MDC1230/MDC1460 Motor Controller Datasheet 1

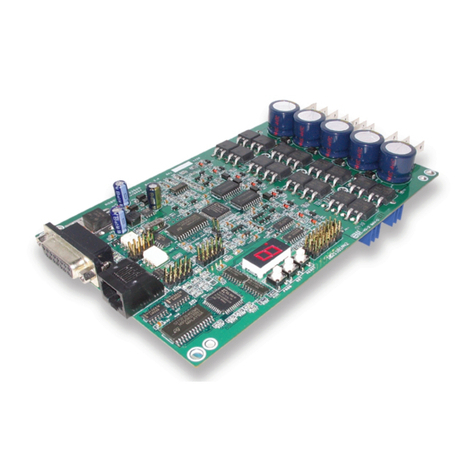

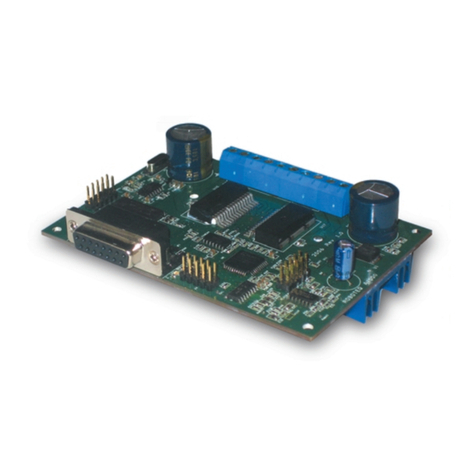

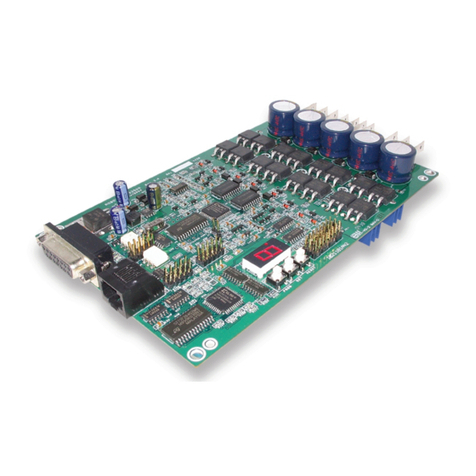

MDC1230/MDC1460

Roboteq’s MDC1230 and MDC1460 controllers are designed

to convert commands received from an RC radio, Analog

Joystick, wireless modem, PC (via RS232) or microcomputer

into high voltage and high current output for driving one

DC motor. Using CAN bus, up to 127 controllers can be

networked on a single twisted pair. Numerous safety features

are incorporated into the controller to ensure reliable and safe

operation.

The controller features a high-performance 32-bit microcom-

puter and quadrature encoder inputs to perform advanced

motion control algorithms in Open Loop or Close Loop (Speed

or Position) modes. The MDC1xxx features several Analog,

Pulse and Digital I/Os which can be remapped as command or

feedback inputs, limit switches, or many other functions.

Numerous safety features are incorporated into the controller

to ensure reliable and safe operation. The controller’s operation

can be extensively automated and customized using Basic

Language scripts. The controller can be reprogrammed in the

field with the latest features by downloading new operating

software from Roboteq.

Applications

• Industrial Automation

• Fan and Pump control

• Winch and Cranes

• Personal transportation

• Automatic Guided Vehicles

• Terrestrial and Underwater Robotic Vehicles

• Automated machines

• Telepresence Systems

• Animatronics

Features List

• RS232, 0-5V Analog, or Pulse (RC radio) command modes

• Auto switch between RS232, Analog, or Pulse based on

user-defined priority

• CAN bus interface at up to 1Mbit/s

• Built-in high-power power drivers for one DC motor at up

to 80A (MDC1230) and 120A (MDC1460)

• Support for 10 KOhm NTC temperature sensors through

analog inputs (requires an external 10 KOhm pull-up

resistor)

• Full forward and reverse control. Four quadrant operation.

Supports regeneration

• Operates from a single power source

• Built-in programming language for automation and

customization

• Programmable current limit up to 80A (MDC1230) or 120A

(MDC1460) for protecting controller, motors, wiring and

battery

• Up to six Analog Inputs for use as command and/or feed-

back

• Up to six Pulse Length, Duty Cycle or Frequency Inputs

for use as command and/or feedback

• Up to six Digital Inputs for use as Deadman Switch, Limit

Switch, Emergency stop or user inputs

• Quadrature Encoder input with 32-bit counter

• Two general purpose 24V, 1A output for brake release or

accessories

• Selectable min/max, center and deadband in Pulse and

Analog modes

• Selectable exponentiation factors for each command

inputs

• Trigger action if Analog, Pulse or Encoder capture are out-

side user selectable range (soft limit switches)

• Open loop or closed loop speed control operation

• Closed loop position control with analog or pulse/fre-

quency feedback

1x80A and

1x120A

Single Channel

Brushed DC Motor

Controller with

Encoder Input,

USB and CAN