Roksan Audio ltd TMS 3 Record Player User Manual

General Use

Version 2.00

All specifications are liable to change without notice. E&OE Page 5 of 27 ENGLISH

The TMS 3 Record Player incorporates many new, unique design features and manufacturing techniques. It is

important to observe the following to avoid any damage and to ensure optimum performance.

T

Th

he

e

S

St

tr

ru

uc

ct

tu

ur

re

e

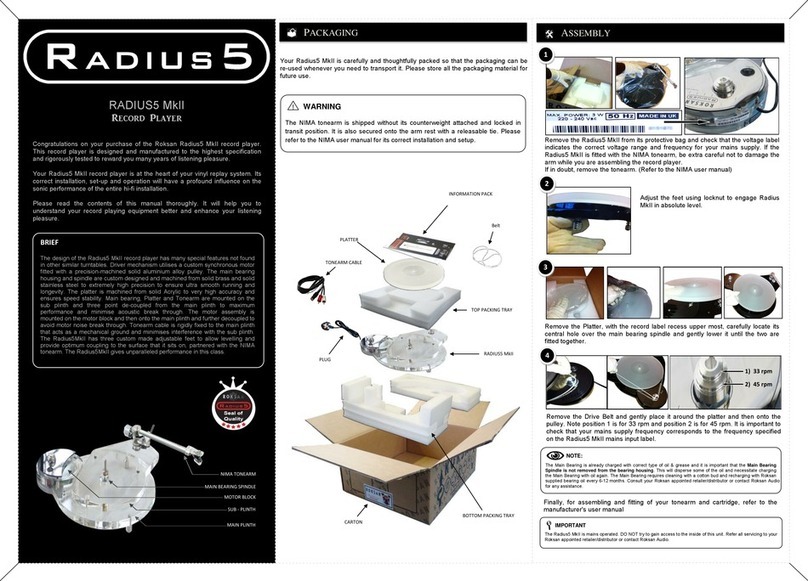

TMS 3 has four separate plinths used for decoupling across a selective frequency band.

1. The bottom plinth is grounded to the supporting surface via three specially designed stainless

steel/Tungsten Carbide adjustable spike feet and bases. This plinth houses the super XPS Roksan motor

supply/speed controller, TMS 3 precision motor assembly and the ‘supple’ Tonearm DIN connector sytem.

2. There is a 3 level adjustable and progressive decoupling from the bottom plinth to the top plinth. The top

plinth features the familiar cut-out, first seen on the original Xerxes, that follows the contour of the sub-

plinth without touching it and supports the middle plinth.

3. The middle plinth supports the sub-plinth through a 3 level decoupling and hangs from the top plinth via a

set of 3 tension decouplers connected to the top plinth through Acetal support inserts.

4. The sub-plinth carries the main bearing/platter assembly and the tonearm and is designed as a reference

platform to preserve the record/cartridge interface from unwanted disturbances. It has been computer

modelled using finite element analysis to determine the optimum shape and of coupling of this platform to

the plinth.

The sub, top, middle and the bottom plinths are designed and manufactured from specific density MDF Piano

lacquered to provide the required rigidity/mass for the sub-plinth support structure. The Bottom plinth utilises two

Stainless steel & Brass Vibration absorbers to ensure maximum signal to noise ratio.

The motor is free to pivot on its own bearing on an axis of rotation coincident with the shaft of the motor. With this

unique dynamic system transient speed changes are absorbed and do not affect the measuring platform.

The arm board, which provides another level of isolation, is machined from a billet of Acetal with complimentary

damping between the tonearm and the sub-plinth. The detachable arm board is fixed by three stainless steel

bolts for easy tonearm mounting and adjustment.

T

Th

he

e

B

Be

ea

ar

ri

in

ng

g

/

/

P

Pl

la

at

tt

te

er

r

A

As

ss

se

em

mb

bl

ly

y

At the heart of TMS 3 is Roksan’s unique and formidable self-centering, self-aligning true single point main

bearing. The innovative design of this bearing provides almost silent, frictionless rotation, precisely defining the

rotational axis. The bearing sleeve is gun-drilled from solid phosphor bronze and honed to provide

spindle/bearing sleeve gap of 2/10,000” along its length! The only contact is between the polished spindle tip and

the captive hardness matched Tungsten Carbide super precision ball.

The spindle is made to within 1 micron from super precision Tungsten Carbide with a taper that locates into the

inner platter without the use of adhesive or the need for pressing.

DESIGN