Hauptsäge

Abmess. Quertisch mm 1420x650

Abmess. Schiebeschlitten mm 3200/3800

Abmessungen Tischverbreit. mm 1100x450

Abmessungen Sägetisch mm 885x700

Abmessungen Tischverläng. mm 650x700

Bohrung mm 30

Durchmesser Hauptsägeblatt max. mm 400

Durchmesser Hauptsägeblatt min. mm 300

Geschwindigkeit Hauptsägeblatt

U/min 3000 / 4000 / 5000

Länge Queranschlag mm 2100

(teleskopisch bis 3000 mm)

Vorritzer

Absaugstutzen mm 120 + 80

Bohrung mm 20

Durchmesser Vorritzsägeblatt mm 120

Geschwindigkeit Vorritzsägeblatt

U/min 8200

Schnitthöhe bei Durchmesser Vorritzblatt

120 mm mm 3,5

Schrägstellung Vorritzsägeblatt ° 90 - 45

Leistung Vorritzmotor kW 0,94

Leistung Hauptsägemotor ps 7, 5

Schrägverstellung ° 90 - 45

Schnittbreite am Parallelanschlag mm 1525

Schnitthöhe maximal (400 mm Blatt)

bei 45° mm 100

bei 90° mm 125

Schnittlänge mm 3200

Konfig.

Abmessungen Verpackung (LxWxH) mm

2270 x 1330 x 1020 + 3250 x 450 x 200

Betriebsspannung Drehstrom V 230 - 400

Gewicht kg 1050

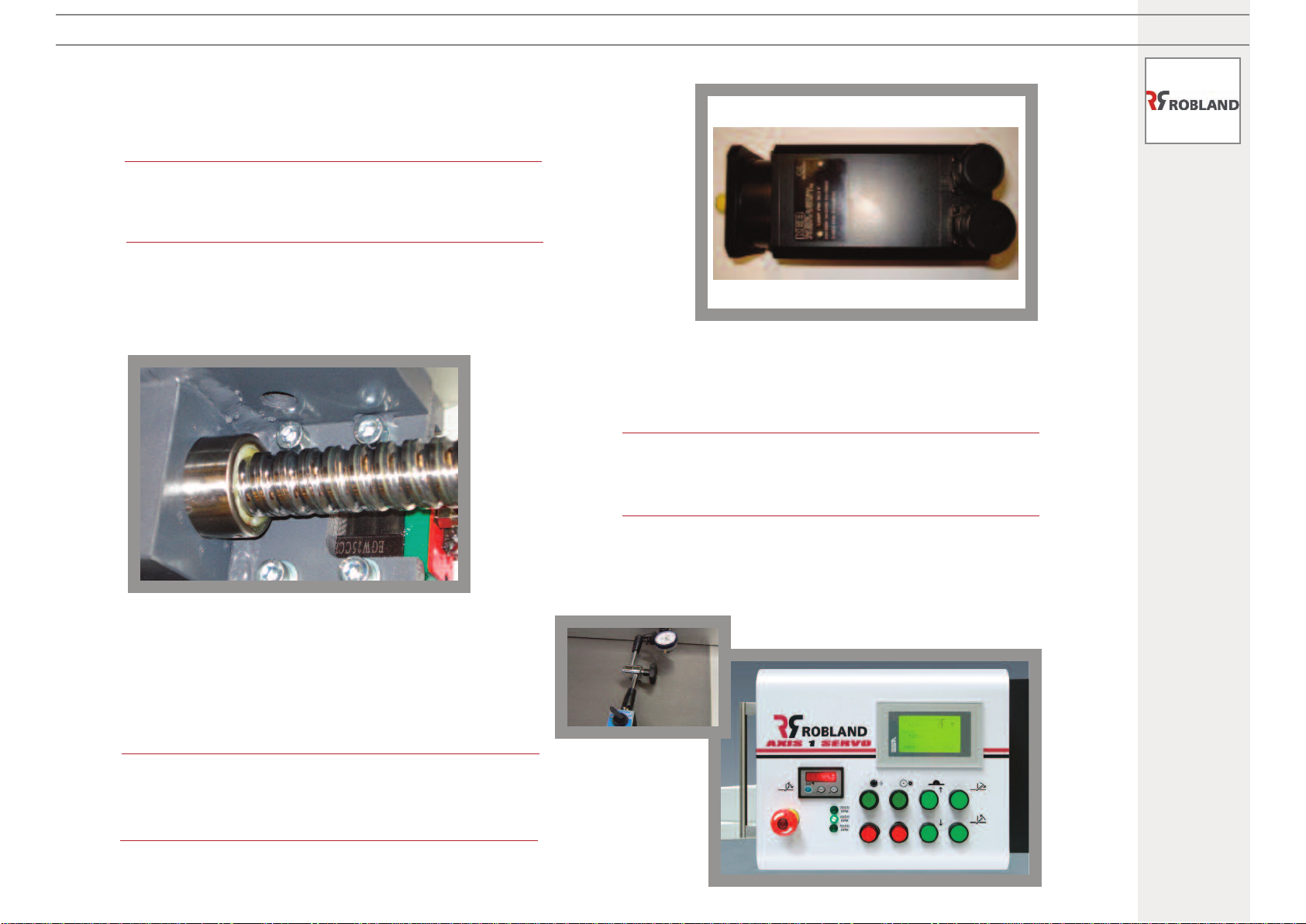

Servoantrieb KEB 0.55 nm mit Resolver. Endlosschleife Sys-

tem für höchste Genauigkeit.

Standardbreite von 1525 Millimeter.

Schweres Alu-Extrusionsprofil.

Kugelumlaufspindel, Spielfrei.

Spielfreies Führungssystem.

Exakter Servo-Regler, sehr höhe Wiederholgenauigkeit.

Ausgestattet mit EMC Filter.

Standard mit Touch Screen.

Technische Daten

Technical Specifications

GR TE MARKT 20 - P STBUS 22

NL-4524 CD SLUIS - NEDERLAND

TEL: +31 (0)117-462880

FAX: +31 (0)117 462888

***

WWW.R BLANDMACHINES.C M

INF @R BLAND.C M

AXIS - ERGO

AXIS - ERGO

Configuration

Dimensions crate (LxWxH) mm 2270 x

1330 x 1020 + 3250 x 450 x 200

Voltage three phase V 230 - 400

Weight kg 1050

Main Saw

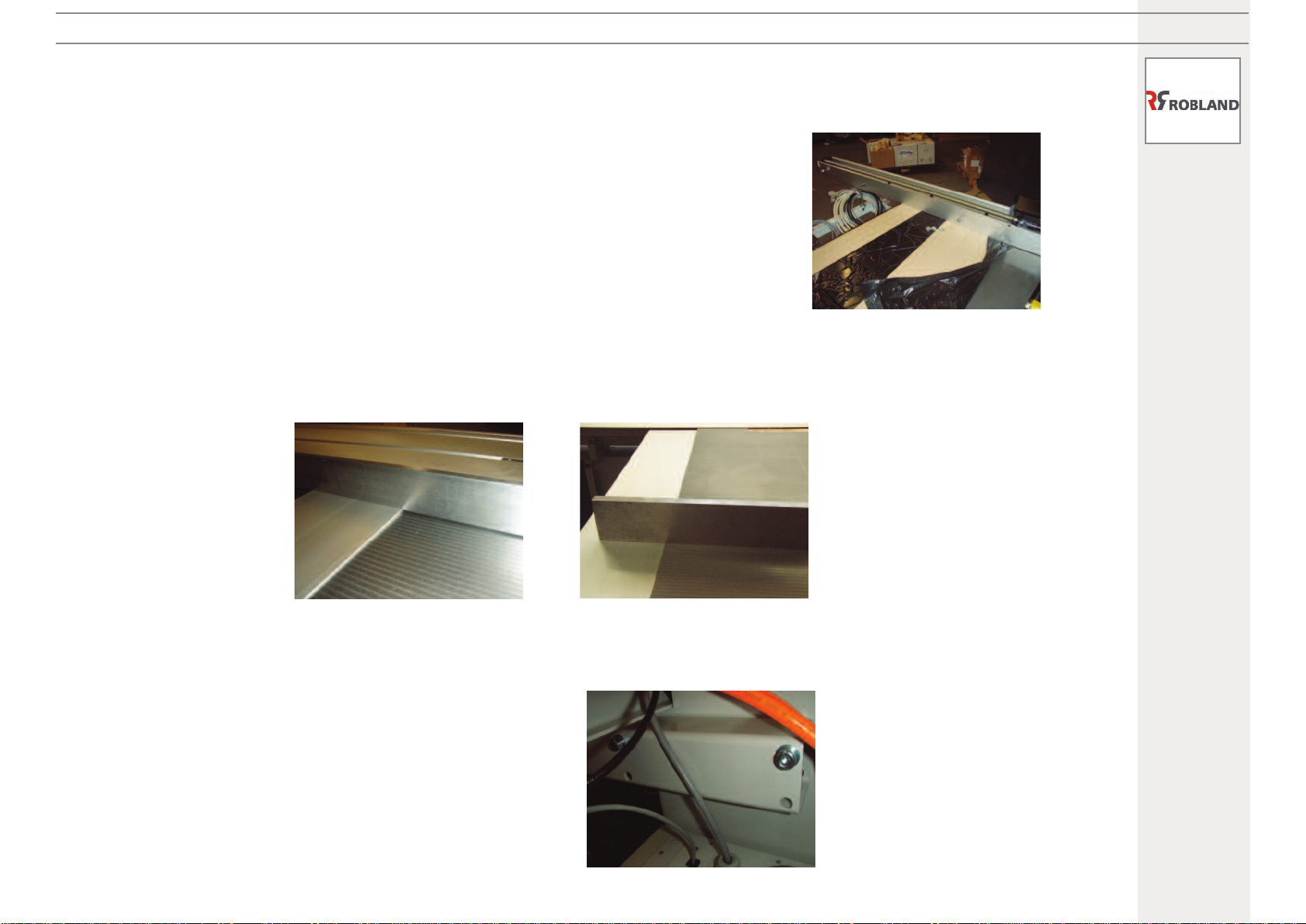

Dimensions cross-cut table mm 1420 x 650

Dimensions sliding table mm 3200/3800

Dimensions right hand table extension mm

1100 x 450

Dimensions sawtable mm 885 x 700

Dimensions saw table extension mm 650 x

700

Scoring saw

Dust suction ports mm 120 + 80

Bore mm 20

Diameter scoring saw blade mm 120

R.P.M. scoring saw R.p.m. 8200

Cutting depth with 120 mm diameter blade

mm 3,5

Scoring saw blade tilt ° 90 - 45

Scoring saw motor power kW 0,94

Auto Star-Delta starter standard.

Motorised rise, fall and tilt of the sawblades

as a standard.

Overhead control switch panel standard.

Bore mm 30

Diameter saw blade maximum mm 400

Diameter saw blade minimum mm 300

R.P.M. main saw blade R.p.m.

3000/4000/5000

Length cross-cut fence mm 2100 (tele-

scopes to 3000 mm)

Motor power main saw hp 7, 5

Sawblade tilting ° 90 - 45

Parallel rip capacity mm 1525

Cutting depth maximum

(400 mm saw blade) at 45° mm 100

Cutting depth maximum

(400 mm saw blade) at 90° mm 125

Saw stroke mm 3200

Servo motor KEB 0.55 nm with resolver. Closed loop system

for high and constant accuracy.

Standard width of 1525 mm.

Based on a stable machined aluminium extrusion.

Ball screw, free of backlash.

Guide free of backlash.

Precise servo-regulator to guarantee a very high

repetition accuracy.

Equipped with EMC filter.

Touch screen, easy to use.