Table of Contents

1. Foreword.................................................................................................................................................... 1

2. Before You Begin....................................................................................................................................... 1

3. Safety Precautions..................................................................................................................................... 2

4. Warranty and Scope of Warranty ............................................................................................................... 3

5. Application Environment ............................................................................................................................ 4

6. Functions and Specifications of Data Input Pendant.................................................................................. 5

6-1 Specifications...................................................................................................................................... 5

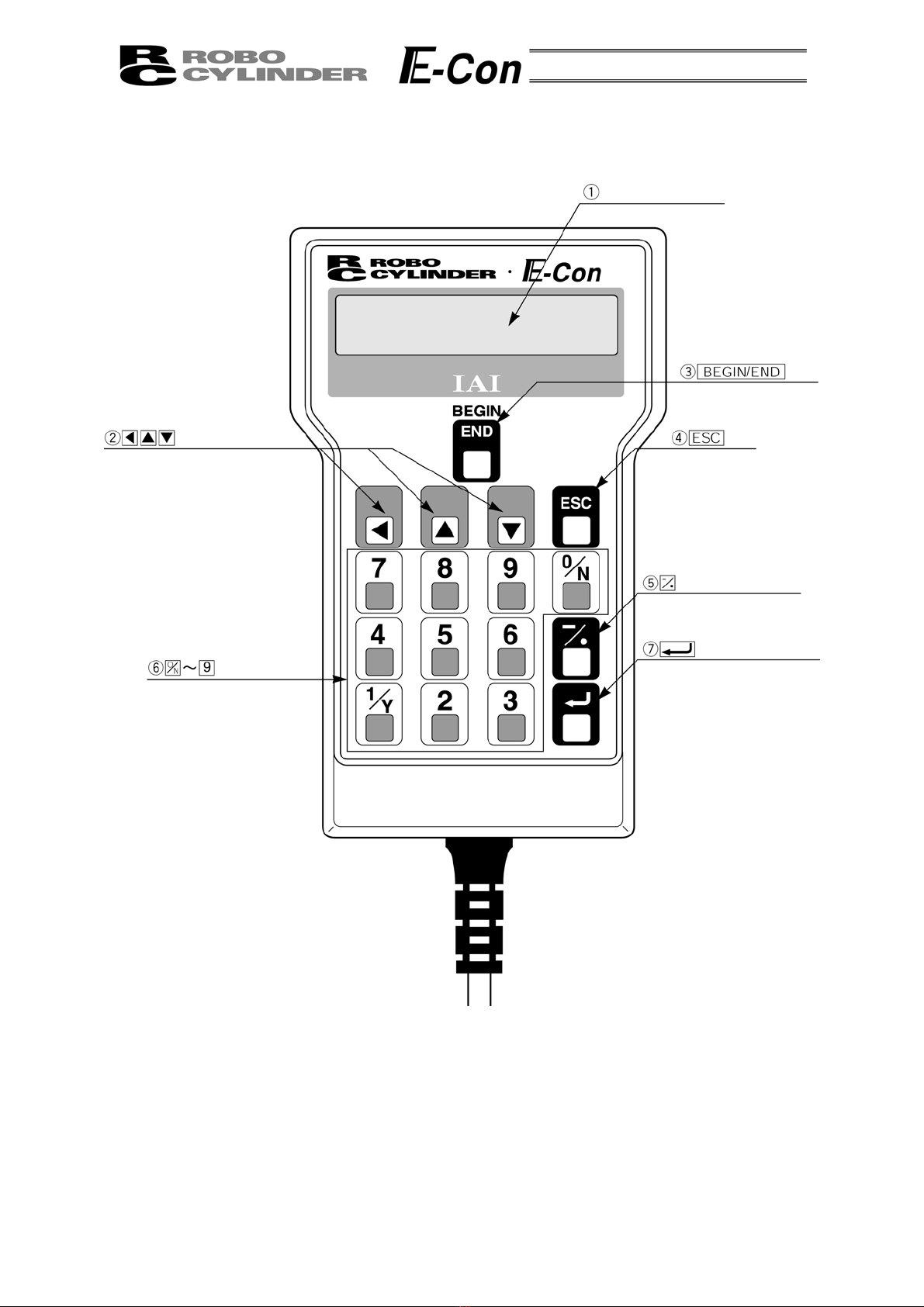

6-2 External View ...................................................................................................................................... 6

6-3 Description of Each Part ..................................................................................................................... 7

7. Connection With the Controller .................................................................................................................. 9

7-1 Connection with the Data Input Pendant............................................................................................. 9

7-2 How to Disengage the Data Input Pendant......................................................................................... 9

8. Operation ................................................................................................................................................. 10

8-1 Initial Screen During Power - UP ...................................................................................................... 12

8-2 Controller Selection (when using multiple units) ............................................................................... 13

8-3 Operation Mode Selection ................................................................................................................ 14

8-4 Edit/Teaching.................................................................................................................................... 15

8-4-1 Edit/Teach Screen ..................................................................................................................... 15

8-4-2 Position Data Table ................................................................................................................... 16

8-4-3 Data Input .................................................................................................................................. 19

8-4-5 Add • Delete............................................................................................................................... 24

8-4-5 Data Modification ....................................................................................................................... 29

8-5 Monitor.............................................................................................................................................. 30

8-6 Error List ........................................................................................................................................... 31

8-7 User Parameter................................................................................................................................. 32

8-8 User Adjustment ............................................................................................................................... 34

8-9 End ................................................................................................................................................... 35

9. Message Area.......................................................................................................................................... 36

9-1 Warning Label Error (Code No. 000h – 07Fh) .................................................................................. 36

9-2 Data Input Pendant Message Level Error ......................................................................................... 37

9-3 Controller Error ................................................................................................................................. 37