EN

OM1606 Rev 0 4

WARNINGS!

SAFETY INFORMATION

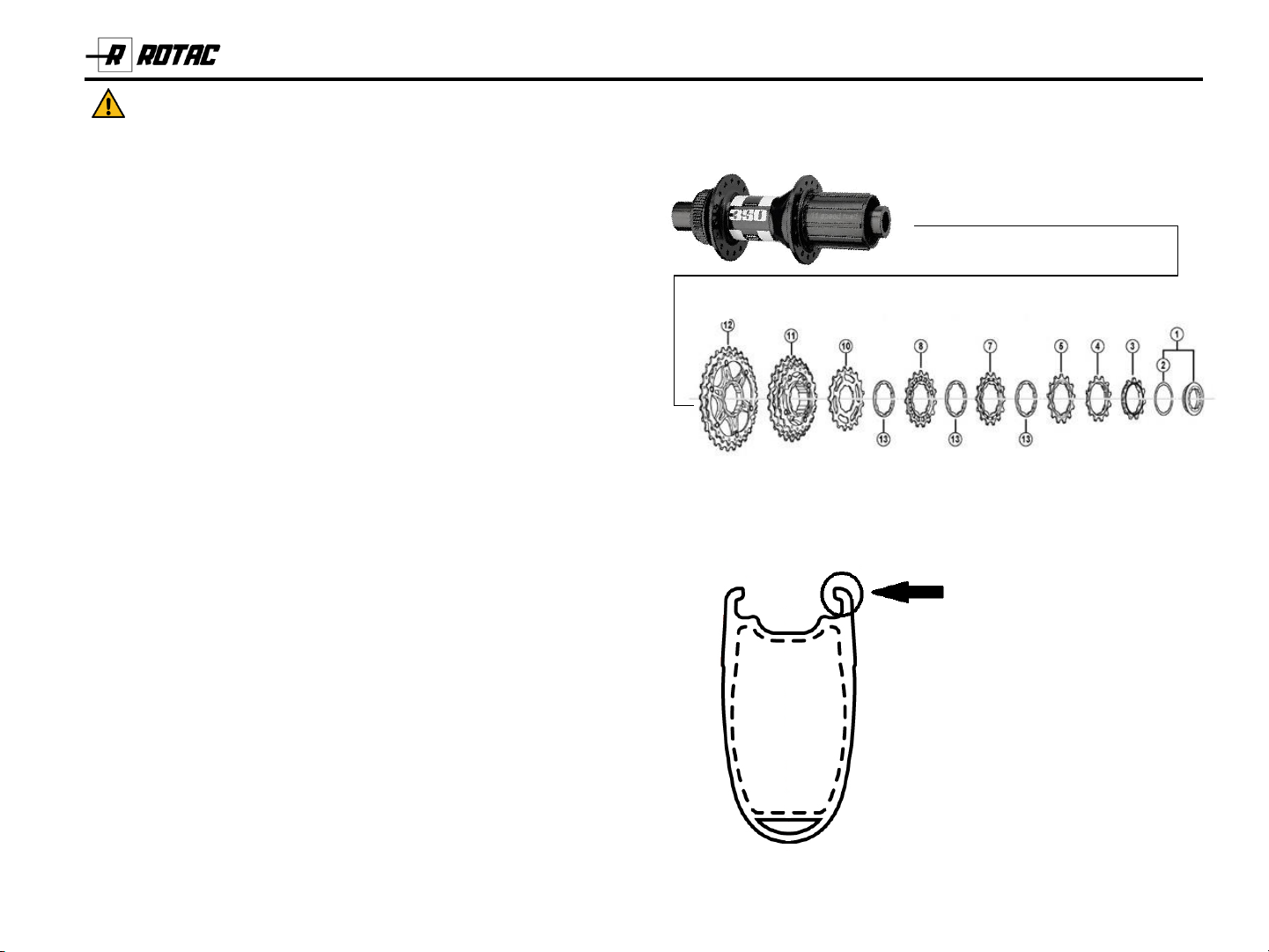

Wheel modification

Do not modify or make changes to wheels. Wheelsets are

manufactured and tested using approved components eg,

hubs, rims, spokes, spoke nipples, valves, specific tyre type.

Changing or substituting any of these parts can result in

damage to the wheel assembly leading to an accident and

voiding of warranties.

Foreign objects

Do not ride over sticks or debris (foreign objects). Foreign

objects can be kicked up, enter the spokes of the front

wheel, and be swept around and either break the fork or

stop the wheel. Riding can be littered with a great variety of

debris such as sticks, branches, auto parts and trash. Scan

ahead and if you see debris avoid as much as possible.

Before moving from your predictable path of travel, look

over your shoulder to be sure you can do so safely. If you are

riding with a group and at the front, warn rear riders and

point out debris.

Storage

Clean wheels to remove contaminants and release air

pressure before storage. Store in cool, dry areas and protect

from incidental damages during storage and from dirt

accumulation. Do not hang wheels from hooks.

Tire Size

See “Technical Specifications”in this manual for the tire size

range applicable to your model wheel. Mounting the wrong

size tires can result in the tires hitting the fork or frame

when riding. If this happens, you can lose control of your

bike and you can be thrown off. The actual measured size of

a tire may be different than its sidewall marking from various

tire manufacturer. Follow the specified tire clearance

recommendations of the frame manufacturer. Each time you

mount a new tire, take the time to inspect the actual

clearance between the rotating tire and all parts of the

frame. The U.S. Consumer Product Safety Commission

(CPSC) requires at least 1/16”(1.6 mm) tire clearance from

any part of the bike. Allowing for lateral rim flex and a wheel

or rim that is out of-true will likely mean choosing a rear tire

that provides even more clearance than the CPSC

recommends. To measure clearance: Inflate tire to operating

air pressure. Measure the space between the tire and frame.

Take measurement along the full length of possible

interference. If the measured clearance is less than specified,

the tire is not compatible and must not be used.

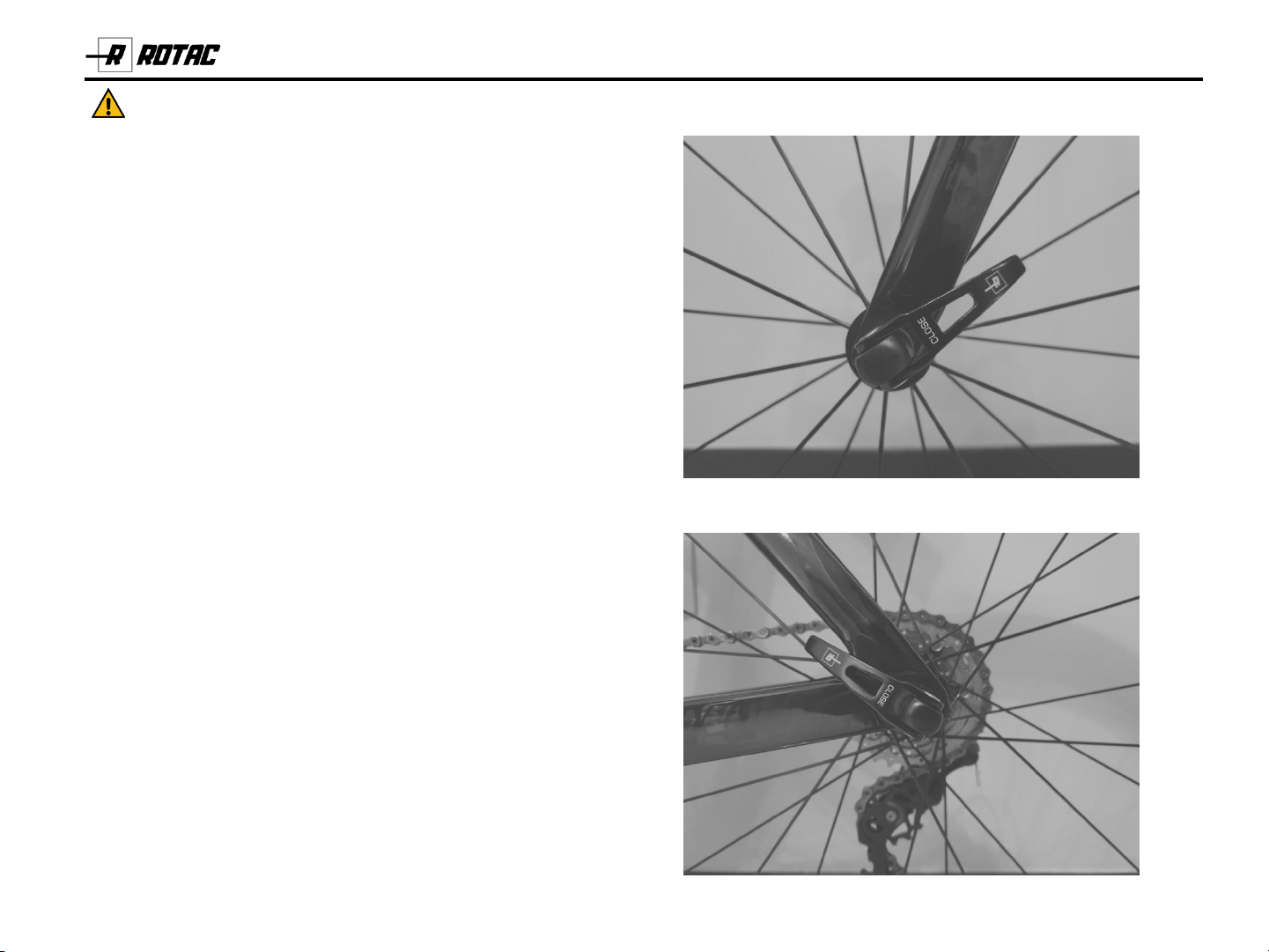

Transporting

Protect the wheels from damage during storage. Do not use

a clamp on any part of the wheel rim, spokes, or hubs. When

transporting on an automobile rack, make sure wheels are

not within 18”of the hot exhaust pipe.