3

OVERVIEW

The Rotovac

360i

maneuvers in the same manner as a rotary floor buffer with a

“heal and toe” left to right cleaning motion. If you have never operated a rotary

floor type machine, this will take a little practice to learn how to control properly.

Once mastered, operating the

360i

is a nearly effortless self propelled side to side

motion. It may take a few jobs to learn how to operate the

360i

efficiently. Be

patient and try it on some really dirty carpets and you will soon discover that the

Rotovac

360i

cleans better, leaves it drier and is much more impressive to your

customers than a traditional wand cleaning. When presented and used properly, the

360i

will impress your customers and lead to a major increase of referral and

repeat business.

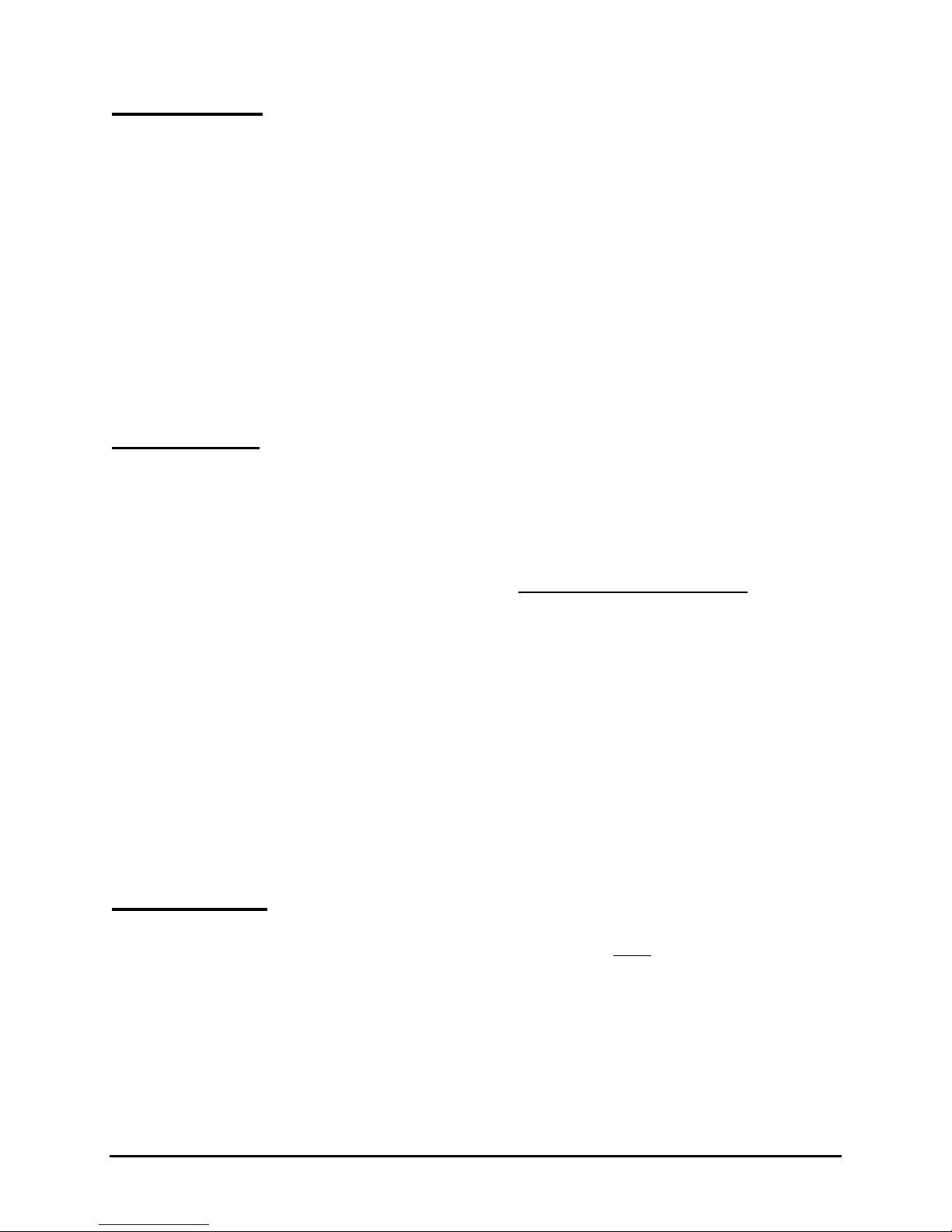

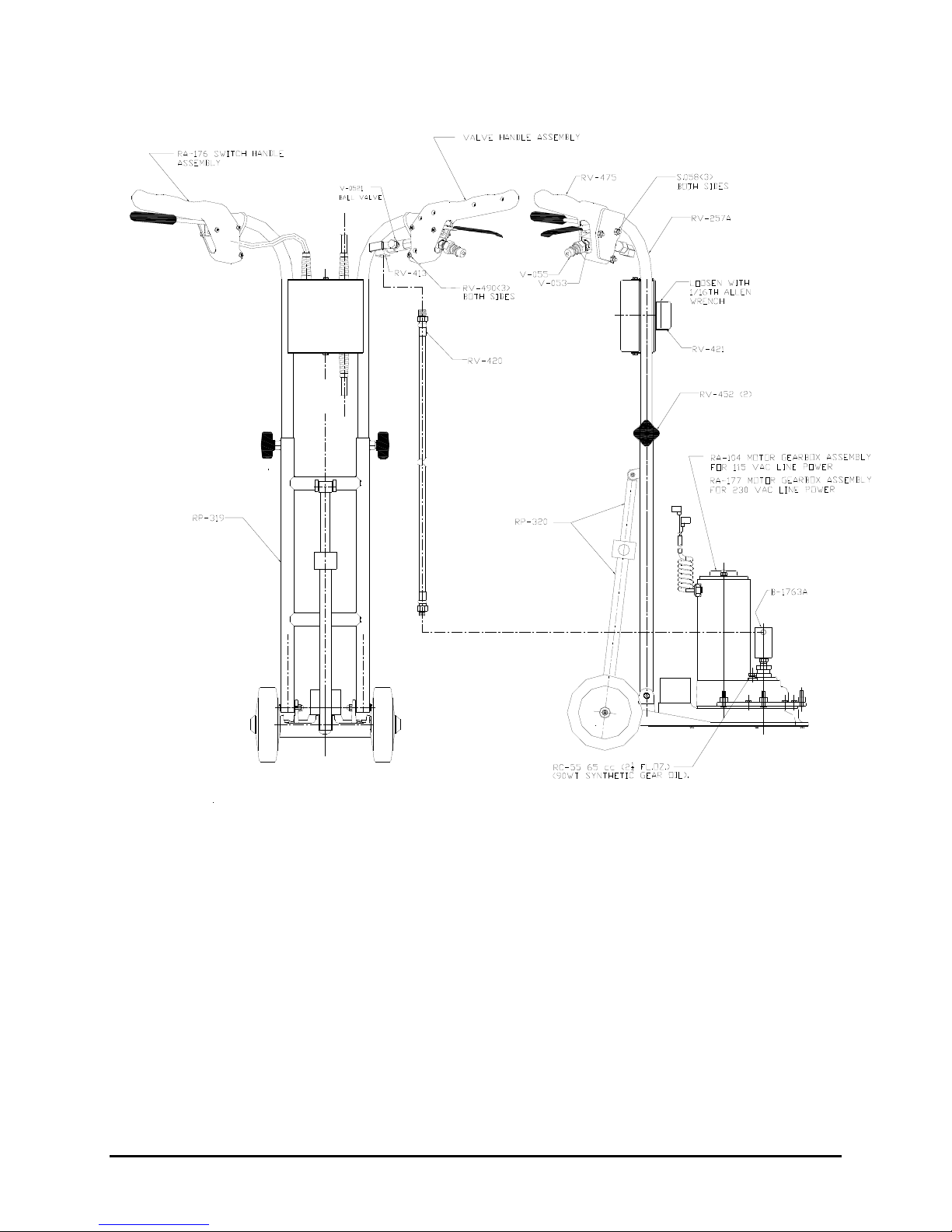

CONTROL:

When operating the

360i

for the first time, you can run it dry (not hooked up to an

extractor) in an open carpeted area to get used to the handling characteristics. Extend the

telescoping handle out to near its fully extended length. Adjust the handle angle to a low

enough position so that your arms are extending almost straight down during operation.

Before turning on, make sure the cleaning head is flat and level on the carpet and the

speed control dial is turned all the way up to 10. Learn how to “hover” the

360i

in one

spot without fighting it. Once you have found the center of balance and proper technique,

you will find the

360i

is very easy to control. The

360i

maneuvers left and right like a

rotary floor scrubber (heel and toe). Lifting up slightly on the handle causes the

360i

to

move to the right. Letting down on the handle causes the

360i

to move to the left.

Slightly twisting the handles clockwise moves forward, counterclockwise rearward.

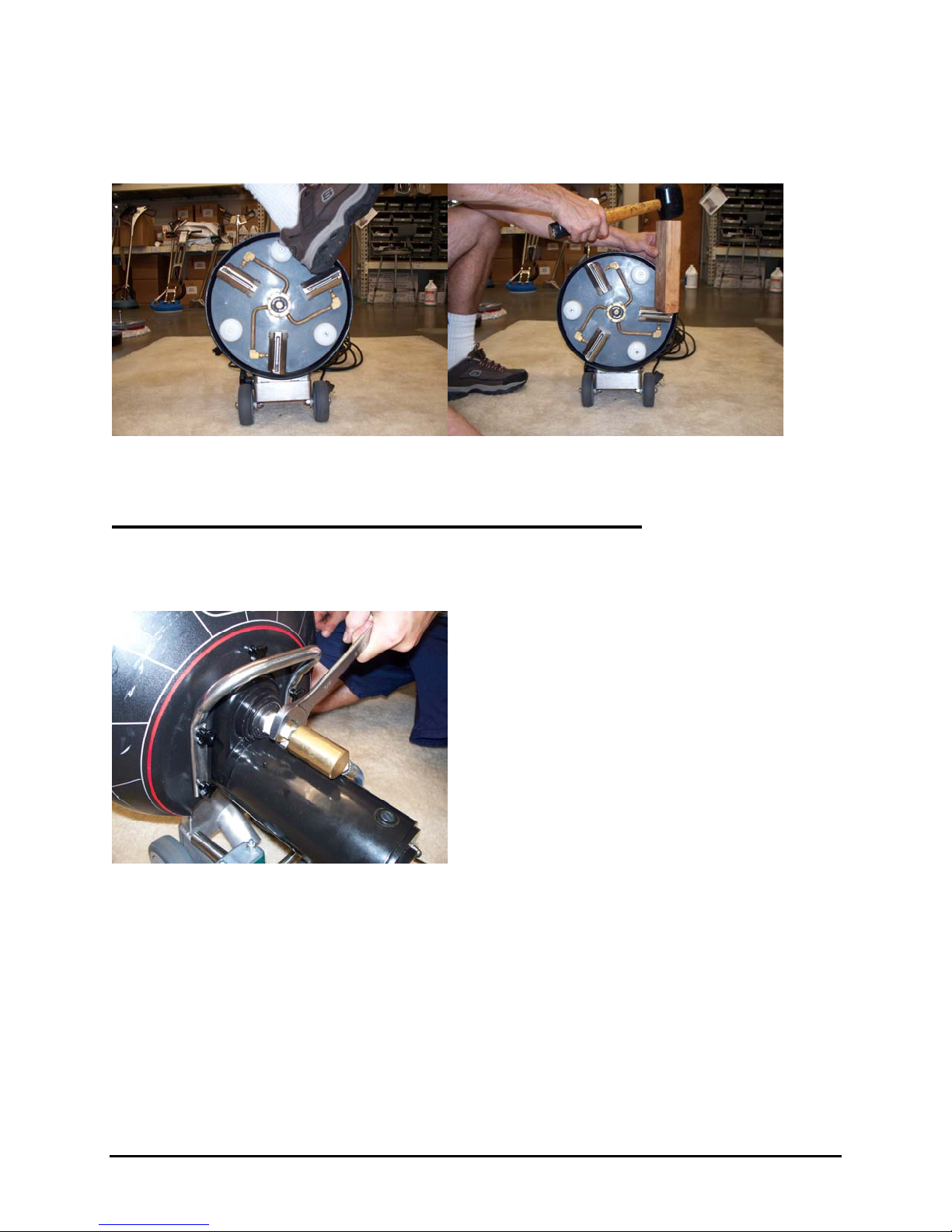

Combined handle movements allow motion in any direction. The on/off trigger is located

under the left handle grip. The head speed control dial is located at the front of the control

box. This allows adjustment of the head speed rpm. The solution valve trigger is located

under the right handle grip. A red lever solution flow control valve allows for the

adjustment of flow rate.

CLEANING:

With the solution trigger activated, make cleaning passes in a slow left and right motion

allowing the

360i

to do the work. Overlap cleaning passes approximately 50% to assure

thorough cleaning. The more soiled the carpet, the slower you should make the cleaning

passes. Clean an area of approximately 4’ X 4’ with solution on and then let off the

solution valve trigger and go back over the carpet with a vacuum only "dry pass" to

provide maximum extraction for faster drying. For normal carpet cleaning spray pressure

we recommend operating between 50 and 300 PSI.