Gex en English

4

b] Never place your hand near the rotating ac-

cessory. Accessory may kickback over your

hand.

.c] Do not position your body in the area where

power tool will move if kickback occurs. Kick-

back will propel the tool in direction opposite to

the wheel’s movement at the point of snagging.

d] Use special care when working corners, sharp

edges, etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

e] Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create fre-

quent kickback and loss of control over the

power tool.

Safety Warnings Specific for Grinding Oper-

ations

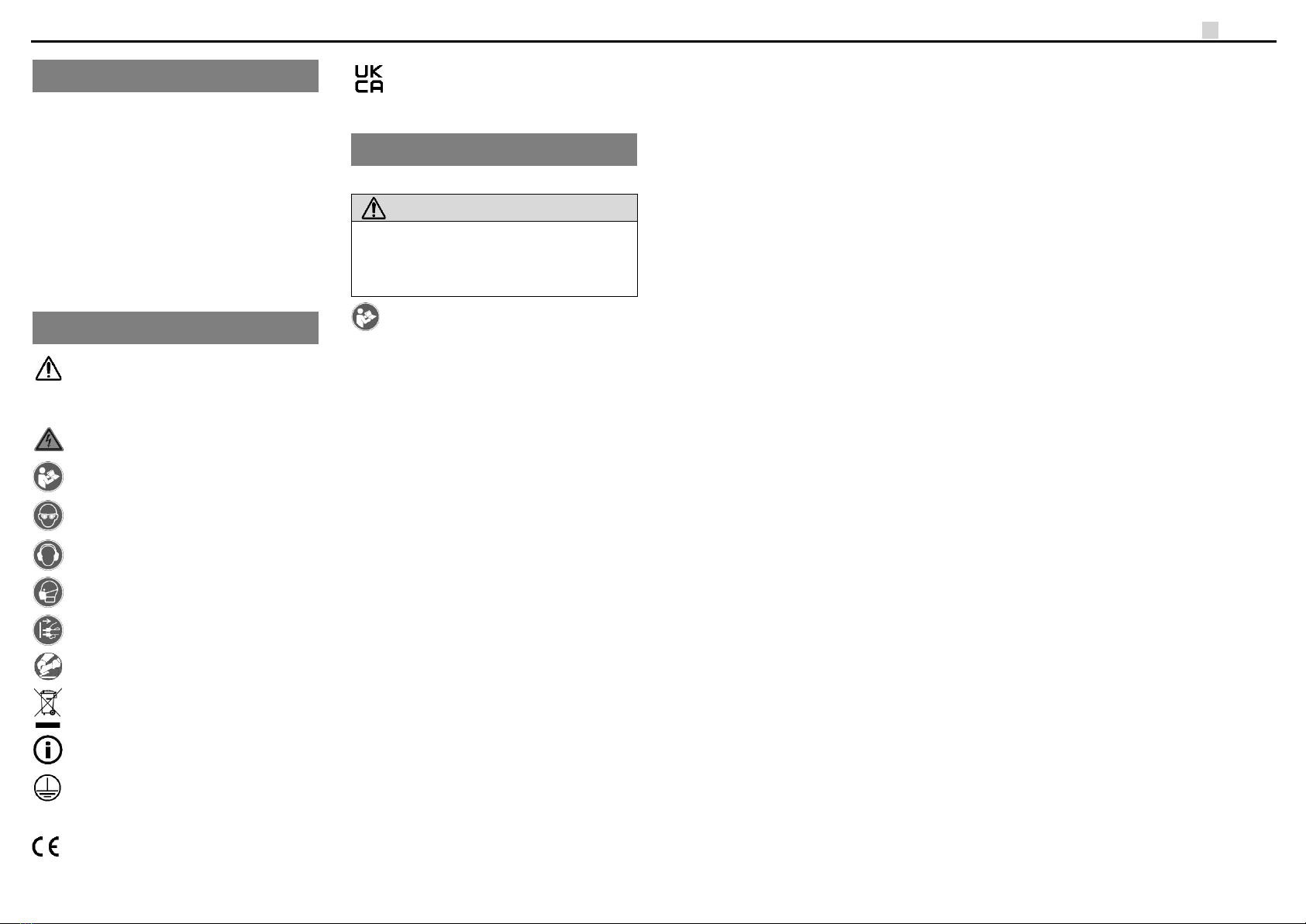

Use only wheel types that are recommended for

your power tool and the specific guard designed

for the selected wheel. Wheels for which the

power tool was not designed cannot be adequately

guarded and are unsafe.

The grinding surface of the centre depressed

wheels must be mounted below the plane of the

guard lip. An improperly mounted wheel that pro-

jects through the plane of the guard lip cannot be

adequately protected.

The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed to-

wards the operator. The guard helps to protect

operator from broken wheel fragments and acci-

dental contact with wheel and sparks which could

ignite clothing.

Wheels must be used only for recommended ap-

plications.

Always use undamaged wheel flanges that are

of correct size and shape for your selected

wheel. Proper wheel flanges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheel flanges.

Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and

may burst.

Safety warnings specific for grinding and

sanding operations

Do not use excessively oversized sanding disc pa-

per. Follow manufacturers recommendations,

when selecting sanding paper. Larger sanding pa-

per extending beyond the sanding pad presents a

laceration hazard and may cause snagging, tearing

of the disc or kickback.

Safety Warnings Specific for Polishing Op-

erations

Do not allow any loose portion of the polishing

bonnet or its attachment strings to spin freely.

Tuck away or trim any loose attachment strings.

Loose and spinning attachment strings can entan-

gle your fingers or snag on the workpiece.

Additional safety instructions

Particles generated when working with this ma-

chine may contain substances that can cause can-

cer, allergic reactions, respiratory diseases, birth

defects or other propagation defects. Some of

these substances include: Lead (in paint containing

lead), mineral dust (from bricks, concrete etc.), ad-

ditives used for wood treatment (chromate, wood

preservatives), some wood types (such as oak or

beech dust), metals, asbestos.

The risk depends on for how long the user or nearby

persons are exposed to the substance.

This dust must not be allowed to enter your body.

Do the following to reduce exposure to these sub-

stances:

- Ensure good ventilation of the workplace.

- Wear appropriate protective equipment, such as

respirators able to filter microscopically small

particles.

- To protect your health, wear a suitable

protective mask.

- Always wear protective goggles to protect

against sanding hazards.

- Connect the electric power tool to a suitable ex-

traction system.

- Sweeping or blowing stirs up dust.

- Vacuum or wash the protective clothing. Do not

blow, beat or brush.

Collect the generated particles at the source, avoid

deposits in the surrounding area.

Observe the relevant guidelines for your material,

staff, application and place of application (e.g. oc-

cupational health and safety regulations, dis-

posal).

If potentially explosive or self-igniting dust is pro-

duced during sanding, the machining instructions

issued by the material manufacturer must always

be followed.

Attention: Risk of fire! Avoid overheating the

grinding material and the sander. Always empty

the dust container before taking a break. Swarf in

the filter bag or filter of the extraction system may

self-ignite in unfavorable conditions such as flying

sparks when grinding metals. Particular danger ex-

ists if the swarf is mixed with paint, polyurethane

residue or other chemical materials and the grind-

ing material is hot after long periods of work.

Damaged, eccentric or vibrating tools must not be

used.

There must be no unprotected persons in the ejec-

tion direction of the tool and the immediate vicinity.

Always use an antistatic suction hose with the

power tool. A slight electric shock may cause you to

panic briefly and become distracted, which may re-

sult in an accident.

When the safety clutch responds, switch off the

machine immediately!

Do not overload the motor for a long period. Engine

noise should be regular (not wave-like). Unsteady

engine performance can be perceived acoustically.

Take a break when the machine is heated up

strongly and let it cool down again. To that let the

motor idle at top speed for some time.

Don’t bend the flexible drive shaft!

Start working with the lowest speed in order to get

a feel for the machine.

Don’t put the running motor on the ground! Dirt may

get sucked in and cause damage.

Always use original ROKAMAT abrasives. Foreign

abrasives are not suitable for the speed of the

sander and may break.

Pull the plug out of the socket before making any

adjustments, converting or servicing the machine.

Ensure sufficient cable clearance. Use only exten-

sion cables permitted for outdoor use.

Keep the carry case out of reach of children. Chil-

dren may suffocate or be strangled when playing

with the carry case.

Emission levels

NOTE! Values for the A-weighted sound pressure

level and for the total vibration values can be found

in the “Technical specifications” table at page 9.

The vibration emission level given in this infor-

mation sheet has been measured in accordance

with a standardized test and may be used to com-

pare one tool with another. It may be used for a

preliminary assessment of exposure.

CAUTION! The indicated measurements refer to

new power tools. Daily use causes the noise and vi-

bration values to change.

The declared vibration emission level represents

the main applications of the tool. However, if the

tool is used for different applications, with differ-

ent accessories or poorly maintained, the vibration

emission may differ. This may significantly in-

crease the exposure level over the total working

period. However, if the tool is used for different ap-

plications, with different accessories or poorly

maintained, the vibration emission may differ. This

may significantly decrease the exposure level over

the total working period.

CAUTION! The noise produced during work

may damage your hearing.

Wear ear protection!

The hand-guided long-neck grinder Gex is intended

for the grinding and polishing of ceilings, walls and

floors, indoors and outdoors. It is suitable for con-

crete and stone grinding, for removing concrete

burrs, coatings, loose render as well as paint and

adhesive residue, for levelling, roughening of

screed and evening out butt joints. It may only be

used for dry grinding. For grinding work, the unit

may only be operated in combination with a suita-

ble vacuum cleaner. The Gex is only intended for

use with ROKAMAT metal and fibre discs.

Only sufficiently qualified and trained personnel is

allowed to work with the grinder.

The intended use includes the observance of the

operating instructions, in particular the safety in-

structions and the observance of generally recog-

nized accident prevention regulations.

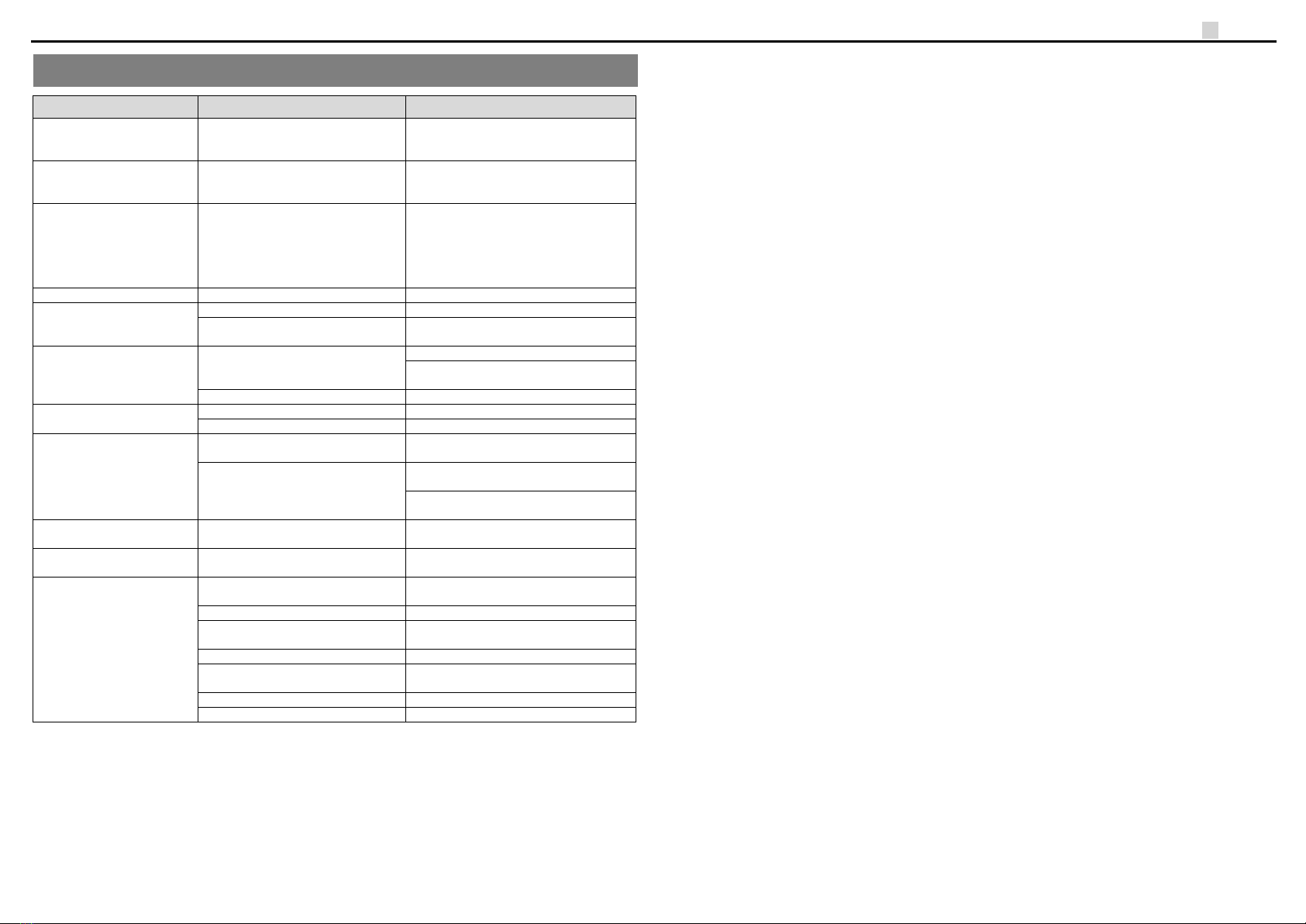

Grinder and polisher Gex Item No. 85000

4. Technical Specifications