SSD Drives 650V User manual

Associated Literature

650V Installation Manual HA467652Uxxx

650V Software Manual HA466358Uxxx

frames C

frames C-

-F

F

15

15-

-150 HP

150 HP

7.5

7.5-

-90 kW

90 kW

SERIAL COMMS

The Serial Communication option is factory in-

stalled and must be ordered with the drive. It can

be used to exchange information between the

Master and Slave drives in RS485/232 format.

Up to 32 units can be connected together.

Volts/Hertz mode – Basic open loop

operation, used in fans/pumps and multi-

motor applications.

Sensorless Vector mode – Tight speed

regulation with good transient torque

capability, without the need for speed

feedback.

CONTROL MODES

650V

650V

Quick Start

Quick Start

Volts/Hertz

Inverters

Sensorless Vector

Visit us at www.ssddrives.com

USA: (704) 588-3246 UK: +44 (0)1903 737000

HA470679U200 Issue 4

CLONING

650V drives may be cloned using the 6514

Clone option that plugs into the keypad port. Set-

tings include to/from, I/O configuration and full/

part transfer.

ADVANCED FEATURES

The 650V has additional features which can be ac-

cessed via the drive menu or using CE_Lite. Refer

to the product manual for details.

Flycatching - When enabled, lets the drive start

into a spinning load by doing a frequency search.

Skip Frequencies – Two selectable avoidance fre-

quencies and associated window for each.

PID – Provides closed loop process control

S-Ramp – When enabled, introduces a second

order slope to the ramp for smoother transitions.

Configurable Outputs – The digital outputs on the

650 can be configured to pick one of 6 parameters.

The outputs on the 650V are totally configurable.

Auto Restart - After a fault, the drive attempts a

number of restarts after a settable delay.

Custom Screens - Allows the use of a Custom pa-

rameter to be displayed.

Encoder – Terminals 12 &13 can be used for a

quadrature (not complementary) encoder input for

steady-state speed feedback.

BEFORE YOU START

This document covers the steps necessary

for a basic start up of the 690+ drive. Drive

start ups should be performed by qualified

electrical technicians who are familiar with

AC drives and their applications. For de-

tailed installation and safety information

refer to the Installation Manual. For ad-

vanced features and applications, refer to

the Software Manual.

Ensure that all local electric codes are met

while installing the drive. Check that all live

parts are covered to protect against electric

shock and that unexpected rotation of the

motor will not result in bodily harm or injury.

This document expects that the drive is

already installed in its intended location

and that all relevant installation procedures

have been followed. Please ensure that the

drive has adequate ventilation so that am-

bient temperature does not exceed 45°C

(112°F) under normal operating conditions.

To access the terminals, loosen the two

retaining screws at the bottom of the drive,

pull up gently on the terminal cover and

slide it off.

3 phase power

3 phase power thermistor

thermistor

~

~

motor

motor

braking

braking

resistor

resistor

3 phase power

3 phase power thermistor

thermistor

~

~

motor

motor

braking

braking

resistor

resistor

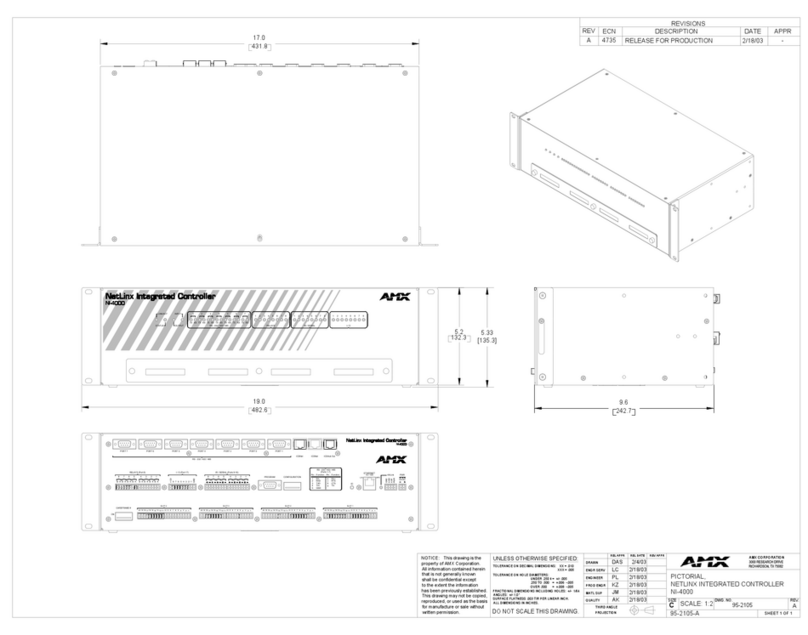

POWER CONNECTIONS

•3-phase supply to L1, L2, L3.

•Motor connections to M1, M2, M3

•Brake resistor between DBR+, DBR-

•Motor thermistor to MOT TEMP

•Common Bus to DC+, DC-

•Frame F only: 115/230V fan supply to

L,N

Ground lugs have been provided for each

of the power circuits. Follow proper ground-

ing and shielding methods as described in

chapter 3 of the Installation Manual,

If the stop time is expected to be less than

the natural coasting time of the load, order

the factory mounted braking module option

on frames D through F. Frame C has a

built-in braking module. Connect the brak-

ing resistor across DBR+ and DBR-.

The power terminals shown are for frame D.

Although other frames may vary slightly in

appearance, their terminal designations and

functionality are identical. However, the

Frame F unit requires an auxiliary supply for

the cooling fan. Refer to Chapter 3.

*HA470679U200*

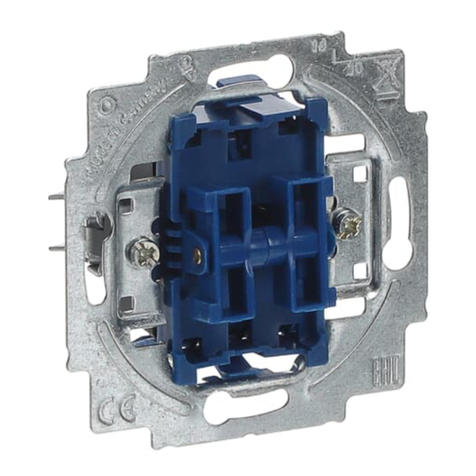

HEALTH RELAY

HEALTH RELAY

N.O. CONTACT

N.O. CONTACT

START

START

JOG

JOG

REV DIR

REV DIR

SPEED REFERENCE

SPEED REFERENCE

+ 24 VDC

+ 24 VDC

CONFIGURATION

CONFIGURATION

PORT P3

PORT P3

HEALTH RELAY

HEALTH RELAY

N.O. CONTACT

N.O. CONTACT

START

START

JOG

JOG

REV DIR

REV DIR

SPEED REFERENCE

SPEED REFERENCE

+ 24 VDC

+ 24 VDC

CONFIGURATION

CONFIGURATION

PORT P3

PORT P3

HEALTH RELAY

HEALTH RELAY

N.O. CONTACT

N.O. CONTACT

START

START

JOG

JOG

REV DIR

REV DIR

SPEED REFERENCE

SPEED REFERENCE

+ 24 VDC

+ 24 VDC

CONFIGURATION

CONFIGURATION

PORT P3

PORT P3

All calibration is done in software, through the keypad

APPLICATION MACROS

SETUP PARAMETERS

P1 Application Select Select the application macro

P2 Max Speed Set max speed in Hz

P3 Min Speed Set min speed in %

P4 Acceleration time Accel time to Max Speed in sec

P5 Deceleration time Decel time from Max Speed in sec

P6 Motor Current Motor full load current in amps

P7 Base Frequency Motor nameplate frequency in Hz

P8 Jog Setpoint Set jog speed in % of max speed

P9 Stop Mode 0=Ramp; 1=Coast; 2=Injection braking

P11 V/Hz shape 0=Linear; 1=Quadratic (fan or square)

P12 Overload Rating 0=150% for 30s.; 1=110% for 10s.

P13 Fixed Boost Set boost in % volts (V/Hz mode only)

P99 Password Set from 0001 to FFFF for protection

M M

M

DIAGNOSTICS

d1 Frequency Output frequency (Hz)

d2 Speed Setpoint Speed SP (% of Max Speed)

d3 DC Link Volts Voltage of DC Bus

d4 Motor Current Motor Current (amps)

After the first power-up, the 650 defaults to the most basic mode of operation, namely speed control. In addition, it has the

capability of being configured for special applications by loading the correct Application Macro.

Selecting an Application: Applications may be loaded during power-up by pressing and holding the STOP button, or by

setting P1 from the Parameters menu. 1=Speed Control; 2=Manual/Auto; 3=Preset Speeds; 4=Raise/Lower; 5=PI Con-

trol; 6=Torque Reference (650Vonly); 9=Custom (650Vonly)

Terminal Assigments: Different applications require different setup parameters, inputs and outputs. When an application

is selected, the 650 internally reassigns its control terminals for the relevant functionality. Also, depending on the applica-

tion selected, an enhanced application-specific set of parameters will be visible, in addition to the regular parameters.

Power-up

screen

REFERENCE AND SEQUENCING

P

P

P

OWER

OWER

OWER

O

O

O

N

N

N

CALIBRATION

•Health volt-free

contacts at 14,15

•Speed potentiometer: 1 (Low), 4 (High),

2 (Wiper) OR

•External speed reference: 1(-) and 2(+)

If using three wire control

•Start button (n.o.) at 6,7

•Stop button (n.c.) at 6,10

The drive powers up in LOCAL MODE. Use the green/

red buttons to start/stop and the up/down arrows to adjust

speed. To switch to REMOTE MODE, hold the STOP

button down until

L0C

disappears. To revert to LOCAL

MODE: At the

rdy

screen, push STOP until

L0C

appears. AUTOTUNE

SPEEDCONTROL

P1=1

MANUAL/AUTO

P1=2

PRESET SPEEDS

P1=3

RAISE/LOWER

P1=4

PI CONTROL

P1=5

App-Specific Parameters

Control Terminal Assign

None

1 Common 0V

2 Speed In (V)

3 Speed In (mA)

4 +10V Supply

5 Speed Output

6 +24V Supply

7 Start button

8Fwd/Rev

9Jog

10 Stop button

IP23 ANIN2 type

OP21 DIGIO2

OP31 Relay

1 Common 0V

2 Manual Ref (V)

3 Auto Ref (mA)

4 +10V Supply

5 Speed Output

6 +24V Supply

7 Manual Start

8 Auto Start

9Man/Auto

10 Fwd/Rev

IP301 Preset 1

IP302 Preset 2

IP303 Preset 3

IP304 Preset 4

IP305 Preset 5

IP306 Preset 6

IP307 Preset 7

IP308 Preset 8

1 Common 0V

2 Speed In (V)

3 Speed In (mA)

4 +10V Supply

5 Speed Output

6 +24V Supply

7Start

8 Preset Digital 1

9 Preset Digital 2

10 Preset Digital 3

P401 Ramp Time

P402 Max Value

P403 Min Value

P404 Reset Value

1 Common 0V

2 Unused

3 Unused

4 +10V Supply

5 Speed Output

6 +24V Supply

7Start

8 Raise Input

9 Lower Input

10 Ramp Reset

P501 Prop. Gain

P502 Integral Gain

1 Common 0V

2 Reference (V)

3Feedback(mA)

4 +10V Supply

5 Speed Output

6 +24V Supply

7 Start button

8Fwd/Rev

9Jog

10 Stop button

M

M

M M

Autotune will not activate if in V/Hz mode.

CONTROL PARAMETERS

CL01 Control Mode 0 = V/Hz; 1 = Sensorless Vector (SV)

CL02 Nameplate RPM Enter RPM from motor nameplate

CL10 Motor Current Enter full load amps from motor nameplate

CL11 Motor Poles 2=3600rpm; 4=1800rpm; 6=1200rpm

CL12 Motor Voltage Enter motor nameplate voltage

CL20 Autotune Mode 0=stationary; 1=rotating (preferred)

CL21 Autotune Enable set to 1 and run the drive to autotune

CL81 Current Limit Current Limit setting as a % of CL10

For sensorless vector (SV) operation, an autotune is highly recommended,

preferably with the motor uncoupled and free to rotate. (if the motor cannot be

uncoupled, set CL20=0. See below).

SAVING

Changes

take effect

as soon as

they are

entered and

parameters

are saved

automatically

in a few

seconds

•Start contact at 6,7

•Jog contact at 6,9

•Reverse Direction

contact at 6,8

M

E

ESCAPE ONE LEVEL

ENTER MENU

SCROLL

UP

SCROLL

DOWN

Other manuals for 650V

2

Other SSD Drives Controllers manuals

Popular Controllers manuals by other brands

KSB

KSB EA-C Series Installation & operating manual

Smartgen

Smartgen ALC700 SERIES user manual

Emerson

Emerson EIM HQ Series Installation, operation and maintenance manual

SEELEY INTERNATIONAL

SEELEY INTERNATIONAL Braemer XE70 owner's manual

CIAT

CIAT FLOWAY Control manual

Omron

Omron CJ1W-CT021 Operation manual