Contents

3 of 82 Publication S703E V1.1 Issue 06/09

Contents:

KNOW YOUR MASTER STATION.............................................................................2

INTRODUCTION.........................................................................................................5

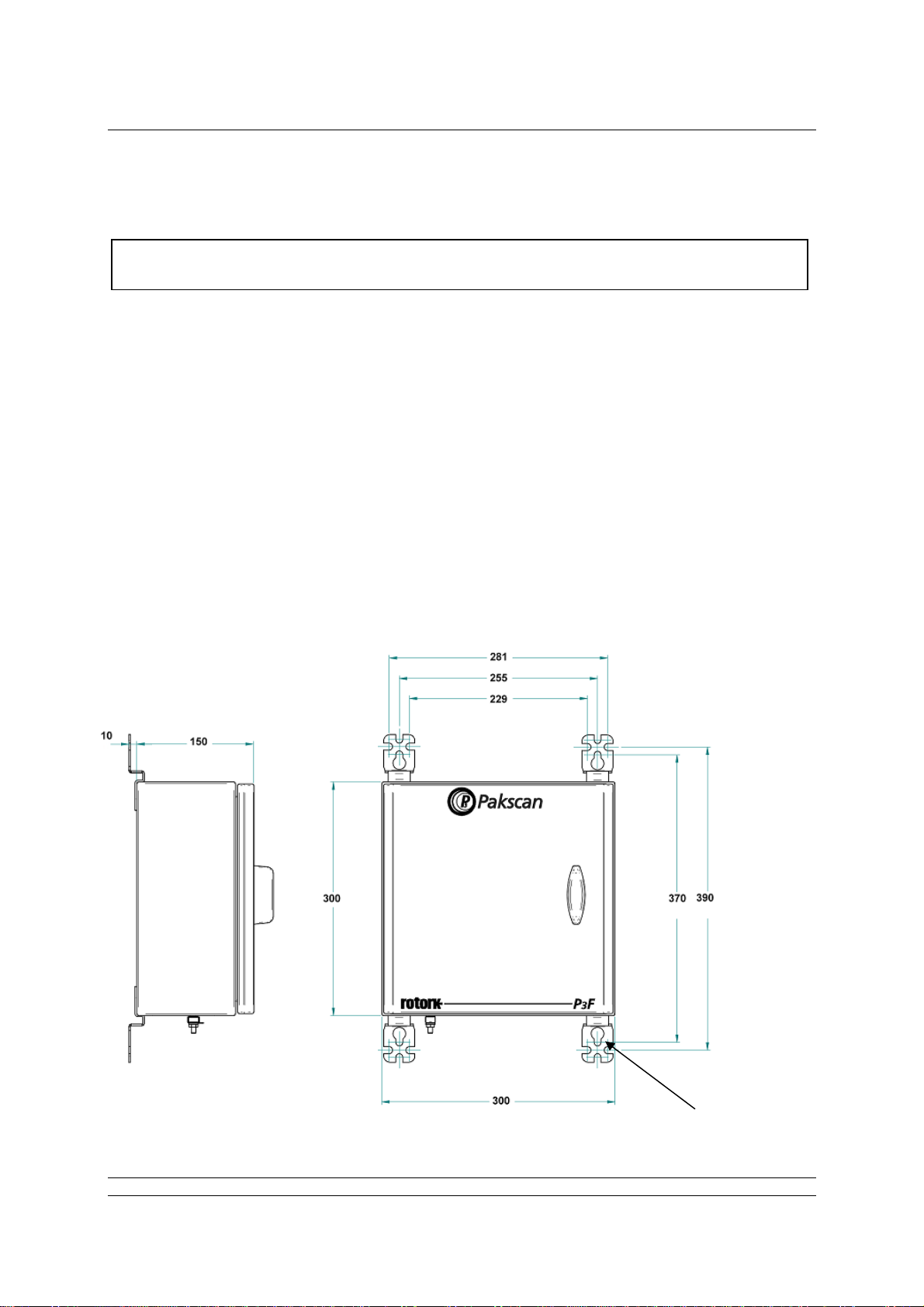

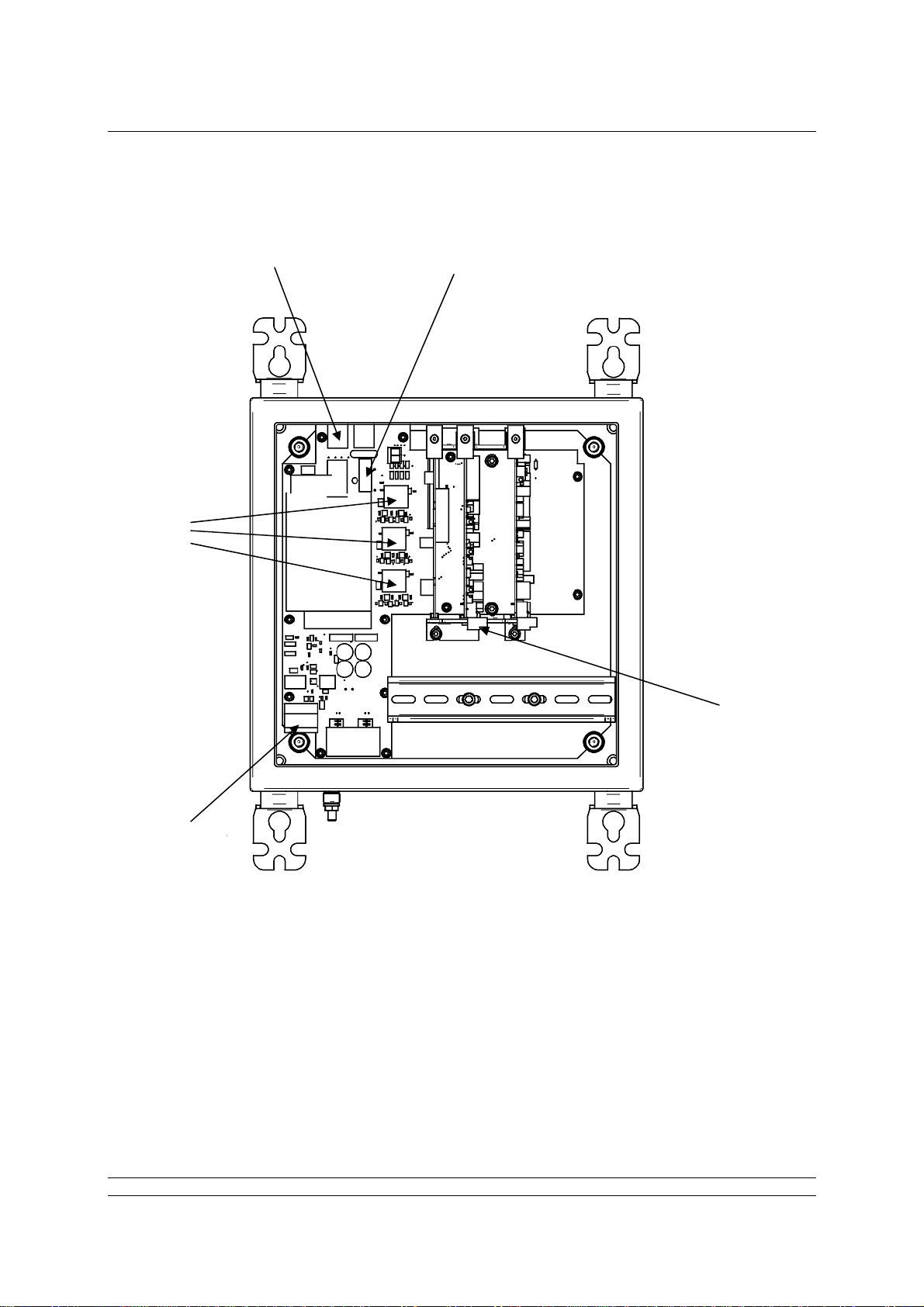

1. MOUNTING AND CONNECTING THE MASTER STATION..............................7

1.1 Mechanical Fixing...................................................................................................................7

1.2 Serial Comms Connections ...................................................................................................8

1.3 Ethernet Comms Connections ..............................................................................................8

1.4 Power Connector and Fuse....................................................................................................8

1.5 ESD and Alarm Output Connector........................................................................................9

1.6 Current Loop Connections.....................................................................................................9

2. THE FIELD NETWORK....................................................................................11

2.1 Loop Checks..........................................................................................................................11

2.1 Loop Checks..........................................................................................................................12

2.2 Connecting Up.......................................................................................................................12

3. SORTING OUT THE SERIAL COMMS LINKS.................................................15

3.1 Setting Port 1 and 2 for RS232 or RS485............................................................................15

3.2 When to Use RS232 ..............................................................................................................17

3.3 When to Use RS485 ..............................................................................................................17

4. USING ETHERNET HOST COMMS.................................................................19

4.1 Setting-Up the Ethernet Comms..........................................................................................19

5. THE INTERNAL WEB PAGES.........................................................................21

5.1 Making an Internet / intranet Connection...........................................................................21

5.2 Connecting a Laptop Directly to the Master Station .........................................................21

5.3 5.3 Adjusting the Network Settings of the Laptop / PC....................................................21

5.3 5.3 Adjusting the Network Settings of the Laptop / PC.....................................................22

5.4 Web Page Structure..............................................................................................................23

5.4.1 User Levels.........................................................................................................23

5.4.2 Overall Web Page Layout...................................................................................23

5.5 The Web Pages in Detail.......................................................................................................25

5.5.1 Log In Screen .....................................................................................................25

5.5.2 Master Station ....................................................................................................25

5.5.2 Master Station ....................................................................................................26

5.5.3 View Configuration .............................................................................................28

5.5.4 System Diagnostics............................................................................................29

5.5.5 Master Station Data Logger................................................................................30

5.5.6 Master Station Host Analyser.............................................................................32

5.5.7 Pakscan 2 Loop Diagnostics..............................................................................33