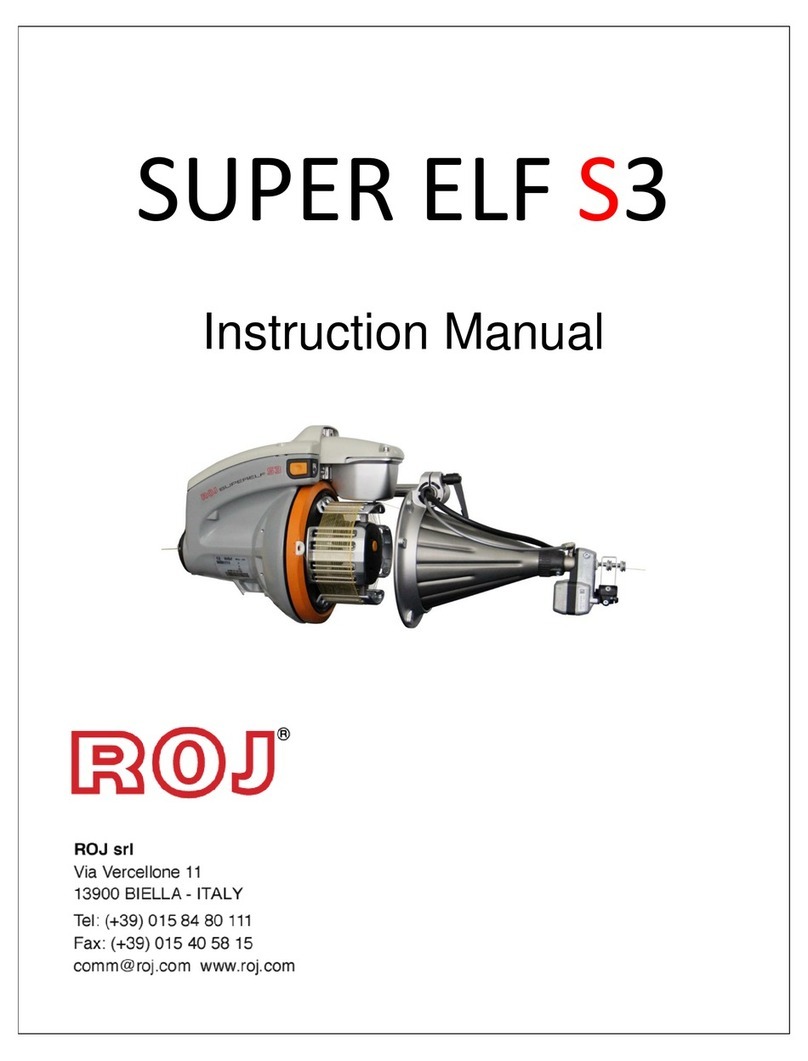

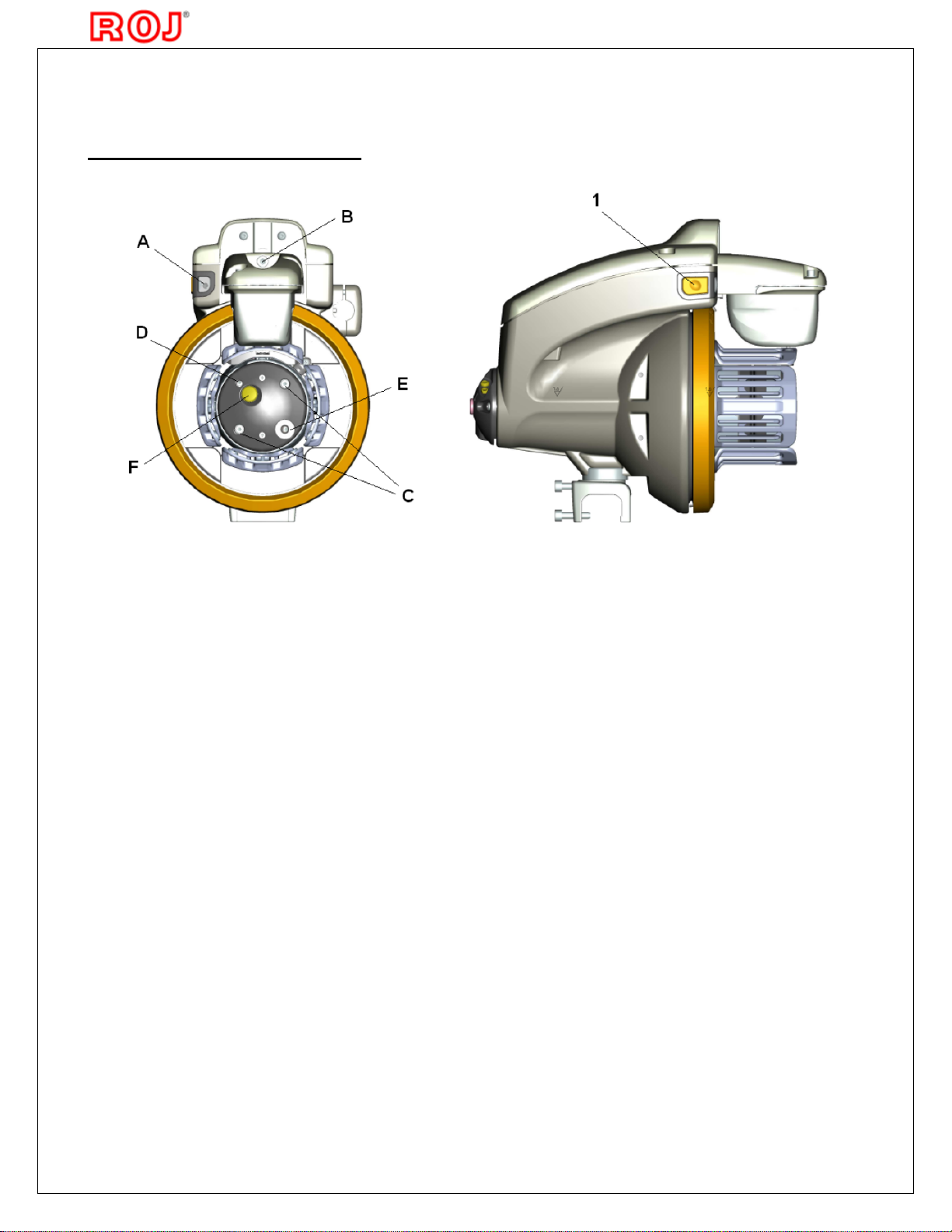

o The Weft Feeder can be set for rotation S or Z depending on the yarn

o Yarn separation is adjustable from 0.7 mm to 2.2 mm.

o Coils detection by means of photocells (Barrier system).

o Storage detection with an integrated

photocell (barrier system).

o Input Weft breakage control through a photocell integrated in the Super

external TFE6 weft Stop Motion device.

o Weft length adjustment, by setting the spool body diameter and the

o Range of weft lengths: from 64 to 672 cm.

: Weft lengths ranging from 87 to 96 cm CANNOT BE MEASURED.

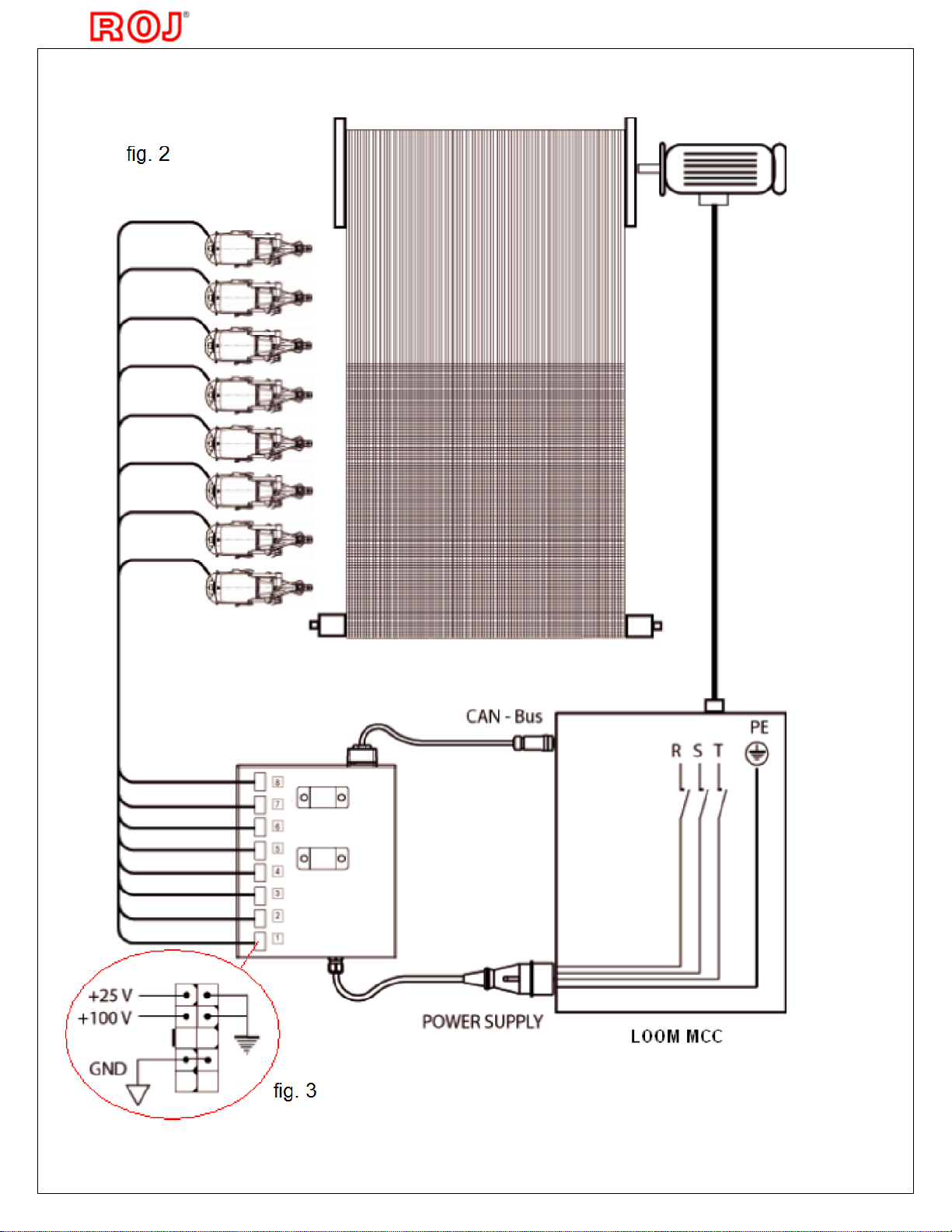

o CAN BUS communication protocol with the loom Control.

o Pulsar HP brake control.

o Full and half weft threading by me

ans of a pneumatic system.

o New Electromagnet design.

o Reserve Storage position Photocell reliable also in dust environments.

o Permanent Magnet motor for more accurate speed control, faster

acceleration, full torque at

all speeds and lower energy

o Sealed motor, photocells housing and cable connections are IP63 Water

balloon design with reclining Funnel simplifies maintenance and

optimizes space requirements for multi