Page 8

TABLE OF CONTENTS

INTRODUCTION .....................................3

WARRANTY .......................................6

TABLE OF CONTENTS ...................................8

SAFETY- STATIONARY MIXER ...............................9

SAFETY- TRAILER MIXER .................................10

SAFETY DECALS ....................................11

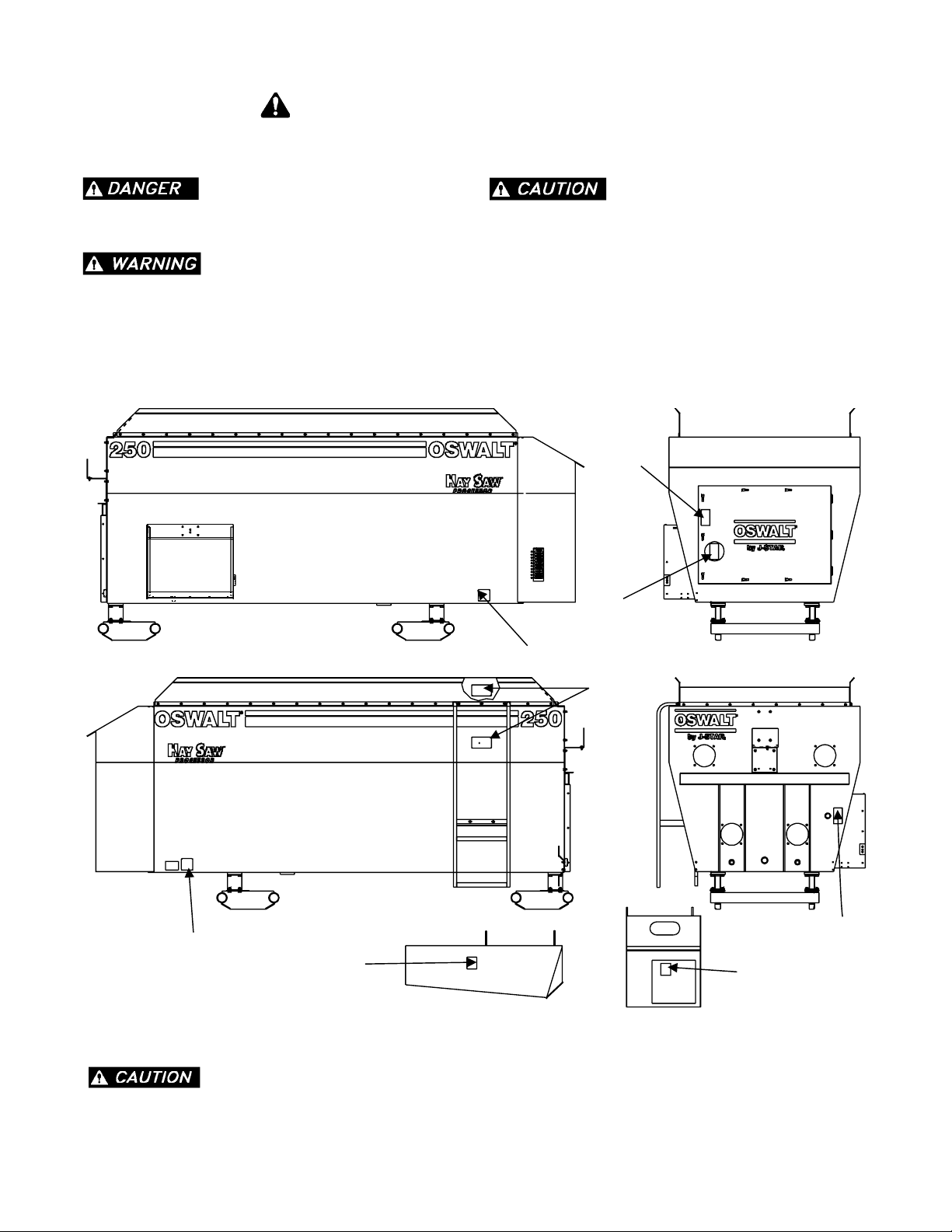

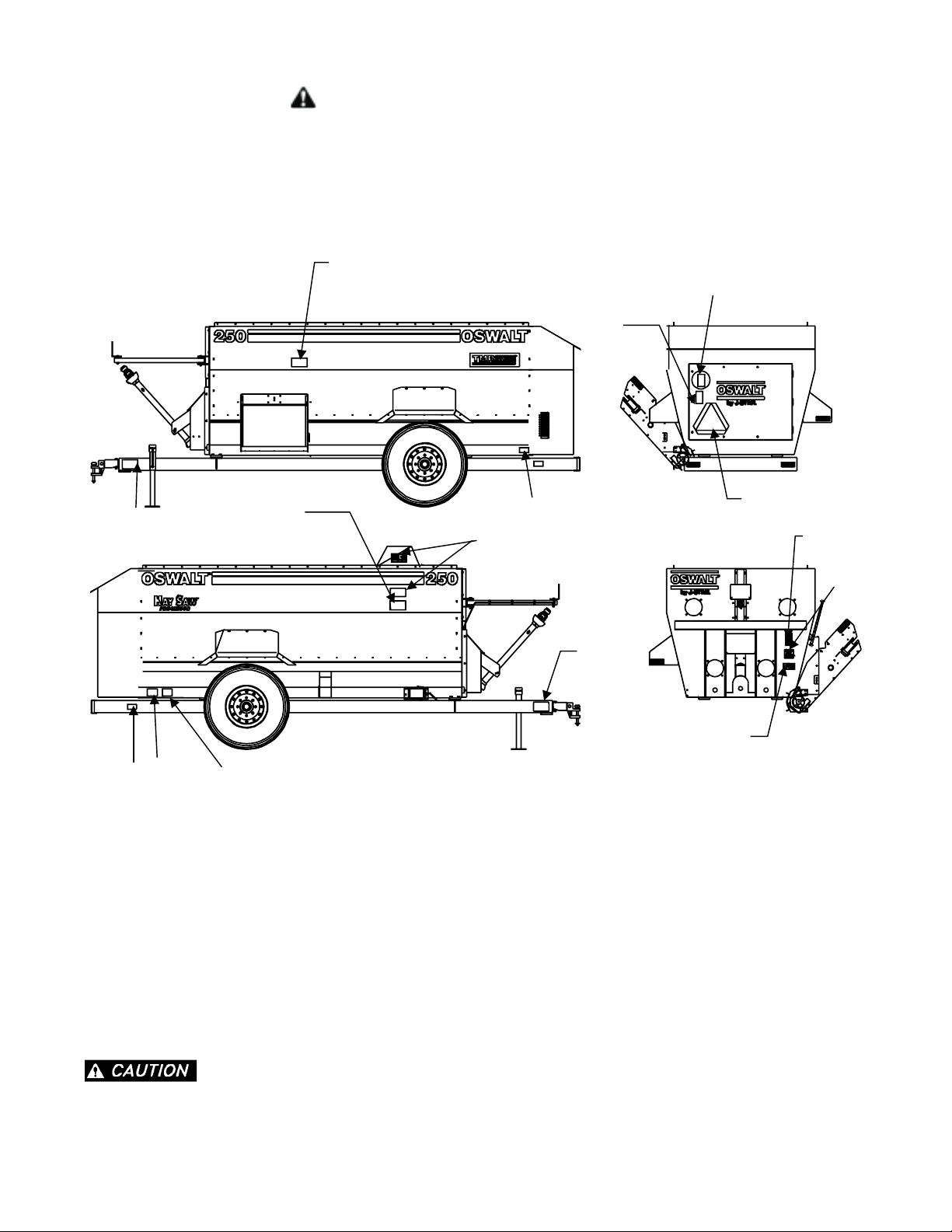

DIMENSIONAL DATA ...................................14

GENERAL INFORMATION .................................15

MIXING CAPACITY ..................................15

ROUGHAGE LENGTH .................................15

USE OF BALED HAY..................................15

LOADING ......................................15

MIXING TIME .....................................16

SHEAR PIN .....................................16

TRACTOR HYDRAULIC SYSTEM

RECOMMENDATIONS .................................16

TRACTOR DRAWBAR .................................16

TRAILER OPERATION ..................................17

PTO ENGAGEMENT ..................................17

CORNERING .....................................17

DISCHARGING FEED .................................17

SCALE SWING MOUNT ................................17

OPTIONAL SINGLE VALVE CONVERSION .........................17

SCALE SYSTEM ...................................17

TRANSPORTING ...................................18

STATIONARY OPERATION.................................19

MOTOR CURRENT ..................................19

DISCHARGING FEED .................................19

ADJUSTMENTS .....................................20

TRAILER ......................................20

TRAILER HITCH CLEVIS ADJUSTMENT (TRAILER MOUNT ONLY) ...............20

STATIONARY ....................................21

STATIONARY AND TRAILER ..............................21

SERVICE JACKSHAFT ASSEMBLY ............................21

DRIVE CHAIN ROUTING ................................22

LUBRICATION ......................................24

TROUBLESHOOTING ...................................25

TRAILER INSTALLATION .................................26

INSTALL CHUTE AND PIVOT BAR ............................26

INSTALLING EXTENDED CONVEYOR

(OPTIONAL) .....................................27

INSTALL OPTIONAL BAFFLE ..............................28

INSTALLING SINGLE PAIR HYDRAULIC VALVE (OPTIONAL) .................29

INSTALLING SCALE INDICATOR.............................30

INSTALLING SCALE TRACTOR SOCKET (SHIPPED WITH MIXER) ...............30

INSTALLING BATTERY ON MIXER ............................31

INSTALLING SCALE SYSTEM ..............................32

INSTALLING MANUAL DOOR OPERATOR .........................35

INSTALLING ELECTRIC DOOR OPERATOR ........................36

INSTALLING TOP GUARD ...............................37

INSTALLING SIDE MOUNT MOTOR ...........................37

INSTALLING SINGLE MOTOR, FRONT MOUNT .......................38

INSTALL DOUBLE MOTOR, FRONT MOUNT ........................38

REPAIR PARTS .....................................39

FINAL FACTORY INSPECTION ...............................72