User guide

T e following recommendations for safe working procedures are given as an example, on top of all information

and c aracteristics of t is mac ine.

- W en working wit t e mac ine, safety equipment must be used.

- Nevert eless, t e user must also follow t e operating instructions to avoid accidents.

Training of the machine operators

It is absolutely essential t at t e mac ine operator gets enoug training regarding operating and adjusting t e

mac ine. In particular:

- t e risks involved in working wit t e mac ine;

- t e operating principles, t e correct use and adjustments of t e mac ine;

- t e correct c oice of t e tool for eac operation;

- t e safe andling of t e parts to be processed;

- t e position of t e and in relation to t e turning parts;

- storing workpieces safely before and after mac ining t em.

Stability of the machine

In order to use t e mac ine safely, it is essential to place it stable on t e ground.

Adjustment and installation

- Disconnect t e mac ine from its power supply for eac adjustment.

- T e recommendations of t e manufacturer ave to be followed w en adjusting and installing t e tools.

- T e tools ave to be suited to t e mac ine in order to assure a safe and efficient usage.

- T e tools ave to be correctly s arpened and installed wit tool olders t at are carefully balanced.

Handling of tools

W en touc ing t e tool t ere is always t e danger to get urt by cutting edges.

- Be cautious w en unpacking or packing, as well as andling.

- Do not touc tools at t e cutting edges.

- Wear safety gloves w en andling tools in your works op.

- Always put t e tools on a soft support.

- Transport clamping adaptors and tools only in a suitable packing.

Machine handling

- C oose for eac action t e most appropriate safety devices.

- Do not remove c ippings, cuttings, dust and waste of wood or particle board by and.

Installing tools

Special equipment, suc as tool setting gauges, are to be used only w en t e mac ine isn't operating.

Table insert rings ave to be used in order to reduce t e space between t e table and t e spindle s aft to a

minimum.

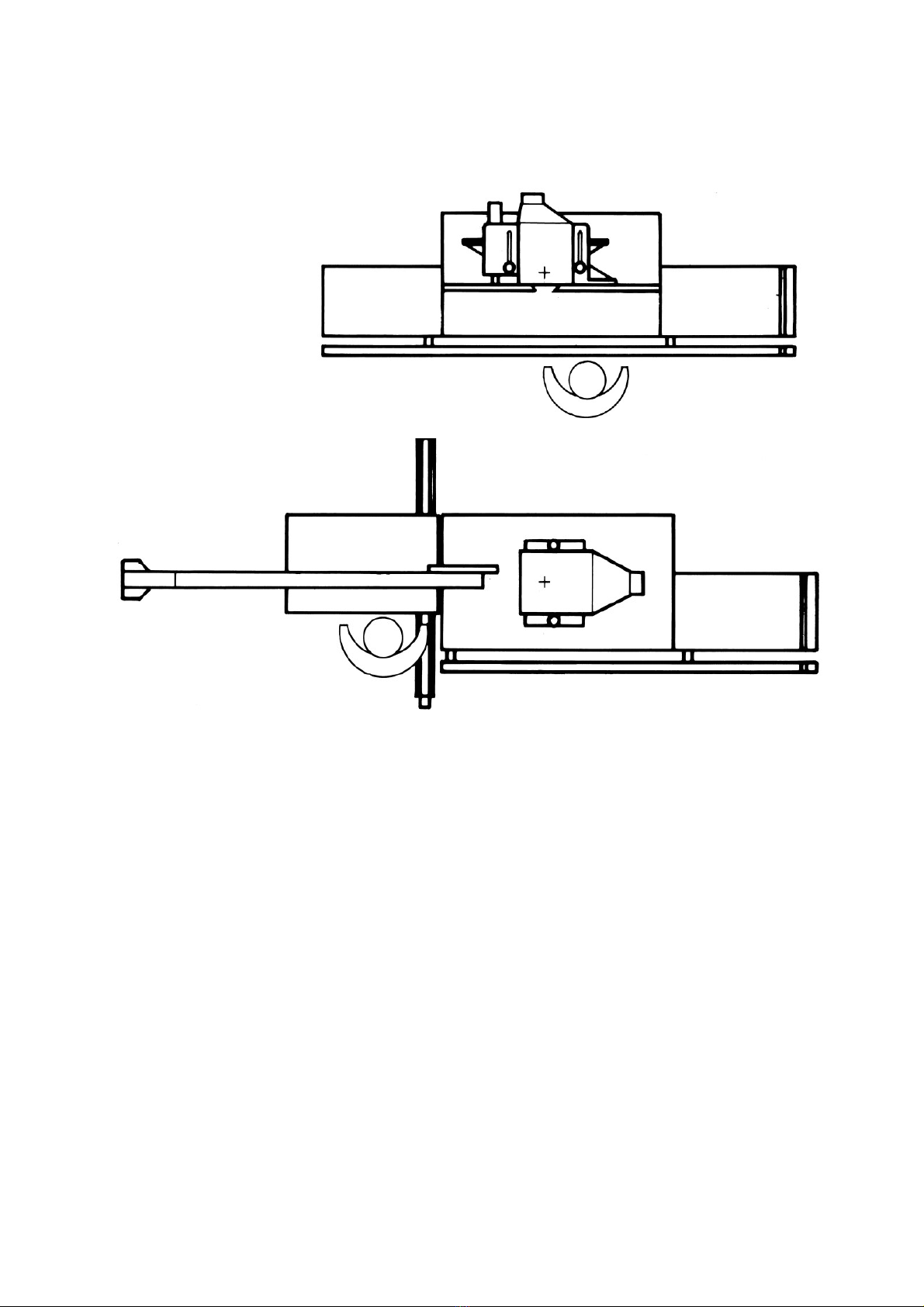

Adjustment of the fences

Working wit t e spindle fences requires special attention:

- a false or integrated fence s ould be used to minimize t e opening between t e tools and t e fences

- a pus stick s ould be used as often as possible

- a wood pus er s ould be used, toget er wit protection, to pus t e piece manually

- long pieces need to be supported wit roller supports

Direction of rotation and choice of speed

It is very important t at t e c osen tool turns in t e rig t direction.

W en t e piece is presented, t e operator must take care t at t e work piece is fed in t e correct direction at

t e correct c osen speed. T e speed also as to be suited to t e tool on t e mac ine.

Functioning of the machine, choice of safety e uipment and adjustments

Because of t e various tasks t at are carried out by various spindle s afts, spindle olders and cutter blocks,

different types of safety equipment ave to be used. Every operation as to be examined separately and t e

appropriate guarding as to be c osen. T e minimal opening in t e table also depends on t e type of cutter

block, t e diameter of t e knives and t e eig t w ic t e cutter block is adjusted in. In t at way, t e opening is

as narrow as possible and t e work piece no longer can flip over and it t e knives.

Using a power feeder can prevent most serious accidents involving ands. Suc feeders easily are adjusted and

adapted to t e size of t e pieces.

W en no power feeder is used, t e wood pus ers ave to be used, t e orizontal and vertical springs making a

tunnel w ere t e piece can slide in. T is pus er, toget er wit ot er safety equipment, reduces t e gap between

4