The cable should hang straight down from the

sensor without touching the feeder bowl or

anything else. The sensor cable should bend

towards the power control with a bend radius of 3

inches or greater. Use a tie-wrap mounting-base

to anchor the sensor’s cable to the machine base

(or a non-vibrating surface). See Figure 2.

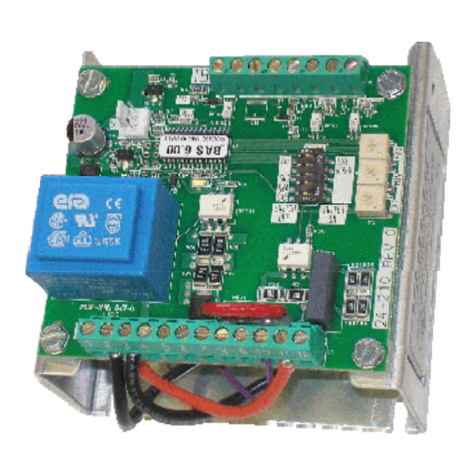

E. CONNECT THE SENSOR to the control. The

sensor’s brown wire connects to +12VDC at TB2-

9. The blue wire connects to the signal input at

TB2-12.

3. TO LIMIT THE MAXIMUM

OUTPUT OF CFR-90 CONTROL:

The MAX Output trimpot must be adjusted to

keep the vibratory feeder from hammering

when the control is turned up to full power.

The feeder must not hammer regardless of

whether it is full of parts or empty. Generally, a

feeder is more prone to hammer when it is empty.

Please note: If the vibratory feeder shakes too

violently to properly feed parts or the feeder speed

oscillates or if the feed rate slows down above a

particular setting on the main control dial, then

adjust the MAX pot counter-clockwise (CCW) to

eliminate these conditions.

NOTE: Output to the feeder must be connected

and the control set for proper output frequency

(60 or 120 pulse) setting. The Run Contact

input must be closed and the Part Sensor must

be calling for parts.

A. Power input should be OFF or disconnected.

B. Open cover to allow access to printed circuit

card.

C. Using CAUTION, turn power ON (no output

should be present).

D. Rotate the MAIN CONTROL DIAL on front

cover slowly to its highest setting.

E. Adjust the MAX Output trimpot so that the

output to the feeder reaches its desired

maximum level.

To take full advantage of the Constant Feed Rate

control’s regulation, it is important not set the

normal operating feed rate to “10” on the dial;

otherwise, the output power cannot be boosted

above the MAX setting when the bowl slows down.

4. CONTROL OPERATION

To operate the control, simply turn ”ON” the control

and adjust the main control dial for the desired feed

rate. It will then automatically maintain that feed

rate until the power is removed from the control.

5. CFR-90 MAIN CONTROL DIAL

The feedback sensor automatically adjusts the

output of the control. After a period of time, the

number setting of the main control dial may no

longer represent the power out of the control

because the control may be regulating at a different

power level than is indicated by the main pot.

If it is desirable to know “where on the dial” you are

operating at, turn the dial to 0 or 10, and then

readjust it for the desired speed. This will reset any

feedback adjustments and reveal what is the real

“number on the dial”. Changing the MAX pot or the

60/120 switch will also reset the feedback

adjustments.

When the main control dial is readjusted 1/64 of a

turn or more, the control will automatically maintain

this setting for the new feed rate. The main control

dial may need to be re-adjusted whenever the

power has been turned back on. Note: there is a

two-second power-up delay before the sensor

circuit begins to regulate the control output.

6. LIMITING MAXIMUM POWER OF

FC-200 CONTROL

The maximum power (Max Pwr) setting can be

lowered to keep the operators from setting the

vibration higher than desired. The maximum

power setting can be found under the “Power

Settings” menu. It can be adjusted from 100.0%

down to 40.0%.

7. Application Tips

By nature vibratory feeder bowls are unstable. If

there are audible changes in the sound of the bowl,

this is normal. The feed rate should remain the

same; however, the changes in the sound of the

bowl indicate that the feedback circuit is correcting

for minor changes in the vibration level of the bowl.

The changes are due to a changing part load, stuck

parts, bunching up of parts, changes in back

pressure or a line voltage fluctuation.

The sensor can monitor up to 18g of vibration. To

determine if the vibration level for the sensor is too

close to 18g in your application, monitor the output

voltage of the sensor: TB2-12 is +, and TB2-4 is

common (-). When the feeder is at its maximum

feed rate, the voltage across these terminals should

be below the maximum voltage of 5.1VDC. If it is at

very near that level, rotate the sensor about 15

degrees so that it its sensitive axis receives less

then 18g of vibration. Typically mounting the sensor

vertically will put the sensor at a 15 angle from the

spring packs.

In rare instances the Rodix control may not

maintain a tight enough tolerance of the vibration. If

this is the case, the sensor should be repositioned

further away from the center of the vibratory feeder.

Ideally, the voltage across terminals TB2-12 and

TB2-4 should be 1.1VDC or higher when the feeder

is at its desired feed rate.

If the need arises to disable the feedback features

of this control, remove power from the control and

remove the sensor’s wiring.

WARNING:

Care should be exercised when handling the

sensor. Drops onto hard surfaces can cause

shocks of greater than 2000g and may exceed

the absolute maximum rating of the device.

RODIX, INC.

Toll Free (800) 562-1868, FAX (815) 316-4701

rodix.com

123-170 CFR 1-17-2019.doc 1/17/2019

-

12

123-170

+

910

Bu or #2

11

TB2

Br or #1