RogersSprayersInc. Toll Free 1-888-975-8294 www.rogerssprayers.com 6

First flushwithwater, then add the cleaning solution to the tankand thoroughlyagitate before flushing.

Alwaysflushwith clean waterto remove the cleaningsolution. Removenozzletipsand screens; clean

themin a strong detergent solution orkerosene, using a soft brush such asan oldtoothbrush. Never

use a metalprobe to clean the orifice ofa spraytip!

Followthe same safetyprecautionsduring cleaning asforapplications. Usea respirator,rubbergloves,

orotherprotective gearasmaybe directed bylabelinstructions.

Ifa nozzle becomesblocked, turnthe sprayeroff. Note that the spraylinescould stillbe pressurized

therefore priorto removing the capon the nozzlebody,propersafetyequipment should beworn, (ie

gloves,eyeprotection, etc).

Sunshine

Manyplasticsprayerpartsare degraded byultravioletlight, especiallythe nozzle flowindicators. Store

the sprayerin the shade toextend the lengthofservice.

Winterizing

Afterthe sprayeristhoroughlycleaned, put 2-5 gallons(7-19 litres) ofrust inhibitororantifreezeinthe

tankpriorto the finalflushing to help prevent corrosion.Asthe waterispumped fromthe sprayer, the

antifreezewillleavea protectivecoating on the inside ofthe tank, pump, and plumbing. Remove nozzle

tips, screensand no-drip valves(ifused)and storethemin a can oflight oil suchasdieselfuelorkero-

sene toprevent corrosion.Closenozzleopeningswithtapeto prevent dirt, insects,mice, orothercon-

taminantsfromentering.

During the finalcleaning, completelycheckthe sprayer. Lookat thehoses, clamps, connections, nozzle

tips, and screensforneeded replacements. Storethe sprayerina reasonablyclean and drybuilding.

Operation

With the unit fullyassembled, attach the batteryclipstothe batteryonyourpowerunit. (be surethat the

toggle switch barisoff, pump should not run once clipsare on battery). (NOTE: red clipisforpositive

post onbattery).With liquid inthetank, loosen the pressure regulatorfully, ie loosen locknut on the

regulatorand turn top knobon pressure regulatorcounterclockwise. Next turn unit on byflippingthe

switch on, slowlytighten pressure regulator(turn clockwise)untilpressure on gauge risesto40 psi(3

bar). (NOTE: to obtain optimumpattern, youshouldalwaystryand operateyourspraynozzlesasclose

to 40psi(3bar) aspossible). Due to lossesin the systemyou might wantto runyoursystemat 42-43

psi, thisshouldgiveyou close to 40 psiat the tip. (NOTE: Be carefulnot to run the pump on an empty

tank, thiscould causea vapourlockin the system. Tofixthe problem,make sure thereissomething in

the tank, remove the output supplyhose on the pump and startthe system, takeprecautionsasyour

chemicalwillstart coming through the pump, once the liquid startsflowing shut the systemoff, reconnect

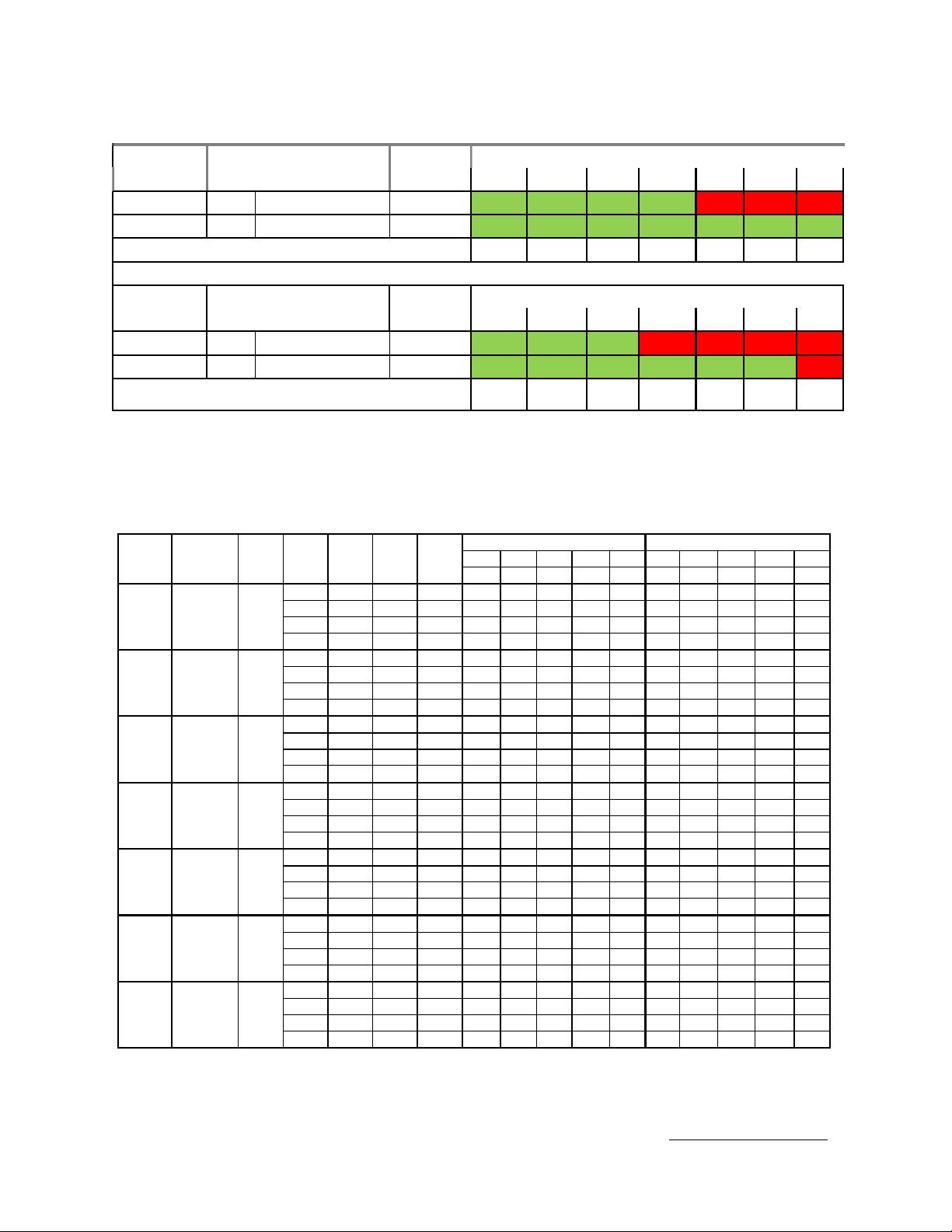

the line and continue spraying). Watch the ballin the flowindicatorasyouspray,If the ball isnot

floating it indicatestipsthat are pluggedorpartiallyplugged. Checkand clean theappropriate tip(s). If

the ballisrightat the top, the flowrate istoo high. Replacethe ball withtherequired ball forthe tips

(see the flow monitorpage).

Test the unit using clearwateron a firmsurface such asasphalt orconcrete before using spraysolution.

Thiswill illustrate the effectiveness ofthe individualspraypatterns.

Note: Asthis isaself contained sprayerwith asmall tankanddoesnot haveaseparatefreshwatertank,

itisrecommendedthatwhen filling and working with chemicals afreshwatersupplyisalwayskeptin

close proximityforsafetyreasons.