16mm Tubular Motor (DC12V) vith ieinote Control System lnstruction

Please fell free to contact us if you have any queritions regarding programming or installation please Contact

web: wwr^;. rol lerhouses.com 4 fter-sa i e enrail : service@ rol lerhouses.com

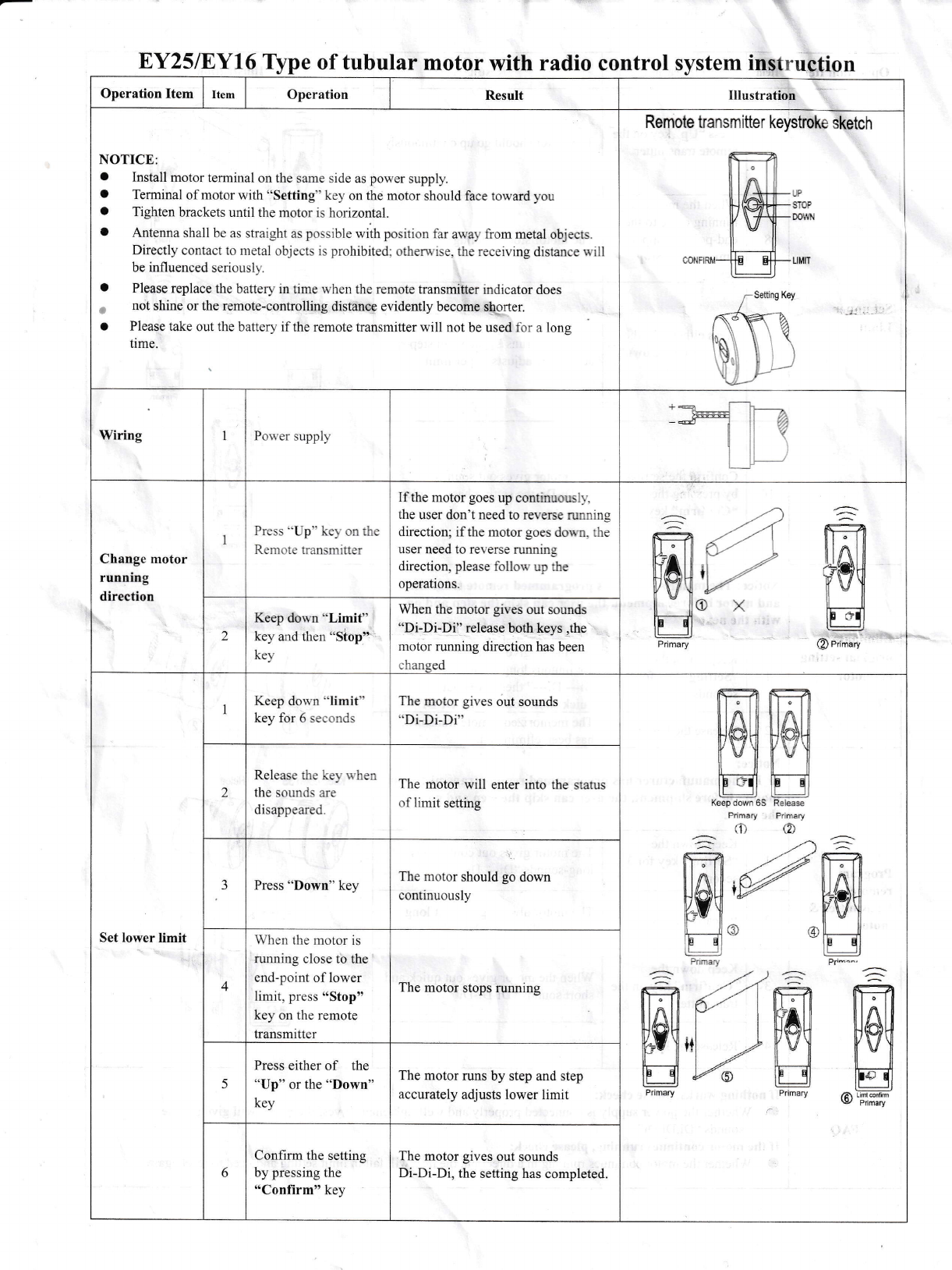

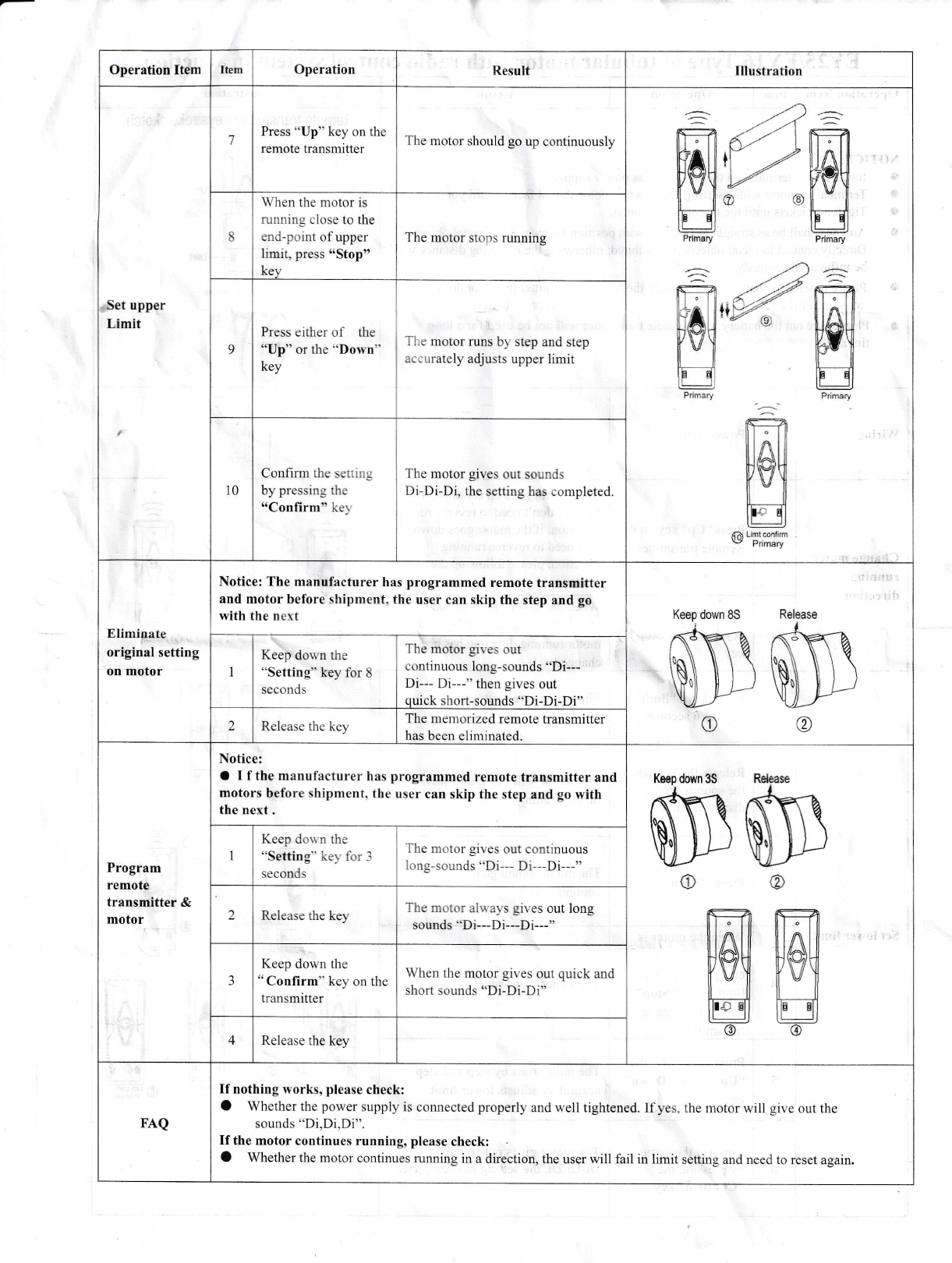

Operation

Technical Data

how to lnstall

roller motor into

the window

shades

l\4otor rubber

!r'eilii tYi€t

Assembly

(To do this step if

you want to

change the rubber

piece)

Wiring

(Note: Please do

not connect with 8

A"& hatteries or 8 D

batteries )

Check the

blind/roiling

Direction

Operation

Model&Voltage: EY1612 DC12V

Torque&Speed: 0.3 N m/25 rpm

Power Supply: 12V DC 500mA

Lift Capacity: 4.alb/Zkg under 3/4"

ie;ult lllustration

Remote transmitter kerstreke sketch

O Terminal of motor with ''Settir,g'

L. ijrepdre rne xoiler 1'ube( i.tole: i e;

correct crown and drive adapters are

us to recommend the right one

2. Align the notches on the croi,.,il .nr

tube. Mount idler and bracket ." :--r'

3. Make the tube fit motor bracke:

4.Pair tlre remote with roller nlJicr r"

71' /1-t/8' .o ier tube

l<ey on thr-. motor should face toward you

se cireir, v/natja your insicie dirnensir.rn of ihe roiier .rube, [.nsi.rre

rsed fo,' tr':e intended system, if yours roller tube is different, message

drive aJapterwith the drivetube, slide and fit the motor into drive

erds

rc e b i c l:t(Tighten brackets until the motor is horizontal)

:- all :stalled well

W

SP f=-

il

11n

t''.--l-r

g-

-- 1l- .*.

A. Remove grease

protector ring by opening

tl:c :plit ,;i:;; and slii;rig

off the motor body

B Fit Crcryr: by opening the

s ;lii ring rr::l slide along the

r' -r],-i,') i) ini;i rl meeis

t e mct-. i..ad

C. Fit the drive

using the cir-clip to

secu re in position

Please Connect with DC

1,2V/2A Power supply,

black+white wire is

+/positive, total black

cable is -/negative

Hold down the SETT|NG

button on the motor

mount

Press the CONFIRM

button on the remote

transmitter within 10

seconds

Press UP button

Hold down LIMIT button

and then press STOP

button on the primary

tra nsm itter

iil siart

beeping( lt indicates

rs successful to

poo'er supply)

t

e

C

Tre mot:-

t i-Dt-D -l

r,rller ml.o

c )nnect " il

-c ncicr plate

::' : ,',,S supplied in

:. ci cr right hand

: n .s reqUired

+€ -L

-FF-a

rl 1

l\ lotor be:p,ing continuously

(ltOTE: Please try once again if

nl beep cr :heck the power

s rpply if co ,nect well)

ir.OiCl' C,l lF..lng IaSt/ nOvV ihe

rr,rnote nas now been paired

v ith the moror

l1 blind gce: up rhe motor

d rectior s : k, if the blind goes

orwn ther i1e motor direction

s rould be cianged

F old bolh blrttons until motor

jr gs, at :.; is inoment the motor

r ,tation i a: been changed

')*,*o,*

FTt

Iirl

llnll

lli: li

U

=

m

lol

g

=

m

l3l

E

m r:R

I ool linl I

gH

,r:)