408- 10309

SDE- SA Commercial Hand Tool Assembly for UTILUX Connectors

Rev D2 of 4 Tyco Electronics Corporation

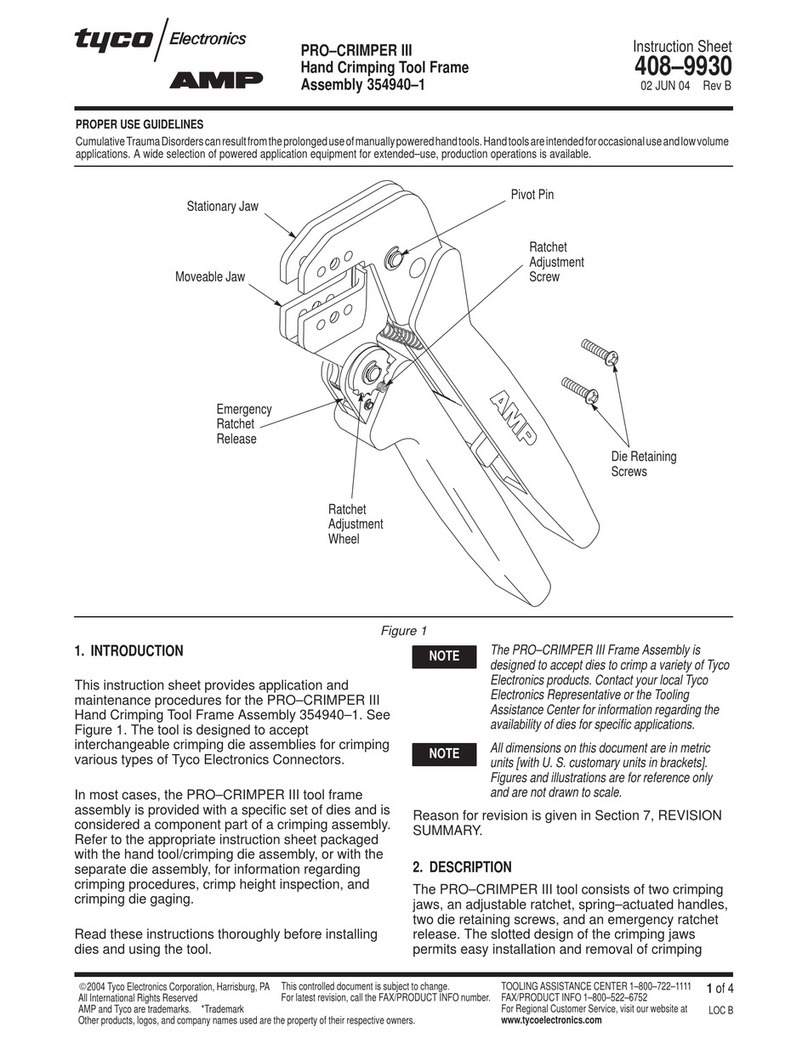

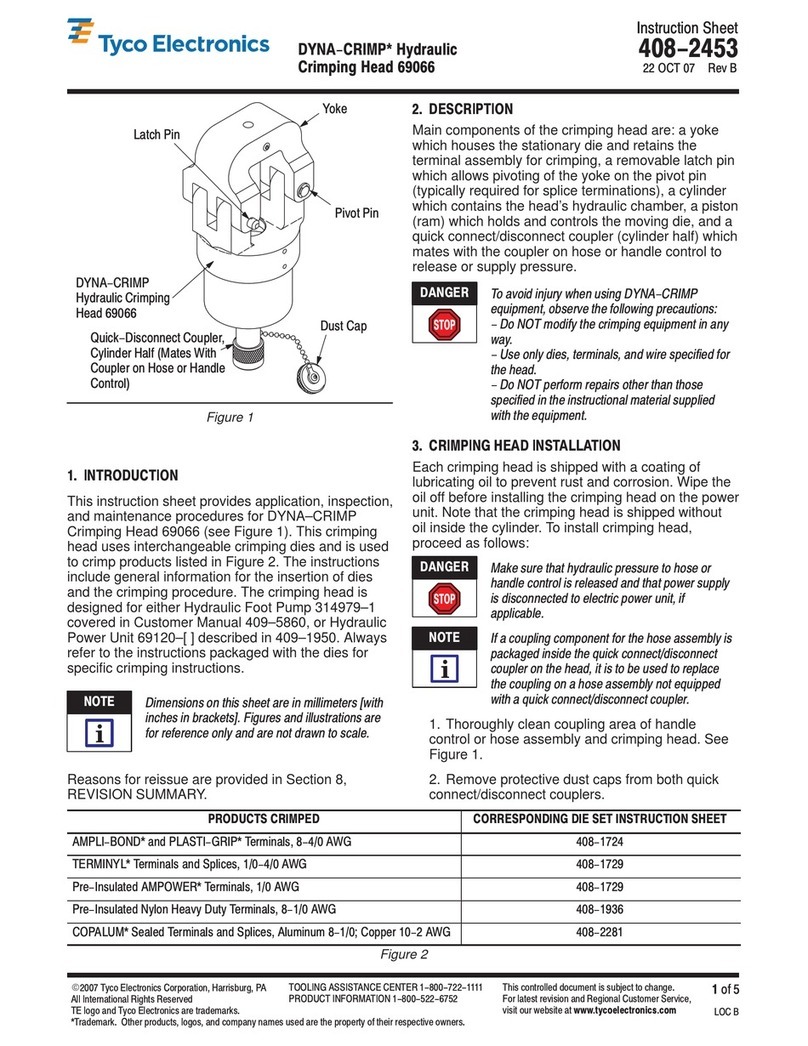

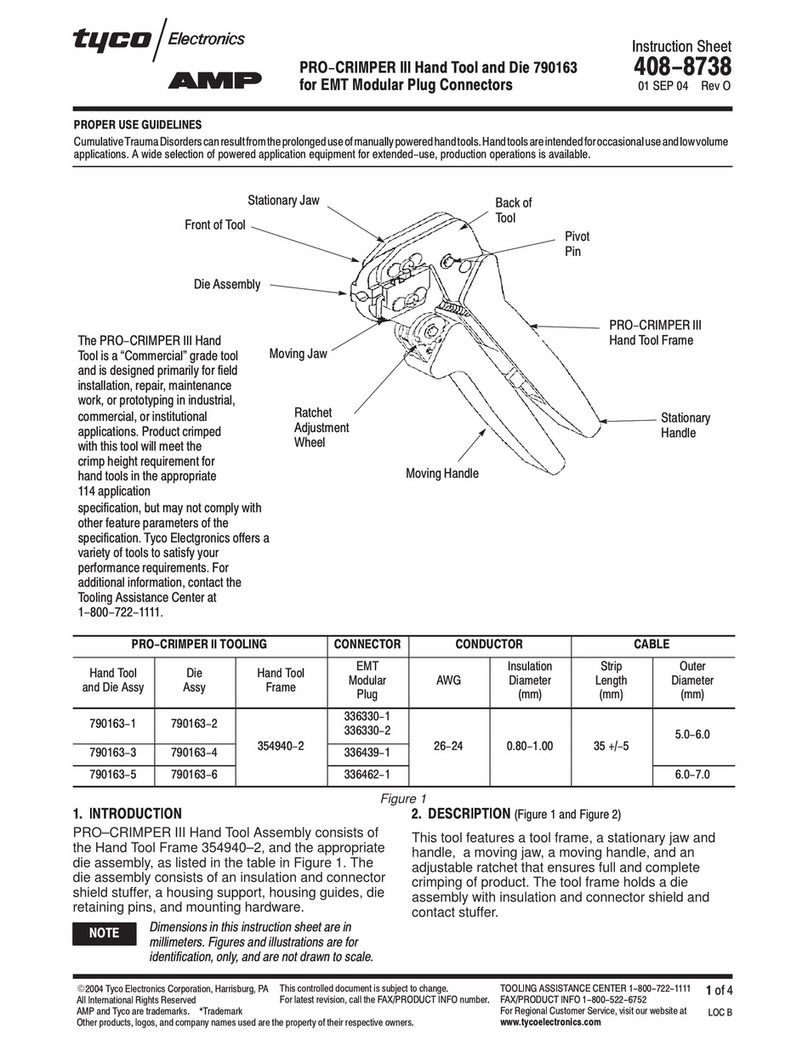

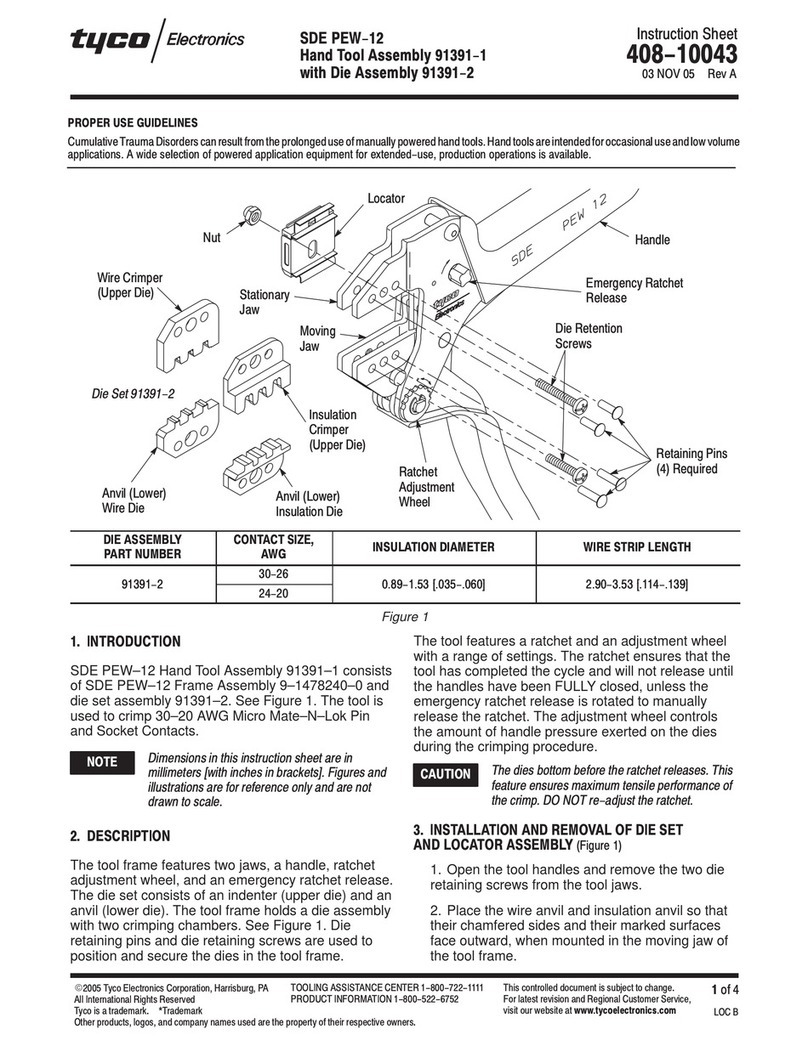

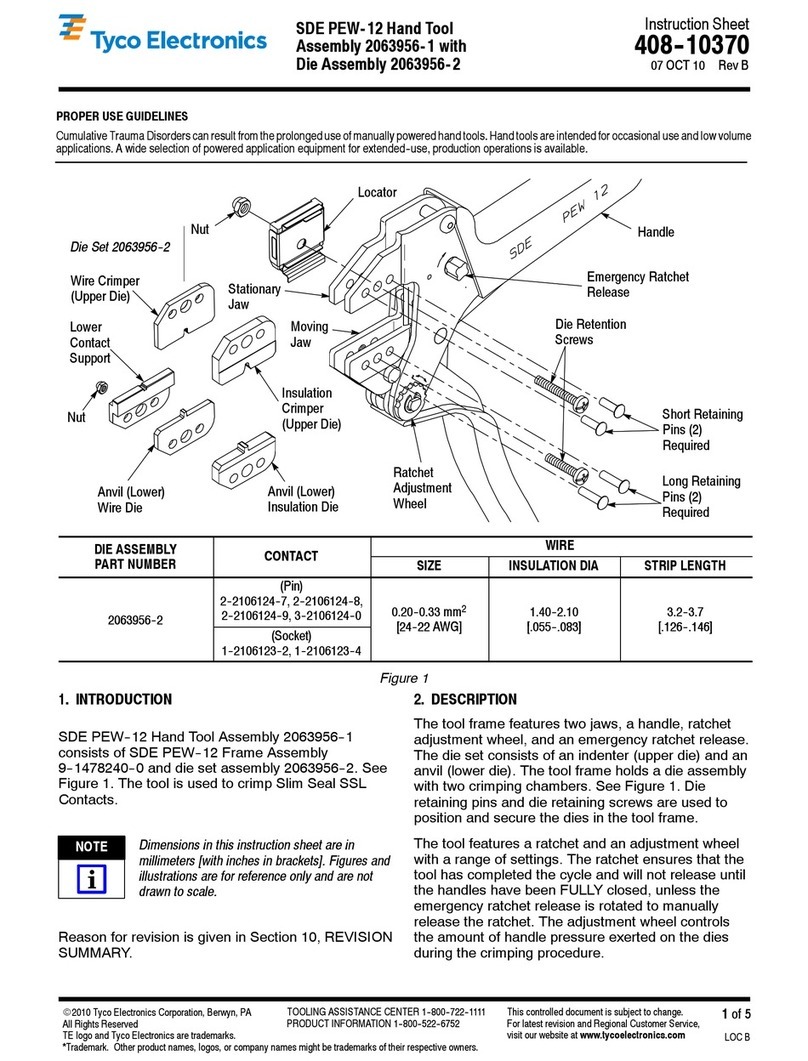

2. DESCRIPTION

The tool frame features two jaws, a handle, ratchet

adjustment wheel, and an emergency ratchet

release.

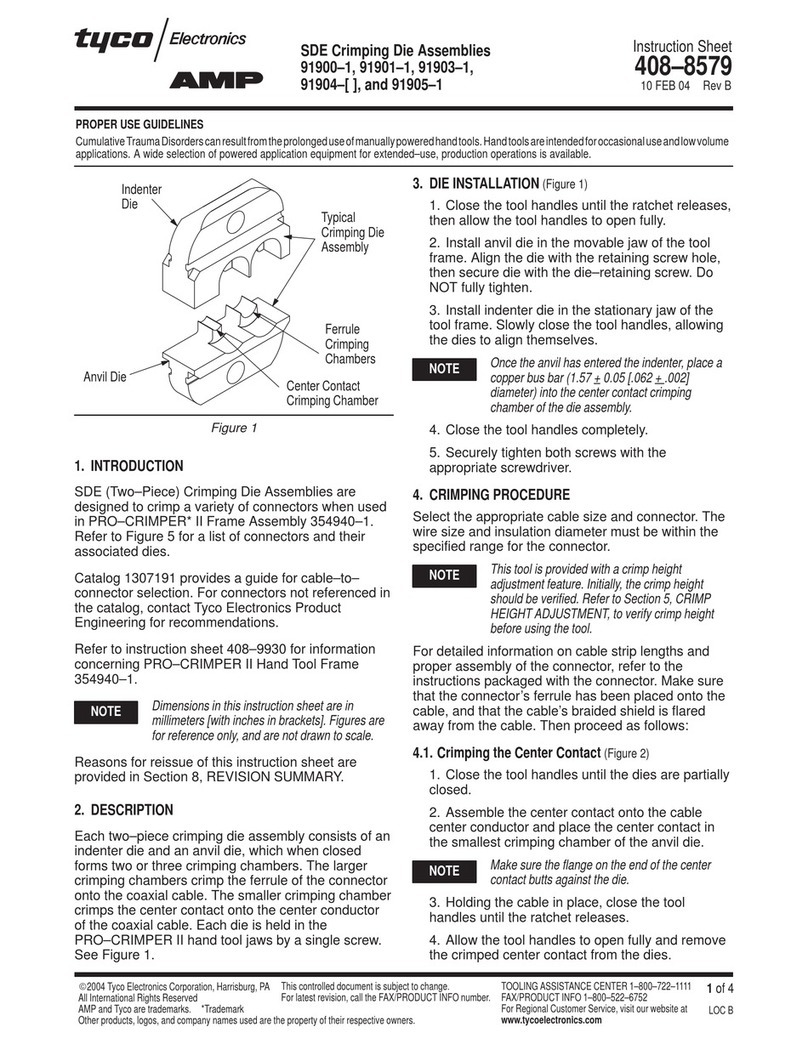

The die set consists of an indenter (upper die) and an

anvil (lower die). The tool frame holds a die assembly

with two crimping chambers. See Figure 1. Die

retaining screws are used to secure the dies in the

tool frame.

The tool features a ratchet and an adjustment wheel

with a range of settings. The ratchet ensures that the

tool has completed the cycle and will not release until

the handles have been FULLY closed, unless the

emergency ratchet release is rotated to manually

release the ratchet. The adjustment wheel controls

the amount of handle pressure exerted on the dies

during the crimping procedure.

The dies bottom before the ratchet releases. This

feature ensures maximum tensile performance of

the crimp. DO NOT re--adjust the ratchet.

3. INSTALLATION AND REMOVAL OF DIE SET

AND LOCATOR ASSEMBLY (Figure 1)

1. Open the tool handles and remove the two die

retaining screws from the tool jaws.

2. Place the wire anvil so that the chamfered side

and the marked surfaces face outward, when

mounted in the moving jaw of the tool frame.

3. Insert the die retaining screw through the jaw

and through the anvil die, and tighten the screw

just enough to hold the die in place. Do not tighten

the screw completely at this time.

4. Place the wire crimper so that the chamfered

side and the marked surface face outward, when

mounted in the stationary jaw of the tool frame.

5. Insert the die retaining screw through the jaw

and through the crimper die, and tighten the screw

just enough to hold the die in place. Do not tighten

the screw completely at this time.

6. Carefully close the tool handles, making sure

that the anvil and crimper align properly. Continue

closing the tool handles until the ratchet in the tool

frame has engaged sufficiently to hold the anvil

and crimper in place, then tighten both die retaining

screws.

7. Place the nut onto the end of the long screw and

tighten the nut enough to hold the locator assembly

in place.

8. To disassemble, close the tool handles until the

ratchet releases, remove the nut, locator assembly,

the four die retaining screws, and slide the anvil

and crimper out of the tool jaws.

The ratchet has detents with audible “clicks” as

the handles are closed. The ratchet releases on

the sixth “click”.

4. CRIMPING PROCEDURE

This tool is provided with a crimp adjustment

feature. Initially, the crimp height should be

verified as specified in Figure 3. Refer to

Section 5, CRIMP HEIGHT INSPECTION, and

Section 6, CRIMP HEIGHT ADJUSTMENT, to

verify crimp height before using the tool to crimp

desired contacts and wire sizes.

Refer to the table in Figure 1 and select wire of the

specified size and insulation diameter. Strip the wire

to the length indicated in Figure 1, taking care not to

nick or cut wire strands.

Figure 2

Insert Wire

Here

Back of Tool

(Wire Side)

Locator

Select an applicable contact and identify the

appropriate crimp section according to the wire size

markings on the tool. Refer to Figure 2 and proceed

as follows:

1. Hold the tool so that the back (wire side) is

facing you. Squeeze tool handles together and

allow them to open fully.

2. Holding the contact by the mating end, insert the

contact through the front of the tool and into the

appropriate crimp section.

CAUTION

!

NOTE

i

NOTE

i