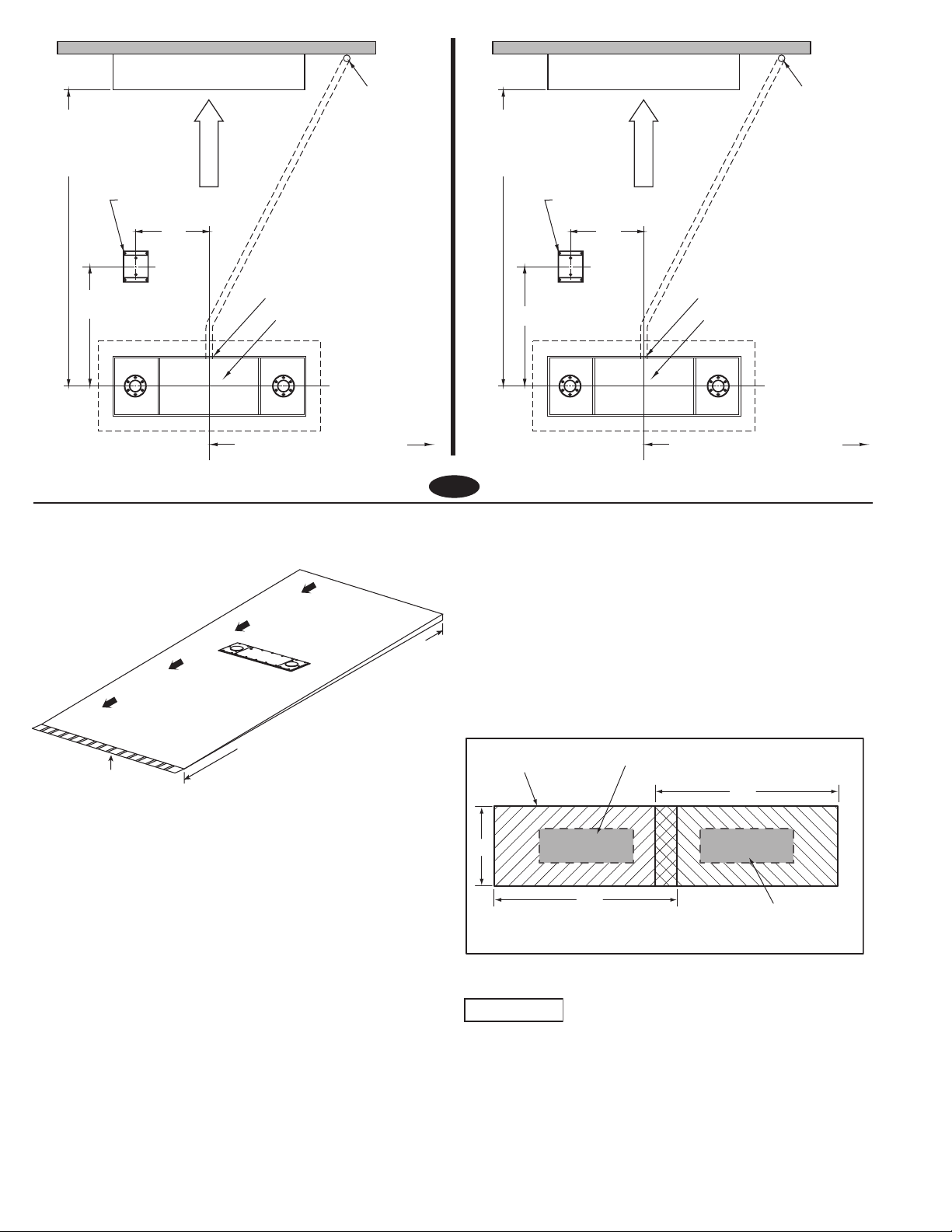

4

Wheel

Spotting Dish

2' 5"

APPROACH

PVC Conduit

Entrance for Air

& Hydraulic Hose

NOTE: Adjust Entrance

For Pedestal Mounting

Installation See Fig. 8a

4' 9" Swing Arm Lifts

5' 0" Moveable Pad Lifts

WORK BENCH (TYPICAL)

12'-0" Min. to

Nearest

Obstruction

or Per

Section 1c

5'-6" Min. to nearest obstruction

Foot traffic only on center cover

SL210i Series

Wheel

Spotting Dish

2' 5"

APPROACH

PVC Conduit

Entrance for Air

& Hydraulic Hose

NOTE: Adjust Entrance

For Pedestal Mounting

Installation See Fig. 8a

4' 9"

WORK BENCH (TYPICAL)

13'-0" Min. to

Nearest

Obstruction

or Per

Section 1c

5'-6" Min. to nearest obstruction

SL212i Series

PVC Inlet Into Containment Tube

Foot traffic only on center cover

PVC Inlet Into Containment Tube

1. Lift Location:

A. Check architect’s layout if available. Lay out lift as shown in

Fig. 1. Recommended floor slope is 1/16" per foot.

B. SL210i: The 5' 6" centerline to side and 12' 0" centerline

to front and rear dimensions should be maintained to provide

adequate working space. The minimum overhead clearance

should be 85" plus height of highest vehicle to be raised. 24' 0"

length bay recommended. Other lengths may be used, provided

ample clearance is maintained at each end of lift.

SL212i: The 5' 6" centerline to side and 13' 0" centerline to front

and rear dimensions should be maintained to provide adequate

working space. The minimum overhead clearance should be

88" plus height of highest vehicle to be raised. 26' 0" length bay

recommended. Other lengths may be used, provided ample

clearance is maintained at each end of lift.

C. Base Unit Lifts: If you are planning to install roll-on/

wheel alignment runways, locate lift per instructions from

superstructure manufacturer. Use superstructure manufacturer's

instructions for fore and aft, side to side, and ceiling clearances.

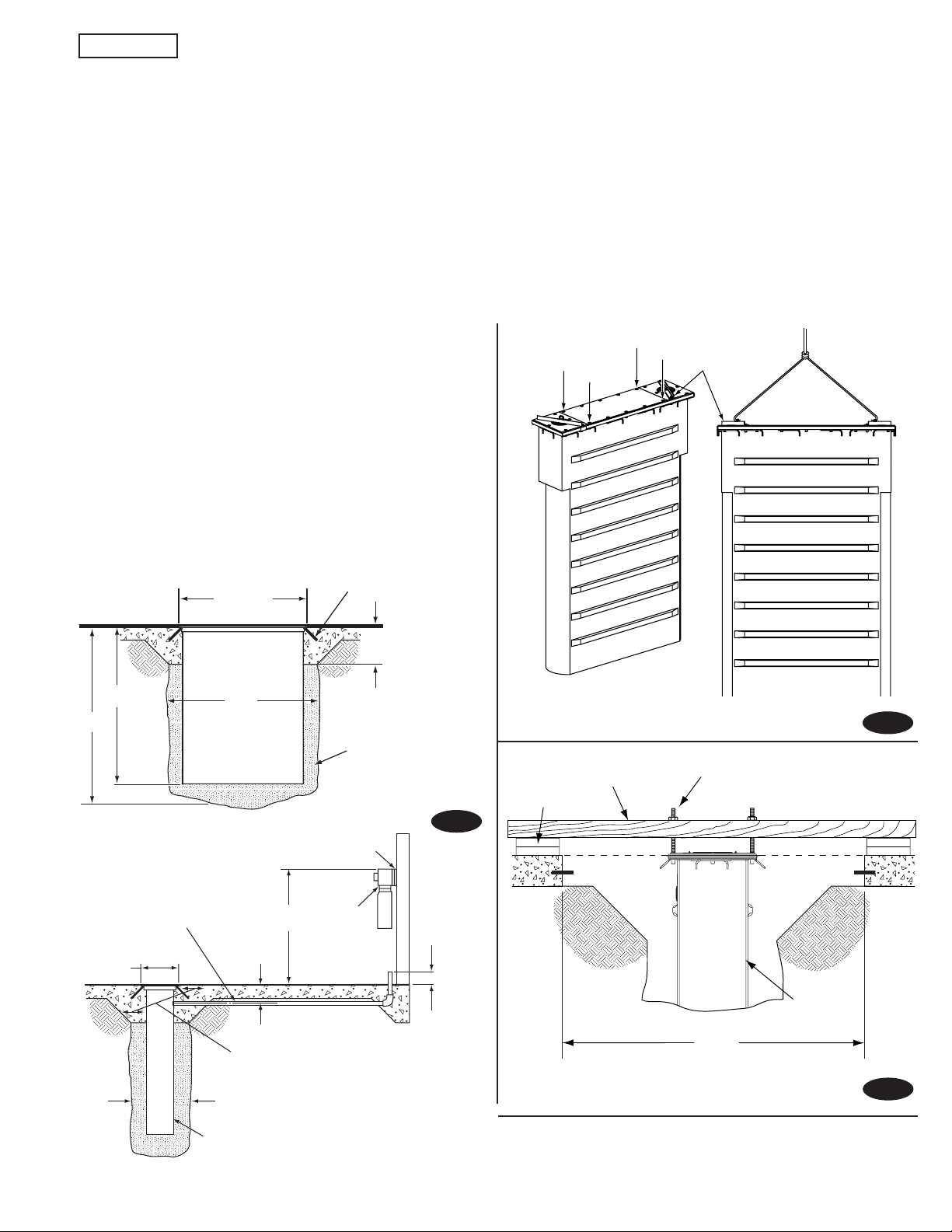

2. Excavation: Excavate hole to dimensions shown in Fig. 2.

Dig trench for 2" PVC pipe between lift and power unit location.

Trench should be dug 11" below finished floor grade. Air line and

hydraulic hose to be contained in this 2" PVC pipe.

3. Concrete Preparation:

A. Run 2" PVC from Control Area to Containment Tube. PVC will

enter the Containment Tube 9-1/2" below finished floor grade.

Hole is centered horizontally in Containment Tube, Fig. 1.

B. Box out a 5' x 10' area around where lift is to be located.

NOTE: For multiple lift installations, boxed out areas will

overlap. Dig continuous trench, see illustration below.

C. Pour concrete floor ensuring not to get concrete in boxed out

area.

NOTE: By using this installation method, the RAI can more

accurately set lift to proper grade relative to finished floor.

Reference Page 2.

Fig. 1

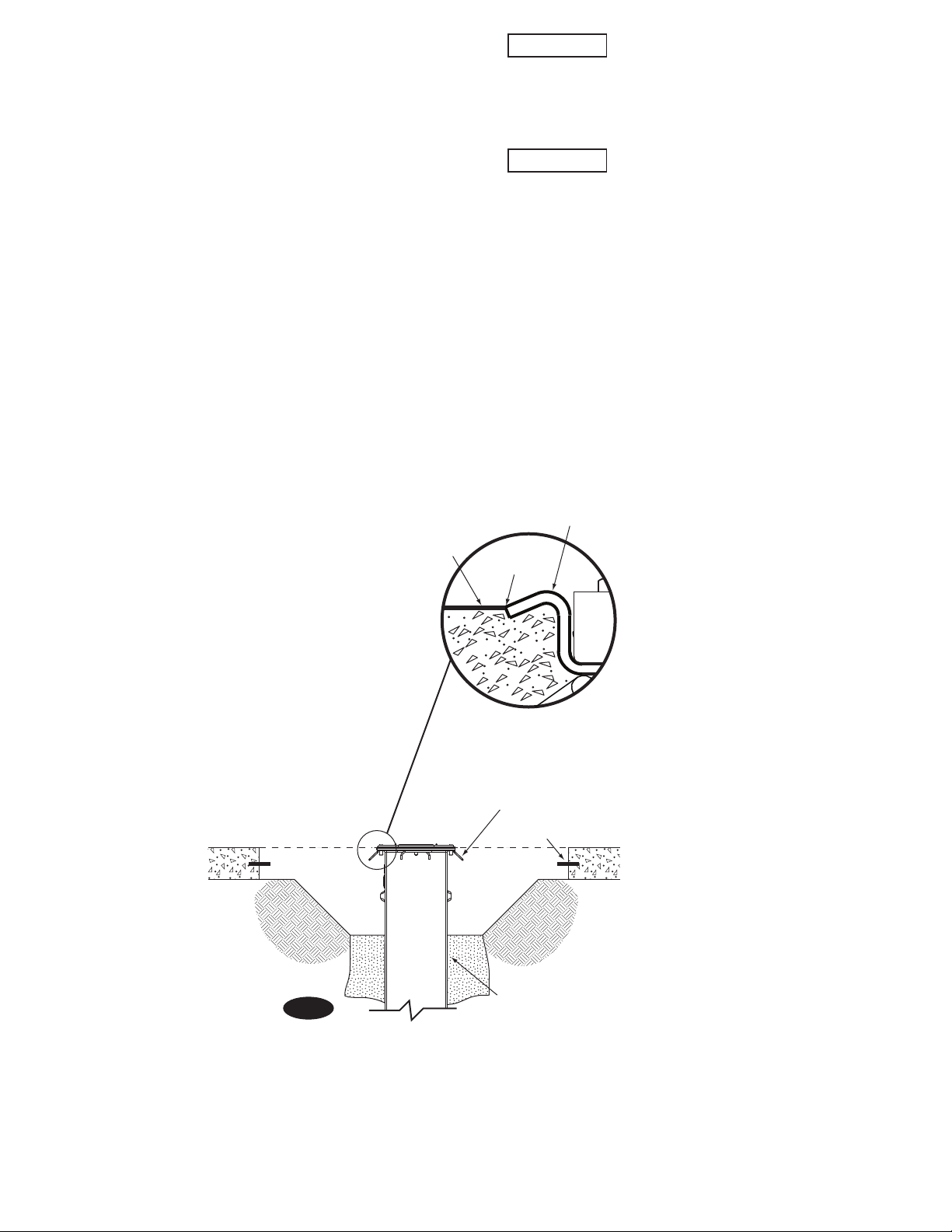

4. Lift Setting:

Check the containment tube for holes due to

shipping damage. Do not install a damaged containment tube.

Contact Rotary Lift Customer Service.

A. Chain hoist must have capacity of 2,500 lbs. with a clear

swing of 9' 0". Rig sling for unit, attaching to the shipping strap,

Fig. 3, and lower assembly into hole. Center lift and be sure lift

containment inlet is located as shown in Fig. 1.

Recommended Floor Slope 0-1/16" Per Ft.

Drainage Direction Drainage Direction

Drain

Continuous Trench

Lift Location

5'

Concrete Floor

10'

10'

Lift Location