SMC Networks C96 Series User manual

Other SMC Networks Controllers manuals

SMC Networks

SMC Networks ITV Series User manual

SMC Networks

SMC Networks ITV SEN DUX02357 Series User manual

SMC Networks

SMC Networks CRB2BW40 Series User manual

SMC Networks

SMC Networks ITV0000 Series User manual

SMC Networks

SMC Networks IN502-44 Series User manual

SMC Networks

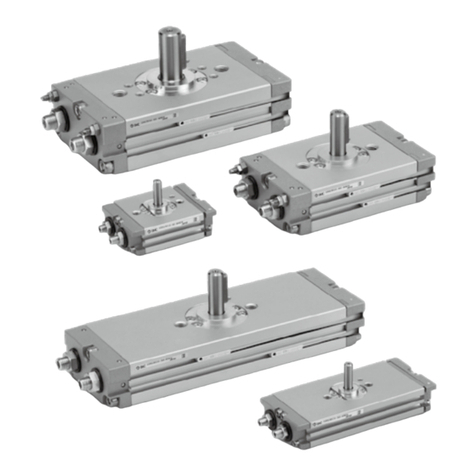

SMC Networks CRQ2 Series User manual

SMC Networks

SMC Networks ITV1000-CC Series User manual

SMC Networks

SMC Networks VXFC-06D User manual

SMC Networks

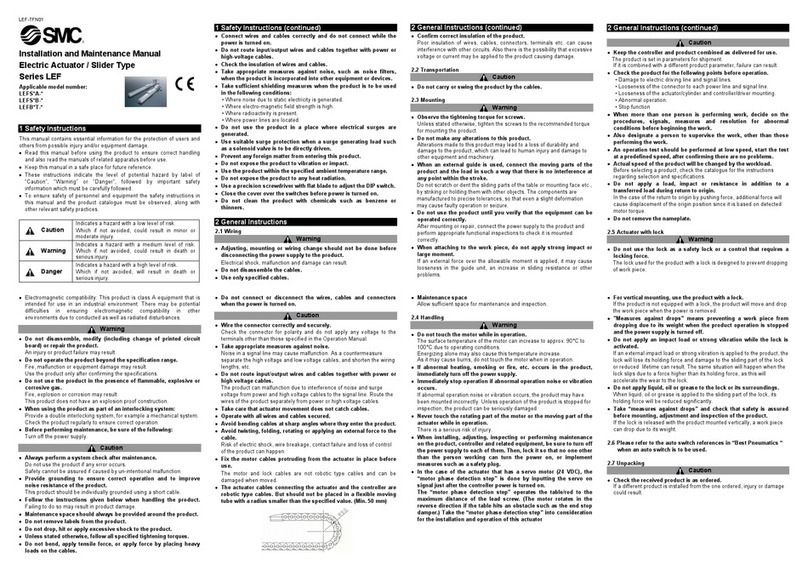

SMC Networks LECP6 Series Manual

SMC Networks

SMC Networks LEC-W2 User manual

SMC Networks

SMC Networks JXCP1 User manual

SMC Networks

SMC Networks LEG Series User manual

SMC Networks

SMC Networks ITV1000 series User manual

SMC Networks

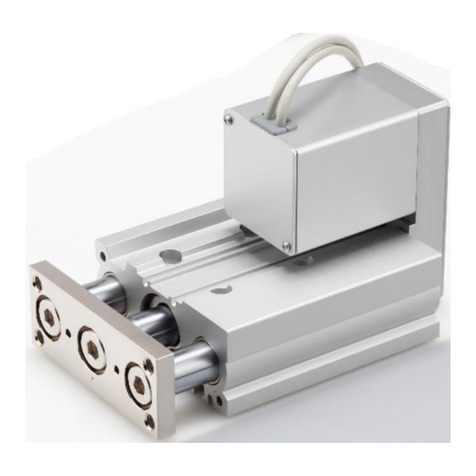

SMC Networks MQ Series User manual

SMC Networks

SMC Networks LEFS 16 Manual

SMC Networks

SMC Networks ITV2050-IL20-X399 Series User manual

SMC Networks

SMC Networks AWM20-01 Series User manual

SMC Networks

SMC Networks AS-FS A Series User manual

SMC Networks

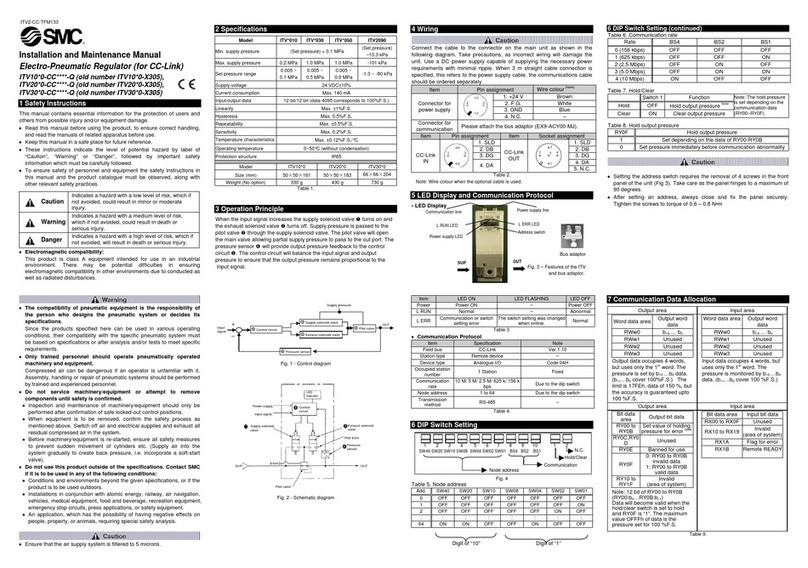

SMC Networks ITV10*0-CC****-Q Series Manual

SMC Networks

SMC Networks CRQ2 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions