RS-600M Intrinsically Safe Barrier Door Installation and Operation Manual

2

Section 1: Introduction.....................................................................................................................................

Section 1.1: Safety............................................................................................................................................................................

Section 1.1.1: Definitions of Signal Words and Symbols....................................................................................................................

Section 1.1.2: Statements....................................................................................................................................................................

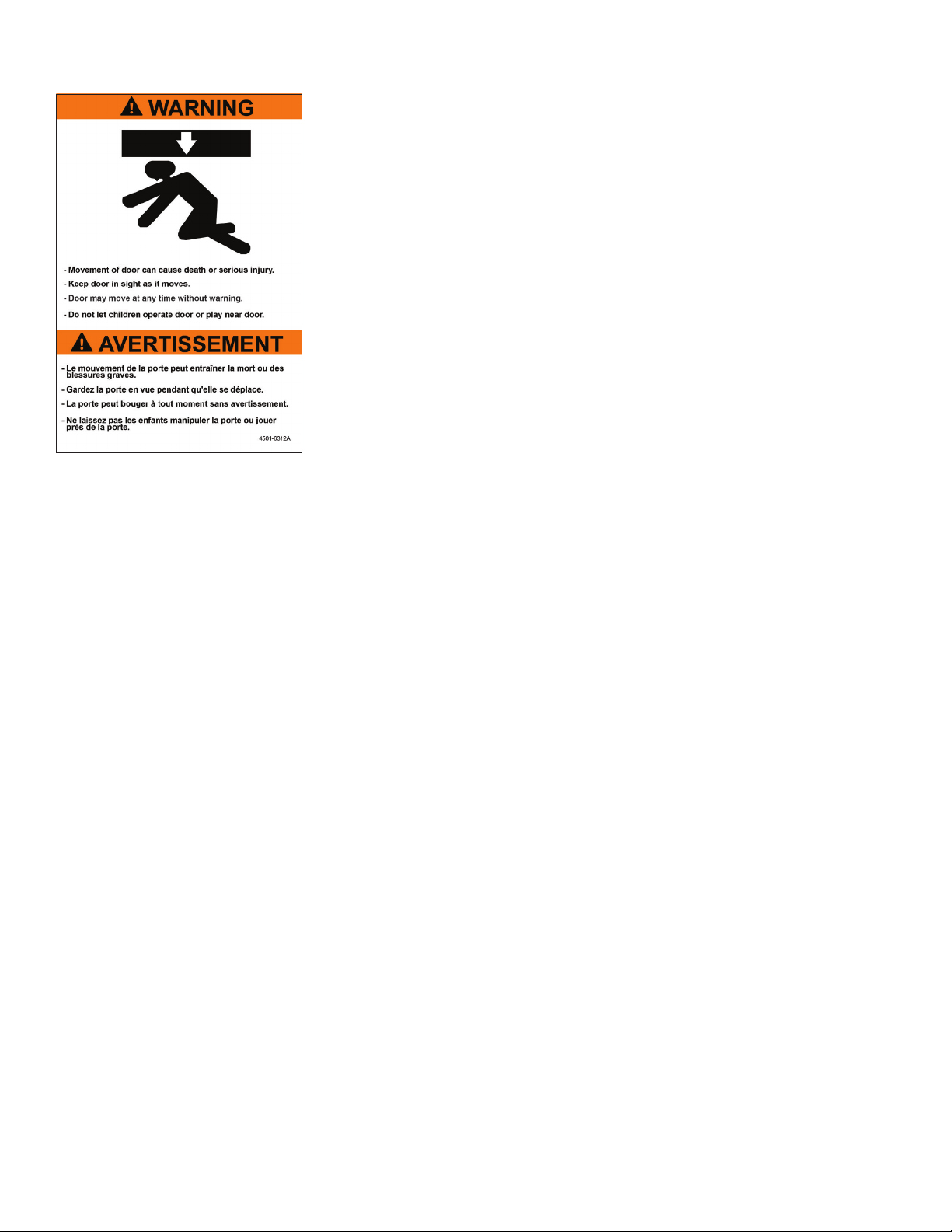

Section 1.1.3: Product Labels..............................................................................................................................................................

Section 1.2: Limited Warranty..........................................................................................................................................................

Section 1.3: Overview.......................................................................................................................................................................

Section 1.4: Dimensions...................................................................................................................................................................

Section 1.4.1: RS-600M ISB Door..........................................................................................................................................................

Section 1.4.2: SC-650M ISB Smart Controller......................................................................................................................................

Section 2: Installation.......................................................................................................................................

Section 2.1: Scope of Work...............................................................................................................................................................

Section 2.2: Adjust Framing and/or Clear Opening.........................................................................................................................

Section 2.3: Splice Tracks (if Taller Than 13')..................................................................................................................................

Section 2.4: Connect Tracks to Head Unit.......................................................................................................................................

Section 2.5: Mount Door to Clear Opening......................................................................................................................................

Section 2.6: Mount and Wire Smart Controller................................................................................................................................

Section 2.7: Mount and Wire Switches............................................................................................................................................

Section 2.7.1: One Wall (Standard).....................................................................................................................................................

Section 2.7.2: Two Parallel Walls Separated by Void.........................................................................................................................

Section 2.7.3: Two Perpendicular Walls with Bridge Plenum............................................................................................................

Section 2.8: Connect Infrared Safety Beam System........................................................................................................................

Section 2.8.1: Connect Extension Harness (if Door is Taller and/or Wider than 15')........................................................................

Section 2.9: Power............................................................................................................................................................................

Section 2.10: Install Motor Crank Handle........................................................................................................................................

Section 2.11: Prepare for Operation................................................................................................................................................

Section 3: Operation.........................................................................................................................................

Section 3.1: Switches and Smart Controller....................................................................................................................................

Section 3.2: Home Sensor and Leading Edge Switch......................................................................................................................

Section 3.3: Infrared Safety Beam....................................................................................................................................................

Section 3.4: Electrical Disconnect....................................................................................................................................................

Section 3.5: Communication Between Smart Controller and Door...............................................................................................

Section 3.6: Smart Controller User Interface..................................................................................................................................

Section 3.6.1: Overview........................................................................................................................................................................

Section 3.6.2: Display Indicator Readings..........................................................................................................................................

Section 3.7: Configuration................................................................................................................................................................

Section 3.7.1: Program Mode..............................................................................................................................................................

Section 3.7.2: Open and Close Speeds................................................................................................................................................

Section 3.7.3: Deceleration Range......................................................................................................................................................

Section 3.7.4: Open and Closed Limits................................................................................................................................................

Section 3.8: Jog Mode......................................................................................................................................................................

Section 3.9: Door Activation Inputs.................................................................................................................................................

Section 3.9.1: Directional Switch.........................................................................................................................................................

Section 3.9.2: Manual Switch..............................................................................................................................................................

Section 3.9.3: Timed Switch................................................................................................................................................................

Section 3.10: Relay Outputs.............................................................................................................................................................

Section 4: Maintenance.....................................................................................................................................

Section 4.1: Cleaning and Adjusting Components..........................................................................................................................

Section 4.1.1: Cleaning Panels and (if Present) Window...................................................................................................................

Section 4.1.2: Adjusting Panels and Tension Pipes............................................................................................................................

Section 4.1.3: Adjusting Brake.............................................................................................................................................................

Section 4.2: Replacing Components................................................................................................................................................

Section 4.2.1: Panels............................................................................................................................................................................

Section 4.2.2: Hook-and-Loop Seal.....................................................................................................................................................

Section 5: Troubleshooting................................................................................................................................

Section 5.1: Manual Operation by Crank Handle............................................................................................................................

Section 5.2: P12 Input Status Indicators..........................................................................................................................................

Section 5.3: Error Codes and Recommended Actions....................................................................................................................

Section 5.4: Drive Board Diagnostic LEDs.......................................................................................................................................

Section 5.4.1: Door Idle........................................................................................................................................................................

Section 5.4.2: Door Moving..................................................................................................................................................................

Section 5.5: Testing Brake Relay......................................................................................................................................................

Table of Contents

4

4

4

4

5

5

6

8

8

9

10

10

11

12

13

14

15

16

16

18

20

21

22

23

24

24

25

25

26

27

27

27

28

28

29

31

31

35

36

36

36

37

37

37

37

38

39

39

39

39

41

42

42

45

46

46

47

48

49

49

49

50