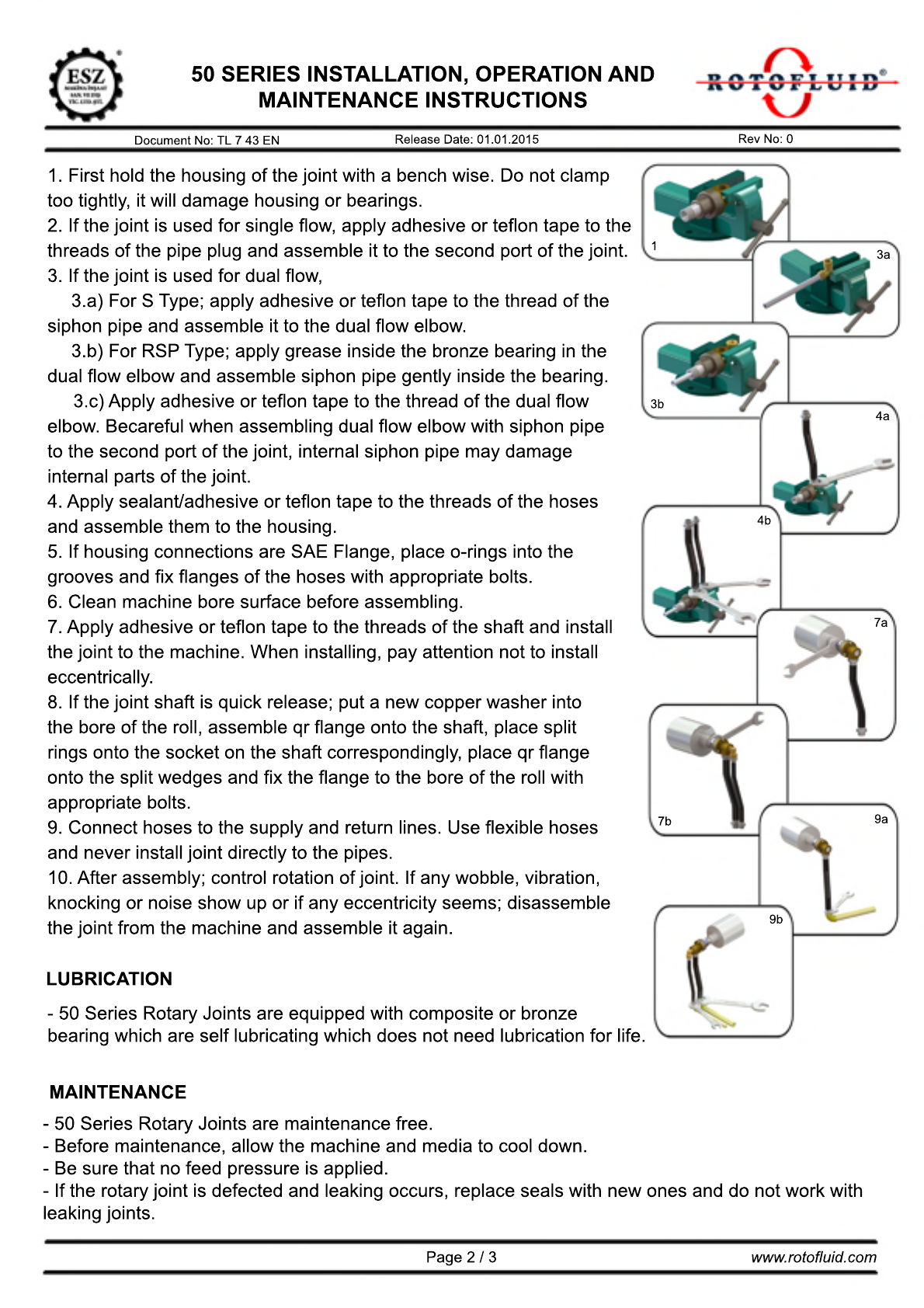

1

3b

4a

4b

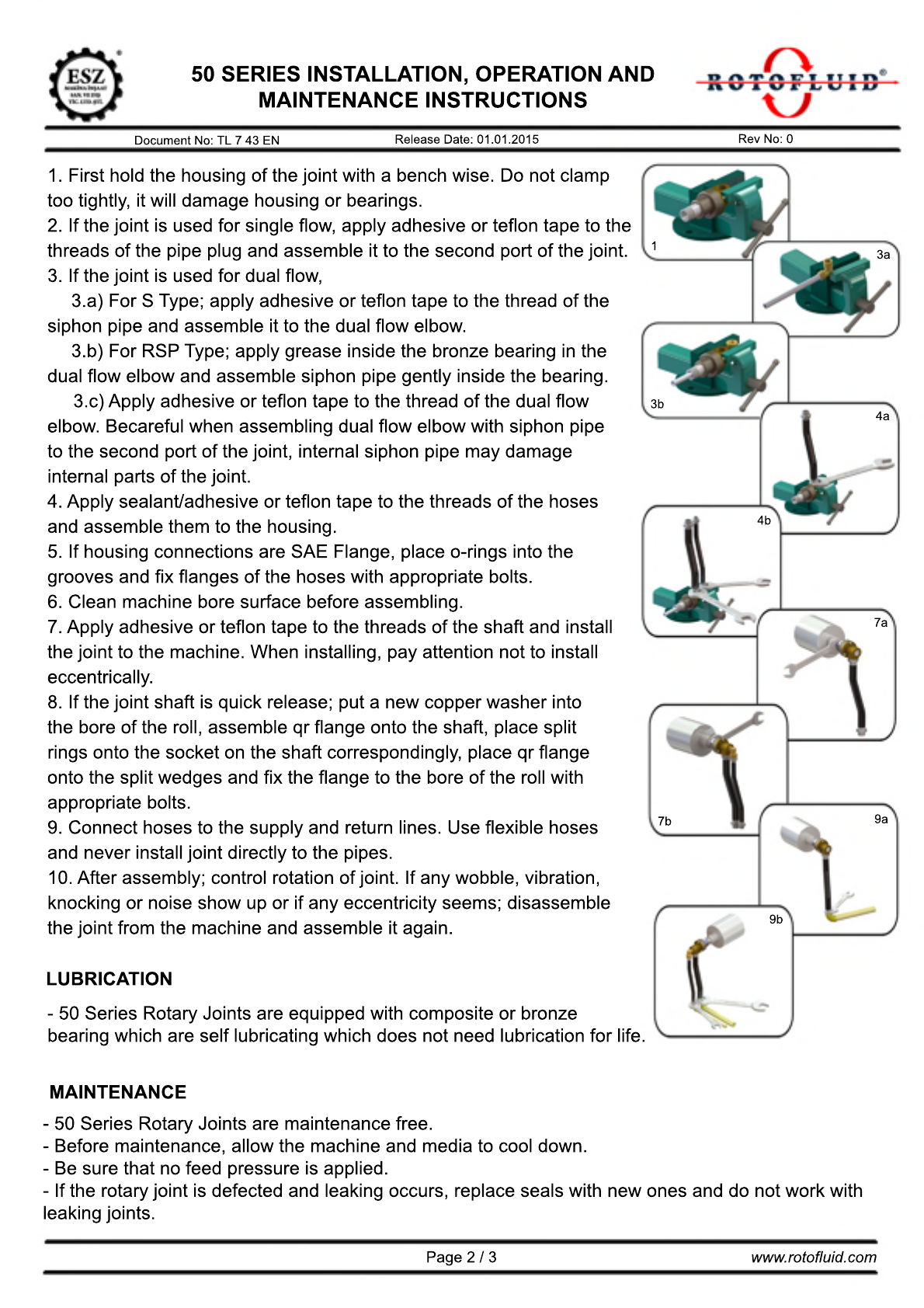

7a

7b 9a

9b

3a

50 SERIES INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

Page 2 / 3 www.rotofluid.com

- 50 Series Rotary Joints are equipped with composite or bronze

bearing which are self lubricating which does not need lubrication for life.

- 50 Series Rotary Joints are maintenance free.

- Before maintenance, allow the machine and media to cool down.

- Be sure that no feed pressure is applied.

- If the rotary joint is defected and leaking occurs, replace seals with new ones and do not work with

leaking joints.

MAINTENANCE

1. First hold the housing of the joint with a bench wise. Do not clamp

too tightly, it will damage housing or bearings.

2. If the joint is used for single flow, apply adhesive or teflon tape to the

threads of the pipe plug and assemble it to the second port of the joint.

3. If the joint is used for dual flow,

3.a) For S Type; apply adhesive or teflon tape to the thread of the

siphon pipe and assemble it to the dual flow elbosiphon pipe and assemble it to the dual flow elbow.

3.b) For RSP Type; apply grease inside the bronze bearing in the

dual flow elbow and assemble siphon pipe gently inside the bearing.

3.c) Apply adhesive or teflon tape to the thread of the dual flow

elbow. Becareful when assembling dual flow elbow with siphon pipe

to the second port of the joint, internal siphon pipe may damage

internal parts of the joint.

4.4. Apply sealant/adhesive or teflon tape to the threads of the hoses

and assemble them to the housing.

5. If housing connections are SAE Flange, place o-rings into the

grooves and fix flanges of the hoses with appropriate bolts.

6. Clean machine bore surface before assembling.

7. Apply adhesive or teflon tape to the threads of the shaft and install

the joint to the machine. When installing, pay attention not to install

eccentricalleccentrically.

8. If the joint shaft is quick release; put a new copper washer into

the bore of the roll, assemble qr flange onto the shaft, place split

rings onto the socket on the shaft correspondingly, place qr flange

onto the split wedges and fix the flange to the bore of the roll with

appropriate bolts.

9. Connect hoses to the supply and return lines. Use flexible hoses

and never install joint directly to the pipes.and never install joint directly to the pipes.

10. After assembly; control rotation of joint. If any wobble, vibration,

knocking or noise show up or if any eccentricity seems; disassemble

the joint from the machine and assemble it again.

LUBRICATION

Document No: TL 7 43 EN Release Date: 01.01.2015 Rev No: 0