Removejumper "J1" ofthis control fromterminals 6

and 7. Connect the Hopper Paddle switch to

alternateterminals 5 and6. Connect TB2terminals

11 and 12 of this control to the "Parts Sensing

Control". Refer to Section B of the OFF/ON

CONTROL GUIDE. Check specific instructions for

the "Parts Sensing Control" wiring. Two FC-40

Seriescontrols will notinterlock to eachothersince

neither one has an interlock output.

C. Low Voltage DC can be used to turn the control

ON and OFF. Movejumper "J1" fromterminal 7, to

terminal 5, (6 remains the same). Then connect

the positive signal (+10 to 30VDC @ 10mA) to

terminal 12 and the negative to terminal 11 of TB2.

Thecontrol will nowturn ON when theDCsignal is

present at terminals 11 and 12 of TB2. Thisinput is

optically isolated.Refer to SectionC ofthe OFF/ON

CONTROL GUIDE.

7. REMOTE SPEED CONTROL

Remote control of the power level can be accomplished

by the following methods:

A. 4-20mA signal from a PLC can be used to remotely

vary the output of the control instead of the Main

Control Dial. The 4-20mA input is automatically in

control whenever a 4-20mA signal is applied to the

control (terminals TB2-8 & 9). The Main Control dial

setting is ignored whenever there is a 4-20mA signal.

The 4-20mA input is transformer isolated from the

power line. In an environment with high electrical

noise, use a shielded cable for the 4-20mA signal.

The“S1 ProgrammingChart” showshow changeto0-

20mAspeed control insteadof the defaultof 4-20mA.

B. A 0-5VDC Analog input signal may be applied in

place of the Main Control Dial at H1. The 0-5VDC

input is transformer isolated from the power line.

8. LINE VOLTAGE COMPENSATION

Fluctuations in the line voltage can causea feeder bowl

to vary its feed rate. The line voltage compensation

feature adjusts the control's output to help compensate

for fluctuations in the supply voltage. If it becomes

necessary to disable this feature, set “Disable LVC”

from the S1 programming chart.

9. SUPPLEMENTARY FEATURES

Special supplementary software features can be

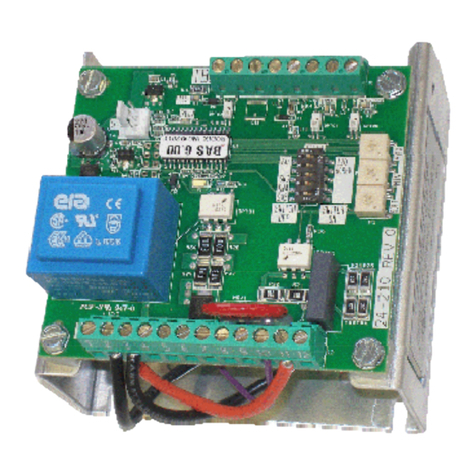

enabled on the 24-210/24-211 circuit boards The

featuresinclude: linearpot taper,0-20mAcontrol,empty

bowl timer, low pulse rates, and two speed pots. See

the S1 Switch Programming Chart. For more feature

information download (or request from RODIX) the

FC-40

Plus

Advanced Application Note 24-210/24-

211.

10. STATUS LEDs

When any of the inputs are active, the associated

LED will turn ON. When theRUNinput conditionsare

met, the RUN LED will turn ON. See section 6 and

the wiring diagram’s ON/OFF Control Guide for more

information on how to satisfy the RUN conditions.

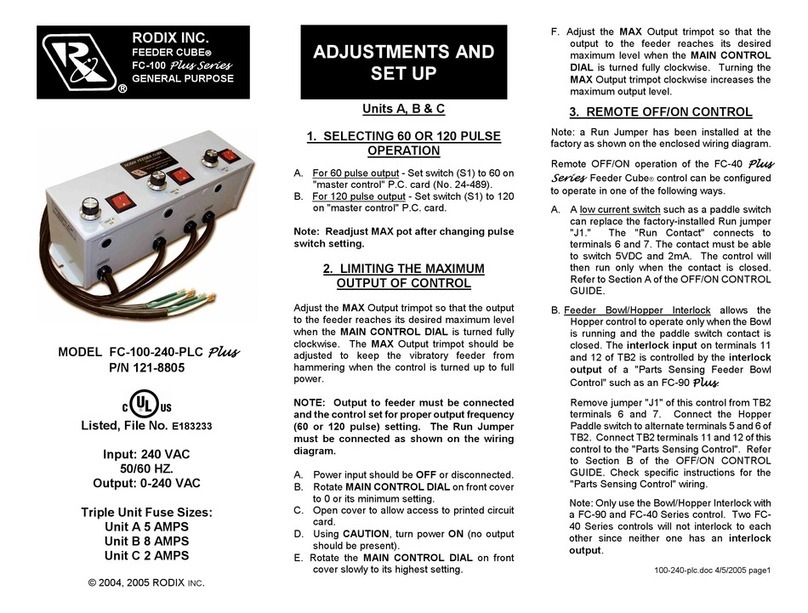

TROUBLESHOOTING

For the control to run: The MAIN CONTROL DIAL

must be turned up or have over 4mA at the 4-20mA

input. Either the DIRECT LED must be lit or both the

INTERLOCK and EXT VOLTS LEDs must be on. To

light the DIRECT LED, connecta RunJumper at TB2-

6 & TB2-7. To light the INTERLOCK LED, a Run

Jumper must connect TB2-5 to TB2-6. To illuminate

the EXT VOLTS LED, TB2-11 & 12 needs a 10-30

VDC signal. See the “FC-40 Plus Troubleshooting

Guide” for more information. If the feeder only hums,

flip the 60/120 dip switch.

WARNING:

Fuses should be replaced with a Bussman ABC

or Littelfuse 3AB "Fast Acting" type or

equivalent of manufacturer's original value.

Mounting this control on a vibrating surface will

void the warranty.

WARRANTY

Rodix Control Products are Warranted to be free from

defects in material and workmanship under normal use

for a period of two years from date ofshipment. Forthe

full description of the warranty, terms, and softwarelicense,

please contact the factory.

For assistance installing or operating your Rodix Feeder

Cube® please call the factory or visit our web site.

Technical help is available to answer your questions and

fax any needed information. To return a control for IN or

OUT of warranty service, please ship it prepaid to:

Rodix Inc., ATTN: Repair Department

If under warranty, Rodix will repair or replace your control at

no charge; If out of warranty, we will repair it and you will be

billed for the repair charges (Time and Material) plus the

return freight. Quotes for repairs are available upon

request. A brief note describing the symptoms helps

our technicians address the issue.

Feeder Cube® is a registered TM of Rodix Inc.

DIMENSIONS

RODIX, INC.

2316 23rd Ave., Rockford, IL 61104

Toll Free (800) 562-1868, FAX (815) 316-4701

www.rodix.com

FC-100 Plus 24-210.doc 10/10/2012 Page 2

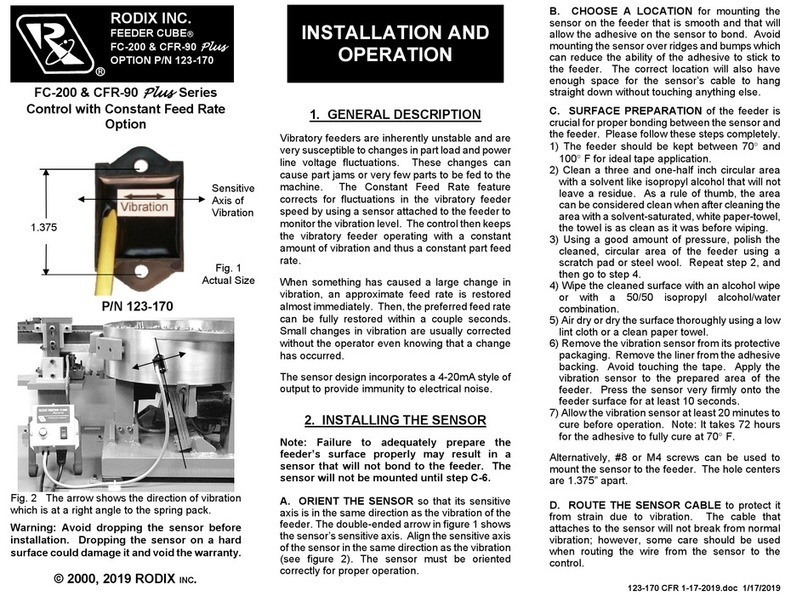

S1 Programming Chart

Program Description S1 Switch Positions

SW3 SW4 SW5

Standard Program 0 0 0

Linear Pot Taper 1 0 0

0-20mA option 0 1 0

Empty Bowl Timer 1 1 0

Disable LVC 0 0 1

2-Speed Operation 1 0 1

30/40 Pulse Operation 0 1 1

Low Amplitude at “1” 1 1 1