped tool to spark or short circuit batteries / other electrical parts causing an explosion.

9.Please strictly follow installation procedure when disconnecting AC or DC terminals. Please refer to

INSTALLATION section (pg 4) of this manual for details.

10.Fuse is provided as over-current protection for the battery supply.

11.GROUNDING INSTRUCTIONS -This inverter/charger should be connected to a permanent grounded

wiring system. Be sure to comply with local requirements and regulation when installing this inverter.

12.NEVER short AC output or DC inputs. Do NOT connect to the grid with a shorted DC input.

13.Warning!!

Only

qualified

personnel

are

able

to

service

this

device.

If

errors

still

persist

after

following

troubleshooting

table,

please

send

this

inverter/charger

back

to

local

dealer

or

service

center

for

maintenance.

EG4 Electronics

www.eg4electronics.com

2

INTRODUCTION

This is a multi-function inverter/charger, combining the capabilities of an inverter, MPPT solar charger,

and battery charger to offer uninterrupted power support in a portable size. Its comprehensive LCD

display offers user-configurable and easy-accessible button operation including: battery charging current,

AC/solar charger priority, and acceptable input voltage based on different applications.

Features

•

Pure sine wave inverter - <3% THD

•

Built-in MPPT solar controller - 120V to 500V

•

Configurable input voltage range for home appliances and personal computers - 65V to 140VAC

•

Configurable battery charging current based on applications - 30A to 80A

•

Configurable AC/Solar Charger priority.

•

Compatible to utility grid or generator power - 120V

•

Auto restart when AC input is restored

•

Overload/ Over temperature/ Short circuit protection

•

Smart battery charger design for optimized battery performance

Basic System Architecture

The following illustration shows basic application for this inverter/charger - including the below-listed

devices needed for a complete running system:

•

Generator or Utility

•

48V Battery

•

PV Modules

Consult with your system integrator for other possible system architectures depending on your requirements.

This inverter can power all kinds of appliances in a home or office environment, including compressor based

appliances such as a refrigerator or air conditioner.

Figure 1 Solar Power System

EG4 Electronics

www.eg4electronics.com

3

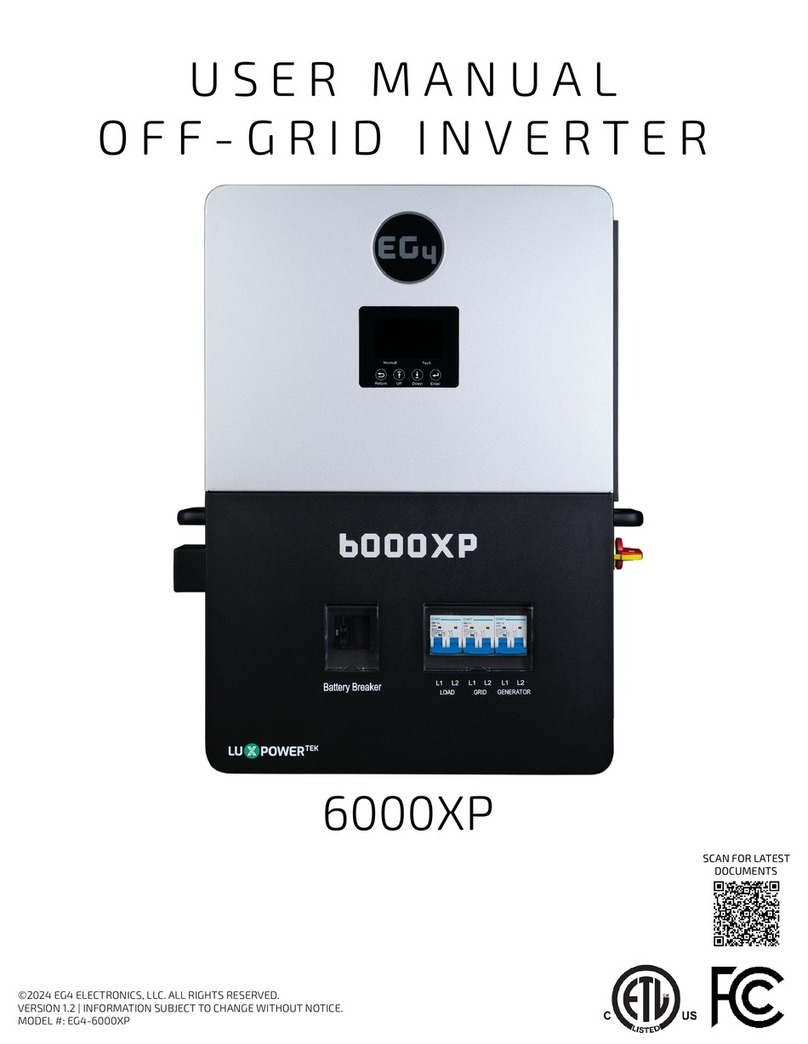

Product Overview

1.

LCD display

2.

Status indicator

3.

Charging indicator

4.

Fault indicator

5.

Function buttons

6.

Power on/off switch

7.

AC input (L - N)

8.

AC output (L - N)

9.

PV input (500Vdc Max)

10.

Battery input (48V Nominal)

11.

AC Input Circuit breaker

12.

RS232 communication port for

WiFi communication

13.

Parallel communication port (only

for parallel model)

14.

Dry contact (Optional)

15.

USB communication port for PC

Applications

16.

RS485 BMS communication port

17.

Grounding Screw

NOTE: For parallel model installation and operation, please check the parallel installation guide (pg. 47) for details.

EG4 Electronics

www.eg4electronics.com

4

INSTALLATION

Unpacking and Inspection

Before installation, please inspect the unit to be sure that nothing inside the package is damaged. You

should have received the following items:

•WiFi Communications Module

•5' RJ11 to DB9 male RS232 Cable

•4' RJ45 patch cable

Preparation

Before connecting all wiring, please remove the bottom cover by removing two screws as shown below.

Mounting the Unit

Consider the following points before selecting where to install:

Do not mount the inverter on flammable

construction materials.

Mount on a solid surface

Install this inverter at eye level in order to allow

the LCD display to be read at all times.

The ambient temperature should be between 0°C

to 55°C (-15°F to 131°F) to ensure optimal operation.

The recommended installation position is to be adhered

to the wall vertically.

Be sure to distance other objects and surfaces as

shown in the right diagram to guarantee sufficient heat

dissipation and to have enough space for removing wires.

SUITABLE FOR INDOOR MOUNTING ON

CONCRETE OR OTHER NON-COMBUSTIBLE

SURFACE ONLY.

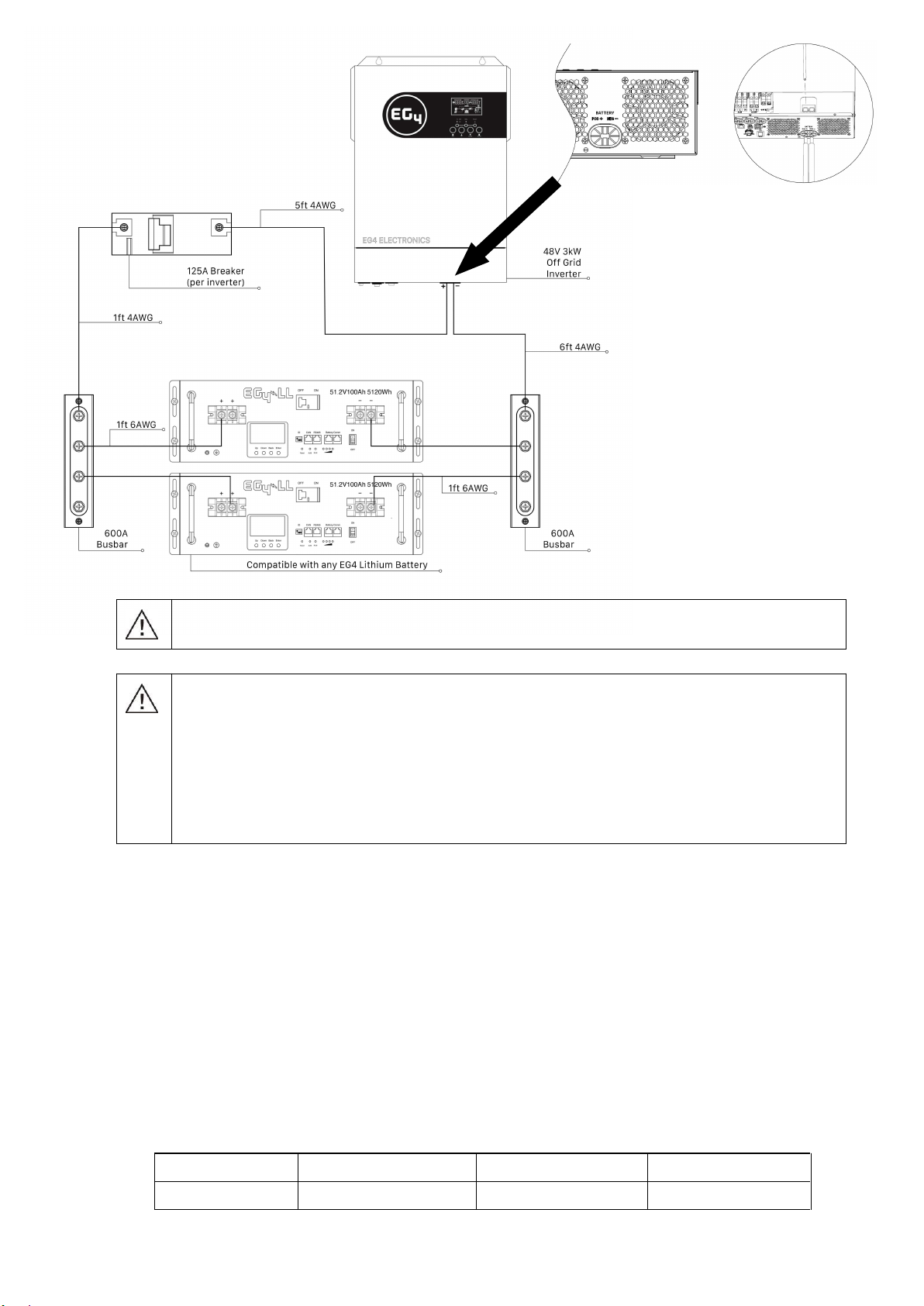

•EG4 3000EHV-48 Inverter

•User manual

•Battery BMS Cable

•125A DC Breaker

•6" DIN Rail

•6' Red and Black 4AWG Battery Cable

EG4 Electronics

www.eg4electronics.com

5

Install the unit by screwing three screws. It’s recommended to use M4 or M5 screws.

Battery Connection

CAUTION:

For

safety

operation

and

regulation

compliance,

it is

recommended

that

a

separate

DC

over-current

protector

or

disconnect

device is installed

between

battery

and

inverter.

Please

refer

to

typical

amperage listed below

for

required

fuse

or

breaker

size.

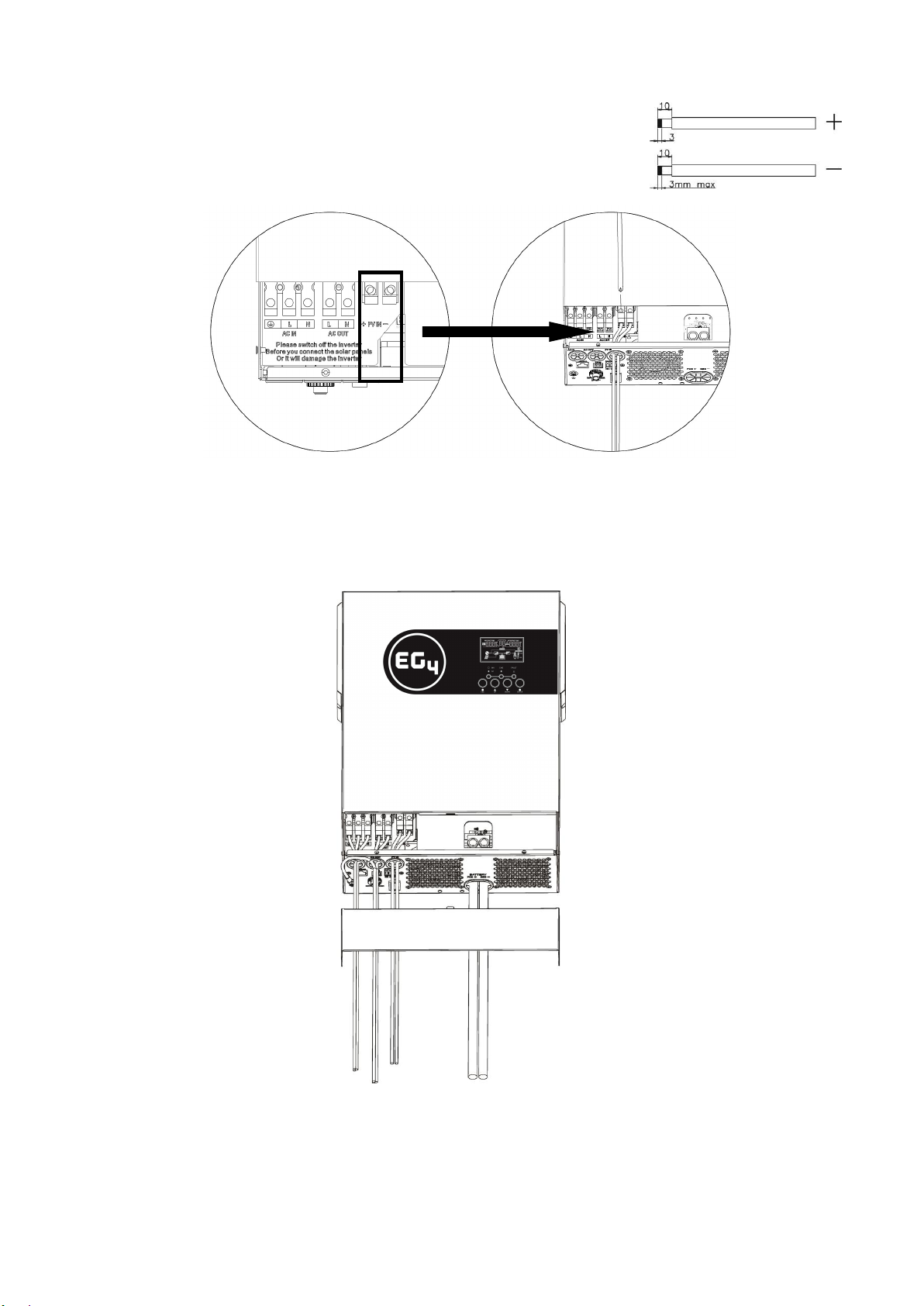

Stripping Length:

WARNING!

We recommend all wiring be performed by a licensed professional.

WARNING!

It is

very

important

for

system

safety

and

efficient

operation

to

use the

appropriate

cable size

for

battery

connection.

To

reduce

risk

of

injury,

please

use

the

recommended

cable, stripping

length(L2),

and tinning length(L1)

in the table

below.

Recommended battery cable, stripping length (L2), and tinning length(L1):

Model Maximum

Amperage

Battery

capacity

Wire Size L1

(mm/in)L 2

(mm/in)

Torque

value

3000EHV-48 80A100AH 4AWG/25 3/0.1" 18/0.7" 2~ 3 Nm

Please follow the following steps to implement battery connection:

1.

Remove insulation sleeve 18 mm for positive and negative cables based on recommended stripping

length.

2.

Connect all battery packs as unit requires, and use recommended battery capacity.

3.

Insert battery cable to the battery connector of inverter and make sure the bolts are tightened

with torque of 2-3 Nm. Make sure polarity at both the battery and the inverter/charge is

correctly connected and battery cables are tightly screwed to the battery connector.

Recommended

Wire Size

Wire Length

6'/1.8m up to 15'/4.6m

Wire Size

AWG/mm2

(7 7/8th Inches)

Please Note: Maximum current drawn by the inverter is 80A. If using EG4 Batteries, the maximum

output is 100A. A 125A breaker is utilized to support maximum battery current of 100A. If using

batteries other than EG4, please consult the manufacturer's manual to ensure proper breaker size.

EG4 Electronics

www.eg4electronics.com

6

WARNING: Shock Hazard

Installation must be performed with care due to high battery voltage in series.

CAUTION!! Do not place anything between the flat part of the inverter terminal. Overheating

may occur.

CAUTION!! Do not apply anti-oxidant substance on the terminals before terminals are

connected tightly.

CAUTION!! Before making the final DC connection or closing DC breaker/disconnector, be sure

positive (+) is connected to positive (+) and negative (-) is connected to negative (-).

AC Input/Output Connection

CAUTION!!

Before

connecting

to

AC

input

power

source,

please

install

a

separate

AC

breaker

between

inverter

and

AC

input

power

source.

This

will

ensure

the

inverter

can

be

securely

disconnected

during

maintenance

and

fully

protected

from AC input

over

current.

Recommended

specification

of

AC

breaker

is

50A

on the input and 30A on the output.

CAUTION!!

There

are

two

terminal

blocks

with

“IN”

and

“OUT”

markings.

Please

do

NOT

mis-connect

input

and

output

connectors.

WARNING!

We recommend all wiring be performed by a licensed professional.

WARNING!

It is

very

important

for

system

safety

and

efficient

operation

to

use

appropriately sized

cable

for

AC

input

connection.

To

reduce

risk

of

injury,

please

use

the

proper

recommended

cable

size

as

below.

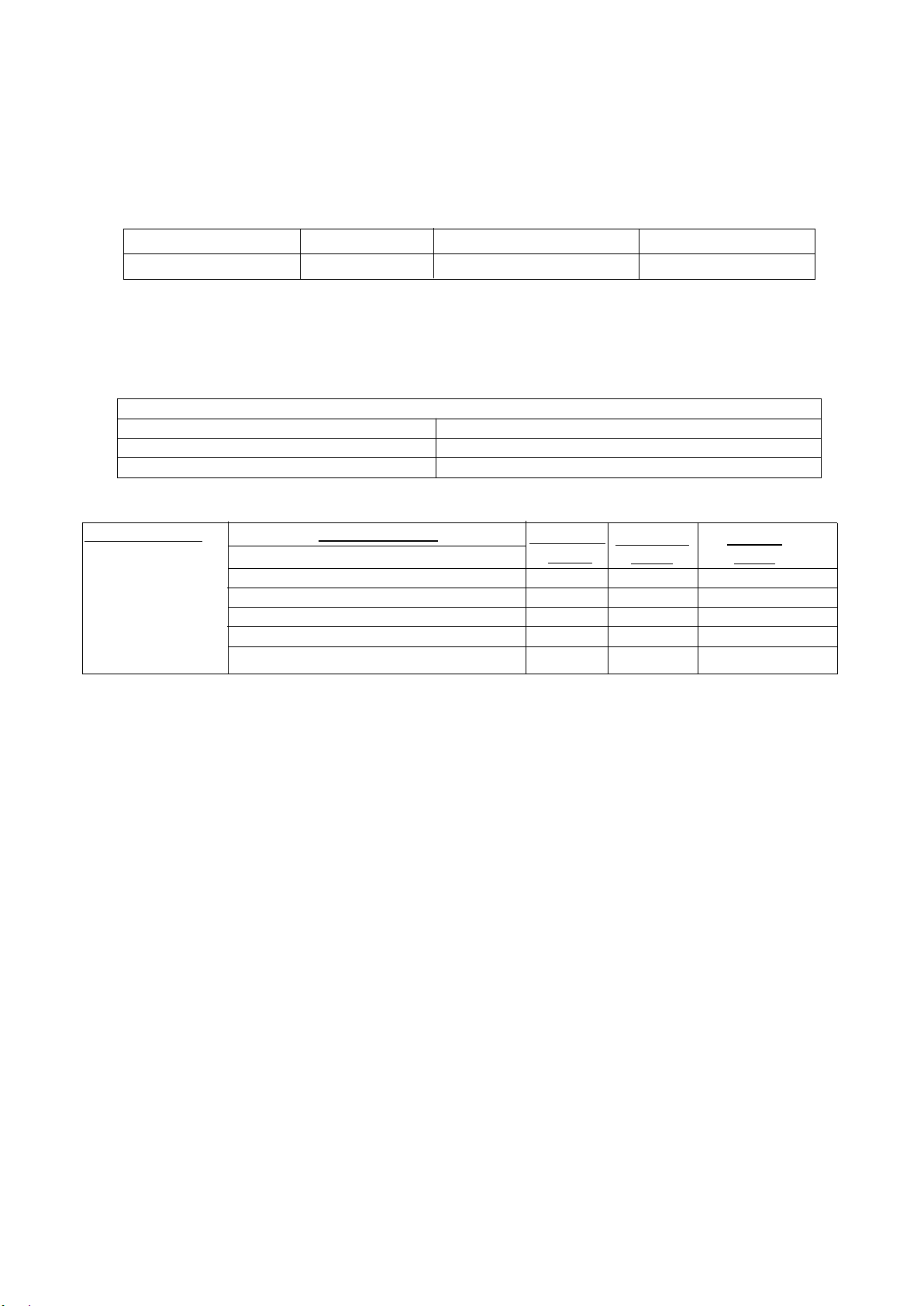

Suggested cable requirement for AC wires

Model Gauge*Torque Value

3000EHV-48 10AWG up to 32'/16.5m 1.4~ 1.6Nm

AC Breaker**

50A Input/ 30A Output

*120V system, 3% max drop, assuming open air. AC output is 25A.

**AC bypass is 25A + 20A charge = 45A with a 60A breaker

EG4 Electronics

www.eg4electronics.com

7

Please follow below steps to implement AC input/output connection:

1.

Before making AC input/output connection, be sure to open DC protector or disconnecter FIRST.

2.

Remove insulation sleeve 10mm for six conductors. And shorten phase L and neutral conductor N 3 mm.

3.

Insert AC input wires according to polarities indicated on terminal block and tighten the terminal

screws. Be sure to connect PE protective conductor ( ) first.

→Ground (Green) L→LINE (Black) N→Neutral (White)

WARNING:

Be sure that AC power source is disconnected before attempting to hardwire it to the unit.

4.

Then, insert AC output wires according to polarities indicated on terminal block and tighten terminal

screws. Be sure to connect PE protective conductor ( ) first.

→Ground (Green)

L→LINE (Black)

N→Neutral (White)

Important to Note:

When the inverter is working in PV mode, battery mode, or standby mode, the output neutral

is connected to the ground of AC output (neutral/ground bonded).

When the inverter is working in AC mode, neutral of output is disconnected to grounding of AC

output and connected to neural of AC input.

5.

Make sure the wires are securely connected.

CAUTION: Important

Be sure to connect AC wires with correct polarity. If L and N wires are reversed, it may cause a

utility short-circuit when these inverters are in parallel operation.

CAUTION: Appliances such as air conditioners require at least 2~3 minutes to restart because to have

enough time to balance the refrigerant gas. If a power outage occurs and recovers in a short time, it

may cause damage to your connected appliances. To prevent this damage, please check the appliance

manufacturer for time-delay start function before installation. The inverter/charger will trigger an overload

fault and cut off the output to protect your appliance which may cause internal damage to the appliance.

EG4 Electronics

www.eg4electronics.com

8

PV Connection

CAUTION:

Before

connecting

to

PV

modules,

please

install a

separate

DC

circuit

breaker

between the

inverter

and

PV

modules.

WARNING!

We recommend all

wiring

be

performed

by

a licensed professional.

WARNING!

It is

very

important

for

system

safety

and

efficient

operation

to

use

appropriate

cable

for

PV

module

connection.

To

reduce

risk

of

injury,

please

use

the

proper

recommended

cable

size

as

below.

Model Maximum Draw Cable Size*Torque

3000EHV-48 18A 10 AWG up to 50'/15.2m 1.4~1.6 Nm

PV Module Selection:

When selecting proper PV modules, please be sure to take into account that the open circuit Voltage

(Voc) of PV modules should not exceed max. PV array open circuit voltage of inverter.

Solar Charging Mode

INVERTER MODEL 3000EHV-48

Max. PV Array Open Circuit Voltage 500DC

PV Array MPPT Voltage Range 120VDC~450VDC

EXAMPLE:

Using a 330W

PV

module and

considering the

above

two system

parameters --

the

recommended

module

configurations

would be as follows:

Solar Panel Spec.

- 330W 60 cell

- Vmp: 33.25Vdc**

-VmpTC: -0.43%/C

- Imp: 9.925A

- Voc: 40.35Vdc**

-VocTC: - 0.31%/C

- Isc: 10.79A

SOLAR INPUT*** Quantity of

panels

Total input

power

Inverter

Model

Min in series: 5 pcs, max. in series: 10 pcs

6 pcs in series 6 pcs 1980W 3000EHV-48

8 pcs in series 8 pcs 3300W 3000EHV-48

10 pcs in series 10 pcs 3300W

6 pieces in series and 2 sets in parallel 12 pcs 3960W

8 pieces in series and 2 sets in parallel 16 pcs 5280W

3000EHV-48

3000EHV-48

3000EHV-48

* Assuming 10% voltage drop free air

** VOC

max @ -25C/-14F = 46.6Vdc and Vmp min @ 40C/104F Ground mount =

27.5Vdc

***Calculate panel configuration for your specific location and panel specifications

Recommended Panel Configuration

When selecting proper PV modules, please be sure to consider the following parameters:

1. Temperature adjusted open circuit voltage (Voc) of PV modules not to exceed maximum PV

array open circuit voltage of the inverter.

2. Temperature adjusted voltage at maximum power (Vmp) of PV modules should be higher than

the startup voltage of the inverter.

EG4 Electronics

www.eg4electronics.com

9

PV Module Wire Connection:

Please follow below steps to implement PV module connection:

1.

Remove insulation sleeve 10 mm/0.4" for positive and negative conductors.

2.

Check correct polarity of connection cable from PV modules and

PV input connectors. Then, connect positive pole (+) of connection cable

to positive pole (+) of PV input connector. Connect negative pole (-) of

connection cable to negative pole (-) of PV input connector.

3.

Make sure the wires are securely connected.

Final Assembly

After connecting all wirings, please put bottom cover back by screwing in the two screws as shown below.

EG4 Electronics

www.eg4electronics.com

10

Dry Contact Signal

There is one dry contact (3A/250VAC) available on the rear panel which can be used to deliver signal to

external device when battery voltage reaches warning level.

Unit Status Condition Dry contact port:

NC & C NO & C

Power Off Unit is off and no output is powered. Close Open

Power On

Output is powered from Utility. Close Open

Output is

powered

from

Battery or

Solar.

Program 01

set as Utility

Battery voltage < Low DC warning

voltage Open Close

Battery voltage > Setting value in

Program 13 or battery charging

reaches floating stage

Close Open

Program 01

is set as

SBU or SUB

or Solar

first

Battery voltage < Setting value in

Program 12 Open Close

Battery voltage > Setting value in

Program 13 or battery charging

reaches floating stage

Close Open

EG4 Electronics

www.eg4electronics.com

11

OPERATION

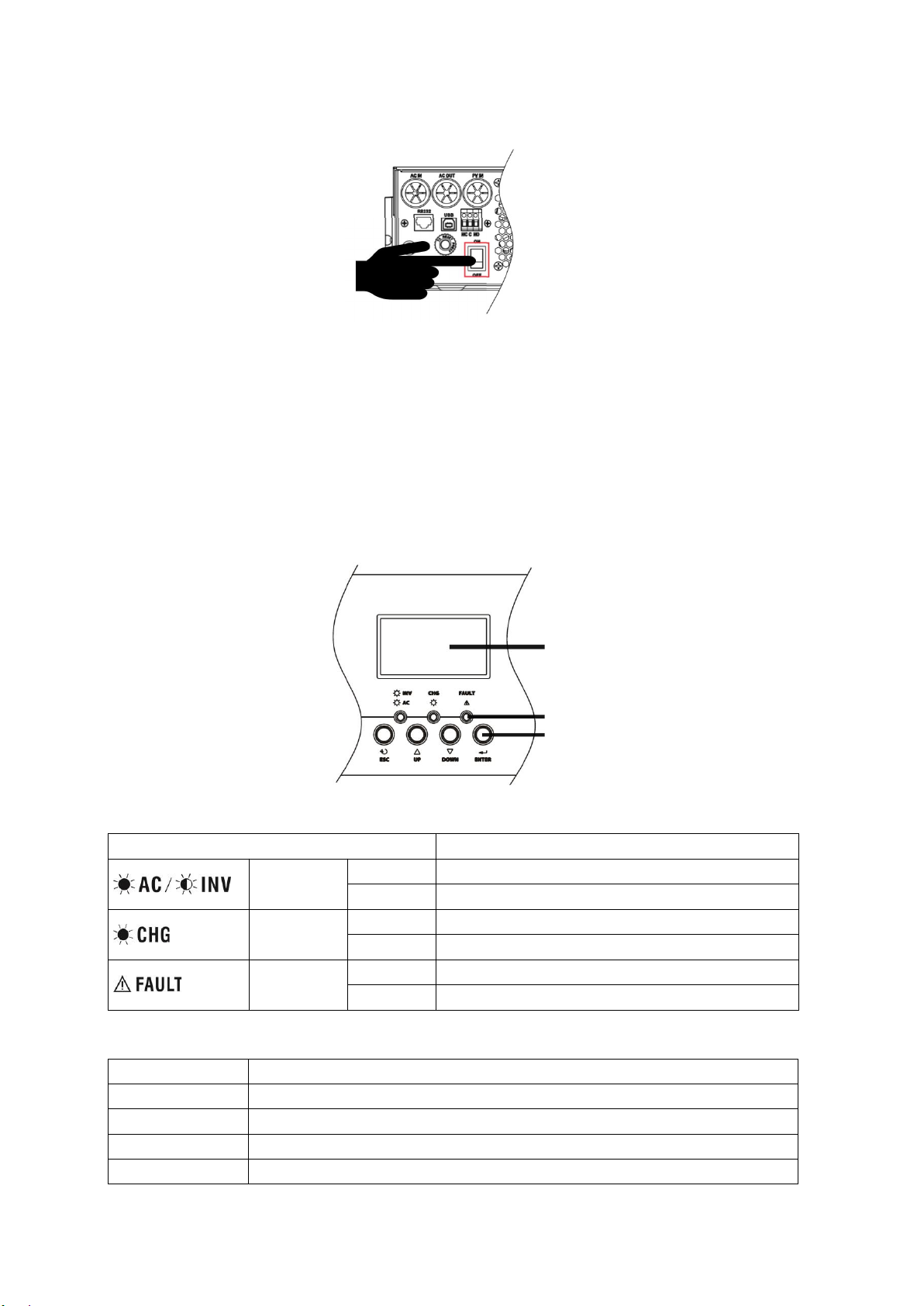

Power ON/OFF

Once the unit has been properly installed and the batteries are connected well, simply press the On/Off switch

(located on the button of the case) to turn on the unit.

Operation and Display Panel

The operation and display panel, shown in the below chart, is on the front panel of the inverter.

It includes three indicators, four function keys, and a LCD display which indicates the operating status,

input/output power information, et cetera.

LCD display

LED indicators

Function keys

LED Indicator

LED Indicator Messages

Green Solid On Output is powered by utility in Line mode.

Flashing Output is powered by battery or PV in battery mode.

Green Solid On Battery is fully charged.

Flashing Battery is charging.

Red Solid On Fault occured in the inverter.

Flashing Warning condition occured in the inverter.

Function Keys

Function Key Description

ESC To exit setting mode

UP To go to previous selection

DOWN To go to next selection

ENTER To confirm the selection in setting mode or to enter setting mode

EG4 Electronics

www.eg4electronics.com

12

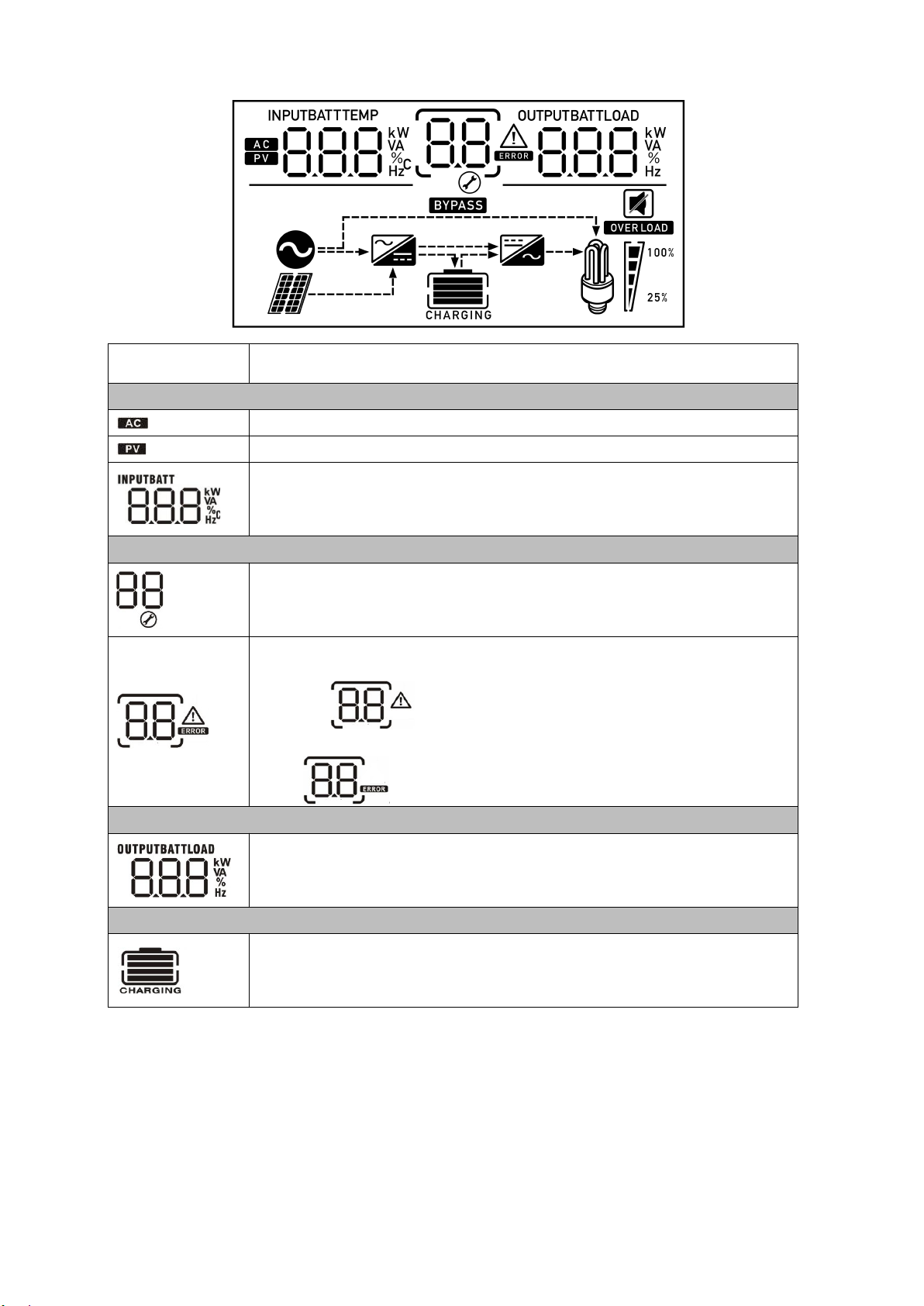

LCD Display Icons

Icon Function description

Input Source Information

Indicates the AC input.

Indicates the PV input

Indicate input voltage, input frequency, PV voltage, battery voltage and

charger current.

Configuration Program and Fault Information

Indicates the program settings

Indicates the warning and fault codes.

Warning: flashes the warning code.

Fault: lights the fault code

Output Information

Indicates the output voltage, output frequency, load percentage, load in

VA, load in Watt and discharge current.

Battery Information

Indicates battery level: 0-24%, 25-49%, 50-74% and 75-100% for each bar

in battery mode and charging status in line mode.

EG4 Electronics

www.eg4electronics.com

13

Load Information

Indicates overload.

Indicates the load level: 0-24%, 25-49%, 50-74% and 75-100%.

0%~24% 25%~49% 50%~74% 75%~100%

Mode Operation Information

Indicates unit is connected to the grid.

Indicates unit is connected to the PV panel.

Indicates load is directly connected to the grid.

Indicates the utility charger circuit is operational.

Indicates the DC/AC inverter circuit is operational.

Mute Operation

Indicates unit alarm is disabled.

EG4 Electronics

www.eg4electronics.com

14

LCD Setting

After pressing and holding the ENTER button for 3 seconds, the unit will enter setting mode. Press UP or DOWN

button to select setting programs. Then, press ENTER button to confirm the selection or ESC button to exit.

Setting Programs:

Program Description Selectable option

01 Output source priority: To

configure load power

source priority

Solar first

Solar energy provides power to

the loads as first priority.

If solar energy is not sufficient to

power all connected loads, battery

energy will supply power to the

loads at the same time. Utility

provides power to the loads only

when one or all of the following

conditions is in play:

-

Solar energy is not available

-

Battery voltage drops to either

low-level warning voltage or the

setting point in

program

12.

Utility first (default)

Utility will provide power to the

loads as first priority.

Solar and battery energy will

provide power to the loads only

when utility power is not

available.

SBU priority

Solar energy provides power to

the loads as first priority.

If solar energy is not sufficient to

power all connected loads, battery

energy will supply power to the

loads at the same time.

Utility provides power to the loads

only when battery voltage drops to

either low-level warning voltage or

the setting point in program 12.

SUB priority

Solar energy is charged first and

then power to the loads.

If solar energy is not sufficient to

power all connected loads, utility

energy will supply power to the

loads at the same time.

EG4 Electronics

www.eg4electronics.com

Other manuals for 3000 EHV-48

1

Table of contents

Other EG4 Inverter manuals